Professional Documents

Culture Documents

Control of Substances Hazardous To Health and Safety Risk Assessment Form

Uploaded by

hemanth_chaturvedulaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Control of Substances Hazardous To Health and Safety Risk Assessment Form

Uploaded by

hemanth_chaturvedulaCopyright:

Available Formats

EEE 5356, Integrated Circuit Technology

University of South Florida

Fall 2014.

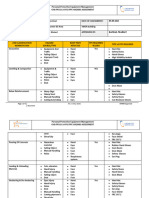

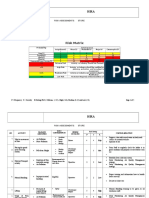

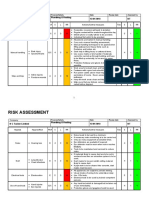

CONTROL OF SUBSTANCES HAZARDOUS TO HEALTH AND

SAFETY RISK ASSESSMENT FORM(1,2)

Date:

10/27/2014

Laboratory:

ENB 111

Course title:

ICT-Lab

Section

number

S1

Materials information

Explanation of Practice

University/ Location / Lab number

Check the MSDS and see of any of these materials are:

Check of any of these materials are

hazardous to health:

(Use of the material as solvent/solute/solution?)

67-56-1

1314-56-3

Methyl Alcohol

CASN

(if available)

Amount

Metals, Acids and oxidizing agents.

have to make contact with?

Note the lowest flash point

PROCESS INFORMATION

Brief description of process and controls in place minimise risk

If suitable, main experimental work should

only be performed by these Engineers/

Scientist/ Staff

Engineer with sufficient experience or a scientist or a well-trained professional.

METHODS OF PREVENTIONS/ ENGINEERING CONTROLS AND MEASURES

Prepared by: Hemanth Kumar Chaturvedula

Carcinogen (C)/

Mutagen (M)/

Teratogens (T)

If ingested

Toxic

(T)

If inhaled

Very

Toxic (T+)

Amount

(mg, g, ml, etc)

Hazardous for

Environment

(N)

Irritant

(Xi)

Oxidising

(O)

64-17-5

Chemical Reactions: Any chemical or material (s) should not

Harmful

(Xn)

Corrosive (C)

Explosive

(E)

Ethyl Alcohol

Materials produced and waste

Highly

Flammable

(F)

Ethyl Acetate

CASN

(if available)

141-78-6

Phosphorus Pentoxide

Extremely

Flammable

(F+)

Material(s) used

If in contact with

eyes

USF/ENB/ 111

as a solution

If in contact with

skin

PHOSPHOROSILICAFILM 5 x 1020

131o F

(open

cup)

EEE 5356, Integrated Circuit Technology

University of South Florida

Fall 2014.

Any less hazardous materials or processes

If yes, why cannot being

replaced?

If yes, provide information

be used?

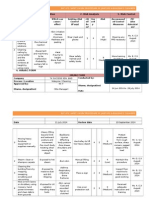

Any of these materials have Workplace

Other: (e.g. Competent

Individuals(I)l/ Back up

person) (B)

Guests (V) / Suppliers

(S) /Cleaners (C)

Pregnant women (PW)

Minors

Engineers /

Researchers(S/R)

Safe Access control:

Employees /Staff

Protective clothing

Engineering measures required to prevent and control risks

Gloves

Respirator

200 ppm

Approved Personal

Protective Equipment

Goggles / Facemask

Methyl Alcohol

Full enclosure/ Glove

Box (GB)

Fume Cupboard (FC)

1000 ppm (skin)

Local Exhaust

Ventilation (LEV)

Short Term Exposure

Limit (mins?)

Ethyl Alcohol

Extra precautions (e.g. Specify types of eye

protection, laboratory coats, gloves, etc)

Engineering Controls

Open Bench (OB)

Ethyl Acetate

below

Threshold Limit Value, or

Permissible Exposure

Limits (PPM)

400 ppm (skin)

Other:

Exposure Limits?

Material(s)

Use clean safety glasses with protection and laboratory coat. Use appropriate NIOSH-approved respirator for organic vapor if exposure is likely to exceed

acceptable limits.

EMERGENCY PROCEDURES AND PRECAUTIONS

First Aid: Action to be taken if any substance(s) are:

Note the necessary procedures to prevent and control accidental leakage, release or spillage

Ingested/Swallowed: Can

cause depression of central nervous system. Nausea,

vomiting, diarrhoea.

In contact with Skin:

In contact with Eyes:

May cause irritation and defatting of skin on prolonged contact

Liquid or vapor may cause irritation

Safety glasses should be worn if there is any danger of splashing. Persons with sensitive skin should wear

gloves and protective clothing.

Note the necessary actions to be taken in the incident of a fire caused by these materials(s)?

(e.g. fighter fighters should wear SCBA, use water fog, alcohol free resistance foam, dry powder, CO2

extinguisher, or other fire precautions)

Dry chemical, Carbon Dioxide, or Alcohol "foam". Water may be ineffective, but should be used to keep fireexposed containers and surfaces cool. If a leak or spill has not ignited, use water spray to disperse vapours

and to protect men attempting to stop leak. Water spray may be used to flush spills away from exposure and

to dilute spills to non-flammable mixtures (NFPA-49 1975).

Fire-fighter should wear self-contained breathing apparatus in the positive mode with full face piece when

there is a possibility of exposure to smoke, fumes or hazardous decomposition products

Handling and storage requirements: Note any special requirements e.g. ventilation, chemical

incompatibility, flash point, etc.

At least 10 air changes per hour for good general room ventilation

Note the Disposal procedure/ treatment of these materials (or not disposed of)?

(e.g (non)halogenated waste, acid waste, photoresist waste, etc)

Observe all federal, state and local laws regarding hazardous waste removal and recycling.

Inhaled:

Exposure to more than above listed threshold limit may cause headache,

Prepared by: Hemanth Kumar Chaturvedula

EEE 5356, Integrated Circuit Technology

University of South Florida

Fall 2014.

Reference of MSDS Information

(e.g. Merck Chemicals. Sigma

drowsiness and lassitude, loss of appetite, throat irritation and inability to

concentrate.

Is heath examination necessary?

Is training necessary for this practice?

Aldrich, etc)

Authorization

EMULSITONE COMPANY

http://www.emulsitone.com/psif5x10_20msds.htm

REASSESSMENT (Yearly)

(e.g. If significant change occurs, change of Lab, pregnancy,

etc)

Assessment

completed By:

Name: Hemanth Kumar Chaturvedula

Signature:

Date:10/26/2014

TA(s):

Name:

Signature:

Date:

Departmental

Professor:

Name:

Signature:

Date:

(1) United States Occupational Safety and Health Administration

(2) COSHH risk assessments form, UK Health and Safety Executive

Prepared by: Hemanth Kumar Chaturvedula

Date for reassessment

Reassess date

reassessed by

You might also like

- Heat Stress: by Manikandan.V HSE AdvisorDocument22 pagesHeat Stress: by Manikandan.V HSE AdvisorManikandan Vijayanarayanan100% (1)

- 14-F02 Ppe Hazard AssessmentDocument3 pages14-F02 Ppe Hazard AssessmentZaheer AhmedNo ratings yet

- Very Very Good Risk Assessment EnvironmentDocument8 pagesVery Very Good Risk Assessment EnvironmentSalley Bukhari100% (1)

- culture of safety A Complete Guide - 2019 EditionFrom Everandculture of safety A Complete Guide - 2019 EditionRating: 5 out of 5 stars5/5 (1)

- Generic Risk Assessment - General Lathe Use v.1Document7 pagesGeneric Risk Assessment - General Lathe Use v.1Darus YasunNo ratings yet

- Occupational health and safety A Complete Guide - 2019 EditionFrom EverandOccupational health and safety A Complete Guide - 2019 EditionNo ratings yet

- First Aid Risk Assessment TemplateDocument3 pagesFirst Aid Risk Assessment TemplateRameeSahibaNo ratings yet

- Pregnancy Risk AssessmentDocument6 pagesPregnancy Risk AssessmentSTEVEN DELAHUNTYNo ratings yet

- COSHH Risk Assessment For RoundUPDocument2 pagesCOSHH Risk Assessment For RoundUPRonnie Murphy Knotweed Surveyor50% (2)

- Toolbox Talks Pneumatic Tools EnglishDocument1 pageToolbox Talks Pneumatic Tools EnglishebbasinghNo ratings yet

- 31.0.9 ALR - Loading & Off-Loading TruckDocument5 pages31.0.9 ALR - Loading & Off-Loading TruckGerrit100% (1)

- 02 General Aspect Impact StudyDocument1 page02 General Aspect Impact StudymakdelNo ratings yet

- Autoclaves - Generic Assessment - L Use of AutoclavesDocument1 pageAutoclaves - Generic Assessment - L Use of AutoclavesaKureishiNo ratings yet

- Heat Stress ProcedureDocument13 pagesHeat Stress ProcedureKneekEy CastleNo ratings yet

- Coshh: Diesel FuelDocument2 pagesCoshh: Diesel FuelIdris Adeshina AdeniranNo ratings yet

- COSHH Form TemplateDocument2 pagesCOSHH Form TemplatePhillipe LysNo ratings yet

- COSHH Assessment RecordDocument4 pagesCOSHH Assessment RecordUwaysNo ratings yet

- PPE MatrixDocument1 pagePPE MatrixcaptainphihungNo ratings yet

- Officeriskassess 259943Document2 pagesOfficeriskassess 259943api-332787463No ratings yet

- Chelston Decorators Health and Safety PolicyDocument13 pagesChelston Decorators Health and Safety PolicySam MurrayNo ratings yet

- Risk Assessments - StoreDocument5 pagesRisk Assessments - Storederwaishjee1100% (1)

- Safe Working PracticesDocument7 pagesSafe Working PracticesDiana ParkerNo ratings yet

- Example COSHH Risk Assessment - Warehouse - COSHHDocument2 pagesExample COSHH Risk Assessment - Warehouse - COSHHWisnu KertaningnagoroNo ratings yet

- Aspect and Impact RegisterDocument3 pagesAspect and Impact RegisterEnimizufa DiepreyeNo ratings yet

- Heat StressDocument13 pagesHeat StressSubhi El Haj Saleh100% (1)

- Monthly Safety ReportDocument1 pageMonthly Safety Reportsafety.engNo ratings yet

- Ohs-Pr-09-09-F31 (A) Leadership Safety Inspection & Walkthrough FormDocument6 pagesOhs-Pr-09-09-F31 (A) Leadership Safety Inspection & Walkthrough FormSiddiqui100% (1)

- Control of Substances Hazordous To HealthDocument16 pagesControl of Substances Hazordous To Healthnathan_roadNo ratings yet

- Heat Stress Management Inspection ChecklistDocument1 pageHeat Stress Management Inspection ChecklistrexivyNo ratings yet

- EVT471Document3 pagesEVT471Nurul AqielaNo ratings yet

- 08.COSHH RegisterDocument38 pages08.COSHH RegisterRichu Pali100% (1)

- Daily HSE ReportDocument5 pagesDaily HSE ReportSayeed MalikNo ratings yet

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDocument1 pageJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingalekyaNo ratings yet

- R-001-Rev.1-Hse Monthly Site November 2021Document3 pagesR-001-Rev.1-Hse Monthly Site November 2021Ravelle JacquireNo ratings yet

- Fire - Risk AssessmentDocument14 pagesFire - Risk AssessmentRameeSahiba100% (1)

- Instructions For Use: Hse-Pro-006A Asbestos Management - Minor Works SwmsDocument21 pagesInstructions For Use: Hse-Pro-006A Asbestos Management - Minor Works SwmsWinstone AudiNo ratings yet

- Chemical Risk Assessment 2013 1 Copy 1 PDFDocument3 pagesChemical Risk Assessment 2013 1 Copy 1 PDFShekel Denino100% (1)

- Hira - 01Document3 pagesHira - 01Angw BasumataryNo ratings yet

- 4.5.5 Safety Management Internal AuditDocument10 pages4.5.5 Safety Management Internal AuditJim AlianNo ratings yet

- Emergency Response Plan Sri City Project Rev 00Document23 pagesEmergency Response Plan Sri City Project Rev 00HSE OFFICENo ratings yet

- Risk AssessmntDocument5 pagesRisk Assessmntapi-456358200No ratings yet

- Control of Substances Hazardous To Health (COSHH) Procedure Ref HS-0001-013-v2Document24 pagesControl of Substances Hazardous To Health (COSHH) Procedure Ref HS-0001-013-v2Tiago FerreiraNo ratings yet

- SOP Workplace InspectionsDocument5 pagesSOP Workplace InspectionskafilussNo ratings yet

- Reactive Indicators Proactive Indicators: Monthly Hse Statistics Project: Month: Year: Report NoDocument1 pageReactive Indicators Proactive Indicators: Monthly Hse Statistics Project: Month: Year: Report NoMd. Ashraful IslamaNo ratings yet

- OHS Baseline Risk Assessment - Catering Contract October 2021Document18 pagesOHS Baseline Risk Assessment - Catering Contract October 2021denoiNo ratings yet

- Fire Extinguisher Training: Instructor: SGT Michael Chism Bco204 Elm ShopDocument37 pagesFire Extinguisher Training: Instructor: SGT Michael Chism Bco204 Elm ShopTimmy CheongNo ratings yet

- FM - HSE COSHH Assessment-2Document3 pagesFM - HSE COSHH Assessment-2anisaanNo ratings yet

- 02-010 Substance Abuse PolicyDocument6 pages02-010 Substance Abuse PolicyJoachimNo ratings yet

- Coshh Assessment: Job / Task: Heavy Duty Degreaser and CleanerDocument6 pagesCoshh Assessment: Job / Task: Heavy Duty Degreaser and CleanerSayed SallamNo ratings yet

- COSHH Assessment FormDocument2 pagesCOSHH Assessment Formsupriyo sarkar100% (1)

- Incident Investigation - Five WhyDocument1 pageIncident Investigation - Five WhytanoycometNo ratings yet

- Life Saving Rules Speaker Support Pack Jan 2012Document33 pagesLife Saving Rules Speaker Support Pack Jan 2012Muhammed AliNo ratings yet

- EHS Induction Training ModuleDocument19 pagesEHS Induction Training ModuleBhaskar ShuklaNo ratings yet

- JHA # 009 - Hot WorkDocument7 pagesJHA # 009 - Hot WorkkumarNo ratings yet

- Guidelines For Personal Protective Equipment (Ppe) : JUNE 2020Document40 pagesGuidelines For Personal Protective Equipment (Ppe) : JUNE 2020Tanri Andita Wicaksono100% (1)

- HSES HandbookDocument48 pagesHSES HandbookNorman Ainomugisha100% (1)

- Risk Assessment - House and BuildingDocument1 pageRisk Assessment - House and Buildingnayanahari0% (1)

- PDS MS 512Document2 pagesPDS MS 512ameliaNo ratings yet

- RAMS For Installation of Fire Fighting SystemDocument24 pagesRAMS For Installation of Fire Fighting SystemAnandu AshokanNo ratings yet

- RA For Plumbing and HeatingDocument8 pagesRA For Plumbing and HeatingAngela DaveyNo ratings yet

- SAMPLE HIRARC - Register - Generic Risk AssessmentDocument12 pagesSAMPLE HIRARC - Register - Generic Risk AssessmentjohainaNo ratings yet

- HSE-CA - StyreneDocument3 pagesHSE-CA - StyreneRobert PilloraNo ratings yet

- COMPETENCY BASED LEARNING MATERIAL MassaDocument97 pagesCOMPETENCY BASED LEARNING MATERIAL MassaLaurice Marie GabianaNo ratings yet

- HTM 03-01 Specialised Ventilation For Health Care PremisesDocument134 pagesHTM 03-01 Specialised Ventilation For Health Care PremisesArvish RamseebaluckNo ratings yet

- Wireline 4Document170 pagesWireline 4William EvansNo ratings yet

- Free Download Chemical and Process Plant Commissioning Handbook A Practical Guide To Plant System and Equipment Installation and Commissioning 2Nd Edition Martin Killcross Full Chapter PDFDocument52 pagesFree Download Chemical and Process Plant Commissioning Handbook A Practical Guide To Plant System and Equipment Installation and Commissioning 2Nd Edition Martin Killcross Full Chapter PDFjohn.hines542100% (16)

- Edoc 18 HealthDocument185 pagesEdoc 18 HealthdedNo ratings yet

- PURELAB Chorus 2 1 Complete Service Manual Issue 9 SERVMAN032 1Document129 pagesPURELAB Chorus 2 1 Complete Service Manual Issue 9 SERVMAN032 1Алексей57% (7)

- Philosophy of SafetyDocument34 pagesPhilosophy of Safetysuraj100% (1)

- Operating and Maintenance Manual: (Project Name)Document75 pagesOperating and Maintenance Manual: (Project Name)Bob MorrisNo ratings yet

- TPT Ol 009 Plaster of ParisDocument7 pagesTPT Ol 009 Plaster of ParisAhmed IdreesNo ratings yet

- Health and Safety Guidance: Risk AssessmentDocument20 pagesHealth and Safety Guidance: Risk AssessmentNijo JosephNo ratings yet

- Gyproc Habito Board DatasheetDocument6 pagesGyproc Habito Board DatasheetJanna BakeerNo ratings yet

- Cello 6S Manual 2137PM9001Document41 pagesCello 6S Manual 2137PM9001Cristian MaiceloNo ratings yet

- MS-PR02705 Training & Certification Standards For Offshore PersonnelDocument22 pagesMS-PR02705 Training & Certification Standards For Offshore PersonnelJansenNo ratings yet

- Sika Latex Self Levelling Safety Data SheetDocument7 pagesSika Latex Self Levelling Safety Data SheetLamHoangminhNo ratings yet

- MS Undercroft Hollowcore Plank Placing Rev A WFDocument12 pagesMS Undercroft Hollowcore Plank Placing Rev A WFChoubi ChoubacaNo ratings yet

- Unit 202 Health and Safety Makeup Beauty Hair Level 2Document6 pagesUnit 202 Health and Safety Makeup Beauty Hair Level 2So Bia IlyasNo ratings yet

- Benning Constuction Health and Safety PolicyDocument198 pagesBenning Constuction Health and Safety PolicyGia Minh Tieu TuNo ratings yet

- Wireline 2Document178 pagesWireline 2William EvansNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingDocument11 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingElliot TecamachaltziNo ratings yet

- TH3 Saturation Pressure PDFDocument56 pagesTH3 Saturation Pressure PDFRiccardo VianelloNo ratings yet

- Safe Working and The Prevention of Infection in The Mortuary and Post-Mortem RoomDocument49 pagesSafe Working and The Prevention of Infection in The Mortuary and Post-Mortem RoommaiNo ratings yet

- Management and Health Safety Handover ChecklistDocument2 pagesManagement and Health Safety Handover ChecklistMariam BakariNo ratings yet

- Data-Sheet HiBrite PDFDocument3 pagesData-Sheet HiBrite PDFRaj H PatelNo ratings yet

- Risk Assessment For Installation of Sanitary Fixtures and Mixers (New)Document12 pagesRisk Assessment For Installation of Sanitary Fixtures and Mixers (New)Anandu Ashokan100% (1)

- Kollidon+90+F 000000000030034978 SDS GEN GB en 9-0Document13 pagesKollidon+90+F 000000000030034978 SDS GEN GB en 9-0Palak AgarwalNo ratings yet

- Arizona, Utah & New Mexico: A Guide to the State & National ParksFrom EverandArizona, Utah & New Mexico: A Guide to the State & National ParksRating: 4 out of 5 stars4/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensFrom EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNo ratings yet

- The Bahamas a Taste of the Islands ExcerptFrom EverandThe Bahamas a Taste of the Islands ExcerptRating: 4 out of 5 stars4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoFrom EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoRating: 5 out of 5 stars5/5 (1)

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptFrom EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptRating: 5 out of 5 stars5/5 (1)

- New York & New Jersey: A Guide to the State & National ParksFrom EverandNew York & New Jersey: A Guide to the State & National ParksNo ratings yet