Professional Documents

Culture Documents

Manual de Cuchilla Clarkson

Uploaded by

Walter IvanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual de Cuchilla Clarkson

Uploaded by

Walter IvanCopyright:

Available Formats

Clarkson KGA Heavy Duty Slurry Knife Gate Valve

3 through 54

Field-proven Clarkson KGA slurry knife gate valves

feature heavy-duty, full port elastomer linings offering

the ultimate in protection against heavy slurries.

Features

Meets a wide range of abrasion,

corrosion, temperature, and pressure

requirements.

May be used in wet or dry services

easily dealing with large, heavy

particles and tramp material.

Heavy-duty, field replaceable

elastomer sleeves.

No metal parts in contact with the

flowing slurry.

Unobstructed flow eliminates

turbulence, minimizes pressure drop

across valve.

100% Isolation; bubble-tight shut-off

results in absolutely zero downstream

leakage.

Double-seated design provides

bi-directional flow and shut-off.

No seat cavity where solids can

collect and prevent full gate closure.

No gate or stem packing is required,

eliminating packing leakage and

maintenance.

Adaptable frame (yoke) design

featuring a top-removal stem nut.

General applications

Technical data

Mining

Size range

: 3 through 24

Operating pressure : 100 psi

Power

Pulp and paper

Alumina

Chemical

Cement

Total Flow Control Solutions

Size range

: 26 through 36

Operating pressure : 75 psi

Size range

: 26 through 54

Operating pressure : 50 psi

Sleeve

: Gum rubber standard

Temperatures

: Standard sleeve

rated to 160F, up to

400F with proper

elastomer selection

Tyco reserves the right to change product design and specifications

without notice. Copyright 2001 by Tyco International Ltd.

CLKMC-0113-US-0112

Clarkson KGA Heavy Duty Slurry Knife Gate Valve

3 through 54

Features

Standard configuration

How the KGA sleeves work: Matching sleeves are placed in the KGA valve housing to seal

against the gate when the valve is closed and seal against each other when the valve is

open. As the gate moves from open to closed position, it separates the facing sleeves. A

stiffener ring molded into the elastomer retains the roundness of the sleeves during opening

and closing cycles. The unique KGA sleeve assembly provides positive sealing action when

the valve gate is closed. When the gate is open, the sleeves provide an unobstructed port

and protect metal parts from the flowing slurry.

Ductile iron valve housing (body)

3 through 42

Fabricated carbon steel housing (body)

above 42

Open position:

Closed position:

Gate positioned above seals

Gate travels completely through sleeves

to provide blind flange shut off and expel

solids.

Mild steel body spacers and actuator

support frames

Metal parts not in contact with slurry

Unobstructed port area eliminates

turbulence, minimizes pressure drop

across valve

No seat cavity where solids can collect

and prevent full gate closure

100% Isolation-bubble tight shut-off

results in absolutely zero downstream

leakage

Double-seated design provides

bi-directional flow and shut-off

316 stainless steel gate rated for

100 psi (3 through 12)

75 psi (26 through 36)

50 psi (42 through 54)

Flat-faced body flanges drilled and

tapped (3 through 10) or slotted

(12 through 54) to match ANSI B16.5

Class 150 (3 through 24) or MSS SP44

(26 through 54) companion flanges

High tear strength gum rubber sleeves

with stiffener rings

Gum rubber covered mild steel sleeve

retainer flanges (10 through 54)

Optional

Various gate materials:

316L SS

317L MN

17-4 PH

Jessop 700

Ferralium 255

317L SS

Alloy 20

Hastelloy C-276

Others

Sleeves (see below)

Stem covers

Splashguards

Actuators (see page 4)

Control accessories

Fabricated housing (body) of most any

weldable alloy in any standard size

Optional sleeve configurations and elastomers

Standard Sleeves external stiffener ring

Optional encapsulated

stiffener ring sleeve

Maintains round configuration of sleeve

Maintains round configuration of sleeve

Relieves stresses on seal

Relieves stresses on seal

Scrapes scaling off gate when it cycles

Used when stiffener ring contact with the

gate is undesirable

J-Ring, 3 - 26

Pipe Ring, 30 - 54

3 - 16

Tyco reserves the right to change product design and specifications

without notice. Copyright 2001 by Tyco International Ltd.

18 - 24

CLKMC-0113

2

Clarkson KGA Heavy Duty Slurry Knife Gate Valve

3 through 54

Available sleeve materials:

Features

Gum Rubber: This category includes all

natural gum elastomers, both filled and

unfilled and synthetic Polyisoprene. Has

high tensile strength, superior resistance to

tear and abrasion and good flexibility at low

temperatures. Maximum continuous

operating temperature 160F.

Heavy-duty frame (yoke) designed to

accept top removal stem nut, bevel gear or

cylinder actuator without welding

Chlorobutyl: Advantages, outstanding

impermeability to gases and vapor, very

good resistance to heat, oxygen, ozone and

sunlight. Excellent energy absorption and

resistance to alkalis and oxygenated

solvents, superior resistance to water and

steam. Limitations, poor resistance to oil,

gasoline and hydrocarbon based solvents,

poor resilience. Maximum continuous

operating temperature 250F.

The stainless steel gate is completely

withdrawn from the process flow in the open

position and can be inspected or replaced

without taking the valve out of service

Optional open and closed lockout/tagout

positions

316 stainless steel gate is standard

Packingless design

Elastomer sleeve molded with an integral

stiffener ring to properly center the sleeve in

the valve body housing and resist the high

shearing forces present when the gate

cycled

EPDM and EPDM-HTP: Advantages, both

types have excellent resistance to heat,

ozone and sunlight, very good flexibility at

low temperature, good resistance to alkalis,

acids, and oxygenated solvents and

superior resistance to water and steam.

Limitations, poor resistance to oil, gasoline,

and hydrocarbon based solvents. Maximum

continuous operating temperature 300F for

EPDM-HTP, 160 for EPDM.

Unobstructed flow area, fully lined with

elastomer sleeves, no metal-to-metal

contact, no guides or wedges

Double sleeved design provides a blind

flange shut-off when the gate is closed.

The valves sealing surface is between two

thick, rubber sleeves that are compressed

into the ductile iron valve housings

Neoprene: Advantages, moderate

resistance to oil and gasoline, very good

resistance to ozone, abrasion, flex cracking,

alkalis and acids. Available in non-black.

Limitations, poor resistance to aromatic and

oxygenated solvents, limited flexibility at low

temperature. Not recommended for high

cycle applications. Maximum continuous

operating temperature 200F.

Elastomer covered retainer flanges

eliminates need for gaskets (optional on

sizes 3 - 8, standard on 10 and larger)

Cast ductile full flanged body housing to suit

ANSI B16.5/150 through 24, sizes 26 and

larger suit MSS-SP44

Nitrile and Nitrile-HTP: Advantages, very

good resistance to oil, gasoline, alkalis and

acids. Good resistance to hydrocarbon

based solvents. Limitations, inferior

resistance to ozone and oxygenated

solvents. Maximum continuous operating

temperature 225F for HTP and 200F for

standard Nitrile.

Hypalon: Advantages, good abrasion

resistance, excellent resistance to alkalis

and acids, moderate resistance to oil and

gasoline. Limitations, poor resistance to

aromatic solvents, limited flexibility at low

temperature. Maximum continuous

operating temperature 200F.

Fluroelastomer: Advantages, outstanding

resistance to high heat, excellent resistance

to oil, gasoline and hydrocarbon solvents.

Very good impermeability to gases, vapor

and oxygen. Limitations, poor resistance to

tear and cut growth, very little resistance to

oxygenated solvents. Maximum continuous

operating temperature 400F (Consult

factory for temperatures higher than 400F).

Mild steel body spacers separate the body

housing halves and serve as an external

guide to the valves knife-edge gate

Clean-out area

Specification

Clarkson KGA slurry knife gate valve

Heavy duty, slurry knife gate valve shall be flat-face flanged, packingless, rubber-lined,

bidirectional valve suitable for a wide range of industrial applications. The full port design shall

have no internal obstructions and will provide a blind flange shut-off when the gate is closed.

The valves sealing surface is to be between two thick, rubber sleeves that are compressed

into the ductile iron valve housings. The sleeve will be molded with an integral stiffener ring

that locates the sleeve in the valve housing and helps the sleeves resist the high shearing

forces present when the gate is driven between them. Mild steel body spacers shall separate

the body housing halves and serve as an external guide to the valves knife-edge gate. The

stainless steel gate shall be completely withdrawn from the process flow when in the open

position, and can be inspected and replaced, if necessary, without taking the valve out of

service. When the valve is in the closed position, the downstream sleeve can be replaced

while the upstream portion of the valve is still holding pressure. The valve body housing to be

full flanged, drilled and tapped or slotted to suit ANSI B16.5/150 through 24 and MSS-SP44

above 24. Valve is equipped with a heavy steel fabricated handwheel frame (yoke) which can

be converted to bevel gear in the field without welding, complete with a 304 stainless steel

rising stem (except cylinder actuated valves). All nonferrous exterior surfaces shall be painted

to factory standard.

Specify Clarkson KGA slurry knife gate valve from Tyco Valves & Controls.

Tyco reserves the right to change product design and specifications

without notice. Copyright 2001 by Tyco International Ltd.

CLKMC-0113

3

Clarkson KGA Heavy Duty Slurry Knife Gate Valve

3 through 54

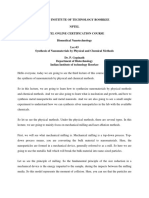

MH

MG

AC

HC

H. Port diameter

J. Inlet diameter

Dimensions and Weights

Centerline to top

Valve

Size

Handwheel

MH

D

MG

E

AC

F

HC

G

A*

B**

7.50

6.88

8.88

18.93

21.38

21.38

9.00

6.88

11.00

22.00

23.33

23.94

11.00

7.00

13.00

28.00

31.82

13.50

7.25

15.25

32.90

14.89

MH

M

MG

M

Weight Weight

MH

MG

Weight

AC

Weight

HC

24.56

2.41

2.81

15.81

12

12

50

127

85

50

27.63

3.33

3.88

16.88

12

12

64

141

130

70

30.18

34.00

5.38

5.81

17.88

16

12

98

175

180

98

35.00

38.31

6.88

7.75

19.00

20

12

135

212

210

135

10

16.00

8.88

16.56

38.75

42.63

40.50

44.25

9.06

9.81

23.40

20

24

198

275

310

175

12

19.00

10.13

21.00

47.45

45.50

53.13

10.75

11.50

25.50

24

427

669

360

14

21.00

10.13

22.75

53.31

53.43

57.80

12.50

13.25

26.38

24

448

720

414

16

23.50

11.00

24.25

57.20

60.19

64.06

14.00

14.75

27.62

24

573

1125

550

18

25.00

12.25

26.50

66.75

67.62

68.75

14.88

16.75

30.35

24

875

1330

950

20

27.50

14.13

28.38

71.94

73.50

74.44

16.56

18.50

31.29

24

1054

1680

1200

24

32.00

14.63

33.80

86.19

88.00

89.63

21.19

23.00

34.75

24

2200

1400

26

34.25

14.66

36.75

93.63

23.50

25.00

1700

30

38.75

15.57

41.50

106.19

26.75

29.00

2150

36

46.25

18.50

48.25

119.25

31.88

35.00

3500

42

53.00

21.03

56.50

145.68

38.25

41.00

5200

48

59.50

21.13

60.35

158.25

43.98

54

66.19

20.75

67.25

172.88

48.98

* Flange diameter: Designed to match ANSI B16.5/150 through 24, MSS-SP44 above 24

**Face-to-face: Add 1/4 to 1/2 for ease of installation

Actuation

Note: Not all actuators shown are available on all valve sizes

MH Manual

Handwheel

BG Manual

Bevel Gear

AC Air Cylinder

HC Hydraulic Cylinder

EM

Electro-mechanical

Hydra-Helper

Valves & Controls

www.tycovalves.com

The data presented in this bulletin is for general information only. Manufacturer is not responsible for acceptability of these products in relation to system requirements. Patents and Patents

Pending in U.S. and foreign countries. All rights reserved. Printed in U.S.A. Tyco reserves the right to change product design and specifications without notice. Copyright 2001.

Tyco reserves the right to change product design and specifications

without notice. Copyright 2001 by Tyco International Ltd.

CLKMC-0113

4

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Title Page Declaration Abstract/Objectives Acknowledgements: 2. Background 3. Single Particle MotionDocument17 pagesTitle Page Declaration Abstract/Objectives Acknowledgements: 2. Background 3. Single Particle Motionkshitij singh rathoreNo ratings yet

- Power Generation With Simultaneous Aeration Using A Gravity Vortex TurbineDocument6 pagesPower Generation With Simultaneous Aeration Using A Gravity Vortex TurbineMunif MoenifNo ratings yet

- Colonial ZF SeriesDocument2 pagesColonial ZF SeriesmndmattNo ratings yet

- React Scales PosterDocument1 pageReact Scales PosterFrancesco ManiscalcoNo ratings yet

- Forensic SerologyDocument19 pagesForensic Serologyrkbagari11No ratings yet

- Bayblend T85 XF ISO enDocument3 pagesBayblend T85 XF ISO enryanNo ratings yet

- Caterpillar Oil Filter Pehj0068-02Document2 pagesCaterpillar Oil Filter Pehj0068-02Parinpa Ketar100% (1)

- Carding For Nonwoven Fabrics: (Lap Form To Web Formation)Document23 pagesCarding For Nonwoven Fabrics: (Lap Form To Web Formation)Shashi sssNo ratings yet

- Act. 6 - Correct Execution of Clearing TechniqueDocument4 pagesAct. 6 - Correct Execution of Clearing Techniquechristian Jay HorseradaNo ratings yet

- VATER Elgate Fence & Gate Systems INFO List JULY19Document6 pagesVATER Elgate Fence & Gate Systems INFO List JULY19GarryNo ratings yet

- Lec 3Document12 pagesLec 3Shraddha JaiswalNo ratings yet

- Rates of Reaction - Disappearing Cross LabDocument3 pagesRates of Reaction - Disappearing Cross Lab4L Anisha SieudassNo ratings yet

- Rilling OP Ata: IG Ccumulator NIT ATA Equired CcumulatorDocument1 pageRilling OP Ata: IG Ccumulator NIT ATA Equired CcumulatorKiryaki FrancisNo ratings yet

- Mass Tranfer AssignmentDocument2 pagesMass Tranfer Assignmentmadhu77No ratings yet

- Fire Safety Unit 1Document102 pagesFire Safety Unit 1Raunaq AroraNo ratings yet

- Advance Applications of Fourier Transform Infrared SpectrosDocument8 pagesAdvance Applications of Fourier Transform Infrared Spectrosnamsaigon316No ratings yet

- Module-6: Managing Health and SafetyDocument35 pagesModule-6: Managing Health and Safetyshubham shahNo ratings yet

- Real-Time Cure Monitoring of Unsaturated Polyester Resin From Ultra-Violet CuringDocument11 pagesReal-Time Cure Monitoring of Unsaturated Polyester Resin From Ultra-Violet CuringDanielApazaNo ratings yet

- Medical (VFT-5) Fortnightly Test-5 (04!09!2023) - NEET-2025 - Questions PaperDocument26 pagesMedical (VFT-5) Fortnightly Test-5 (04!09!2023) - NEET-2025 - Questions Paperharsh sharmaNo ratings yet

- LUBCON Cutting Oils Corrugator enDocument2 pagesLUBCON Cutting Oils Corrugator enOmin PostingNo ratings yet

- BS en 438-9-2010Document18 pagesBS en 438-9-2010Abey VettoorNo ratings yet

- Intertek Minerals Schedule of Services and Charges 2022 AUS PDFDocument60 pagesIntertek Minerals Schedule of Services and Charges 2022 AUS PDFJGGNo ratings yet

- Class IX Holiday HomeworkDocument9 pagesClass IX Holiday Homeworkanubh50No ratings yet

- Fire Plant Room BoqDocument16 pagesFire Plant Room BoqRashel HasanNo ratings yet

- Whitewares (Class-04)Document40 pagesWhitewares (Class-04)Zahid HasanNo ratings yet

- Normosol-M and Dextrose DescriptionDocument1 pageNormosol-M and Dextrose Descriptioned120888No ratings yet

- Transport Phenomena Data Companio PDFDocument160 pagesTransport Phenomena Data Companio PDFLavanya ChandrashekarNo ratings yet

- Circulaire Filtration Fume Cabinets With VisionaireDocument9 pagesCirculaire Filtration Fume Cabinets With VisionaireAkhmad Rosul RaisNo ratings yet

- HRSG Steam Velocity AnalysisDocument3 pagesHRSG Steam Velocity Analysisaliscribd46No ratings yet

- LPG Recovery and Condensate StabilizationDocument6 pagesLPG Recovery and Condensate StabilizationWaqar AhmedNo ratings yet