Professional Documents

Culture Documents

320, 320L Medicion de Presiones Bomba Hidraulica PDF

Uploaded by

rprimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

320, 320L Medicion de Presiones Bomba Hidraulica PDF

Uploaded by

rprimCopyright:

Available Formats

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

1 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Producto: EXCAVATOR

Modelo: 320 L EXCAVATOR 1KL

Configuracin: 320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP

(MACHINE) POWERED BY 3066 ENGINE

Pruebas y Ajustes

320 AND 320L EXCAVATORS HYDRAULIC AND ELECTRONIC SYSTEMS

Nmero de medio -SENR5473-02

Fecha de publicacin -18/08/1994

Fecha de actualizacin -11/10/2001

Testing And Adjusting

Introduction

This manual contains information on the troubleshooting procedures of the electronic control and hydraulic

systems in the 320 and 320 L Excavator. This manual is divided into the following three main sections:

1. Electronic System Testing And Adjusting

2. Checking Procedures

3. Hydraulic System Testing And Adjusting

NOTE: As a general rule, if there is a doubt as to the cause of a problem, the electronic system should be

checked first.

Reference: For information on Systems Operation of the above, make reference to: "Systems Operation,

Electronic System", Form SENR5463 and/or "Systems Operation, Hydraulic System", Form SENR5464.

For troubleshooting the engine components, refer to: "Systems Operation, Testing And Adjusting, Basic

Engine Components 3306 Engine", Form SENR5546.

Checking Procedures

In each checking procedure, it is assumed that the engine operation is normal unless otherwise specified.

Electronic Control System

The monitor and electronic controller are the main components of the electronic control system. The

monitor and electronic controller have a self diagnostic function. Self diagnostic checks of the monitor,

electronic controller, and the communication line between them are the first steps when troubleshooting the

problem(s) in the electronic system.

Action alarm indicators on the monitor panel, alert an operator to a problem in the electronic system. The

controller service program "Data Mode" can also be used to identify the problems (see the section of this

module "Data Mode"). If the service program is activated during machine operation, problem(s) that are

monitored by the monitoring system are indicated on the character display. If the service program is

activated when the machine operation is stopped, all existing problems and past problems (problems that

have not been corrected) are indicated on the character display. To activate the controller service program

"Data Mode", refer to the "Data Mode" section in this module.

Operational Tests

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

2 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

If the electronic power unit control system display indicates it is operating correctly, then do operational

tests. Operate the machine, following the procedures described in the section "Hydraulic System Testing

And Adjusting". Compare the results of the operational tests with specifications to determine the extent of

the trouble. In operational tests, it is important to determine whether or not enough hydraulic force or

implement speed is a problem that extends over the entire machine or with only a specific operation.

If there are any faults in the circuits between the main or pilot pumps and the control valves, the overall

performance of the machine will decrease. This type of problem in the hydraulic system is not detected by

the self diagnostic functions of the electronic control system described above (no action alarm indication on

character display.). To detect such a problem, it is necessary to check the flow characteristics of the pumps,

the main relief pressure, pilot pressure, etc.

Service Program

Electronic Monitor Panel

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

3 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

(1) Engine coolant temperature gauge. (2) Fuel gauge. (3) Action lamp. (4) Character display. (5) Monitor panel. (6) Hydraulic oil

temperature gauge. (7) Work mode selector switch. (8) Air heater indicator. (9) Charge alarm indicator. (10) Engine coolant

temperature alarm indicator. (11) Hydraulic oil temperature alarm indicator. (12) Engine oil pressure alarm indicator. (13)

Controller alarm indicator. (14) Monitor alarm indicator. (15) Work mode boom priority indicator. (16) Work mode swing priority

indicator. (17) Power mode selector switch. (18) Power mode III indicator. (19) Power mode II indicator. (20) Power mode I

indicator. (21) Work mode fine control indicator. (22) Light switch. (23) Light 1 indicator. (24) Light 2 indicator. (25) Wiper 2

indicator. (26) Travel speed HIGH (rabbit) indicator. (27) Travel speed LOW (tortoise) indicator. (28) Travel speed control

switch. (29) AEC indicator. (30) Switch panel. (31) AEC switch. (32) Wiper 1 indicator. (33) Washer indicator. (34) Washer

switch. (35) Wiper switch. (36) Alarm cancel switch. (37) Service switch. (38) Alarm cancel indicator.

Introduction

The electronic Monitor Panel activates and displays the output received from the Electronic Controller. The

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

4 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Electronic Controller Service Program is divided into two program modes. Each program mode has a

particular function as follows:

1. Data Mode;

This program mode contains eight function modes and provides the necessary information for the

mechanic to determine the machine condition.

2. Calibration Mode;

This program mode contains ten function modes and provides information used to adjust and confirm

system/component functions after replacement of electronic control system components. This

program level is also used to help the mechanic troubleshoot machine problems.

To activate the service program mode functions, use the control switches provided on the electronic monitor

panel.

NOTE: Unexpected character display readings due to random operation of switches should be disregarded.

To select a desired function mode, first start a proper service program mode (see the section "Data Mode

Start-up" and/or "Calibration Mode Start-up"). Next, operate the control switch(es) as specified, until the

desired information is indicated on the character display.

When the selected service program function is no longer needed, use the proper procedure (see the section

"Data Mode Stop Procedure" and/or "Calibration Mode Stop Procedure") to cancel.

Data Mode

NOTE: Activation of service program "Data Mode" does not affect any machine controls and operations

except for the following:

The LED indicators for power mode switch, travel speed control switch, light switch, and wiper switch come

ON only in flashing mode during activation of service program "Data Mode".

The Data Mode contains the following function modes which provide eight categories of information.

1. Power shift pressure.

2. Engine speed.

3. Engine coolant temperature.

4. Hydraulic oil temperature.

5. A/D (Analog/Digital) conversion.

6. Real time error.

7. Digital input.

8. Output control display.

Data Mode Start-up

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

5 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Electronic Monitor Panel (Data Mode Start-up)

(4) Character display. (17) Power mode selector switch. (18) Power mode III indicator. (36) Alarm cancel switch. (38) Alarm

cancel indicator.

NOTE: To access and view the eight available functions in the "Data Mode", the engine can either be

running or shut down. If the engine is running the eight Data Mode functions can be viewed as operating

values. If the engine is not running the starter switch must be in the "ON" position.

1. Depress and hold alarm cancel switch (36) until alarm cancel indicator (38) starts flashing.

2. While alarm cancel switch (36) is depressed, push power mode selector switch (17) until power mode III

indicator (18) begins to flash. Release alarm cancel switch (36) and power mode selector switch (17).

3. The service program "Data Mode" is now activated and character display (4) will display the first function

mode (power shift pressure) value.

NOTE: If switch (17) is held too long, the character display will sequence through the eight available

function modes in the "Data Mode" program.

Data Mode Function Selection

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

6 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Electronic Monitor Panel (Data Mode Function Selection)

(4) Character display. (17) Power mode selector switch. (18) Power mode III indicator. (36) Alert cancel switch.

1. Repeatedly push first alarm cancel switch (36) and then power mode switch (17) until the desired

function mode is displayed on character display (4).

2. Each time both switches are pushed, the function mode changes in an increasing number sequence of the

eight function modes in a repetitious manner.

3. At the same time that the function mode character is displayed the corresponding switch indicator comes

on. To determine the function mode selected, look for the switch indicator which is flashing.

NOTE: If alarm cancel switch (36) is depressed for more than 2 seconds the Data Mode stops and character

display (4) displays the engine speed dial position.

NOTE: Accessing the "Data Mode Functions" must be performed in the sequence shown in the following

chart.

Each of the eight Data Mode functions has a designated indicator light. The following chart shows the eight

Data Mode functions and their designated indicator lights:

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

7 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Power Shift Pressure

Electronic Monitor Panel (Power Shift Pressure)

(4) Character display. (17) Power mode selector switch. (18) Power mode III indicator. (36) Alarm cancel switch.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

8 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

When this function mode is selected, power mode III indicator (18) flashes. The character display (4)

displays "P" in the first position and actual power shift pressure in the second and third positions. The unit of

power shift pressure is in kgf/cm2. 1 kgf/cm2 is approximately the same as 100 kPa (14 psi).

Engine Speed

Electronic Monitor Panel (Engine Speed)

(4) Character display. (19) Power mode II indicator.

When this function mode is selected, power mode II indicator (19) flashes. Character display (4) will display

the engine speed in rpm, regardless of the machine load. Multiply the rpm values in character display (4) by

10 to determine actual rpm.

Engine Coolant Temperature

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

9 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Electronic Monitor Panel (Engine Coolant Temperature)

(4) Character display. (20) Power mode I indicator.

When this function mode is selected, power mode I indicator (20) flashes. Character display (4) displays the

engine coolant temperature within a range of 14C to 127C (57F to 260F). The engine coolant

temperature units are displayed in 1C (1.8F) increments. If the character display reading is below 0C, the

first position on the character display reads "-".

NOTE: Character display (4) displays the engine coolant temperature in degrees Celsius.

Hydraulic Oil Temperature

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

10 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Electronic Monitor Panel (Hydraulic Oil Temperature)

(4) Character display. (23) Light 1 indicator.

When this function mode is selected, light 1 indicator (23) flashes. Character display (4) displays the

hydraulic oil temperature within a range of 14C to 127C (57.2F to 260.6F). The hydraulic oil

temperature units are displayed in 1C (1.8F) increments.

NOTE: Character display (4) displays the hydraulic oil temperature in degrees Celsius.

A/D (Analog/Digital) Conversion

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

11 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Electronic Monitor Panel (A/D Conversion)

(4) Character display. (24) Light 2 indicator.

When the analog/digital conversion function mode is selected, light 2 indicator (24) flashes. Character

display (4) displays the analog information for eight machine functions. A conversion chart is needed to

understand the digital information indicated. Description of the eight machine functions omitted since this

information is not needed for service or diagnosis.

Real Time Error Codes

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

12 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Electronic Monitor Panel (Real Time Error Codes)

(4) Character display. (26) Travel speed HIGH (rabbit) indicator.

When this mode is selected, travel speed HIGH (rabbit) indicator (26) flashes. Character display (4) displays

the codes for problems that have occurred. They are displayed in an increasing number sequence according

to "Problem List" shown below, in a repetitious manner. A character display code remains displayed for 2

seconds with an interval of 1 second between codes.

NOTE: A display code of [E00] indicates that there are no system errors.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

13 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

NOTE: Go to the appropriate "Electronic Sequence Chart" to troubleshoot the problem of [E33] in

accordance with the following:

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

14 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Digital Input

Electronic Monitor Panel (Digital Input)

(4) Character display. (7) Work mode switch. (17) Power mode selector switch. (27) Travel speed LOW (tortoise) indicator. (36)

Alarm cancel switch.

When this mode is selected, travel speed LOW (tortoise) indicator (27) flashes. This mode displays 21 types

of information on character display (4).

1. Depress and hold alarm cancel switch (36) and then depress power mode switch (17) until travel speed

LOW (tortoise) indicator (27) flashes. Release alarm cancel switch (36) and power mode switch (17).

2. Character display (4) will display [0 9]. The "0" indicates that this is the first of 21 "ports" or additional

types of information. The " 9" indicates the wiring harness code for the 320 and 320 L Excavators with 3066

engine.

3. To sequence through the 21 "ports", first depress and hold alarm cancel switch (36) and then work mode

switch (7) until the character display reads the desired "port".

NOTE: This mode is capable of providing a total of 21 types of information. Eight of the 21 "ports"

(additional types of information) are spares.

The following chart gives a listing of the 21 "ports" and their components:

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

15 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

NOTE: Ports "0" and "1" give no indication of "[ O n] or [ o F] on the character display.

Typical Examples:

[0 9]: Indicates the machine model of "320" or "320 L" excavator with 3066 engine. If a different code

appears in the second and third positions, check the circuit for good grounding.

[1 1]: Engine speed dial is in position "1".

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

16 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

[110]: Engine speed dial is in position "10".

[1Er]: There is a problem in engine speed dial or circuit between speed dial and controller. (Er:error)

[2On]: Travel pressure switch is ON.

[2oF]: Travel pressure switch is OFF.

NOTE: To check the travel pressure switch, activate the travel control with the pressure switch in ON

position. If the character display does not read [2On], it is an indication of a possible problem in the travel

pressure switch and/or its circuit.

Output Control Display

Electronic Monitor Panel (Output Control Display)

(4) Character display. (32) Wiper 1 indicator.

When this function mode is selected, wiper 1 indicator (32) flashes. Character display (4) displays the code

that represents current pump output. The initial code displayed will be [L00] for a normal pump output

control. The character display code remains ON for 2 seconds with an interval of 0.5 seconds between

codes.

Typical Examples:

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

17 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

[L00]: Output control is normal.

[L A]: Pump output control when governor actuator feedback sensor is abnormal.

[L b]: Pump control under too low hydraulic oil temperature.

NOTE: [L b] is displayed only when one of the controls is activated.

NOTE: During "Output Control Display" function, the AEC system and one touch low idle do not activate.

The engine speed dial switch controls the engine speed only under a no load condition.

Reference: For more information on the pump output control, refer to module, "Systems Operation,

Electronic System", Form SENR5463.

Data Mode Stop Procedure

Electronic Monitor Panel (Stop Procedure)

(4) Character display. (36) Alarm cancel switch.

Use either of the following two methods.

1. Turn the engine start switch to the OFF position.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

18 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

2. Keep alarm cancel switch (36) depressed at least 2 seconds until character display (4) displays the engine

speed dial position.

Calibration Mode

NOTE: The procedures for each function in "Calibration Mode" are independent of each other. The engine

does not need to be running for all the functions listed in the following chart. The following chart lists the

functions in "Calibration Mode" and whether the engine must be running for each of the functions:

Calibration Mode Start-up

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

19 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Electronic Monitor Panel (Calibration Mode Start-up)

(1) Engine coolant temperature gauge. (2) Fuel gauge. (3) Action lamp. (4) Character display. (6) Hydraulic oil temperature gauge.

(8) Air heater indicator. (9) Charge alarm indicator. (10) Engine coolant temperature alarm indicator. (11) Hydraulic oil

temperature alarm indicator. (12) Engine oil pressure alarm indicator. (13) Controller alarm indicator. (14) Monitor alarm

indicator. (37) Service switch.

NOTICE

Before to starting the Calibration Mode, the engine speed dial switch

should be set at dial position "1" and the engine start switch must be in

the OFF position.

1. Depress service switch (37) and start the engine. As shown in the chart above, the engine does not need to

be started to obtain information for certain functions in the "Calibration Mode".

2. Continue to depress service switch (37) until action lamp (3) comes ON and character display (4) displays

[20H]. All the alarm indicators except character display (4) will turn OFF.

3. The "Calibration Mode" is now accessed and character display (4) displays the first of the 10 functions

(machine and engine model numbers) as shown in the chart above. Action lamp (3) remains ON during all

calibration function modes.

NOTE: Activation of the "Calibration Mode" overrides the function of engine coolant temperature gauge

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

20 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

(1), fuel gauge (2), action lamp (3), hydraulic oil temperature gauge (6), air heater indicator (8), charge

alarm indicator (9), engine coolant temperature alarm indicator (10), hydraulic oil temperature alarm

indicator (11), engine oil pressure alarm indicator (12), controller alarm indicator (13), and monitor alarm

indicator (14).

Calibration Mode Function Selection

Electronic Monitor Panel (Function Selection)

(3) Action lamp. (4) Character display. (17) Power mode selector switch. (22) Light switch. (28) Travel speed control switch. (31)

AEC switch. (35) Wiper switch.

Power mode selector switch (17), light switch (22), AEC switch (31), wiper switch (35), and travel speed

control switch (28) are pushed each time to obtain one of ten function modes.

Machine And Engine Model

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

21 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Electronic Monitor Panel (Machine And Engine Model)

(4) Character display. (17) Power mode selector switch. (18) Power Mode III indicator.

1. Start "Calibration Mode". See the section, "Calibration Mode Start-up".

Upon accessing the "Calibration Mode", the machine and engine model is the first function accessed. To

obtain this function again after viewing or accessing any of the other functions, depress power mode selector

switch (17) until power Mode III indicator (18) comes ON.

2. Character display (4) displays [20H] for a "320" or "320 L" excavator equipped with a 3066 engine. The

first and second positions of character display (4) shows the code for the model excavator. The third

position of character display (4) shows the code for the engine model.

3. Stop "Calibration Mode" (unless another function selection is desired). See the section, "Calibration Mode

Stop Procedure".

NOTE: Activation of the "Calibration Mode" overrides the AEC function and keeps the power shift

pressure constant at a pressure level equivalent to a no-load condition. The engine speed dial switch works

normally.

Controller/Monitor Software Version

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

22 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Electronic Monitor Panel (Controller/Monitor Software Version)

(4) Character display. (17) Power mode selector switch. (19) Power Mode II indicator. (31) AEC switch.

1. Start "Calibration Mode". See the section, "Calibration Mode Start-up".

2. Depress power mode selector switch (17) until power Mode II indicator (19) comes ON.

3. Character display (4) displays [17C] for example. The "17" in the character display represents a two digit

numeral particular to the software for each machine mode. The "C" represents the controller.

4. To determine the software version for the monitor depress AEC switch (31). Character display (4)

displays [20P] for example. The "20" in the character display represents a two digit numeral particular to the

software for each machine mode. The "P" represents the software version.

NOTE: Each time AEC switch (31) is depressed, the character display will alternate between the two

software codes [17C] and [20P] for example.

5. Stop "Calibration Mode" (unless another function selection is desired). See the section, "Calibration Mode

Stop Procedure".

NOTE: Activation of the "Calibration Mode" overrides the AEC function and keeps the power shift

pressure constant at a pressure level equivalent to a no-load condition. The engine speed dial switch works

normally.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

23 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Error log

Electronic Monitor Panel (Error Log)

(4) Character display. (17) Power mode selector switch. (20) Power Mode I indicator. (28) Travel speed control switch. (31) AEC

switch. (34) Washer switch.

1. Start "Calibration Mode". See the section, "Calibration Mode Start-up".

2. Depress power mode selector switch (17) until power Mode I indicator (20) comes ON.

3. Character display (4) displays [Hd ]. This display indicates that the list of stored error codes can be

viewed. The controller has a continual self-diagnostic function during machine operation. The controller will

store error codes if a fault is detected, even an intermittent fault. The list of error codes is stored in the error

history on important systems until the memory is cleared.

4. The error codes are viewed on the character display either in ascending or descending order. Each time

AEC switch (31) is depressed, the ascending sequential list of stored error codes are displayed as shown in

the following example:

[Hd ][F 6][F10][F40][F41][End]

5. Each time washer switch (34) is depressed, the descending sequential list of stored error codes are

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

24 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

displayed as shown in the following example:

[End][F41][F40][F10][F 6][Hd]]

NOTE: A "F" in the first position of character display (4) represents a stored error code (error history). An

"E" in the first position of character display (4) represents a real time error code.

6. To clear the error codes and error history, push and hold in sequence for approximately three seconds the

following three buttons:

* AEC switch (31)

* Power mode selector switch (17)

* Travel speed control switch (28)

7. The error codes are cleared from the error history memory when character display (4) displays [CLr] and

then returns to display [Hd ].

Reference: For a listing of error codes, see the section in this module "Data Mode, Real Time Errors

Codes".

NOTE: Information about a problem is stored by this function mode until the correct clearing procedure is

completed. Always clear the error history after the problem has been corrected.

NOTE: Activation of the error log mode overrides the function of the AEC system and keeps the power

shift pressure constant at the no load pressure level. The engine speed dial works normally.

8. Stop "Calibration Mode" (unless another function selection is desired). See the section, "Calibration Mode

Stop Procedure".

NOTE: The following error log codes are not displayed on the character display during activation of this

calibration mode.

F1 to F5, F7, F9, F12, F15, F32, F34, F37, F38, F39, and F48.

NOTE: Activation of the "Calibration Mode" overrides the AEC function and keeps the power shift

pressure constant at a pressure level equivalent to a no-load condition. The engine speed dial switch works

normally.

Digital Output Test

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

25 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Electronic Monitor Panel (Digital Output Test)

(4) Character display. (22) Light switch. (23) Light 1 indicator. (29) AEC indicator. (31) AEC switch. (33) Washer indicator. (34)

Washer switch. (36) Alarm cancel switch.

1. Start "Calibration Mode". See the section, "Calibration Mode Start-up".

2. Depress light switch (22) until light 1 indicator (23) comes ON.

3. Character display (4) displays [0oF] which represents the first of 10 components that can be tested. There

are 16 "ports" available of the electrical connections for various controller output components (similar to the

"Digital Input" information accessed in "Data Mode"). Six of the "ports" are spares. The code in the first

position of the character display represents the particular "port" of each component.

The "ports" and their components are shown in the following chart:

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

26 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

4. Each time AEC switch (31) is pushed, a different port code appears in character display (4) in an

ascending order. Press washer switch (34) to view the ports in descending order.

5. Press alarm cancel switch (36) to turn the component for each port, either ON or OFF. Character display

(4) displays as shown in the chart above as each port is turned ON or OFF. If an over current occurs at a

component, the character display (4) displays [OEr].

6. Stop "Calibration Mode" (unless another function selection is desired). See the section, "Calibration Mode

Stop Procedure".

NOTE: Activation of the "Calibration Mode" overrides the AEC function and keeps the power shift

pressure constant at a pressure level equivalent to a no-load condition. The engine speed dial switch works

normally.

Proportional Reducing Valve Sweep Test

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

27 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Pilot Oil Manifold Compartment

(39) Connector.

1. Stop the engine and disconnect connector (39) from the proportional reducing valve.

2. Connect the test harness to connector (39).

Main Pump Compartment

(40) Power shift pressure tap.

3. Install a 4900 kPa (700 psi) pressure gauge at power shift pressure tap (40).

4. The pump backup switch must be in the "AUT" position.

5. Start "Calibration Mode". See the section, "Calibration Mode Start-up".

NOTE: The engine must be running to obtain accurate information for this test.

6. Warm the hydraulic oil to normal operating temperature.

7. Run the engine at maximum no-load rpm.

8. All controls must be in the NEUTRAL position.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

28 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Electronic Monitor Panel (Proportional Reducing Valve Sweep Test)

(4) Character display. (22) Light switch. (24) Light 2 indicator.

9. Start the "Proportional Reducing Valve Sweep Test" as follows:

a. Depress light switch (22) until light 2 indicator (24) comes ON.

b. The left column of character display (4) displays the letter "P". The "P" in the first column indicates

that the proportional reducing valve is being tested.

NOTE: The purpose of this function is to check whether the proportional reducing valve is activating with a

current signal from the controller. When this function is selected, the second and third column in character

display (4) changes in an ascending number sequence from of 0 to 32. One cycle range from 0 to 32 takes

about five seconds. The character display (4) sequences form [P 0] to [P32].

10. As the "PRV Sweep Test" is being performed, monitor the multimeter and the 4900 kPa (700 psi)

pressure gauge.

The multimeter reading changes within a range of 0.16 to 0.63 amps in approximately five seconds. The

pressure gauge at power shift pressure tap (40) simultaneously ranges from 0 to 3150 kPa (0 to 455 psi).

NOTE: During the "PRV Sweep Test" the multimeter and pressure gauge readings should cycle at a uniform

rate of increase or decrease (no "spike" or quick changes). Also, during activation of this function mode,

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

29 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

AEC functions do not activate, but speed dial activates as normal.

11. Stop "Calibration Mode" (unless another function selection is desired). See the section, "Calibration

Mode Stop Procedure".

Engine Speed Change

NOTE: This test is useful to measure no load engine speeds in increments of 20 to 30 rpm, from the factory

preset LOW IDLE to HIGH IDLE positions of the governor speed dial switch. This test is suitable for noise

level measurement tests.

Electronic Monitor Panel (Engine Speed Change)

(4) Character display. (29) AEC indicator. (31) AEC switch. (32) Wiper 1 indicator. (33) Washer indicator. (34) Washer switch.

(35) Wiper switch.

1. Start "Calibration Mode". See the section, "Calibration Mode Start-up".

2. Depress wiper switch (35) until wiper 1 indicator (32) comes ON.

3. Put the governor speed dial switch in the best position for the test requirement (the position that comes

closest to the desired engine rpm setting).

4. Depress AEC switch (31) to increase the engine rpm, and depress washer switch (34) to decrease engine

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

30 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

rpm. Each time AEC switch (31) is depressed, AEC indicator (29) comes ON. Each time washer switch (34)

is depressed, washer indicator (33) comes ON.

5. Character display (4) will increment by 1 (10 rpm).

6. Stop "Calibration Mode" (unless another function selection is desired). See the section, "Calibration Mode

Stop Procedure".

NOTE: Activation of the "Calibration Mode" overrides the AEC function and keeps the power shift

pressure constant at a pressure level equivalent to a no-load condition. Immediately after this mode has been

canceled, engine speed recovers to the original speed dial setting.

Fixed Power Shift Pressure

NOTE: This test allows the power shift pressure command signal to remain constant at a desired pressure

level. The constant power shift pressure command signal is necessary to allow testing and adjusting

procedures to be performed to line relief valves and also perform pump "P-Q" tests.

Electronic Monitor Panel (Fixed Power Shift Pressure)

(4) Character display. (25) Wiper 2 indicator. (31) AEC switch. (34) Washer switch. (35) Wiper switch. (36) Alarm cancel switch.

1. Start "Calibration Mode". See the section, "Calibration Mode Start-up".

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

31 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

2. Depress wiper switch (35) until wiper 2 indicator (25) comes ON.

3. Character display (4) will display "P" in the first position and the selected power shift pressure in the

second and third positions. As a example the value shown in character display (4) of [P25] is in kgf/cm2. To

convert kgf/cm2 to kPa, multiply the value shown in character display (4) by 100. The resultant power shift

pressure is 2450 kPa (355 psi).

4. Depress AEC switch (31) to increase the power shift pressure command signal by 1 kgf/cm2 within a

range of 3 to 30 kgf/cm2 [290 to 2950 kPa (42 to 430 psi)].

5. Depress washer switch (34) to decrease the power shift pressure command signal by 1 kgf/cm2 within a

range of 3 to 30 kgf/cm2 [290 to 2950 kPa (42 to 430 psi)].

NOTE: Depressing alarm cancel switch (36) causes character display (4) to display alternately between the

power shift pressure and the engine rpm.

NOTE: Refer to "Engine Speed Change" to determine the value of engine speed displayed on character

display (4).

6. Stop "Calibration Mode" (unless another function selection is desired). See the section, "Calibration Mode

Stop Procedure".

NOTE: Activation of the "Calibration Mode" overrides the AEC function. The engine speed dial switch

works normally.

Engine Speed Dial Setting Check

NOTE: This test is used to verify that the selected engine speed dial switch position value is meeting the

factory engine speed setting value.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

32 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Electronic Monitor Panel (Engine Speed Dial Setting Check)

(4) Character display. (26) Travel speed HIGH (Rabbit) indicator. (28) Travel speed control switch.

1. Start "Calibration Mode". See the section, "Calibration Mode Start-up".

2. Depress travel speed control switch (28) until travel speed HIGH (Rabbit) indicator (26) comes ON.

3. Character display (4) displays the engine rpm value characteristic to the setting of the engine speed dial

switch position.

4. Stop "Calibration Mode" (unless another function selection is desired). See the section, "Calibration Mode

Stop Procedure".

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

33 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

NOTE: Activation of the "Calibration Mode" overrides the AEC function and keeps the power shift

pressure constant at a pressure level equivalent to a no-load condition. The engine speed dial switch works

normally.

Automatic Governor Actuator (G/A) Calibration

NOTICE

The hydraulic oil temperature must be at the normal operating

temperature before this calibration procedure is performed.

NOTE: This procedure must be performed any time the governor actuator or controller has been replaced or

reinstalled.

NOTE: Activation of this mode overrides the AEC system function, and keeps the power shift pressure

constant at the no load pressure level. The engine speed dial can be placed at any position since it cannot

activate until the governor actuator calibration has been completed. The governor backup switch must be in

AUT (not backup) position.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

34 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Electronic Monitor Panel (Automatic Governor Actuator Calibration)

(4) Character display. (26) Travel speed HIGH (Rabbit) indicator. (28) Travel speed control switch. (31) AEC switch. (34)

Washer switch. (36) Alarm cancel switch.

1. Start "Calibration Mode". See the section, "Calibration Mode Start-up".

2. Depress travel speed control switch (28) until travel speed HIGH (Rabbit) indicator (26) comes ON.

3. Depress and hold AEC switch (31) then depress and hold washer switch (34). Character display (4)

displays [AC] in a flashing mode.

4. While still depressing AEC switch (31) and washer switch (34), depress alarm cancel switch (36) until

character display (4) stops flashing and changes to [ACP]. The automatic calibration mode is now started

and the governor actuator motor has moved to the initial high idle stop position. The governor actuator is

now calibrated to the factory engine rpm setting designated for position "10" of the engine speed dial switch.

5. Once character display (4) displays [ACt], the calibration procedure can be completed.

6. Depress AEC switch (31) and washer switch (34) in sequence until character display (4) displays [AC1].

The calibration procedure for the factory engine rpm setting designated for positions "1" through "10" of the

engine speed dial switch is now started. The calibration procedure from this point takes approximately two

minutes. Character display (4) will change as follows:

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

35 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

NOTE: After initial setting has been completed, check to be sure that the governor lever is correctly

positioned (in contact with the high idle stopper) by rotating the pulley by hand.

* [AC1]

* [AC2]

* [AC3]

* [AC4]

* [AC5]

* [AC6]

* [AC7]

* [AC8]

* [AC0]

When [AC0] appears in character display (4), the calibration procedure is complete.

NOTE: If the data is not correct or within specified limits, character display (4) will indicate an error code

as shown in the following chart:

NOTE: If character display (4) displays [AC2] and [- *] (*: error code shown in the following chart)

alternately during Automatic G/A Calibration procedure, it is an indication of the following possible

problems. Have necessary repairs made. If character display (4) displays [AC0] after taking corrective

action, it indicates that the automatic governor actuator calibration has been completed correctly.

NOTE: If the error code [- 1], [- 2], [-3], [-15], or [-16] is indicated on character display (4), readjust the

accelerator/decelerator cables. See the section "Adjustment After Replacement Of Major Components".

NOTE: If the error code [-4] through [-12] or [-14] is indicated on character display (4), check the

corresponding checking procedure in the section "Checking Procedures (Electronic Control System)".

NOTE: When character display (4) displays [-13], return all controls to the NEUTRAL position. If the

problem code still exists, check the pressure switches and circuits.

NOTE: Even if any of error code [-51], [-52], or [-53] appears after character display (4) has displayed

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

36 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

[AC0], the machine does not need to be stopped, but can continue to be operated. Since the three codes

indicates that the accelerator cable needs further adjustment, readjustment can be performed later using the

following procedure.

a. If [-51] is displayed for two seconds, readjust the accelerator cable. See the section, "Adjustment After

Replacement Of Major Components".

b. If character display (4) alternates between [-52] and [ 10], every two seconds for example, decrease the

tension in the cable by loosening the adjusting nut of the accelerator cable by one turn. (If [ 15] is indicated,

then loosen the nut one and a half turns.)

c. If character display (4) alternates between [-53] and [ 10], every two seconds for example, increase the

tension in the cable by tightening the adjusting nut of the accelerator cable by one turn.

7. Stop "Calibration Mode" (unless another function selection is desired). See the section, "Calibration Mode

Stop Procedure".

Calibration Of Proportional Reducing Valve

NOTE: This calibration procedure must be performed when either the proportional reducing valve and/or

the controller has been replaced. This procedure is made at two power shift pressure points of 5 kgf/cm2

[490 kPa (72 psi)] and 25 kgf/cm2 [2450 kPa (355 psi).

Main Pump Compartment

(40) Power shift pressure tap.

1. Stop the engine and install a 4900 kPa (700 psi) pressure gauge to power shift pressure tap (40).

2. Make sure that the pump control backup switch is in the "AUT" position.

3. Start the "Calibration Mode". Refer to the section "Calibration Mode Start-up".

NOTE: The engine must be running and have a hydraulic oil temperature of approximately 50C (122F) to

perform this calibration procedure.

4. Run the engine with engine speed dial switch at position "10".

NOTE: Activation of this calibration mode overrides the AEC function. If the engine speed dial switch is

not at position "10" character display (4) will show an "E" in the first column. The engine speed must be

corrected within specifications to continue the calibration procedure.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

37 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Electronic Monitor Panel (Calibration Of Proportional Reducing Valve)

(4) Character display. (27) Travel speed LOW (tortoise) indicator. (28) Travel speed control switch. (31) AEC switch. (34)

Washer switch. (36) Alarm cancel switch.

5. Depress travel speed control switch (28) until travel speed LOW (tortoise) indicator (27) comes ON.

6. Character display (4) now displays [1 0]. The "1" indicates that the first calibration point has been

accessed and the "0" indicates that the middle step of the 19 individual calibration steps has been accessed.

Each step will change the power shift pressure by approximately 50 kPa (7.5 psi).

7. To change the power shift pressure:

a. To increase the power shift pressure, depress AEC switch (31) once. This will change character

display (4) to [1 1]. Each time AEC switch (31) is depressed, character display (4) increases by one

until character display (4) displays [1 9]. Also, the pressure reading at power shift pressure tap (40)

increases by approximately 50 kPa (7.5 psi) for each increase. The following is an example of

character display (4) readings in increasing order:

* [1-9]

* [1-8]

* [1-7]

* [1-6]

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

38 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

* [1-5]

* [1-4]

* [1-3]

* [1-2]

* [1-1]

* [1 0] = Middle Step

* [1 1]

* [1 2]

* [1 3]

* [1 4]

* [1 5]

* [1 6]

* [1 7]

* [1 8]

* [1 9]

b. To decrease the power shift pressure, depress washer switch (34) once to lower the value displayed

in character display (4). Each time washer switch (34) is depressed, character display (4) decreases by

one in descending order until character display (4) displays [1-9]. Also, the pressure reading at power

shift pressure tap (40) decreases by 50 kPa (7 psi) for each decrease. The following is an example of

character display (4) readings in decreasing order:

* [1 9]

* [1 8]

* [1 7]

* [1 6]

* [1 5]

* [1 4]

* [1 3]

* [1 2]

* [1 1]

* [1 0] = Middle Step

* [1-1]

* [1-2]

* [1-3]

* [1-4]

* [1-5]

* [1-6]

* [1-7]

* [1-8]

* [1-9]

8. To set "Calibration Point No. 1", perform the following steps:

a. Depress washer switch (34) until the pressure reading at tap (40) is less than 490 kPa (72 psi).

b. Depress AEC switch (31) until the pressure reading at tap (40) increases to approximately 490 kPa

(72 psi).

NOTE: Pressure adjustments must always be made as the pressure is being increased.

c. Depress alarm cancel switch (36) to store the data in the controller.

d. Once the data is stored in the controller, display (4) changes to [2 0], which indicates that the first

calibration point has been accepted and the second calibration point can be performed. At this time,

the character display flashing light mode will change to a continuous lighting mode.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

39 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

9. To set "Calibration Point No. 2", perform the following steps:

a. Depress washer switch (34) until the pressure reading at tap (40) is less than 2450 kPa (355 psi).

b. Depress AEC switch (31) until the pressure reading at tap (40) increases to approximately 2450

kPa (355 psi).

NOTE: Pressure adjustments must always be made as the pressure is being increased.

c. Depress alarm cancel switch (36) to store the data in the controller.

d. Once the data is stored in the controller, display (4) will change to [1 0], which indicates that the

second calibration point has been accepted and the controller has reset to the first calibration point.

10. Stop "Calibration Mode" (unless another function selection is desired). See the section, "Calibration

Mode Stop Procedure".

Calibration Mode Stop Procedure

Electronic Monitor Panel (Stopping Calibration Mode)

(4) Character display. (37) Service switch.

Use either of the following two methods:

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

40 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

1. Place engine in low idle position and turn the engine start switch to the OFF position.

2. Depress service switch (37) for a minimum of two seconds until character display (4) changes from

"Calibration Mode" to engine speed dial position.

Adjustment After Replacement Of Major

Components

When major components of the electronic control system have been replaced, adjustment is required.

The major components include:

* Governor actuator

* Proportional reducing valve

* Engine speed sensor

* Controller

Governor Actuator (Machines With Decelerator Cable)

Pump Compartment

(1) Accelerator cable. (2) Governor actuator. (3) Decelerator cable.

Engine Compartment

(4) Pulley. (5) Outer cable wire (decelerator). (6) Inner cable wire (accelerator).

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

41 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Installation Of Accelerator And Decelerator Cables

(1) Accelerator cable. (3) Decelerator cable. (4) Pulley. (5) Outer cable wire (decelerator). (6) Inner cable wire (accelerator). (7)

Locknut. (8) Nut. (9) Support. (10) Nut. (11) Slot. (12) Locknut.

Initial Setting Of Governor Actuator

NOTE: This procedure is not necessary for a new governor actuator that is correctly calibrated for the

initial (factory) dial setting position "10".

1. Connect the harness of governor actuator (2) to the connector.

2. Determine the high idle position "10" (initial setting) by activating the automatic actuator calibration

mode. See the section in this module "Calibration Mode", Automatic Governor Actuator (G/A) Calibration"

Adjustment Of Accelerator Cable

1. Accelerator cable (1) is identified by its seal (5). Turn nut (6) and locknut (8) of accelerator cable (1)

counterclockwise until they are as far apart as possible.

NOTE: If the identification seal is missing, accelerator cable (1) is the upper cable when viewed from the

governor actuator (2).

2. Place inner wire (6) into the inner groove (groove closest to the engine) of pulley (4).

3. Wrap inner wire (6) around (counterclockwise as viewed from the front of the machine) pulley (4).

4. Put the "T" end of inner wire (6) into slot (11). Make sure the "T" end of inner wire (6) is in line with the

inner groove (groove closest to the engine) after installation.

5. Put the threaded portion of accelerator cable (1) in the upper notch of support (9).

6. Turn pulley (4) clockwise (as viewed from the front of the machine) to the high idle stop position (full

rotation position).

7. Hold pulley (4) against the high idle stop position and turn nut (8) clockwise until the slack is removed

from inner wire (6). Tighten nut (8) approximately an additional two turns by hand.

8. Torque (standard torque) locknut (7) against support (9).

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

42 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Adjustment Of Decelerator Cable

1. Turn nut (10) and locknut (12) of decelerator cable (3) counterclockwise until they are as far apart as

possible.

2. Place outer wire (5) into the outer groove (groove farthest from the engine) of pulley (4).

3. Wrap outer wire (5) around (clockwise as viewed from the front of the machine) pulley (4).

4. Put the "T" end of outer wire (5) into slot (11). Make certain the "T" end of outer wire (5) is in line with

outer groove (groove farthest from the engine) after installation.

5. Put the threaded portion of decelerator cable (3) in the upper notch of support (9). Make certain outer

wire (5) remains in outer groove of pulley (4).

6. Finger tighten nut (10) against support (9).

7. Loosen nut (10) approximately two turns to provide slack in outer wire (5).

8. Torque (standard torque) locknut (12) against support (9). Make certain nut (10) remains in position of

threaded portion of decelerator cable (3) while tightening locknut (12) against support (9).

9. Reinstall clamps to decelerator cable (3) and accelerator cable (1). Do not allow the cables to twist.

NOTE: Check to be sure that the governor lever is in contact with the high idle stop lever. Also make sure

nuts (8) and (10) are correctly tightened so that accelerator cable (1) is under tension and decelerator cable

(3) has a small amount of slack. Failure to do so could result in incorrect engine speed setting, or overload

the governor actuator. Governor actuator (2) must not be operated until the calibration procedure is

complete. If actuator (2) is operated before the calibration procedure is complete, recalibrate.

Calibration Of Governor Actuator

Reference: Make reference to the section in this module, "Calibration Mode", "Automatic Governor

Actuator Calibration".

1. Start the engine and perform the "Automatic Governor Actuator Calibration" by activating "Calibration

Mode Start-up".

2. After correctly calibrated, clear the error log information.

Reference: Make reference to the section in this module, "Calibration Mode", "Error Log".

Governor Actuator (Machines Without Decelerator Cable)

Controller Compartment (Behind Cab)

(1) Governor actuator. (2) Accelerator cable.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

43 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Engine Compartment (Viewed From Top)

(2) Accelerator cable. (3) Support. (4) Nut (5) Locknut. (6) Bellows. (7) Lever.

Adjustment Of Accelerator Cable

NOTE: An accelerator cable is a part of the governor actuator assembly. When installing a new governor

actuator and accelerator cable, the initial setting of the governor actuator is not necessary. However, if the

accelerator cable end position is changed from the factory setting by activating the engine speed dial, for

example, before the new governor actuator and accelerator cable are installed correctly, the governor

actuator needs to be calibrated to the initial (factory) engine rpm setting designated for dial position "10". If

the current accelerator cable was disconnected from the governor lever, the initial calibration procedure is

required. See the section in this module, "Calibration Mode, Automatic Governor Actuator Calibration".

1. Turn nut (4) and locknut (5) of accelerator cable (2) counterclockwise until they are as far apart as

possible.

2. Put the threaded "L" end of accelerator cable (2) through the hole in lever (7) and install a nut to hold it

in position.

3. Put the other threaded portion of accelerator cable (2) in the notch of support (3).

4. Turn lever (7) counterclockwise (as viewed from the rear of the machine) to the high idle stop position

(full rotated position).

5. While holding lever (7) against the high idle stop, turn nut (4) clockwise until the slack is removed from

bellows (6). Tighten nit (4) approximately two additional turns.

6. Tighten locknut (5) against support (3). Make certain nut (4) remains in position of threaded portion of

accelerator cable (2) while tightening locknut (5) against support (3).

7. Reinstall two clamps to accelerator cable (2). Do not allow cable (2) to twist.

NOTE: Check to be sure that the governor lever is in contact with the high idle stopper. Also make sure nut

(4) is correctly tightened so that accelerator cable (2) is under correct tension. Failure to correctly tighten

the cable could result in incorrect engine speed setting or overload of the governor actuator.

Calibration Of Governor Actuator

Reference: Make reference to the section in this module, "Calibration Mode", "Automatic Governor

Actuator Calibration".

1. Start the engine and perform the "Automatic Governor Actuator Calibration" by activating "Calibration

Mode Start-up".

2. After correctly calibrated, clear the error log information.

Reference: Make reference to the section in this module, "Calibration Mode", "Error Log".

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

44 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Proportional Reducing Valve

1. Calibrate the proportional reducing valve.

Reference: See the section of this module, "Calibration Of Proportional Reducing Valve" in "Calibration

Mode".

2. After the proportional reducing valve is correctly calibrated, clear the error log information.

Reference: See the section of this module, "Error Log" in "Calibration Mode".

Engine Speed Sensor (Magnetic Pickup)

Installation Of Engine Speed Sensor

(1) Speed sensor. (2) Locknut. (3) Magnetic core. (4) Gear. (5) Flywheel housing.

NOTICE

The engine must not be running prior to adjustment of the engine speed

sensor.

1. With the engine stopped, slowly tighten speed sensor (1) into flywheel housing (5) until magnetic core (3)

is in contact with gear (4).

2. Back out speed sensor 3/4 turn and temporarily tighten locknut (2).

3. With the engine speed dial switch set at position "1" (LOW IDLE position) start the engine.

4. Start service program "Data Mode" and select the engine speed display function.

Reference: Make reference to the section in this module, "Data Mode", "Engine Speed".

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

45 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

5. The character display should read a speed of approximately 800 rpm.

6. If the character display does not read correct rpm, gradually tighten speed sensor (1). Do not turn more

than 120.

7. If satisfactory, stop the engine and tighten locknut (2) to a torque of 44 Nm (32 lb ft).

8. After the speed sensor calibration is correct, clear the error log information.

Reference: See the section in this module, "Error Log" in "Calibration Mode".

Controller

1. Before removal/installation of the controller, be sure to turn the disconnect switch to the OFF position.

2. Perform the automatic governor calibration procedure.

Reference: See the section in this module, "Automatic Governor Actuator Calibration" in "Calibration

Mode".

3. Perform the proportional reducing valve calibration procedure.

Reference: See the section in this module, "Calibration Of Proportional Reducing Valve" in "Calibration

Mode".

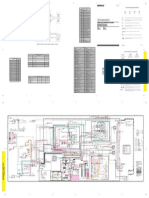

Controller Input And Output Schematic (Voltage Signals In Normal

Operating Condition)

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

46 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Terminal (Pin) Numbers Of Controller Connection And Voltage

Specifications

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

47 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Voltage Specifications (Governor Actuator With Decelerator Cable)

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

48 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

49 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Voltage Specifications (Governor Actuator Without Decelerator

Cable)

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

50 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

51 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Checking Procedures

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

52 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Harness And Wire Identification

The colors and sizes of wires shown in the Electric Circuit Diagram are identified as described in the

following chart:

Example; [308] - BK - (18)

[308] = Circuit identification code.

BK = Wire color.

(18) = Wire size specified by AWG (American Wiring Gauge). If not indicated, wire size is AWG No. 16.

Electrical Components, Connectors, And Harness Location

This section includes information on how to use the separate module "Electric Schematic", Form SENR6015

to determine location of the electric components, connectors, and harnesses.

The location charts are made up of electric components, connectors, and harnesses. The views contain

general views and area views. Area views include the following:

* Area A: Cab

* Area B: Right console

* Area C: Left console

* Area D: Relay panel

* Area E: Main control valve compartment

Below is a guide to read components and harness/connector location charts.

* Component location chart:

The component location chart uses white circles as location labels in the general and area views.

Alphabetical letters in the connector and vehicle location column indicate location in the area views.

* Harness and connector location chart:

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

53 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

The harness and connector location charts use black circles as location labels in the general and area

views. Alphabetical letters in the connector and vehicle location column indicate the area views where

they are located. the "*" indicates that it is connected to the component in its harness and/or

components column.

NOTE: Harnesses in partial electric schematics given in the "Checking Procedures" are identified by A, B,

and C, which are also indicated in the general and area views.

NOTE: The material in this module is intended to be used with the separate module, "Electrical Schematic"

Form SENR6015.

Checking Procedures (Electronic Control System)

Introduction

Problem Description

The problem description indicates problems represented by the character display on the monitor panel.

Solution

The solution provides two types of information;

* Connector check provides information on the connectors that have to be checked before

troubleshooting using the checking procedure chart. Check the connectors specified for improper

connections. A loose contact between two connectors can be caused by water in the connectors.

Check the connectors before troubleshooting.

* Checking procedure chart provides information on troubleshooting problems indicated by the error

code on the character display on the monitor panel.

Example Chart

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

54 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Electronic Control System Checking Procedure Chart

(1) Preparations. (2) Problem description. (3) Error code on character display (Ch. D.). (4) Check items. (5) Probable causes. (6)

Solution.

NOTE: The character display on the monitor panel indicates error code on character display (3) assigned

for the real time errors and error log, if problem(s) occurs. The charts that follow should be used to

troubleshoot problems indicated by error code on character display (3).

Preparations (1) provide information on the preliminary arrangements that must be made before

troubleshooting.

Problem description (2) indicates problems shown by the character display on the monitor panel.

Error code on character display (3) indicates specific codes for real time errors and error log. Service

Program selection determines the pattern of the character display.

Check items (4) list items that must be checked with a multimeter.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

55 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

a. In the check items (4), "0Ohms" means "there is continuity", whereas "infinite Delta " means that

"there is no continuity".

b. Connector check - [other than()]: 0Ohms.

NOTE: [other than()] means all the terminals and pins except the one specified in ().

The following is an explanation of the terms in "Check items (4)":

Example; (1) - (2) of CONN46M

(1) = Pin number.

- = Short circuit indication.

CONN46 = Connector number.

M = The male (M) or female (F) half of the connector.

Probable causes (5) shows probable cause(s) of a problem.

Solution (6) shows the corrective action that should be taken to solve a particular problem. The statement

"Replace" includes "Repair if possible".

When a continuity check is to be performed, "turn the starter switch to the OFF position". This stops the

power supply to prevent damage to the tester or short-circuiting the power supply.

When a voltage check is to be made, "turn the starter switch to the ON position" to allow power supply. The

engine should be in operation unless otherwise specified. Stable inputs and outputs of controller cannot be

obtained without the engine running.

NOTICE

To avoid damage to electrical components when the power supply is

ON, make sure disconnected connectors and wires do not come in

contact with the machine.

[Elec #1] Controller Self-Diagnostic LED Display

Controller Compartment

(1) LED lamp. (2) Controller.

[Elec #1-1] Normal

Normal: Green LED lamp (1) comes ON.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

56 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

[Elec #1-2] Yellow And Green LED Lamp ON

Problem:

Problem in communication line between controller and monitor causes the yellow and green LED lamps to

come ON.

Solution:

Check problem according to [Elec #10-1] and [Elec #10-2].

[Elec #1-3] Green And Red LED Lamp ON

Problem:

Problem in controller causes the green LED lamp to come ON in continuous lighting mode and red LED

lamp to come ON in continuous lighting mode or flashing mode. In some cases, yellow LED lamp may come

ON.

Solution:

Replace the controller.

[Elec #1-4] No Power To Controller And LED Lamps ON

Problem:

No power supply to controller causing LED lamp (1) to not come ON.

Solution:

Check problem according to [Elec #1-5].

[Elec #1-5] No Power To Controller

Problem:

No power supply to controller.

Solution:

Check to ensure that CONN1, 3, and 24 are properly connected. If the problem still exists, troubleshoot

according to the following checking procedure chart.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

57 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

[Elec #2-1] PRV Circuit Is Open

Problem:

Proportional reducing valve circuit is open.

Solution:

Check to ensure that CONN56, 8, 1, and 17 are properly connected. If the problem still exists, troubleshoot

according to the following checking procedure chart.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

58 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

[Elec #2-2] PRV Circuit Is Shorted To Body Ground

Problem:

Proportional reducing valve circuit is shorted to body ground.

Solution:

Check to ensure that CONN56, 8, 1, and 17 are properly connected. If problem still exists, troubleshoot

according to the following checking procedure chart.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

59 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

60 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

[Elec #2-3] PRV Circuit Is Shorted To Battery Voltage

Problem:

Proportional reducing valve circuit is shorted to battery voltage.

Solution:

Check to ensure that CONN56, 8, 1, and 17 are properly connected. If the problem still exists, troubleshoot

according to the following checking procedure chart.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

61 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

62 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

[Elec #3] Engine Speed Sensor Is Open Or Not Installed Correctly

Problem:

Engine speed sensor (magnetic pickup) circuit is open or speed sensor is not installed correctly (engine

speed problem).

Solution:

Check to ensure that CONN42, 9, and 2 are properly connected. If the problem still exists, troubleshoot

according to the following checking procedure chart.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

63 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

[Elec #4-1] Travel Pressure Switch Circuit Is Open Or Shorted To

Body Ground

Problem:

Travel pressure switch circuit is open or shorted to body ground.

Solution:

Check to ensure that CONN52, 10, and 2 are properly connected. Check to ensure orifice in signal passage

to pressure switch is not blocked. If the problem still exists, troubleshoot according to the following checking

procedure chart.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

64 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

[Elec #4-2] Implement/Swing Pressure Switch Circuit Is Open Or

Shorted To Body Ground

Problem:

Implement/swing pressure switch circuit is open or shorted to body ground.

Solution:

Check to ensure that CONN51, 10, and 2 are properly connected. Check to ensure orifice in signal passage

to pressure switch is not blocked. If the problem still exists, troubleshoot according to the following checking

procedure chart.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

65 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

[Elec #4-3] Boom Raise Pressure Switch Circuit Is Open Or Shorted

To Body Ground

Problem:

Boom raise pressure switch circuit is open or shorted to body ground.

Solution:

Check to ensure that CONN50, 10, and 2 are properly connected. Check to ensure orifice in signal passage

to pressure switch is not blocked. If the problem still exists, troubleshoot according to the following checking

procedure chart.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

66 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

[Elec #5] Controller Receives Signal Of Engine Speed Other Than

Specified "10"

Problem:

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

67 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Controller receives signal of engine speed other than specified "10" from engine speed dial.

Solution:

Check to ensure that CONN27, 24, and 1 are properly connected. If the problem still exists, troubleshoot

according to the following checking procedure chart.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

68 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

[Elec #6-1] Governor Actuator Feedback Sensor Circuit Is Open Or

Shorted To Battery Voltage

Problem:

Governor actuator feedback sensor circuit is open or shorted to battery voltage.

Solution:

Check to ensure that CONN44, 3, and 2 are properly connected. If the problem still exists, troubleshoot

according to the following checking procedure chart.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

69 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

[Elec #6-2] Governor Actuator Feedback Sensor Circuit Is Shorted

To Body Ground

Problem:

Governor actuator feedback sensor circuit is shorted to body ground.

Solution:

Check to ensure that CONN44, 3, and 2 are properly connected. If the problem still exits, troubleshoot

according to the following checking procedure chart.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

70 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

[Elec #6-3] Governor Actuator Motor Circuit Is Shorted To Body

Ground.

Problem:

Governor actuator motor circuit is shorted to body ground.

Solution:

Check to ensure that CONN44, 3, 1, and 18 are properly connected. If the problem still exists, troubleshoot

according to the following checking procedure chart.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

71 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

[Elec #6-4] Governor Actuator Motor Does Not Rotate Or

Governor Actuator Motor Circuit Is Shorted To Battery Voltage

Problem:

Governor actuator motor does not rotate or governor actuator motor circuit is shorted to battery voltage.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

72 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Solution:

Check to ensure that CONN44, 3, 1, and 18, and the circuits of speed change switch and governor backup

switch are properly connected. If the problem still exists, troubleshoot according to the following checking

procedure chart.

[Elec #6-5] Governor Actuator Motor Circuit Is Open Or Governor

Backup Switch Is In "MAN" Position.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

73 of 181

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retur...

Problem:

Governor actuator motor circuit is open or governor backup switch is in "MAN" position.

Solution:

Check to ensure that CONN44, 3, 1, and 18 are properly connected. If the problem still exists, troubleshoot

according to the following checking procedure chart.

19/10/2010 20:32

320, 320L TRACK-TYPE EXCAVATORS 1KL00001-UP (MACHINE...

74 of 181