Professional Documents

Culture Documents

Astm A 515

Uploaded by

rameshdattaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm A 515

Uploaded by

rameshdattaCopyright:

Available Formats

SPECIFICATION FOR PRESSURE VESSEL PLATES,

CARBON STEEL, FOR INTERMEDIATE- AND

HIGHER-TEMPERATURE SERVICE

SA-515/SA-515M

(Identical with ASTM Specification A 515/A 515M-92.)

1.

Scope

2.

1.1 This specification covers carbon-silicon steel

plates primarily for intermediate- and higher-temperature

service in welded boilers and other pressure vessels.

Referenced Document

2.1 ASTM Standard:

A 20/A 20M Specification for General Requirements for

Steel Plates for Pressure Vessels

1.2 Material under this specification is available in

four grades having different strength levels as follows:

3.

Grade U.S. [SI]

Tensile Strength,

ksi [MPa]

60 [415]

65 [450]

70 [485]

6080 [415550]

6585 [450585]

7090 [485620]

3.1 Material supplied to this material specification

shall conform to Specification A 20/A 20M. These

requirements outline the testing and retesting methods

and procedures, permissible variations in dimensions,

and mass, quality and repair of defects, marking, loading, etc.

1.3 The maximum thickness of plates is limited only

by the capacity of the composition to meet the specified

mechanical property requirements; however, current

practice normally limits the maximum thickness of

plates furnished under this specification as follows:

Grade U.S. [SI]

Maximum Thickness,

in. [mm]

60 [415]

65 [450]

70 [485]

8 [200]

8 [200]

8 [200]

General Requirements and Ordering

Information

3.2 Specification A 20/A 20M also establishes the

rules for the ordering information that should be complied with when purchasing material to this specification.

3.3 In addition to the basic requirements of this

specification, certain supplementary requirements are

available when additional control, testing, or examination is required to meet end use requirements. These

include:

1.4 The values stated in either inch-pound units or

SI units are to be regarded separately as standard.

Within the text, the SI units are shown in brackets. The

values stated in each system are not exact equivalents;

therefore, each system must be used independently of

the other. Combining values from the two systems may

result in nonconformance with the specification.

3.3.1 Vacuum treatment,

3.3.2 Additional or special tension testing,

3.3.3 Impact testing, and

3.3.4 Nondestructive examination.

917

98

SA-515/SA-515M

1998 SECTION II

3.4 The purchaser is referred to the listed supplementary requirements in this specification and to the detailed

requirements in Specification A 20/A 20M.

5.2 Plates over 2 in. [50 mm] in thickness shall be

normalized.

3.5 If the requirements of this specification are in

conflict with the requirements of Specification A 20/

A 20M, the requirements of this specification shall

prevail.

4.

6.

6.1 The steel shall conform to the chemical requirements shown in Table 1 unless otherwise modified

in accordance with Supplementary Requirement S17,

Vacuum Carbon-Deoxidized Steel, in Specification A

20/A 20M.

Manufacture

4.1 Steelmaking PracticeThe steel shall be killed

and made to a coarse austenitic grain size practice.

5.

Chemical Requirements

7.

Heat Treatment

5.1 Plates 2 in. [50 mm] and under in thickness are

normally supplied in the as-rolled condition. The plates

may be ordered normalized or stress relieved, or both.

Mechanical Requirements

7.1 Tension Test RequirementsThe material as represented by the tension-test specimens shall conform

to the requirements shown in Table 2.

918

PART A FERROUS MATERIAL SPECIFICATIONS

SA-515/SA-515M

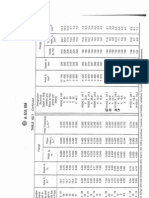

TABLE 1

CHEMICAL REQUIREMENTS

Composition, %

Grade 60

[Grade 415]

Elements

Carbon, maxA:

1 in. [25 mm] and under

Over 1 to 2 in. [25 to 50 mm], incl

Over 2 to 4 in. [50 to 100 mm], incl

Over 4 to 8 in. [100 to 200 mm], incl

Over 8 in. [200 mm]

Manganese, max:

Heat analysis

Product analysis

Phosphorus, maxA

Sulfur, maxA

Silicon:

Heat analysis

Product analysis

A

Grade 65

[Grade 450]

Grade 70

[Grade 485]

0.24

0.27

0.29

0.31

0.31

0.28

0.31

0.33

0.33

0.33

0.31

0.33

0.35

0.35

0.35

0.90

0.98

0.035

0.035

0.90

0.98

0.035

0.035

1.20

1.30

0.035

0.035

0.150.40

0.130.45

0.150.40

0.130.45

0.150.40

0.130.45

Applies to both heat and product analyses.

TABLE 2

TENSILE REQUIREMENTS

Grade

Tensile strength, ksi [MPa]

Yield strength, min, ksi [MPa]

Elongation in 8 in. [200 mm], min, %

Elongation in 2 in. [50 mm], min, %

A

60 [415]

65 [450]

70 [485]

6080 [415550]

32 [220]

21A

25A

6585 [450585]

35 [240]

19A

23A

7090 [485620]

38 [260]

17A

21A

See Specification A 20/A 20M.

919

SA-515/SA-515M

1998 SECTION II

SUPPLEMENTARY REQUIREMENTS

Supplementary requirements shall not apply unless specified in the order.

A list of standardized supplementary requirements for use at the option of the

purchaser is included in ASTM Specification A 20/A 20M. Those which are considered suitable for use with this specification are listed below by title.

S1.

Vacuum Treatment,

S2.

Product Analysis,

S3.

Simulated Post-Weld Heat Treatment of

Mechanical Test Coupons,

S4.1 Additional Tension Test,

S5.

Charpy V-Notch Impact Test,

S6.

Drop-Weight Test,

S7.

High-Temperature Tension Test,

S8.

Ultrasonic Examination in accordance with

Specification A 435/A 435 M,

S9.

Magnetic Particle Examination,

S11. Ultrasonic Examination in accordance with

Specification A 577/A 577M,

S12. Ultrasonic Examination in accordance with

Specification A 578/A 578M,

S14. Bend Test, and

S17. Vacuum Carbon-Deoxidized Steel.

920

PART A FERROUS MATERIAL SPECIFICATIONS

ADDITIONAL SUPPLEMENTARY REQUIREMENTS

Also listed below is an additional optional supplementary requirement suitable for

this specification:

S61. Austenitic Grain Size

S61.1 The material shall have a carburized austenitic

grain size of 1 to 5.

921

SA-515/SA-515M

You might also like

- Sa 612Document5 pagesSa 612Luis MuñozNo ratings yet

- A299 A299m (2001) Standard Specification For Pressure Vessel Plates, Carbon Steel, Manganese-Si PDFDocument2 pagesA299 A299m (2001) Standard Specification For Pressure Vessel Plates, Carbon Steel, Manganese-Si PDFGagan SinghNo ratings yet

- Piping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature ServiceDocument10 pagesPiping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature ServiceNagLakshmananNo ratings yet

- ASTM A105 Material Properties Asme b16.5 - Shijiazhuang Metalsin Pipeline Tech Co., LTDDocument5 pagesASTM A105 Material Properties Asme b16.5 - Shijiazhuang Metalsin Pipeline Tech Co., LTDYilia WangNo ratings yet

- Astm A106 1999Document13 pagesAstm A106 1999Rolando CastilloNo ratings yet

- ASME VIII-2-Service Restrictions, Joint Efficiencies, RadiographyDocument34 pagesASME VIII-2-Service Restrictions, Joint Efficiencies, RadiographyMohammed AnshafNo ratings yet

- ASME SA240 304 (S30400) Stainless Steel Plate - A516Gr70 - S355J2 - SA516GR70 - A516 Grade 70 - SA516 Grade 70 - A572GR50 Steel Plate PDFDocument7 pagesASME SA240 304 (S30400) Stainless Steel Plate - A516Gr70 - S355J2 - SA516GR70 - A516 Grade 70 - SA516 Grade 70 - A572GR50 Steel Plate PDFJA KNo ratings yet

- Astm A161Document2 pagesAstm A161TeoTyJayNo ratings yet

- Carbon Steel Piping Comp. StandardsDocument2 pagesCarbon Steel Piping Comp. StandardsSoumitra GuptaNo ratings yet

- Asmeviii Uw EDocument196 pagesAsmeviii Uw ETâm NgôNo ratings yet

- BS en 10204Document14 pagesBS en 10204Kalyan Chakravathi A G100% (1)

- ASTM A370 - 97a PDFDocument53 pagesASTM A370 - 97a PDFbaolengocNo ratings yet

- En 10025 S235JR SteelDocument2 pagesEn 10025 S235JR SteelAgung Nak OtomotifNo ratings yet

- Asme Section Ii A Sa-426 PDFDocument6 pagesAsme Section Ii A Sa-426 PDFAnonymous GhPzn1xNo ratings yet

- International Standard: Metallic Materials - Brinell Hardness TestDocument8 pagesInternational Standard: Metallic Materials - Brinell Hardness TestFilipe AlmeidaNo ratings yet

- Is 7754 1975 PDFDocument14 pagesIs 7754 1975 PDFkarthikkanda0% (1)

- Is 2708 1993Document10 pagesIs 2708 1993ghosh_ranjoyNo ratings yet

- Astm A351 16Document7 pagesAstm A351 16Nguyen JohnNo ratings yet

- Astm A293-2022Document10 pagesAstm A293-2022CarlosNo ratings yet

- Astm A 564Document7 pagesAstm A 564GeorgeAzmirNo ratings yet

- Steel Data ChartDocument2 pagesSteel Data Chartsmartcad60No ratings yet

- Astm A351Document5 pagesAstm A351Srinivasan KrishnamoorthyNo ratings yet

- Astm A 143M-03Document3 pagesAstm A 143M-03MritunjayNo ratings yet

- Seamless and Welded Ferritic Stainless Steel Feedwater Heater TubesDocument7 pagesSeamless and Welded Ferritic Stainless Steel Feedwater Heater TubesMina RemonNo ratings yet

- Astm E7Document30 pagesAstm E7Akki SaudiNo ratings yet

- AS 1544.2-2003 Hoja2 Pag2Document1 pageAS 1544.2-2003 Hoja2 Pag2elmerNo ratings yet

- Metals Identification, Grade Verification, and Sorting: Standard Guide ForDocument12 pagesMetals Identification, Grade Verification, and Sorting: Standard Guide ForRajan SteeveNo ratings yet

- Air Compressor Guide AICIP and CAAA - Guidelines and Requirements For Asset Management of Pressure VesselsDocument4 pagesAir Compressor Guide AICIP and CAAA - Guidelines and Requirements For Asset Management of Pressure VesselsTim WilsonNo ratings yet

- A176Document2 pagesA176Claudenir AlvesNo ratings yet

- BS en 10021-2006Document20 pagesBS en 10021-2006peymanNo ratings yet

- A498Document13 pagesA498rgi178No ratings yet

- Stainless Steel Tube SpecificationsDocument7 pagesStainless Steel Tube Specificationsgkamesh84No ratings yet

- 7050 Aluminum Sheet SuppliersDocument12 pages7050 Aluminum Sheet Supplierssanghvi overseas incNo ratings yet

- B729Document3 pagesB729LambertWayneNo ratings yet

- B16.15 Fittings BMI CanadaDocument9 pagesB16.15 Fittings BMI CanadaSagar KadamNo ratings yet

- Detecting Detrimental Intermetallic Phase in Duplex Austenitic/Ferritic Stainless SteelsDocument9 pagesDetecting Detrimental Intermetallic Phase in Duplex Austenitic/Ferritic Stainless SteelsIsmail Tp100% (1)

- ASTM A633 GR E Data Sheet 2012 04 01Document2 pagesASTM A633 GR E Data Sheet 2012 04 01FrancescoGuglielmo100% (1)

- Astm F 519-97 E98Document12 pagesAstm F 519-97 E98JORGE ARTURO TORIBIO HUERTA100% (1)

- Astm A319Document2 pagesAstm A319Mailson RochaNo ratings yet

- Ductile Iron Data For Design EngineersDocument3 pagesDuctile Iron Data For Design EngineersSourav HaitNo ratings yet

- Din 17205Document1 pageDin 17205PeterWayNo ratings yet

- A322-13 Standard Specification For Steel Bars, Alloy, Standard GradesDocument4 pagesA322-13 Standard Specification For Steel Bars, Alloy, Standard GradesDiego Egoávil Méndez100% (1)

- Astm A847Document5 pagesAstm A847Mohamed FaroukNo ratings yet

- En1564-1 2017Document4 pagesEn1564-1 2017Dan PopaNo ratings yet

- Astm A216-98Document3 pagesAstm A216-98panap25100% (1)

- CBT Questions: (2) Peel TestDocument18 pagesCBT Questions: (2) Peel TestMOHAMEDNo ratings yet

- Bisalloy: Bunge Industrial Steels Pty. LimitedDocument65 pagesBisalloy: Bunge Industrial Steels Pty. Limitedramaus100% (1)

- Astm b425Document5 pagesAstm b425singaravelan narayanasamyNo ratings yet

- Sa 961 PDFDocument10 pagesSa 961 PDFaruntpeNo ratings yet

- Sa 325 PDFDocument12 pagesSa 325 PDFMo'men Abu-SmaihaNo ratings yet

- ASTM A297 (HN) SpecificationDocument5 pagesASTM A297 (HN) SpecificationGuglielmo CancelliNo ratings yet

- ASTM A270-98ae1Document5 pagesASTM A270-98ae1NadhiraNo ratings yet

- 27 Astm A995Document5 pages27 Astm A995FYNo ratings yet

- ASTMDocument10 pagesASTMDenisse LeinesNo ratings yet

- Astm A376 PDFDocument7 pagesAstm A376 PDFAmrut KanungoNo ratings yet

- Astm A 515 PDFDocument5 pagesAstm A 515 PDFsenthil4youNo ratings yet

- Sa 299Document3 pagesSa 299Web LogueandoNo ratings yet

- Asme Section II A Sa-202 Sa-202mDocument4 pagesAsme Section II A Sa-202 Sa-202mAnonymous GhPzn1xNo ratings yet

- Ref SA 515Document5 pagesRef SA 515nachoircNo ratings yet

- Asme Section II A-2 Sa-455 Sa-455mDocument4 pagesAsme Section II A-2 Sa-455 Sa-455mAnonymous GhPzn1xNo ratings yet

- Iso GD&TDocument39 pagesIso GD&TSanjay Kumar SinghNo ratings yet

- ASTM H Beam SizesDocument1 pageASTM H Beam SizesrameshdattaNo ratings yet

- Arcelor Mittal Ürün Katalog PDFDocument29 pagesArcelor Mittal Ürün Katalog PDFBurak KececiNo ratings yet

- EN10034 Beams Rolling TolerancesDocument2 pagesEN10034 Beams Rolling Tolerancesrameshdatta100% (1)

- Is Rebar Specs IS1786-2008Document16 pagesIs Rebar Specs IS1786-2008rameshdattaNo ratings yet

- Catalogo Cadenas de Ingenieria PDFDocument136 pagesCatalogo Cadenas de Ingenieria PDFGlicerio Bravo GaticaNo ratings yet

- Electricity and MagnetismDocument84 pagesElectricity and Magnetismamalina rohaizanNo ratings yet

- Thermal Stress MonitoringDocument78 pagesThermal Stress MonitoringSIVA KAVYANo ratings yet

- Crystallinity in Polymers-1Document19 pagesCrystallinity in Polymers-1anbuchelvanNo ratings yet

- Physics Enrich Test STPM Sem 1Document17 pagesPhysics Enrich Test STPM Sem 1雷顺开No ratings yet

- A Mini Project ReportDocument37 pagesA Mini Project ReportChintuu Sai100% (2)

- Marine Hydrodynamics - J. N. Newman PDFDocument450 pagesMarine Hydrodynamics - J. N. Newman PDFfarazali2919100% (4)

- Car Plate Recognition by Neural Networks and Image Processing Using Integration of WaveletsDocument5 pagesCar Plate Recognition by Neural Networks and Image Processing Using Integration of Waveletsjamal fathiNo ratings yet

- Signal Flow GraphDocument38 pagesSignal Flow Graphgaurav_juneja_4No ratings yet

- E 777 - Gidarakos 2005 - Ultimate - C and HDocument5 pagesE 777 - Gidarakos 2005 - Ultimate - C and HTamara Aulia RachimNo ratings yet

- Liquid SO2.1Document13 pagesLiquid SO2.1Musyafa WiryantoNo ratings yet

- MCQ 4 GroundwaterDocument6 pagesMCQ 4 GroundwaterAnonymous EvbW4o1U7100% (4)

- FluidMechanicsI HW01Document1 pageFluidMechanicsI HW01AzlNo ratings yet

- XII Maths Exercise 3.1 (Solution)Document11 pagesXII Maths Exercise 3.1 (Solution)mansoor100% (5)

- Topic 2 - ComplexationDocument48 pagesTopic 2 - ComplexationLokesh JaiswalNo ratings yet

- Analysis of Shear Walls For Multi-Storey Timber BuildingsDocument54 pagesAnalysis of Shear Walls For Multi-Storey Timber BuildingsrahimmullaNo ratings yet

- Manual On Experimental Stress AnalysisDocument31 pagesManual On Experimental Stress AnalysisrmontandonNo ratings yet

- Eye TrackingDocument13 pagesEye TrackingRohit KoulNo ratings yet

- Multi Meter Triplett 630-NA Tested by ZS1JHGDocument2 pagesMulti Meter Triplett 630-NA Tested by ZS1JHGJohn Howard GreenNo ratings yet

- Dow Elite 5401G TDSDocument3 pagesDow Elite 5401G TDSAli RazuNo ratings yet

- Air Pollution by Grade 6Document4 pagesAir Pollution by Grade 6Eljay VinsonNo ratings yet

- BOF Plant Write UpDocument20 pagesBOF Plant Write UpKalyan HalderNo ratings yet

- Current Electricity WorksheetDocument6 pagesCurrent Electricity WorksheetRohan ChackoNo ratings yet

- Comparison of Heald Frame Motion Generated by Rotary Dobby and Crank & Cam Shedding MotionsDocument6 pagesComparison of Heald Frame Motion Generated by Rotary Dobby and Crank & Cam Shedding MotionsKannan KumarNo ratings yet

- D 6988 - 03 Medicion de CalibreDocument7 pagesD 6988 - 03 Medicion de CalibreMiguelAngelPerezEsparzaNo ratings yet

- Vectors 05 Notes PDFDocument21 pagesVectors 05 Notes PDFADSaksoulNo ratings yet

- Basf Processing Styrinic Polymers and CopolymersDocument14 pagesBasf Processing Styrinic Polymers and CopolymersTejender SinghNo ratings yet

- Lutein Micro Encapsulation Using CoacervationDocument8 pagesLutein Micro Encapsulation Using CoacervationSilky Pradeep KumarNo ratings yet

- Sajb 411952 969Document18 pagesSajb 411952 969samirNo ratings yet

- Csi ReferDocument502 pagesCsi Referrenzo wilber bernedo beltranNo ratings yet