Professional Documents

Culture Documents

23 141217

Uploaded by

Gajanan DeshmukhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

23 141217

Uploaded by

Gajanan DeshmukhCopyright:

Available Formats

Indo American Journal of Pharmaceutical Research, 2014

ISSN NO: 2231-6876

FORMULATION AND EVALUTION OF FLOATING DRUG DELIVERY SYSTEM OF

GUAIFENESIN TABLET

*

S.G.Waghmare1, Dr.D.M.Sakarkar2

Hi-Tech College of Pharmacy,Chandrapur.

Sudhakarrao Naik Institute of Pharmacy,Pusad.

ARTICLE INFO

Article history

Received 06/12/2014

Available online

19/12/2014

Keywords

Gastric Retention,

Floating Tablet,

Extended Release/

Sustained Release,

Guaifenesin.

ABSTRACT

Oral controlled release drug delivery have recently been of increasing interest in

pharmaceutical field to achieve improved therapeutic advantages, such as ease of dosing

administration, patient compliance and flexibility in formulation. Drugs that are easily

absorbed from gastrointestinal tract (GIT) and have short half-lives are eliminated quickly

from the systemic circulation. To avoid this limitation, the development of oral sustainedcontrolled release formulations is an attempt to release the drug slowly into the

gastrointestinal tract (GIT) and maintain an effective drug concentration in the systemic

circulation for a long time. The present study involves preparation of floating tablet of

Guaifenesin with HPMC K100 M and HPMC K15M floating tablet were designed to achieve

the extended release or retentions in GIT which may result enhance in absorption n leads to

increment in bioavaiblity. Enhanced floatability of tablet and its retentions period in GIT

directly enhanced bioavaiblity of drug and decreases the frequency of administration of drug.

Comparing the HPMC polymer grades K100 and K15 it concludes that the K100M shows

good result in a F4 batch.

Copy right 2014 This is an Open Access article distributed under the terms of the Indo American journal of Pharmaceutical

Research, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

www.iajpr.com

Page

Please cite this article in press as Suchita Gulabrao Waghmare et al. Formulation and Evalution of Floating Drug Delivery

System of Guaifenesin Tablet. Indo American Journal of Pharm Research.2014:4(12).

5750

Corresponding author

Suchita Gulabrao Waghmare

Assistant Professor ,Hi-Tech College of Pharmacy,

Padoli phata,Nagpur-Chandrapur High-way,

At Morwa, Chandrapur.44.

Suchitawaghmare26@gmail.com

Vol 4, Issue 12, 2014.

Suchita Gulabrao Waghmare et al.

ISSN NO: 2231-6876

INTRODUCTION

One of the essential factors is the residence time of the drug at the absorption site. Over the last two decades,

numerous Gastroretensive dosage forms have been designed to prolong gastric residence time. They may be broadly classified

into: high-density (sinking) systems, low-density (floating) systems, expandable systems super porous hydrogel systems,

mucoadhesive systems and magnetic systems. They enable oral therapy by drugs with a narrow absorption window in the upper

part of the gastrointestinal tract or drugs with a poor stability in the colon. Furthermore, the drug can act locally within the

stomach and prolonged intimate contact with the absorbing membrane increases efficacy. [1]

One of the novel approaches in the area of oral sustained release drug delivery is gastro retentive drug delivery system

(GRDDS). Drugs those are having a narrow absorption window and having more solubility in gastric region are suitable candidates for

GRDDS[ 2].

Gastroretensive systems can remain in the gastric region for several hours and hence significantly prolong the gastric

residence time of drugs. Prolonged gastric retention improves bioavailability, reduces drug waste and improves solubility for drugs

that are less soluble in a high pH environment. It has applications also for local drug delivery to the stomach and proximal small

intestines. Gastro retention helps to provide better availability of new products with new therapeutic possibilities and substantial

benefits for patients [3]. This application is especially effective in delivery of sparingly soluble and insoluble drugs

Guaifenesin may be commonly used as an expectorant in both productive and non-productive coughs; it is especially useful

in the treatment of dry, Non-productive coughs which tend to injure the respiratory mucous membranes. Guaiphenesin helps loosen

phlegm (mucus) and thin bronchial secretions to rid the bronchial passageways of bothersome mucus, drain bronchial tubes, and make

coughs more productive. Helps loosen phlegm and thin bronchial secretions in patients with stable chronic bronchitis. : Plasma half

life is approximately 1 hour. , makes it a useful candidate for controlled release dosage form and stability in the acidic environment is

useful for gastro-retentive drug delivery system.

The objective of this study include (1) developing floating drug delivery system containing drug and polymers (2) study on

the effect of polymers concentrations and processing parameter on floating and drug release behavior of the system and (3) selection

of the best formulation based on optimization techniques using evaluation parameters like floating lag time, total floating time and

release profile.

The objective of choosing the Guaifenesin was its short half life and to reduce dosing frequency in case cough.

MATERIAL AND METHOD

The following materials that were Pharma grade or the best possible Laboratory Reagent were used as supplied by the

manufacturer without further purification or investigation. Guaifenesin IP, HPMC K15M IP, HPMC K100M IP, Sodium Bicarbonate

LR, Citric Acid LR, Talc LR, Aerosil LR, Magnesium Stearate LR provided by blessing pharmaceutical India , Nagpur.

Preparation of Floating Tablets

Floating tablets of Guaifenesin were prepared by direct compression technique using different grades of polymer with varying

concentration. As shown in table. All the ingredients except magnesium Stearate were blended in mortor uniformly. After the

sufficient mixing of drug as well as other components, magnesium Stearate was added and again mixed for additional 2-3 min. The

well mixed mixture equivalents to 740 mg were compressed using 12mm flat faced punch on clit compression machine.

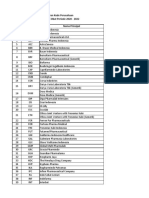

Table 1:The tablet formulation used in current studies shown in following.

Ingredients

F1

F2

F3

F4

F5

F6

F7

F8

F9

Guaifenesin

300

300

300

300

300

300

300

300

300

HPMC K-100M

240

260

280

300

--

--

HPMC K-15M

--

--

--

--

240

260

280

300

150

Sodium Bicarbonate

70

80

90

90

70

80

90

90

90

Citric acid

10

10

10

10

10

10

10

10

Talc

10

10

10

10

10

10

10

10

10

Aerosil

20

20

20

20

20

20

20

20

20

Magnesium Stearate

90

60

30

10

90

60

30

10

10

Total Weight

in mg.

740

740

740

740

740

740

740

740

740

150

5751

--

Page

10

--

In vitro evaluations of floating tablet

Weight variation

Weight variation test was done according to USP.

www.iajpr.com

Vol 4, Issue 12, 2014.

Suchita Gulabrao Waghmare et al.

ISSN NO: 2231-6876

Tablet Hardness:

For each formulation, the hardness of 6 tablets was determined using the Monsanto hardness tester. (Cadmach).

Uniformity of Content:

Five tablets of each formulation were taken and amount of drug present in each tablet was determined. The individual

tablets were crushed and required amount of 0.1N Hydrochloric acid was added to extract the drug and volume was made up to 100

ml with 0.1N hydrochloric acid pH 1.2, filtered through whatman filter paper, 1 ml of filtrate were diluted to 10 ml with 0.1N

hydrochloric acid. The samples were analyzed in spectrophotometer at 276 nm.

Polymer Swelling or Water Uptake Studies:

The rate of test medium uptake by the polymer was determined by equilibrium weight gain method. The study was carried out

in the USP/NF dissolution apparatus I. The polymer matrices were accurately weighed placed in dissolution baskets, immersed in 0.1N

hydrochloric acid pH 1.2 and maintained at 370.5 0C in the dissolution vessels. At regular intervals, the pre weighed basket-matrix

system was withdrawn from the dissolution vessel, lightly blotted with a tissue paper to remove excess test liquid and re-weighed.

The percent water uptake, i.e. degree of swelling due to absorbed test liquid, was estimated at each time point using the

following equation:

Wt. of Swollen Tablet Initial Wt. of the Tablet

S.I. % = ----------------------------------------------------------------------------- 100

Initial wt. of the tablet

Floating Behavior

Floating Behavior studies were carried in a USP Dissolution Testing Apparatus II (paddle type) at paddle speed 50 rpm in

900 ml 0.1 N HCl at 370C for 12 h to mimic in vivo condition. The time interval between the introduction of the tablet into the

dissolution medium and its buoyancy to the top of dissolution medium was taken as buoyancy lag time the duration of system

floatation and also the relative matrix integrity was observed visually .

Floating lag time

This test was performed in beaker containing 200 ml 0.1 N HCl as a testing medium maintained at 370C. The time required

for the tablet to rise to the surface and float was determined as floating lag time .

Dissolution Studies

The release rate of Guaifenesin floating tablets was determined using USP Dissolution Testing Apparatus II (Paddle type).

The dissolution test was performed using 900 ml of 0.1N HCl, at 37 0.5C with 50 rpm. Aliquot (5 ml) of the solution was collected

from the dissolution apparatus hourly for 12 hours and were replaced with fresh dissolution medium. The aliquots were filtered

through Whatmann filter paper no. 41. Absorbance of these solutions was measured at 276nm. Aliquots were withdrawn at one hour

interval from a zone midway between the surface of dissolution medium and the top of rotating paddle not less than 1 cm apart from

the vessel wall. Cumulative percentage drug release was calculated using an equation obtained from a standard curve. Release studies

were performed in triplicate. Analysis of data was done by using PCP Disso V-3 software, India.

Drug release models

Drug release mechanisms and kinetics are the two important characteristics of a drug delivery system in describing drug

dissolution profile. To describe the kinetics of the drug release from tablet, mathematical models such as zero-order, first order,

Higuchi, Hixson-Crowell and Korsmeyer-Peppas models were used.

RESULT AND DISCUSSION

The tablet were prepared by direct compression method following extensive preformulation studies to select the appropriate

formulation components(mainly polymer) the two grades of HPMC(K100M and K15M) to provide sufficient swelling as well as drug

release retardation and sodium bicarbonate was selected as the suitable gas generating agent to reduce floating lag time to provide

sufficient buoyancy to the tablets.

Page

5752

Drug polymer interaction studies by FTIR

Result shows that there was no incompatibility seen in between drug Guaifenesin and polymer (i.e. HPMC K100M) used, as

there was no significant change in the pattern of peaks of optimized batch with pure drug.

www.iajpr.com

Vol 4, Issue 12, 2014.

Suchita Gulabrao Waghmare et al.

ISSN NO: 2231-6876

120

%T

105

90

75

60

45

30

15

4500

pure drug 2

4000

3500

3000

2500

2000

1750

1500

1250

1000

750

500

1/cm

Graph 1: FTIR spectra of pure drug.

25

0%

T

22

5

20

0

17

5

15

0

12

5

10

0

7

5

5

0

2

5

0

450

400

Drug + hpmc k

0

0

100 M

350

0

300

0

250

0

200

0

175

0

150

0

125

0

100

0

75

0

50

1/c

0

m

Graph 2: FTIR spectra of mixture of drug and hpmc K100M.

Evaluation of Floating tablet of Guaifenesin.

www.iajpr.com

Weight Variation

741.411.12

739.960.54

740.010.75

741.500.01

739.562.55

741.891.42

741.920.27

740.811.52

739.421.07

Page

Formulation Thickness Hardness Friability

F1

6.30.04

6.00.06 0.4440.08

F2

6.50.06

6.40.05 0.4530.10

F3

6.50.08

6.50.02 0.4320.14

F4

6.50.08

6.00.02 0.4280.04

F5

6.30.06

6.00.05 0.4310.11

F6

6.50.04

6.00.05 0.4260.11

F7

6.50.02

6.30.02 0.4280.09

F8

6.40.09

5.80.06 0.4520.12

F9

6.30.06

6.00.04 0.4420.08

*All the values are represents as Mean S. D. (standard deviation) (n=3)

5753

Table no.2

Vol 4, Issue 12, 2014.

Suchita Gulabrao Waghmare et al.

ISSN NO: 2231-6876

Table no.2 Swelling Index study.

Time (hrs)

Batch 3

6

9

F1

0.57 0.85 0.77

F2

0.59 0.86 0.78

F3

0.60 0.90 0.81

F4

0.61 0.92 0.82

F5

0.53 0.79 0.74

F6

0.56 0.83 0.76

F7

0.59 0.89 0.80

F8

0.60 0.91 0.80

F9

0.61 0.93 0.82

*All the values are represents as Mean S. D. (standard deviation) (n=3)

12

0.69

0.70

0.72

0.74

0.65

0.66

0.72

0.74

0.75

Graph no 3: swelling index of floating tablets.

The hydration ability of the polymer is important because it influences: (i) tablet buoyancy, (ii) adhesion ability of swellable

polymers as HPMC K15M, HPMC K100M in contact with the test fluid and (iii) drug release kinetics.Among all the batches the

greater swelling index i.e.0.93% was observed in F9 batch.

Table No. 3 Floating lag time and Buoyancy duration.

Buoyancy duration (hrs)

>10

>11

>11

>12

>9

>10

>10

>12

>12

5754

Floating lag time (sec)

210.14

220.02

180.04

160.02

250.09

210.06

200.02

160.04

180.06

Page

Formulation

F1

F2

F3

F4

F5

F6

F7

F8

F9

www.iajpr.com

Vol 4, Issue 12, 2014.

Suchita Gulabrao Waghmare et al.

ISSN NO: 2231-6876

Table No. 4 In-vitro drug release study.

F1

0

21.26

37.10

55.66

64.03

73.07

84.40

90.54

99.56

F2

0

20.39

34.60

53.69

61.03

69.83

71.56

78.33

83.88

91.44

98.29

F3

0

22.12

28.00

34.08

39.69

46.34

52.66

59.16

64.94

71.22

77.49

82.74

87.05

F4

0

23.58

29.85

36.37

43.34

49.07

54.66

60.89

67.87

74.58

80.07

86.43

92.34

F5

0

21.59

36.38

54.81

63.31

73.91

84.98

92.32

99.63

F6

0

20.00

34.33

53.10

60.50

69.37

70.98

77.50

83.50

91.38

98.79

F7

0

18.60

25.29

30.73

36.17

42.13

47.69

52.81

88.63

65.07

70.43

74.34

78.39

F8

0

21.79

27.14

33.42

38.84

46.21

52.01

58.90

64.17

70.71

77.05

82.11

86.05

F9

0

21.26

26.02

31.45

36.69

41.61

46.85

52.42

56.97

62.22

67.28

73.90

79.01

Graph 5: Percent cumulative release of F5,F6,F7,F8,F9.

5755

Graph 4 :Percent cumulative release of F1,F2,F3,F4.

Page

Time(hrs)

0

1

2

3

4

5

6

7

8

9

10

11

12

www.iajpr.com

Vol 4, Issue 12, 2014.

Suchita Gulabrao Waghmare et al.

ISSN NO: 2231-6876

Optimization of formulation

Analysis of the results obtained from formulation f4 concluded that the formulation containing HPMC K100M 300mg was

devised as optimized formula. Formulation F4 shows the satisfactory results in terms of flow property, friability, hardness, Floating

lag time, swelling index, Percent drug released. So formulation F4 is an optimized batch and chooses for further stability study. The

results of the various tests performed on this batch were as given in below

Table 5: Optimization parameters.

Sr. No.

1.

2.

3.

4.

5.

6.

7.

8.

Parameters

Appearance

Dimensions

Hardness

Weight variation

Ex- vivo Floating time

Ex-vivo Floating lag time

Surface pH

In-vitro drug release

Results

Good

Diameter:10.09 mm 0.1 mm

Thickness- 6.50.08

6.00.02 kg/cm2

Passes

More than 12 hrs.

160.02

57

92.34% in 12 hrs

Table 6: Kinetic model fitting of release data.

R2 values

Batch No.

F1

F2

F3

F4

F5

F6

F7

F8

F9

Zero order

0.996

0.994

0.954

0.908

0.995

0.973

0.925

0.913

0.888

First order

0.972

0.971

0.908

0.958

0.978

0.995

0.962

0.956

0.934

Higuchi

Model

0.967

0.964

0.995

0.996

0.966

0.964

0.997

0.993

0.994

Hixson-Crowell

0.995

0.992

0.941

0.944

0.997

0.993

0.952

0.944

0.92

Korsmeyar-Peppas

0.9911

0.9713

0.9760

0.982

0.9939

0.9712

0.89

0.9727

0.975

n value(release exponent(n)

0.784

0.786

0.453

0.457

0.778

0.793

0.5

0.458

0.417

www.iajpr.com

Page

FUTURE SCOPE

Using the above formulation the drugs can be targeted to the specific region of body (stomach) in vicinity of absorption site.

All over the present investigation may put forth new areas for research and development and new formulation techniques to deal

with certain diseases in which drug residence time and bioavailability may be a problem of great concern.

To study in-vivo gastro retentive gamma-Scintigraphic.

To study in-vivo - in-vitro correlation (IVIVC).

To study the floating tablets prepared with different polymers and gas generating agents with different polymer combinations and

concentrations.

To study of floating concept and release of the drug at the stomach pH

To develop more cost affecting formation of Guaifenesin by using polymers. Which are cheap, easily available.

To carry out In-vivo study of optimized formulation and to determine various important pharmacokinetic such as T max , C max, AUC

To evaluate the floating performance of various polymers alone and in combination.

The floating concept can also be utilized in the development of various anti-reflux formulations.

5756

CONCLUSION

The present work showed that promising controlled-release floating matrix tablets of Guaiphenesin were successfully

formulated by effervescent technique.

Tablets containing HPMC K100M, NaHCO3 (formula F4) showed satisfactory results with respect to floating lag time, total

floating duration, swelling ability, and controlled drug release rates. Concentration and viscosity of polymer showed directly

proportional relationship with swelling characteristics of tablet. As viscosity and concentration of polymers increased, release rate of

drug was retarded. As the concentration of HPMC increases, percent drug release rate and floating lag time decreases. So it is

concluded that HPMC can act as floating enhancer. Drug release profiles on model fitting of optimized formulation F4 follows matrix

as best fit model which indicate that drug release is controlled by diffusion of drug through the pores.

Finally it was concluded that, the formulating stomach specific floating tablet of Guaifenesin by using direct compression

technique has been prepared successfully.

Vol 4, Issue 12, 2014.

Suchita Gulabrao Waghmare et al.

ISSN NO: 2231-6876

REFERENCES

1. Bardonnet P. L., Gastroretentive dosage forms: Overview and special case of Helicobacter pylori. J. Control. Rel., 111 (2005); 118.

2. Ichikawa M, Kato T, Kawahara M, Watanabe S, Kayano M. A new multiple-unit oral floating dosage system. II: In vivo

evaluation of floating and sustained-release characteristics with p-amino benzoic acid and isosorbide dinitrate as model drugs. J.

Pharm. Sci. 1991; 80: 11531156.

3. Mayavanshi A.V. and Gajjar S.S. , Floating drug delivery systems to increase gastric retention of drugs: Research J. Pharm. and

Tech. 1(4): Oct.-Dec. 2008

4. Yie W. Chien; Novel Drug Delivery Systems, 2nd Edition, pp. 1, 139,164

5. Donald L. Wise; Handbook of Pharmaceutical Controlled Release Technology, pp. 465.

6. Chiao CSL, Robinson JR. Sustained release drug delivery systems, in Remingtons: The science and Practice of Pharmacy, A.R.

Gennaro, Editor. 1995, Mark Publishing Company: Pennsylvania. p 126-132.

7. Singh G., Gastroretentivity: Its Drug Delivery Potential, I. J. P. S. 2002; 2:282

8. Lachman L., Liebermann H. A., Kanig J. L., The theory and practice of industrial pharmacy, 3 rd Edn, Lea and Fibiger

Philadelphia., 1987; 430-431.

9. Jain N. K., Advances in controlled and novel drug delivery.1st Edn, 2001; 1-7.

10. Aulton M. E., Pharmaceutics: The Science of Dosage Form Design. 2 nd Edn. Published by Livingstone C. Elsevier science Ltd.

2002; 315-320.

Page

5757

54878478451141217

www.iajpr.com

You might also like

- Dipti PAN Paper PWCOPDocument1 pageDipti PAN Paper PWCOPGajanan DeshmukhNo ratings yet

- 50 141269Document7 pages50 141269Gajanan DeshmukhNo ratings yet

- 44 141241Document10 pages44 141241Gajanan DeshmukhNo ratings yet

- 41 141218Document11 pages41 141218Gajanan DeshmukhNo ratings yet

- 48 141231Document6 pages48 141231Gajanan DeshmukhNo ratings yet

- 40 141138Document10 pages40 141138Gajanan DeshmukhNo ratings yet

- 46 141252Document6 pages46 141252Gajanan DeshmukhNo ratings yet

- 49 141267Document10 pages49 141267Gajanan DeshmukhNo ratings yet

- 47 141235Document9 pages47 141235Gajanan DeshmukhNo ratings yet

- 45 141244Document9 pages45 141244Gajanan DeshmukhNo ratings yet

- 42 141229Document13 pages42 141229Gajanan DeshmukhNo ratings yet

- 43 141230Document11 pages43 141230Gajanan DeshmukhNo ratings yet

- 38 141213Document8 pages38 141213Gajanan DeshmukhNo ratings yet

- 39 141120Document6 pages39 141120Gajanan DeshmukhNo ratings yet

- 35 141248Document10 pages35 141248Gajanan DeshmukhNo ratings yet

- 36 141238Document6 pages36 141238Gajanan DeshmukhNo ratings yet

- 34 141234Document11 pages34 141234Gajanan DeshmukhNo ratings yet

- 37 141242 PDFDocument6 pages37 141242 PDFGajanan DeshmukhNo ratings yet

- 33 141204Document9 pages33 141204Gajanan DeshmukhNo ratings yet

- 32 141144Document7 pages32 141144Gajanan DeshmukhNo ratings yet

- 28 141164Document4 pages28 141164Gajanan DeshmukhNo ratings yet

- 31 141119Document4 pages31 141119Gajanan DeshmukhNo ratings yet

- 26 141210Document7 pages26 141210Gajanan DeshmukhNo ratings yet

- 30 141236Document5 pages30 141236Gajanan DeshmukhNo ratings yet

- 27 141221Document10 pages27 141221Gajanan DeshmukhNo ratings yet

- 22 141208Document10 pages22 141208Gajanan DeshmukhNo ratings yet

- 29 141227Document5 pages29 141227Gajanan DeshmukhNo ratings yet

- 25 141214Document3 pages25 141214Gajanan DeshmukhNo ratings yet

- Current Status of Leukotriene Antagonists in Bronchial AsthmaDocument5 pagesCurrent Status of Leukotriene Antagonists in Bronchial AsthmaGajanan Deshmukh100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Certificate For COVID-19 Vaccination: Beneficiary DetailsDocument1 pageCertificate For COVID-19 Vaccination: Beneficiary DetailsDDHS KANCHEEPURAMNo ratings yet

- 8B - Antianginal DrugsDocument70 pages8B - Antianginal Drugslalitrajindolia100% (1)

- Alphabetic Paediatric Doses 3Document44 pagesAlphabetic Paediatric Doses 3yayuk100% (1)

- Kode Perusahaan Peserta Standarisasi Obat PDFDocument3 pagesKode Perusahaan Peserta Standarisasi Obat PDFHandry HuaNo ratings yet

- Archana J R 11th AprilDocument2 pagesArchana J R 11th AprilArchana J RetinueNo ratings yet

- Catalog WellcareDocument36 pagesCatalog WellcareMichelangeloTiberiiNo ratings yet

- Drug Study SurgeryDocument1 pageDrug Study SurgerygorgeazNo ratings yet

- Prescriptions Examples PDFDocument2 pagesPrescriptions Examples PDFkat100% (1)

- Daftar Pustaka: Pharmaceutical Sciences, New York, Marcel Dekker IncDocument2 pagesDaftar Pustaka: Pharmaceutical Sciences, New York, Marcel Dekker IncIqbal HafidzNo ratings yet

- Drug Study - AmpicillinDocument1 pageDrug Study - AmpicillinJet BautistaNo ratings yet

- Aspirin Cardio 100mg X 30cp Film Gastrorez-Btagde1Document4 pagesAspirin Cardio 100mg X 30cp Film Gastrorez-Btagde1Cristina Mariuca AndreiNo ratings yet

- Daftar Harga Vaksinasi Oktober 2022Document1 pageDaftar Harga Vaksinasi Oktober 2022IF RS Surya AsihNo ratings yet

- Daftar ObatDocument1 pageDaftar ObatNPDNo ratings yet

- Common Medication Administration Forms and Delivery MethodsDocument19 pagesCommon Medication Administration Forms and Delivery MethodsJonica AngNo ratings yet

- Asmol Syrup Salbutamol Sunward Pharmaceutical SDN BHD 22jan2016 Eng1Document2 pagesAsmol Syrup Salbutamol Sunward Pharmaceutical SDN BHD 22jan2016 Eng1Nadia SalwaniNo ratings yet

- Clinical Pharmacy Answer Key-PINK PACOP PDFDocument37 pagesClinical Pharmacy Answer Key-PINK PACOP PDFArk Olfato ParojinogNo ratings yet

- Managing Nausea and Vomiting of PregnancyDocument2 pagesManaging Nausea and Vomiting of PregnancyAnna LiachenkoNo ratings yet

- Pfizer COVID vaccine preparation and administration guideDocument3 pagesPfizer COVID vaccine preparation and administration guideL Jossenel Mejido-AñanoNo ratings yet

- Slu Pcal Notes PDFDocument7 pagesSlu Pcal Notes PDFMieNo ratings yet

- Pharma Handouts Rev 3Document34 pagesPharma Handouts Rev 3Aphrill Pearl PacisNo ratings yet

- Efficacy and Adverse Events of Oral Isotretinoin For Acne: A Systematic ReviewDocument10 pagesEfficacy and Adverse Events of Oral Isotretinoin For Acne: A Systematic ReviewFerryGoNo ratings yet

- Dopamine HCLDocument1 pageDopamine HCLIvanne Hisoler100% (3)

- Bonus Product Sales March-2023Document3 pagesBonus Product Sales March-2023Mahbub Alam SarkerNo ratings yet

- Pharmaco DynamicsDocument8 pagesPharmaco DynamicsPradnya ParamitaNo ratings yet

- Common Pharmacy Abbreviation & Dosage FormsDocument14 pagesCommon Pharmacy Abbreviation & Dosage FormsKENNETH GENER JAMES SOMERANo ratings yet

- Ropivacaine Vs Bupivacaine PDFDocument6 pagesRopivacaine Vs Bupivacaine PDFJessica LawrenceNo ratings yet

- Tetanus ProphylaxisDocument4 pagesTetanus ProphylaxisRifda LatifaNo ratings yet

- Ma Huang Ephedrae Herba Setting The Record StraightDocument13 pagesMa Huang Ephedrae Herba Setting The Record StraighttiaraNo ratings yet

- Alevo Alkem (Ulticare) (Levofloxacin) : Strength Presentation PriceDocument21 pagesAlevo Alkem (Ulticare) (Levofloxacin) : Strength Presentation Pricepathan mohidNo ratings yet

- Pedia Notes Compilation MKDoseDocument18 pagesPedia Notes Compilation MKDosemefav7778520No ratings yet