Professional Documents

Culture Documents

Specification of Bulb Turbine(结构说明)- PL1

Uploaded by

An NguyenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specification of Bulb Turbine(结构说明)- PL1

Uploaded by

An NguyenCopyright:

Available Formats

BAI THUONG HYDROPOWER PROJECT

Zhejiang Jinlun Electromechanic Co., Ltd

BIDDING DOCUMENTS - PACKAGE BT-20

TECHNICAL PROPOSAL

Appendix 1. SPECIFICATION FOR BULB TURBINES

1.1 General

The turbine will be of the horizontal single shaft single runner of adjustable blades,

axial flow, and bulb type for direct coupling to generators housed in the bulb. The direction

of rotation will be clockwise when looking from the upstream of the generator. Each bulb

turbine will be so designed and constructed that all removable parts including runner, shaft,

guide bearing, shaft seal, guide apparatus etc., can be easily removed. Suitable vertical

access shaft will be provided to permit access from above to the turbine compartment. This

shaft may also contain oil and water piping. The design will also permit removal of runner

blades for repairs etc., without dismantling the turbines. It shall be possible to repair/ replace

turbine shaft seal without dewatering the draft tube for which purpose additional repair seal

shall be provided.

Turbine main parameter:

Capacity:

3.125MW2Unit

Head (m):

6.65/6.0/5.08

Output (kW) :

3125

Discharge (m3/s):

56.98

Speed (r/min):

136.4

Runner diameter (mm):

3000

1.2 Constructional features

Each turbine will be a horizontal shaft bulb type, with movable wicket gates and

adjustable runner blades. The turbine will be directly coupled to a generator. The turbine

and the generator will be housed in an absolutely water tight bulb shaped steel casing and

installed in a water passage. The rotating part of generator and turbine will be supported by

two guide bearings.

The turbine will consist of (1)fixed parts embedded in concrete, such as the outer stay

cones, stay column and the draft tube liner, and(2)the stationary parts which can be

dismantled, such as the discharge, and outer and inner guide ring, and(3)the rotating parts

such as the main shaft, the runner ,guide bearing and main shaft seal and oil head.

(1) General

The turbine runner will have four adjustable blades, designed to be operated by means of

oil pressure from the governor system.

SPECIFICATION FOR BULB TURBINES

BAI THUONG HYDROPOWER PROJECT

Zhejiang Jinlun Electromechanic Co., Ltd

BIDDING DOCUMENTS - PACKAGE BT-20

TECHNICAL PROPOSAL

The runner blades will be casting made of stainless cast steel (13%Cr~4%Ni). The

runner blades must be machined with 5-axis or 4-axis computerized numerical control

(CNC) boring/milling machine. The profile of the runner blades will be designed so as to

have highest efficiency and to prevent occurrence of cavitation.

The runner blades will be carefully shaped and ground to conform to the contours of the

homologous model turbine runner blades.

The runner blades will be designed and constructed to safely withstand the stresses

due to operation at maximum runaway speed under conditions of maximum operating head

with no load on the generator.

The runner blades will be assembled will the hub, the control mechanism and the cone

at the factory, and will be statically balanced and action test before shipment.

(2) Runner blades control mechanism

Runner will be of pistons-stationary and cylinder-move type. The runner blades will be

operated by the runner servomotor with the levers which is mounted in the runner hub, by

means of pressure oil from the governor though an oil distributing head located at the

upstream end of the generator auxiliary shaft. The piston and the rod are stationary, the

cylinder moves to operate the link structures and rotate the blades.

(3) Runner blades seal

Seal of trunnion and runner hub will be of Vtype packing. Vtype packing will be

pressed by spring and oil pressure, which can assure seal with runner blade even producing

abrasion by long operation. Vtype packing shall be easily assembled and dismantled, and

can be replaced without dismantling the blades, very convenience.

(4) Runner hub

The runner hub will be a integral steel casting (20SiMn). In order to meet pressurize

require and reduce the clearance between the blade and hub possibility, The runner hub

must be machined with 16m numerical control boring/milling machine. The runner hub will

be flanged-bolted to the main shaft and the runner cone.

The runner hub will transfer torque to the main shaft by pin. The runner hub will be

provided with a cone of welded plate steel to direct to flow as it leaves the runner.

Oil pressure inside the runner hub will be always kept greater than the hydraulic pressure

in the water passage, so this can avoid water to come into runner hub.

1.3.1 Discharge ring

(1) General

SPECIFICATION FOR BULB TURBINES

BAI THUONG HYDROPOWER PROJECT

Zhejiang Jinlun Electromechanic Co., Ltd

BIDDING DOCUMENTS - PACKAGE BT-20

TECHNICAL PROPOSAL

The discharge ring will be made of welded steel plate, complete with carton steel

ribbings on its outside.

The portion of the inside surface surrounding the runner blades will spherically

machined for close running clearance with the runner blades. The throat section of the

discharger ring easily subject to cavitation will be made of stainless steel plate.

The discharge ring will be divided two sections for handling and shipping, with flange

and bolt connection.

The discharge ring will be connected to the outer gate ring at the upstream end by

bolted flange.

1.3.2 Erection joint

(1) General

The erection joint will consist of active flange, packing and packing cover. The

erection joint will be installed between discharge ring and draft tube, which allows for a

longitudinal expansion, will be provided to facilitate erection and dismantling of the

discharge ring.

(2)Material

Active flange: A240-316L

Pressurize cover: GB Q235-B/ASTM A283.GrD

Packing:

rubber

1.3.3 Main shaft

(1) General

The main shaft will be made of forged carbon steel (A240-316L+SM45C) with

integrally forged coupling flanges for connection to the turbine and to the generator rotor.

The thrust runner will be made of forged carbon steel ,which is mounted on main shaf

t.

(2) Material

Main shaft forged carbon steel A240-316L+SM45C

Bolt

Pin

Carbon steel

Carbon steel

1.3.4 Shaft seal device

The shaft seal will be of packing type with carbon fiberfill. It shall be able to be

adjusted or replaced without dismantling the radial bearing of the turbine.

Sleeve of the shaft seal will be made of stainless steel, A self-adjusting device for

SPECIFICATION FOR BULB TURBINES

BAI THUONG HYDROPOWER PROJECT

Zhejiang Jinlun Electromechanic Co., Ltd

BIDDING DOCUMENTS - PACKAGE BT-20

TECHNICAL PROPOSAL

adjusting the shaft seal compressibility shall be provided.

The shaft seal will be lubricated by clean water. The pressure of water will be

0.15~0.25MPa.

Leakage water from the sealing device will be led and drained out of the bulb by

gravity.

The maintenance seal with compressed air inflatable rubber will be provided in order

to replace the mechanical seal without dewatering in the draft tube. The charge pressure of

inflatable rubber seal will be 0.7MPa.

1.3.5Turbine guide bearing

(1) General

The turbine guide bearing will be of forced-oil-lubricated type.

The turbine guide bearing will be supported by the bearing support, which is mounted

on inside of the inner turbine cone.

The bearing shell will be made of steel plate lined with high quality Babbitt metal on

its inner surface, and will be divided into two halves to facilitate assembling and

disassembly for maintenance.

The bearing shell will be having oil seal covers for both ends.

The lubricating oil will be the same grade as the oil of the governor pressure oil and the

runner hub oil, it is L-TSA68 steam turbine oil

(2) Material

Bearing shell: GB Q235-B+ white metal/ASTM A283, GrD+ASTM B 23 No.3

1.3.6Oil-distributing head

(1) General

The distributing head will be mounted on the upstream end of the generator auxiliary

shaft.

Pressure oil from the governor for controlling the servomotor will be distributed to the

double pipes which will consist of the outer pipe and inner pipe for leading oil the closing

and opening sides of the servomotor respectively.

Runner hub oil will be also be supplied through the distributing head, to keep the oil

pressure in the hub not less than maximum water pressure even when the unit is show

down.

(2) Material

Shell GB Q235-B/ASTM A283, GrD

SPECIFICATION FOR BULB TURBINES

BAI THUONG HYDROPOWER PROJECT

Zhejiang Jinlun Electromechanic Co., Ltd

BIDDING DOCUMENTS - PACKAGE BT-20

TECHNICAL PROPOSAL

BearingGB Q235-B+ white metal/ASTM A283, GrD+ASTM B 23 No.3

1.3.7 Stay cones

(1) General

The stay cones will be made of steel plate, and will consist of an outer and an inner

conical rings and two stay columns, which are welded with each other.

The outer stay cone will have suitable numbers of ribs and anchors to increase its

rigidity to concrete structures and will be capable of transferring into the concrete structure

of the load due to water thrust, rotating torque and maximum torque short circuit on the

terminals of the generator. The outer stay cone will be divided into two parts to facilitate to

transportation. The divided sections shall be assembled each other at site by welding.

The suitable number of the turn buckles and pipe jacks will be used for installation

and fixing the out stay cone at the position.

The inner stay cone also will be divided into two parts. The divided sections will be

assembled with parts of the stay columns by welding at site.

The inner stay cone also will be divided into two halves in direction of water flow, for a

flange connection.

The inner stay cone will be also flange-connected with the generator stator frame for

upstream side, and with the inner gate ring for downstream side.

The stay columns will be hollow in order to allow the passage of:

a. Various pipings for:

(1) Lubrication oil

(2) WaterAir pipe

(3) Evacuation of water leaking from the shaft seal

(4) Control cables

b. Maintenance personnel for the turbine

(2) Material

Inner stay cone:

GB Q235-B/ASTM A283.GrD

Outer stay cone:

GB Q235-B/ASTM A283.GrD

Turbine stay column: GB Q235-B/ASTM A283.GrD

1.3.8 Generator cover board and nose liner

(1) General

Generator cover board will be used to install and maintenance of generator stator and

rotor. Generator cover board will be of welded steel plate and have sufficient ribs in

SPECIFICATION FOR BULB TURBINES

BAI THUONG HYDROPOWER PROJECT

Zhejiang Jinlun Electromechanic Co., Ltd

BIDDING DOCUMENTS - PACKAGE BT-20

TECHNICAL PROPOSAL

order to support hydraulic pressure.

The cover board will be connected to the generator frame embedding concrete by means

of flanges.

The nose liner will be furnished between generator hole for accessing and turbine

column, which make the water current smooth.

(2) Material

Generator cover board: A240-316L

Generator frame:

Nose liner:

A240-316L

A240-316L

1.3.9Distributor

(1) General

The distributor will be of conoid type, operated by servomotor. Wicket gate will be

furnished between the outer and inner gate ring. The inner and outer guide bearing will

be of ball pivot structure, which can avoid the influence by relatively distortion under the

transient conditions such as the turbine start-up or load rejection. The bearing will be of

self-lubricating type.

The outer gate ring will be made of steel plate by welded, it will be connected to the

outer stay cone and to the discharge ring, for upstream and downstream side, respectively

by means of bolted flanges.

The inner gate ring will be made of steel plate by welded also, it will be flangeconnected with the inner stay cone for upstream side.

The inner gate ring will support the weight and power of guide bearing and main shaft

seal.

The surfaces of the gate ring which face to the wicket gates, will be accurately machined

to keep close clearance with the wicket gates at closed position of wicket gate.

The inner and outer guide bearing will be of self-lubricating type.

(2) Material

Inner gate ring: A240-316L

Outer gate ring: A240-316L

1.3.10 Guide vane and operating mechanism

(1) General

Sixteen guide vanes will be furnished between the outer and inner guide ring, to direct

the water entering the runner with a minimum of hydraulic loose.

SPECIFICATION FOR BULB TURBINES

BAI THUONG HYDROPOWER PROJECT

Zhejiang Jinlun Electromechanic Co., Ltd

BIDDING DOCUMENTS - PACKAGE BT-20

TECHNICAL PROPOSAL

The guide vane will be made of welded plate steel or casing.

The sealing faces of each guide vane will be accurately machined and finished to

minimize water leakage though the vanes at full closed position, and all vanes will be

interchangeable.

The design of operating mechanism will consider max. Operation moment. When

accident happening and producing abnormity power, the operating mechanism can selfprotecting by bending link and bending link broken detection.

(2) Material

Wicket gate: A743-CFMN

Sealing faces of guide vane: A743-CFMN

1.3.11 Guide vane servomotor

(1) General

The turbine will supply two capacity sufficient servomotor to operate guide distributor.

Under maximum head and minimum effective oil pressure, the servomotors can close or

open the guide vanes in a specified time under the max. hydraulicy moment and friction

moment. Otherwise, guide vane operating ring will supply the counter weight, which can

close guide vanes celerity when oil pressure disappearing or accident happening.

Operating pressure of 16 Mpa of servomotor.

(2) Material

Cylinger: QT500-7

Piston:

cast iron

1.3.12Draft tube liner

(1) General

The draft tube liner will be of conical shape and made of fabricated steel plate.

The draft tube liner will have sufficient ribs and suitable numbers of anchor bars. The

suitable spiders as the reinforcement during placing of concrete and transportation will be

supplied with the draft tube liner.

(2) Meterial

Draft tube liner: A240-316L

1.4 Lubricating oil system

One lubricating oil system will be provided for each generating unit.

The lubricating oil system will supply the lubricating oil to the turbine guide bearing,

the upstream guide bearing, and the thrust bearing and supply the high pressure oil to keep

SPECIFICATION FOR BULB TURBINES

BAI THUONG HYDROPOWER PROJECT

Zhejiang Jinlun Electromechanic Co., Ltd

BIDDING DOCUMENTS - PACKAGE BT-20

TECHNICAL PROPOSAL

oil film on the guide bearing shoes of generator and turbine when the unit starts or stop.

The lubricating oil system will consist of the followings:

* Two a-c motorized lubricating oil pumps

* One oil sump tank which will be capable to contain all necessary oil for lubricating oil

system

* One elevated oil tank

* One oil cooler

* All pipes and valves necessary for the system

* One d-c motorized and one a-c motorized high pressure oil pumps

* One motor starters and controls which will be housed in a wall mount type

One of

oil pump will be used for normal operation and the other one for stand-by use, and

selection of normal or stand-by pump can be done by selection switch on the panel.

The normal pump will be direct-started, and the stand-by oil pump will be started

automatically at the failure of the normal-use oil pump.

Cooling water system will supply necessary water for oil cooler.

1.5 Special tools

We will supply one whole special tools .

1.6 Spare parts

We will supply necessary spare parts.

SPECIFICATION FOR BULB TURBINES

You might also like

- Selection of Pump Turbine For Pump Storage Power PlantDocument7 pagesSelection of Pump Turbine For Pump Storage Power PlantSunil MaharjanNo ratings yet

- Guide Lines For DimensioningDocument50 pagesGuide Lines For DimensioningDina KaranNo ratings yet

- Attachment 1. HydraulicDocument36 pagesAttachment 1. HydraulicAnonymous R4c2XlRNNo ratings yet

- Toshiba HydrogeneratorsDocument13 pagesToshiba Hydrogeneratorsrakesh1987_careersNo ratings yet

- Hydro Turbines - Bulb, The Complete Solution For Low HeadsDocument12 pagesHydro Turbines - Bulb, The Complete Solution For Low HeadspalanaruvaNo ratings yet

- Reversible Pump-Turbine (1956)Document16 pagesReversible Pump-Turbine (1956)Suraj KumarNo ratings yet

- Optimize Headrace Tunnel Cross-Section for 66MW Hydropower PlantDocument13 pagesOptimize Headrace Tunnel Cross-Section for 66MW Hydropower PlantraghurmiNo ratings yet

- HYDG20749Document108 pagesHYDG20749NARENDER KUMARNo ratings yet

- Mavel Turbine BrochureDocument12 pagesMavel Turbine BrochureDustin Soria VNo ratings yet

- Catalogo 13 Eng - Nuovo Needle ValvesDocument8 pagesCatalogo 13 Eng - Nuovo Needle ValvesDheeraj ThakurNo ratings yet

- Kaigah HPP - Executive SummaryDocument27 pagesKaigah HPP - Executive SummaryAli Nawaz Khan100% (1)

- Appl 17 Protection of Three Winding Transformer enDocument10 pagesAppl 17 Protection of Three Winding Transformer enSristi MitraNo ratings yet

- Ufc 3 401 01 Mechanical EngineeringDocument22 pagesUfc 3 401 01 Mechanical EngineeringNoli T. CaronanNo ratings yet

- 22kv Simosec EngDocument44 pages22kv Simosec Engmimran18No ratings yet

- ABB 1HDX580101en ELK04Document32 pagesABB 1HDX580101en ELK04gejiro73100% (1)

- Tehri Hydro Development Corporation India LimitedDocument40 pagesTehri Hydro Development Corporation India LimitedKuldeep SemwalNo ratings yet

- Belajar VBA Sangat Simple TerpakaiDocument32 pagesBelajar VBA Sangat Simple TerpakaiKaharuddin JamesNo ratings yet

- Turbina Kaplan BulboDocument87 pagesTurbina Kaplan BulboJuanRamosNo ratings yet

- 3-Guidelines For Design - Pumped Storage HydroDocument25 pages3-Guidelines For Design - Pumped Storage Hydrojoey mallariNo ratings yet

- 3.6 Guidelines For Electrical Design For SHP Plants Including SwitchyardDocument160 pages3.6 Guidelines For Electrical Design For SHP Plants Including SwitchyardFarid Ahmad Shalahuddin100% (1)

- B7C6A Va Tech Hydro Bulb Turbines GeneratorsDocument24 pagesB7C6A Va Tech Hydro Bulb Turbines Generatorsjoaoaugusto79100% (1)

- 98r06 PDFDocument75 pages98r06 PDFElias GabrielNo ratings yet

- LEMP-synchronous Electric MotorsDocument65 pagesLEMP-synchronous Electric MotorsadnanhusikaNo ratings yet

- With Arraylists: FIT9131 Semester 2 2019 Assignment 2Document8 pagesWith Arraylists: FIT9131 Semester 2 2019 Assignment 2Syed Faiq FreelancerNo ratings yet

- Hewa Khola-B Small Hydro Power Project Pre Feasibility Study ReportDocument133 pagesHewa Khola-B Small Hydro Power Project Pre Feasibility Study ReportDipendra Bista93% (15)

- Introduction To Hydropower Francesco CarrascoDocument102 pagesIntroduction To Hydropower Francesco Carrascojcasafranca100% (2)

- Medium Voltage Devices - Range ProductsDocument17 pagesMedium Voltage Devices - Range Productsfelipe1501No ratings yet

- Simulation of Hydroelectric System ControlDocument24 pagesSimulation of Hydroelectric System Controlstipe_curlin5242No ratings yet

- Abb SKDocument27 pagesAbb SKtonNo ratings yet

- Calculation of Flow Duration CurveDocument7 pagesCalculation of Flow Duration Curvepushkar078No ratings yet

- EvaPower For HydropowerDocument15 pagesEvaPower For HydropowerTamboli EnergiNo ratings yet

- Reversible Pump Turbine Flow Stability Aspects Within Pumped Storage Hydropower Plants: A ReviewDocument15 pagesReversible Pump Turbine Flow Stability Aspects Within Pumped Storage Hydropower Plants: A ReviewDr. Binama MaximeNo ratings yet

- Tehri Pumped Storage Plant Project Challenges of High Head VariationsDocument16 pagesTehri Pumped Storage Plant Project Challenges of High Head VariationsrrsemNo ratings yet

- TidongDocument162 pagesTidongSandeep AggarwalNo ratings yet

- Tr01 11e Shunt Reactors Revision 9Document73 pagesTr01 11e Shunt Reactors Revision 9Sakthi RajNo ratings yet

- Hydraulic Turbines PDFDocument12 pagesHydraulic Turbines PDFHyoungyoon John MoonNo ratings yet

- 6910-Article Text-26607-1-10-20210930Document12 pages6910-Article Text-26607-1-10-20210930dile garciaNo ratings yet

- Branch CalcDocument111 pagesBranch CalcAnonymous 6S9tcbh100% (2)

- 3.1 Selection of Turbine and Governing System PDFDocument72 pages3.1 Selection of Turbine and Governing System PDFtanujaayer100% (1)

- Static Frequency Converter - TS150Document1 pageStatic Frequency Converter - TS150rafieeNo ratings yet

- GEA33306 BN Hydro Application Guide - R7Document48 pagesGEA33306 BN Hydro Application Guide - R7Viet DinhTrongNo ratings yet

- Daneshkah (2010) - Parametric Design of A Francis Turbine (Método Inverso)Document11 pagesDaneshkah (2010) - Parametric Design of A Francis Turbine (Método Inverso)HorácioNo ratings yet

- AEPC Guidelines For Detailed Feasibility Study For ProjectsDocument0 pagesAEPC Guidelines For Detailed Feasibility Study For Projectssantoshbce20No ratings yet

- Pump Storage WBSEDCLDocument33 pagesPump Storage WBSEDCLDave ChaudhuryNo ratings yet

- Guidelines For Selection of Turbines, Preliminary Dimensioning and Layout of Surface Hydroelectric Power HousesDocument17 pagesGuidelines For Selection of Turbines, Preliminary Dimensioning and Layout of Surface Hydroelectric Power HousessubasratnaNo ratings yet

- (ED 01-2017) DoubleFlangedButterfly - WEBDocument28 pages(ED 01-2017) DoubleFlangedButterfly - WEBGourav SharmaNo ratings yet

- National Hydroelectric Power Corporation LimitedDocument67 pagesNational Hydroelectric Power Corporation Limitedapi-382513983% (6)

- Zelio EMR Product SelectorDocument365 pagesZelio EMR Product SelectorchahbounnabilNo ratings yet

- UnitTest HandoutDocument13 pagesUnitTest HandoutĐoàn Sinh HùngNo ratings yet

- MPD 500 User Manual PDFDocument72 pagesMPD 500 User Manual PDFpdrich8100% (1)

- Hydropower 97 - ProcedingsDocument173 pagesHydropower 97 - ProcedingsEdward Hcr100% (3)

- Evaluation of CFD Model For Kaplan Draft TubeDocument67 pagesEvaluation of CFD Model For Kaplan Draft Tubeteguh hady aNo ratings yet

- C200-018-08 TM-210.2 1.687 Motorhead Assembly - STD ServiceDocument14 pagesC200-018-08 TM-210.2 1.687 Motorhead Assembly - STD ServicesamanNo ratings yet

- Standard S2000 HH Specifications Stancor PumpsDocument2 pagesStandard S2000 HH Specifications Stancor PumpsBryanPresleyNo ratings yet

- DLU TechDocument20 pagesDLU Techqwerty_conanNo ratings yet

- TDBFP ManulDocument266 pagesTDBFP ManulJackSparrow8678% (9)

- Monsoon Horizontal Paddlewheel Aerator Specification: A. GeneralDocument4 pagesMonsoon Horizontal Paddlewheel Aerator Specification: A. GeneralAhmed WagihNo ratings yet

- C200-019-23 TM-210.1 2.875 Motorhead AssemblyDocument13 pagesC200-019-23 TM-210.1 2.875 Motorhead AssemblysamanNo ratings yet

- Motor Head AssemblyDocument16 pagesMotor Head AssemblyAhmed100% (1)

- ALAMARIN-JET OY Technical SpecificationDocument21 pagesALAMARIN-JET OY Technical SpecificationAndi PurwantoNo ratings yet

- Search Topicality GuidelinesDocument2 pagesSearch Topicality GuidelinesAn NguyenNo ratings yet

- Search Intent Satisfaction GuidelinesDocument3 pagesSearch Intent Satisfaction GuidelinesAn NguyenNo ratings yet

- Linhson TransDocument2 pagesLinhson TransAn NguyenNo ratings yet

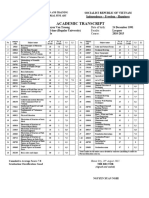

- University Transcript TH BDDocument7 pagesUniversity Transcript TH BDAn NguyenNo ratings yet

- Lease AgreementDocument7 pagesLease AgreementAn NguyenNo ratings yet

- No.22 Banking LicenceDocument4 pagesNo.22 Banking LicenceAn NguyenNo ratings yet

- Socialist Republic of Vietnam Independence - Compassion - HappinessDocument1 pageSocialist Republic of Vietnam Independence - Compassion - HappinessAn NguyenNo ratings yet

- Notification of Seal SpecimenDocument1 pageNotification of Seal SpecimenAn NguyenNo ratings yet

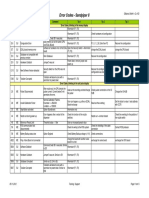

- Table of ContentsDocument4 pagesTable of ContentsAn NguyenNo ratings yet

- Yêu Cầu Lựa Chọn Thiết Bị Gửi FUMINDocument3 pagesYêu Cầu Lựa Chọn Thiết Bị Gửi FUMINAn NguyenNo ratings yet

- V-AnhDocument1 pageV-AnhAn NguyenNo ratings yet

- Dieu Le VADocument5 pagesDieu Le VAAn NguyenNo ratings yet

- Bo Sung GP 2055Document2 pagesBo Sung GP 2055An NguyenNo ratings yet

- 78146 Việt AnhDocument9 pages78146 Việt AnhAn NguyenNo ratings yet

- Insurance Contract Compulsory Fire and Extended RisksDocument7 pagesInsurance Contract Compulsory Fire and Extended RisksAn NguyenNo ratings yet

- Bo SungDocument9 pagesBo SungAn NguyenNo ratings yet

- Chap Thuan Ly HonDocument4 pagesChap Thuan Ly HonAn NguyenNo ratings yet

- Dich Song NG A-VDocument4 pagesDich Song NG A-VAn NguyenNo ratings yet

- V-A Ms VânDocument3 pagesV-A Ms VânAn NguyenNo ratings yet

- 81133-Q&A For SalesDocument4 pages81133-Q&A For SalesAn NguyenNo ratings yet

- Dang Ky Doanh Nghiep TDK-translatedDocument5 pagesDang Ky Doanh Nghiep TDK-translatedAn NguyenNo ratings yet

- Dang Ky Kinh Doanh12Document5 pagesDang Ky Kinh Doanh12An NguyenNo ratings yet

- USA Elections in BriefDocument92 pagesUSA Elections in BriefBureau of International Information Programs (IIP)No ratings yet

- Dich NgeDocument1 pageDich NgeAn NguyenNo ratings yet

- Hình 1.4.1-1.5.1 Cua File 12 - Vie - 10 MayDocument3 pagesHình 1.4.1-1.5.1 Cua File 12 - Vie - 10 MayAn NguyenNo ratings yet

- TECHCOMBANK Di9chDocument13 pagesTECHCOMBANK Di9chAn NguyenNo ratings yet

- Huong Dan Su Dung TDDDocument3 pagesHuong Dan Su Dung TDDAn NguyenNo ratings yet

- Working Instrument Sheet: PackingDocument2 pagesWorking Instrument Sheet: PackingAn NguyenNo ratings yet

- Maritime EnglishDocument132 pagesMaritime EnglishAn NguyenNo ratings yet

- Thuat Ngu Xi MangDocument72 pagesThuat Ngu Xi MangAn NguyenNo ratings yet

- The SF6 Transition - PresentationDocument16 pagesThe SF6 Transition - Presentationjunior_jazzzNo ratings yet

- ATSDocument8 pagesATSserban_elNo ratings yet

- Physics: OxfordDocument224 pagesPhysics: OxfordMusic Life100% (1)

- Heat Exchangers of PolypropyleneDocument2 pagesHeat Exchangers of PolypropyleneTan So100% (1)

- Training Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IIDocument5 pagesTraining Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IICharlie ShowNo ratings yet

- Alok Mitra NotesDocument5 pagesAlok Mitra NotesSukanya GuhaNo ratings yet

- ME1130 Mechanism of SolidificationDocument15 pagesME1130 Mechanism of SolidificationShivam RajNo ratings yet

- Solar GeometryDocument34 pagesSolar GeometryPatricia Franchette AmoraNo ratings yet

- Quat KrugerDocument52 pagesQuat Krugerruby0808No ratings yet

- Fcu Pressure Drop PDFDocument18 pagesFcu Pressure Drop PDFvishalNo ratings yet

- Manta To Richmond SIMOPS Risk Matrix FINALDocument1 pageManta To Richmond SIMOPS Risk Matrix FINALDesmond Chang50% (2)

- Equivalent Circuits and Parameters of Power System Plant: Network Protection & Automation GuideDocument38 pagesEquivalent Circuits and Parameters of Power System Plant: Network Protection & Automation GuideShailesh ChettyNo ratings yet

- Produktkatalog 2019 WebDocument280 pagesProduktkatalog 2019 WebbagastcNo ratings yet

- YVAA0490 - DataSheetSpec. - Rev01pdfDocument2 pagesYVAA0490 - DataSheetSpec. - Rev01pdfMohamed AskarNo ratings yet

- ComponentsDocument8 pagesComponentsprbthapa2055No ratings yet

- Engineering Physics - G. AruldhasDocument100 pagesEngineering Physics - G. AruldhasJaya sankarNo ratings yet

- Concentrating Solar Power: Clean Energy For The Electric GridDocument14 pagesConcentrating Solar Power: Clean Energy For The Electric Gridfran01334No ratings yet

- Physics 219 Practice Exam 1 Multiple Choice QuestionsDocument6 pagesPhysics 219 Practice Exam 1 Multiple Choice QuestionserjayprakashpatelNo ratings yet

- Gas Turbine Heat Rejection and Refrigeration Cycle CalculationsDocument8 pagesGas Turbine Heat Rejection and Refrigeration Cycle CalculationsRENE JOSHUA PECASONo ratings yet

- Ventilation of The Industrial Environment PDFDocument7 pagesVentilation of The Industrial Environment PDFnelson escuderoNo ratings yet

- 1st PU Chemistry May 2015 PDFDocument2 pages1st PU Chemistry May 2015 PDFPrasad C M69% (16)

- Planar Linkages Mechanism GuideDocument8 pagesPlanar Linkages Mechanism GuideAlbert ArominNo ratings yet

- 29B - Acid Gas Removal TechnologyDocument17 pages29B - Acid Gas Removal Technologyarlucky5459100% (1)

- Engine Fundamentals 1Document3 pagesEngine Fundamentals 1anuradhaNo ratings yet

- Advances in Graphene Based Semiconductor Photocatalysts For Solar Energy ConversionDocument27 pagesAdvances in Graphene Based Semiconductor Photocatalysts For Solar Energy ConversiondevNo ratings yet

- FisicaDocument352 pagesFisicaCg Tonio100% (1)

- ZF Servocomà ® RAS Rear Axle Steering System - ZF LenksystemeDocument2 pagesZF Servocomà ® RAS Rear Axle Steering System - ZF Lenksystemewurtukuk50% (2)

- Effectiveness of Sootblowers in Boilers Thermal Power StationDocument7 pagesEffectiveness of Sootblowers in Boilers Thermal Power Stationdillipsh123No ratings yet

- Aluminum Electrolytic Capacitors Aluminum Electrolytic CapacitorsDocument6 pagesAluminum Electrolytic Capacitors Aluminum Electrolytic CapacitorsAvs ElectronNo ratings yet

- Concrete CoolingDocument19 pagesConcrete CoolingAbdulrahman AlnagarNo ratings yet