Professional Documents

Culture Documents

Lecture 1

Uploaded by

Elmokadem EinsteinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture 1

Uploaded by

Elmokadem EinsteinCopyright:

Available Formats

Lecture 1

Introduction

Lecture 1: Introduction

Dr. Eng. Sameh Shaaban

10-May-07

0/14

Typical Efficiency of Different Plants

Lecture 1: Introduction

Dr. Eng. Sameh Shaaban

10-May-07

1/14

Economic and Operation Characteristics of Plants

Lecture 1: Introduction

Dr. Eng. Sameh Shaaban

10-May-07

2/14

Advantages of a Gas Turbine Plant

The advantages of a gas turbine plant as compared to a steam plant

of comparable horsepower include:

1.

2.

3.

4.

5.

6.

7.

They are small in size, mass (70% weight reduction), and initial

cost per unit output.

Their delivery time is relatively short and they can be installed

quickly.

They are quick starting (as low as 10 s), often by remote control.

They are smooth running and have a capacity factor (percent of

time the unit is operating at full power) of 96 to 98 percent.

They have quicker response time (faster

acceleration/deceleration)

They can use a wide variety of liquid and gaseous fuels

including gasified coal and synthetic fuels.

They are subject to fewer environmental restrictions than other

prime movers.

Lecture 1: Introduction

Dr. Eng. Sameh Shaaban

10-May-07

3/14

Comparison Between Gas Turbine and Diesel Engine (1)

The gas turbine competes with the high and medium speed diesel

engines in all non-aero shaft power applications up to 10MW.

Lecture 1: Introduction

Dr. Eng. Sameh Shaaban

10-May-07

4/14

Comparison Between Gas Turbine and Diesel Engine (2)

The gas turbine competes with the high and medium speed diesel

engines in all non-aero shaft power applications up to 10MW.

Lecture 1: Introduction

Dr. Eng. Sameh Shaaban

10-May-07

5/14

Comparison Between Gas Turbine and Diesel Engine (3)

Where the application can use the waste heat from the engine the gas

turbine has a significant advantage.

The gas turbine has significantly lower weight per unit of power output.

For example a 5MW aero-derivative gas turbine will have a specific

weight of less than 1 ton/MW, whereas a medium speed diesel would be

nearer 5 ton/MW.

The gas turbine has significantly lower volume per unit of output power.

In the 5MW example above the packaged volume of the gas turbine

would approach 50% of that for the diesel engine.

The start time to idle for a gas turbine is typically 1060 seconds in

applications where it would compete with a high speed diesel. The

diesel engine has the advantage of being able to start in less than 5 sec.

Lecture 1: Introduction

Dr. Eng. Sameh Shaaban

10-May-07

6/14

Comparison Between Gas Turbine and Diesel Engine (4)

The gas turbine can have dual fuel capability, being able to transfer

from natural gas to diesel fuel while running.

The potential for low emissions of pollutants is an order of magnitude

better for gas turbines.

Maintenance costs for a gas turbine are generally lower than for a

diesel engine.

The gas turbine intrinsically has a lower vibration level than a diesel

engine.

Lecture 1: Introduction

Dr. Eng. Sameh Shaaban

10-May-07

7/14

Development of engine pressure ratio over the years

Lecture 1: Introduction

Dr. Eng. Sameh Shaaban

10-May-07

8/14

Trend in improvement of firing temperature

Lecture 1: Introduction

Dr. Eng. Sameh Shaaban

10-May-07

9/14

Overall cycle efficiency

Lecture 1: Introduction

Dr. Eng. Sameh Shaaban

10-May-07

10/14

Essential Criteria For the Gas Turbine Design (1)

1. High efficiency

2. High reliability and thus availability

3. Ease of service

4. Ease of installation and commission

5. Conformance with environmental standards

6. Incorporation of auxiliary and control systems, which have high

degree of reliability

7. Flexibility to meet various services and fuel needs

Lecture 1: Introduction

Dr. Eng. Sameh Shaaban

10-May-07

11/14

Essential Criteria For the Gas Turbine Design (2)

High efficiency requires:

1. High pressure ratio

(for axial compressors pC increased from 7:1 to 40:1)

2. High turbine inlet temperature

(55.5C increase in turbine inlet temperature results

in 10% increase in work and about 1-0.5% increase

in efficiency)

3. Regeneration

Lecture 1: Introduction

Dr. Eng. Sameh Shaaban

10-May-07

12/14

Essential Criteria For the Gas Turbine Design (3)

Reliability and availability:

Lecture 1: Introduction

Dr. Eng. Sameh Shaaban

10-May-07

13/14

Categories of Gas Turbines

Frame Type Heavy-Duty Gas Turbines.

3 MW to 480 MW in a simple cycle configuration, with efficiencies

ranging from 30-46%.

Aircraft-Derivative Gas Turbines Aero-derivative.

2.5 MW to about 50 MW. The efficiencies of these units can range

from 35-45%.

Industrial Type-Gas Turbines.

2.5 MW-15 MW. This type of gas turbine is used extensively in many

petrochemical plants for compressor drive trains. The efficiencies of

these units are in the low 30s.

Small Gas Turbines.

0.5 MW-2.5 MW. They often have centrifugal compressors and radial

inflow turbines. Efficiencies in the simple cycle applications vary from

15-25%.

Micro-Turbines.

20 kW-350 kW.

Lecture 1: Introduction

Dr. Eng. Sameh Shaaban

10-May-07

14/14

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- RLT DatasheetDocument12 pagesRLT DatasheetElmokadem EinsteinNo ratings yet

- 10L-02 201107Document1 page10L-02 201107Elmokadem EinsteinNo ratings yet

- PlanatDocument1 pagePlanatElmokadem EinsteinNo ratings yet

- Plan 6Document1 pagePlan 6Elmokadem EinsteinNo ratings yet

- Nicollette Miller: Summary of QualificationsDocument1 pageNicollette Miller: Summary of QualificationsElmokadem EinsteinNo ratings yet

- Plan 2Document1 pagePlan 2Elmokadem EinsteinNo ratings yet

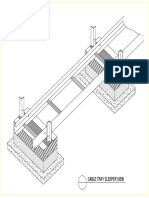

- Cable Tray Sleeper and Support Design 3Document5 pagesCable Tray Sleeper and Support Design 3Elmokadem EinsteinNo ratings yet

- Machine IdDocument1 pageMachine IdElmokadem EinsteinNo ratings yet

- PlaneDocument1 pagePlaneElmokadem EinsteinNo ratings yet

- PlanDocument1 pagePlanElmokadem EinsteinNo ratings yet

- PlanationDocument1 pagePlanationElmokadem EinsteinNo ratings yet

- ContentsDocument1 pageContentsElmokadem EinsteinNo ratings yet

- Photographer Résumé Nicollette MillerDocument1 pagePhotographer Résumé Nicollette MillerGiannis GouliasNo ratings yet

- Hiren Boot CDDocument20 pagesHiren Boot CDGabriel Illanes BurgoaNo ratings yet

- CompaniesDocument1 pageCompaniesElmokadem EinsteinNo ratings yet

- ChangeshjhjkhjkDocument5 pagesChangeshjhjkhjkChilmy FarouqNo ratings yet

- Eng. ProgramsDocument1 pageEng. ProgramsElmokadem EinsteinNo ratings yet

- تحسين اداء 7Document1 pageتحسين اداء 7Elmokadem EinsteinNo ratings yet

- تحسين اداء 7Document1 pageتحسين اداء 7Elmokadem EinsteinNo ratings yet

- Reading Pump and Engine Performance CurvesDocument4 pagesReading Pump and Engine Performance CurvesElmokadem EinsteinNo ratings yet

- تحسين اداء 7Document1 pageتحسين اداء 7Elmokadem EinsteinNo ratings yet

- Final 1 ModelDocument1 pageFinal 1 ModelElmokadem EinsteinNo ratings yet

- InstallDocument1 pageInstallgsaqswdeNo ratings yet

- Required DataDocument1 pageRequired DataElmokadem EinsteinNo ratings yet

- Ets403 Method of Identification For Instrument WiringDocument18 pagesEts403 Method of Identification For Instrument WiringElmokadem EinsteinNo ratings yet

- LSERVRCDocument50 pagesLSERVRCamitNo ratings yet

- WECs Very BasicsDocument5 pagesWECs Very BasicsChristopher TheobaldNo ratings yet

- LocationsDocument1 pageLocationsElmokadem EinsteinNo ratings yet

- Swing Lip Technical DataDocument1 pageSwing Lip Technical DataElmokadem EinsteinNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Astm E1647Document4 pagesAstm E1647Jorge SuarezNo ratings yet

- EAST+NDT+CHINA Calibration BlocksDocument6 pagesEAST+NDT+CHINA Calibration BlocksmgmqroNo ratings yet

- Remedy API call log analysisDocument2 pagesRemedy API call log analysisLuis A. VarelaNo ratings yet

- Parliamentary Procedure in A MeetingDocument2 pagesParliamentary Procedure in A MeetingGiordann MadejaNo ratings yet

- 6 SQ - MM Standard Feed Through Terminal Blocks: Cat. No. Description Std. PackDocument3 pages6 SQ - MM Standard Feed Through Terminal Blocks: Cat. No. Description Std. PackKaran SanghviNo ratings yet

- Revit - Orion IntegrationDocument44 pagesRevit - Orion IntegrationMohd Faizal100% (2)

- INTECONT® Tersus For Measuring Systems: % Compact Weighing Electronics ForDocument4 pagesINTECONT® Tersus For Measuring Systems: % Compact Weighing Electronics Forgnazareth_100% (1)

- Telegram Listing Nav350Document82 pagesTelegram Listing Nav350caskibNo ratings yet

- Project Risk: Group 1Document20 pagesProject Risk: Group 1Group 8No ratings yet

- 06-086-098 Weld Ring GasketsDocument13 pages06-086-098 Weld Ring GasketsRitesh VishambhariNo ratings yet

- Viscosity-Graded Asphalt Binder For Use in Pavement ConstructionDocument3 pagesViscosity-Graded Asphalt Binder For Use in Pavement ConstructionHugo EscalanteNo ratings yet

- Standard Test Methods for Particle-Size Analysis of SoilsDocument4 pagesStandard Test Methods for Particle-Size Analysis of SoilsMiller De Leon CutoraNo ratings yet

- Asterisk BrochureDocument7 pagesAsterisk BrochureOmar WaheedNo ratings yet

- DOORS DXL - Adventures in Microsoft OLE AutomationDocument32 pagesDOORS DXL - Adventures in Microsoft OLE AutomationLuci OpreaNo ratings yet

- Access Integrated Project 2Document7 pagesAccess Integrated Project 2Mohini SharmaNo ratings yet

- ASME IX Interpretation Part1 PDFDocument51 pagesASME IX Interpretation Part1 PDFalisyalala100% (3)

- Types of Forging ProcessesDocument9 pagesTypes of Forging ProcessesAryan Singh100% (1)

- Burndy Grounding CountermatDocument1 pageBurndy Grounding CountermatwilmanzitoNo ratings yet

- 1 SM401Document55 pages1 SM401Yennhi NguyenNo ratings yet

- Pom Assignment EditedDocument21 pagesPom Assignment EditedKarl Gio GonocruzNo ratings yet

- Telenor (Introduction)Document22 pagesTelenor (Introduction)Bilal SayalNo ratings yet

- SDLC AssignmentDocument6 pagesSDLC Assignmentshahzeb1978No ratings yet

- LPS Earth Test Report of Liberty Knitwear LTD 30.10.2022.docx222Document22 pagesLPS Earth Test Report of Liberty Knitwear LTD 30.10.2022.docx222roniNo ratings yet

- Advanced Cost Accounting Review SheetDocument2 pagesAdvanced Cost Accounting Review Sheetwsw31No ratings yet

- Computer Graphics BCA 33Document131 pagesComputer Graphics BCA 33Mohiddin SahebNo ratings yet

- Reich Cat 2011Document149 pagesReich Cat 2011drakula85No ratings yet

- EVO Maintenance Solutions: ® The Perfect Fit For Your After Market BusinessDocument4 pagesEVO Maintenance Solutions: ® The Perfect Fit For Your After Market BusinessSeyedAli TabatabaeeNo ratings yet

- 9xL74SctSQC9qRmfy7Og - CCVSA Online Lab GuideDocument48 pages9xL74SctSQC9qRmfy7Og - CCVSA Online Lab GuideCarlos Eduardo de Souza de SilvaNo ratings yet

- 1400p ManualDocument21 pages1400p ManualrugerNo ratings yet