Professional Documents

Culture Documents

Oil/water separation technologies guide

Uploaded by

rohitkushOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oil/water separation technologies guide

Uploaded by

rohitkushCopyright:

Available Formats

Oil/water separation technologies

Where stable emulsions cannot be removed mechanically, the application of

demulsifiers, coagulants and flocculants accelerates the separation process

BERTHOLD OTZISK

Kurita Europe

mulsions can cause fouling and

under-deposit corrosion problems in distillation columns,

heat exchangers and reboilers.

Commercial methods for breaking

emulsions include settling, heating,

distillation, centrifuging, electrical

treatment, chemical treatment and

filtration. These separation technologies can be used in combination to

secure optimum results.

Emulsions can be classified as

oil-in-water and water-in-oil types.

The type of emulsion can be determined by adding a drop of

emulsion into a beaker containing

water and oil. If the emulsion is of

the water-in-oil type, the drop

diffuses through the oil but remains

in water. The oil-in-water emulsion

diffuses through the water, but not

through the oil. Both types of emulsions can co-exist in crude oil side

by side.

Separation of water-in-oil emulsions

In this type of emulsion, water is

the internal dispersed or discontinuous phase, while oil is the external

or continuous phase. Separation by

the different gravity of the two

phases is a very slow process, but

can be accelerated by the assistance

of chemicals. The chemicals used

are termed demulsifiers, emulsion

breakers or wetting agents. These

additives are surfactants, which

migrate to the oil/water interface.

They adsorb on the oil films

surrounding water droplets and

break the oil films. Then, water

droplets aggregate to form water

drops large enough to gravitationally separate them from the oil.

Non-ionic surfactants having both

lipophilic

and

hydrophilic

www.eptq.com

groups are

demulsifiers.

mainly

used

as

Typical applications in refineries

Tank farm treatment

Crude oil, intermediates and

finished products are stored in the

tank farm. It is the first facility in a

refinery where free water can be

removed by settling from the oil.

Pumped crude oil from the well

contains water in emulsified and

free states. A crude oil emulsion

consists of small globules of water

surrounded by oil. Water is the

internal phase and oil is the exter-

The nature of the

emulsion changes

from crude to crude,

which can influence

the performance of

the emulsion breaker

programme

nal phase, which can easily be

detected by microscope. With the

help of gravity, small water droplets coalesce to form bigger

droplets. An adequate residence

time is essential for separation into

two phases. The bigger droplets

finally settle down to be removed

by drainage.

Most of the time, emulsified

water cannot be separated effectively by gravity settling only, as

the emulsion can separate into

three phases:

Oil on the top

Water

at the bottom

emulsion

in

the

middle or below the water layer.

To break such a persistent emulsion, chemicals have to be applied.

A number of demulsifiers are

commercially available with varying degrees of performance and

selectivity. Generally, demulsifiers

are diluted with an organic solvent

and injected into crude oils. The

nature of the emulsion changes

from crude to crude, which can

influence the performance of the

emulsion breaker programme. This

necessitates the evaluation of cost

effectiveness and performance in

breaking the emulsion.

Persistent

Crude oil desalting

Crude oil fed from the tank farm to

the crude distillation unit still

contains water, salts, sludge and

various kinds of impurities. This

can cause corrosion, fouling, plugging and catalyst degradation in

the downstream refining units. The

main purpose of electrostatic

desalting is therefore to remove

impurities, such as inorganic

microparticles, suspended solids

and water-soluble contaminants,

together with the water.

The major variables and effects

on the desalter operation are:

Wash water mixing

Wash water quality and rate

Desalting temperature

Electric field

Retention time

Use of demulsifiers.

Wash water is added in front of

the mixing valve to the crude oil to

prepare a temporary emulsion. A

key point of desalting is an appropriate mixing of crude oil with the

PTQ Q2 2013 87

wash water to obtain a

sufficient desalting rate.

Heating lowers the viscosity of crude oil. This

promotes demulsification

and the formation of large

water droplets from the

emulsion. An electric field

is induced by AC or DC

current in the oil/water

mixture to improve water

coalescence. The electrical

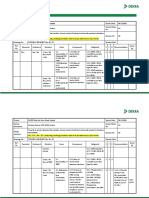

field imposes an electrical Figure 1 Evaluation of demulsifiers

charge on the small water

droplets entrained in the temporary glasses. With the exception of the

emulsion. The water droplets blank sample, 10 ppm of different

coalesce into bigger droplets, which demulsifiers were added into the

can settle by gravity. Therefore, centrifuge glasses and thoroughly

sufficient retention time in a mixed again. After 24 hours, the

desalter is required for efficient water content and salt content was

water and oil separation. A suitable determined to find the best

demulsifier is commonly used to performing demulsifier. In this

promote the separation of water case, Kurita EB-4110 and Kurita

and oil. The desalted crude oil is EB-4113 showed the highest desaltcontinuously fed from the desalter ing and dehydration efficiency for

vessel to the atmospheric crude this crude oil. EB-4110 is an oildistillation column. The desalter soluble demulsifier, which is typieffluent water is discharged from cally injected into crude oil in front

the desalter vessel to the wastewa- of the desalter mixing valve.

ter treatment facility.

EB-4113 is a water-soluble demulsiFigure 1 shows the laboratory fier, which is typically injected into

evaluation of demulsifiers in desalter wash water.

comparison with an untreated

crude oil sample (blank). For the Separation of oil-in-water emulsions

evaluation of a demulsifier, the In aqueous systems, the hydrocarcrude oil was mixed with 4 wt% bons generally carry a negative

wash water and agitated with an charge at their surface. Often, they

electric stirrer. This mixture was are steady dispersed into small

transferred into several centrifuge droplets because of their repellent

Agglomeration

Creaming

Coalescence

Creaming and

coalescence

Emulsion

Figure 2 Oil-in-water emulsion breaking process

88 PTQ Q2 2013

forces.

A

cationic

charged long-chain polymer

neutralises

the

negatively charged oil

droplets. The repellent

forces are weakened and

oil droplets are brought

together. This resolves

the emulsion of water

and oil. The emulsion-breaking

process

involves three steps:

Agglomeration

Creaming

Coalescence.

Figure 2 illustrates the physical

process of oil-in-water emulsion

breaking. Agglomeration is the

association of small dispersed

phase droplets (clusters). Creaming

is the concentration of the dispersed

phase. Coalescence is the drainage

of the continuous phase. The oil

droplets agglomerate by forming

bigger droplets and clusters, and

are collected at the surface. The

addition of an emulsion breaker

additive helps to accelerate the

separation process. These types of

emulsion breakers are surface

active components, which destabilise the dispersed phase.

Typical applications in refineries and

petrochemical plants

Ethylene production

Ethylene is mainly produced by

steam cracking. This process

includes thermal cracking, cooling,

compression and separation. Light

liquid hydrocarbons (naphtha) and

gases are converted mainly into

unsaturated smaller molecules,

which are separated by compression and distillation. The hot gases

leaving the cracking furnaces are

immediately quenched in oil

quench and water quench columns.

The purpose of the cooling is to

prevent polymerisation and the

formation of unwanted byproducts.

The collected quench water is separated from heavy hydrocarbons in

the oil/water separator. Often, the

separated quench water still

contains hydrocarbons, which are

dispersed in the aqueous phase.

Demulsifiers are usually applied

to improve the separation of hydrocarbons from the quench water. It

is mandatory to provide the correct

www.eptq.com

amount of chemical to avoid

overdosing of the demulsifier,

because at higher concentrations

demulsifiers have the tendency to

act as emulsifiers instead of

breaking the emulsion, they form a

more stable emulsion with hydrocarbons. A simple beaker test is a

good tool to check how much

demulsifier is required for the separation of hydrocarbons and water.

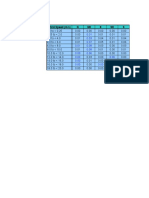

Figure 3 shows the result of a

laboratory evaluation to find the

best performing emulsion breaker

for quench water. In this case, no

demulsifier was applied in front of

the oil/water separator. The separated

water

still

contained

hydrocarbons, which were dispersed

in the aqueous phase. It was not

possible to remove these hydrocarbons in the oil/water separator. The

target of the laboratory test was to

select an emulsion breaker that

significantly improves the removal

of hydrocarbons from water within

10 minutes residence time. In this

case, the emulsion breaker added to

bottle No. 3 showed the best performance. Within the defined time

frame, an impressive hydrocarbon

layer was formed, while other

samples showed no effects or poor

separation. The good results of the

laboratory test were confirmed later

in a field trial.

Wastewater treatment

Water is used intensively in refineries and petrochemical processes,

and during its use it becomes

contaminated with hydrocarbons,

increasing the biological (BOD) and

chemical oxygen demand (COD) of

the effluent water. Cooling water,

process effluents, rain water and

surface water are collected at the

wastewater plant together with a

very briny effluent stream from the

desalting process. Typical pollutants are hydrogen sulphide,

ammonia, cyanides, metals and

suspended solids. Effective waste

treatment technologies are required

to comply with all legal requirements. The wastewater treatment

methods are generally classified

into three categories of mechanical,

chemical and biological treatments,

and a wastewater plant is typically

designed in three steps:

www.eptq.com

Figure 3 Quench water from oil/water separator

Mechanical

separation

and biological treatment

Filtration and polishing.

The main purpose of the primary

treatment is the separation of oil

and water. The removal of oil is a

very important step to reduce the

loading to the downstream treatment processes, because high oil

levels are toxic for the microorganisms used in biological treatment.

The wastewater typically contains

oil in water emulsions, with oil

dispersed in the continuous water

phase.

Common primary treatment units

are:

API oil/water separator

Corrugated

plate

interceptor

(CPI)

Dissolved air flotation (DAF)

Induced air flotation (IAF).

The function of an API oil/water

separator is based on the difference

in specific gravity of oil and water.

Suspended heavy particles settle to

the bottom of the separator to be

scraped by a rake into the sludge

pit, which is discharged continuously. The oil rises to the top of the

separator. The wastewater accumulates as a middle layer between the

settled solids and the oil phase. It

can be sent to a flotation unit for

further treatment. Substances such

as oil or particles can be separated

from water by flotation. Mechanical

flotation and dissolved air flotation

are applied to increase the flotating

velocity of particles. Fine air

bubbles are generated in water. The

upward flow of the bubbles and the

adhesion of bubbles with particles

Chemical

improves the efficiency of the flotation. The floating oil is skimmed

continuously to be pumped into the

slop oil system.

Conclusions

Oil/water emulsions appear in

many areas of refineries and petrochemical plants, and can cause

operational problems as well as

infringement of environmental

regulations. There is a variety of

separation equipment available on

the market to separate the oil phase

from the water phase. In such

cases, where stable emulsions are

formed that cannot be removed

mechanically, the application of

demulsifiers, coagulants and flocculants accelerates the separation

process and improves mechanical

performance. This helps to fulfil

legal requirements, reduces corrosion and fouling risks, and results

in reduced maintenance costs and

higher equipment availability.

Further reading

1 Kurita Handbook of Water Treatment, 2nd

English Ed, Kurita Water Industries Ltd, Japan,

1999.

2 Ullmanns Encyclopedia of Industrial

Chemistry The Ultimate Reference, Release

2012, 8th Ed, Wiley Online Library, Wiley-VCH.

3 Hartinger L, Handbuch der Abwasser-und

Recyclingtechnik, 2nd Auflage, 1991, Hanser,

Germany.

Berthold Otzisk is a Consulting Engineer in the

Technical Department of Kurita Europe GmbH,

Viersen, Germany, where he focuses on refinery

and petrochemical applications.

Email: otzisk@kurita.de

PTQ Q2 2013 89

You might also like

- Chapter 10: Emulsion & Oil/Water Separation: I. Oil Export SpecificationDocument21 pagesChapter 10: Emulsion & Oil/Water Separation: I. Oil Export SpecificationThanh Tùng PhạmNo ratings yet

- Demulsification &desalinationDocument59 pagesDemulsification &desalinationnilay05No ratings yet

- EmulsionsDocument44 pagesEmulsionsMax SinghNo ratings yet

- Emulsion BreakerDocument19 pagesEmulsion BreakerNovrie50% (2)

- Emulsion Breaking PDFDocument22 pagesEmulsion Breaking PDFNovrie100% (1)

- DemulsifiersDocument3 pagesDemulsifiersAnand ChristyNo ratings yet

- Lecture on Surface Production Operations and DemulsificationDocument88 pagesLecture on Surface Production Operations and DemulsificationASHISH NAGARNo ratings yet

- The Effective Way of Separating WaterDocument38 pagesThe Effective Way of Separating WaterIrshad Muhammad100% (4)

- Chemiphase Oilfield Demulsifier Testing ProcedureDocument4 pagesChemiphase Oilfield Demulsifier Testing ProcedureBen Wiggins100% (1)

- Effective Electrostatic Dehydration and Desalting of Crude OilDocument2 pagesEffective Electrostatic Dehydration and Desalting of Crude OilMilena Lemus Fonseca100% (1)

- Crude Oil Emulsions A State-Of-The-Art ReviewDocument11 pagesCrude Oil Emulsions A State-Of-The-Art Reviewmalyari2002255100% (3)

- Oil Demulsifier Selection and OptimizationDocument5 pagesOil Demulsifier Selection and OptimizationAhmed Abu-AlharethNo ratings yet

- Crude Oil DesaltingDocument25 pagesCrude Oil DesaltingNaumanNo ratings yet

- Hydrate Inhibitor in Oil and Gas FieldDocument45 pagesHydrate Inhibitor in Oil and Gas FieldguruhnurizalNo ratings yet

- Oil Demulsifier Selection and Optimization - PetroWikiDocument10 pagesOil Demulsifier Selection and Optimization - PetroWikiahmedNo ratings yet

- Optimize Crude Oil Desalting with Membrane FiltrationDocument14 pagesOptimize Crude Oil Desalting with Membrane FiltrationDucViking100% (1)

- Defo AmerDocument31 pagesDefo AmerM. ade Dwi MaesandiNo ratings yet

- Oilfield DemulsifierDocument72 pagesOilfield Demulsifieragahkhaerul sanniNo ratings yet

- Oil/Water Separators: T P: O WDocument4 pagesOil/Water Separators: T P: O Wvgogulakrishnan100% (1)

- Desalter PresentationDocument17 pagesDesalter PresentationGeorge J Alukkal100% (3)

- 2005 Crude Oil Emulsions - A State-Of-The-Art ReviewDocument9 pages2005 Crude Oil Emulsions - A State-Of-The-Art ReviewOscar RoaNo ratings yet

- Desalter PDFDocument132 pagesDesalter PDFAlzahraa Alhaj AliNo ratings yet

- Electrostatic Coalescer (Laminar Flow)Document3 pagesElectrostatic Coalescer (Laminar Flow)Yusof SundangNo ratings yet

- Advances in Electrostatic Treatment of Crude OilDocument5 pagesAdvances in Electrostatic Treatment of Crude OilAnonymous bHh1L1No ratings yet

- PETRECO Bilectric Desalters: State-Of-The-Art Efficient SystemsDocument2 pagesPETRECO Bilectric Desalters: State-Of-The-Art Efficient SystemsRoyster CabralNo ratings yet

- Crude Oil Desalting ProcessDocument24 pagesCrude Oil Desalting ProcessamirejazNo ratings yet

- Demilusfer Bottle TestDocument8 pagesDemilusfer Bottle TestSarbast H. Saeed100% (2)

- Using Demulsifiers For Phase Breaking of Water - Oil EmulsionDocument5 pagesUsing Demulsifiers For Phase Breaking of Water - Oil EmulsionCarlosGamasOchoaNo ratings yet

- Investigation of the Effect of Pour Point Depressants on Wax Deposition and Crude Oil Flow BehaviorDocument38 pagesInvestigation of the Effect of Pour Point Depressants on Wax Deposition and Crude Oil Flow BehaviorAfzal AktharNo ratings yet

- Baker Hughes DesalterDocument5 pagesBaker Hughes DesalteralexHuy88No ratings yet

- Demulsifiers-Specialty Oilfield ChemicalsDocument117 pagesDemulsifiers-Specialty Oilfield ChemicalsMichael Medina100% (2)

- Degassing and DesaltingDocument15 pagesDegassing and DesaltingMuhammad MohtashimNo ratings yet

- Reclamation Q & ADocument11 pagesReclamation Q & AchomiNo ratings yet

- Desalter Operation OptimizationDocument3 pagesDesalter Operation OptimizationRexx MexxNo ratings yet

- Demulsifier Bottle TestDocument42 pagesDemulsifier Bottle Testguruhnurizal100% (5)

- Dewatering and Desalting Crude OilDocument2 pagesDewatering and Desalting Crude OilRichard ObinnaNo ratings yet

- Heater TreaterDocument5 pagesHeater TreaterImmanuel100% (1)

- Desalting of Crude Oil: Table 1. Table 2Document15 pagesDesalting of Crude Oil: Table 1. Table 2Mattew1712No ratings yet

- Day 1 - Demulsification APAC 2022Document55 pagesDay 1 - Demulsification APAC 2022Andres MerloNo ratings yet

- Desalting Part 2 May 2009Document51 pagesDesalting Part 2 May 2009ermusatNo ratings yet

- Electro-Dynamic Desalter 2Document2 pagesElectro-Dynamic Desalter 2Dadi Draou100% (1)

- Desalting EfficiencyDocument5 pagesDesalting EfficiencyKandanNo ratings yet

- Desalting HandbookDocument310 pagesDesalting HandbookFREDIELABRADORNo ratings yet

- Desalting Part 1 May 2009Document104 pagesDesalting Part 1 May 2009ermusatNo ratings yet

- De SaltersDocument15 pagesDe SaltersMuhammad Arslaan100% (2)

- Desalter Control PDFDocument2 pagesDesalter Control PDFmotalebyNo ratings yet

- Basic Production ChemicalsDocument16 pagesBasic Production Chemicalsjps21No ratings yet

- A Quick Look at DesaltingDocument12 pagesA Quick Look at Desaltingananth2012No ratings yet

- Demulsifier - Bottle Testing and Information CollectionDocument28 pagesDemulsifier - Bottle Testing and Information CollectionMichael Medina100% (2)

- Section 3: Desalters: Reduced Crude Unit Corrosion. at The High Temperatures Found in Crude UnitDocument48 pagesSection 3: Desalters: Reduced Crude Unit Corrosion. at The High Temperatures Found in Crude Unitrvkumar61No ratings yet

- Flowsolve™ 212Ln: Asphaltene DispersantDocument1 pageFlowsolve™ 212Ln: Asphaltene DispersantIrelena RomeroNo ratings yet

- Oil-Water Separation TechnogiesDocument4 pagesOil-Water Separation TechnogiesBrian FreireNo ratings yet

- Oil Water Separation - PTQ - Q22013 PDFDocument3 pagesOil Water Separation - PTQ - Q22013 PDFMohamed TallyNo ratings yet

- Chapter 7 Crude Oil DehydrationDocument34 pagesChapter 7 Crude Oil DehydrationFatima Al-n100% (1)

- Wet Crude ProcessingDocument39 pagesWet Crude ProcessingMohanad HussienNo ratings yet

- Chapter 2 EmulsionsDocument52 pagesChapter 2 Emulsionsplq_macrossNo ratings yet

- Emulsion Treating Part 1: Understanding Crude Oil EmulsionsDocument6 pagesEmulsion Treating Part 1: Understanding Crude Oil EmulsionsRizwan FaridNo ratings yet

- Crude Oil Emulsions - Petroleum Engineers Handbook PDFDocument34 pagesCrude Oil Emulsions - Petroleum Engineers Handbook PDFMichael Grayson100% (3)

- Emulsion Treating Part 1 OverviewDocument7 pagesEmulsion Treating Part 1 OverviewSandy Msd100% (1)

- Academic Word List PDFDocument28 pagesAcademic Word List PDFukchaudharyNo ratings yet

- IELTS Reading Answer SheetDocument1 pageIELTS Reading Answer Sheetskuppal50% (2)

- RelaibilityDocument10 pagesRelaibilityrohitkushNo ratings yet

- Supercritical Velocity GraphDocument1 pageSupercritical Velocity GraphrohitkushNo ratings yet

- Fault Tree PDFDocument1 pageFault Tree PDFrohitkushNo ratings yet

- Flare Temp Vs Time CurveDocument1 pageFlare Temp Vs Time CurverohitkushNo ratings yet

- LPG QuestionaireDocument1 pageLPG QuestionairerohitkushNo ratings yet

- Static Charge RemoverDocument4 pagesStatic Charge RemoverrohitkushNo ratings yet

- Fire and Risk AssessmentDocument4 pagesFire and Risk AssessmentrohitkushNo ratings yet

- J1237 Asian Paints HAZOP WSDocument98 pagesJ1237 Asian Paints HAZOP WSrohitkushNo ratings yet

- Essay Task-1 SampleDocument1 pageEssay Task-1 SamplerohitkushNo ratings yet

- Wind RoseDocument1 pageWind RoserohitkushNo ratings yet

- Flare Grid ResultsDocument1 pageFlare Grid ResultsrohitkushNo ratings yet

- Risk MatrixDocument1 pageRisk MatrixrohitkushNo ratings yet

- Pool Burn RateDocument1 pagePool Burn RaterohitkushNo ratings yet

- Exceedance CurveDocument1 pageExceedance CurverohitkushNo ratings yet

- Radiation ContourDocument1 pageRadiation ContourrohitkushNo ratings yet

- Radiation of FlareDocument1 pageRadiation of FlarerohitkushNo ratings yet

- When Two Phase Flow Before Control Valve is Acceptable or NotDocument1 pageWhen Two Phase Flow Before Control Valve is Acceptable or NotrohitkushNo ratings yet

- Expectations For The Mi ProgramDocument3 pagesExpectations For The Mi ProgramrohitkushNo ratings yet

- Wind Speed (M/S) N NE E SE SDocument3 pagesWind Speed (M/S) N NE E SE SrohitkushNo ratings yet

- Explosion ResultsDocument9 pagesExplosion ResultsrohitkushNo ratings yet

- Data Requisition For HAZOPDocument1 pageData Requisition For HAZOProhitkushNo ratings yet

- HAZID WorksheetDocument1 pageHAZID WorksheetrohitkushNo ratings yet

- Risk RankingDocument1 pageRisk RankingrohitkushNo ratings yet

- PSM GoalDocument2 pagesPSM GoalrohitkushNo ratings yet

- Criterion for hazard ranking procedureDocument1 pageCriterion for hazard ranking procedurerohitkushNo ratings yet

- Results For Vent SizingDocument3 pagesResults For Vent SizingrohitkushNo ratings yet

- Hazard RiskDocument1 pageHazard RiskrohitkushNo ratings yet

- PSM Goal PDFDocument2 pagesPSM Goal PDFrohitkushNo ratings yet

- Bio Sci Chapter 2 Lesson 1 Module 3Document26 pagesBio Sci Chapter 2 Lesson 1 Module 3Vimbee Cefre Alipoon EresuelaNo ratings yet

- Dextra Prestressing Bar Rev 11 Oct 2016Document14 pagesDextra Prestressing Bar Rev 11 Oct 2016Natthawut CheencharoenNo ratings yet

- Calculating Electrical Load and Wire SizingDocument7 pagesCalculating Electrical Load and Wire SizingMarcelo CondinoNo ratings yet

- Chemistry: Pearson EdexcelDocument16 pagesChemistry: Pearson EdexcelHosni ShowikeNo ratings yet

- Pushover Analyses of TwoDocument6 pagesPushover Analyses of TwogazmirNo ratings yet

- Concrete Mix Design With Fly Ash and Silica FumesDocument8 pagesConcrete Mix Design With Fly Ash and Silica FumesC-78 Munna TripathiNo ratings yet

- IEC20091118133046Document5 pagesIEC20091118133046SEANMNo ratings yet

- Analysis and Design of Steel I-Girder Bridge Using CSI-Bridge SoftwareDocument300 pagesAnalysis and Design of Steel I-Girder Bridge Using CSI-Bridge SoftwareChinmay TejaswiNo ratings yet

- Permatex Plastic WeldDocument1 pagePermatex Plastic Welduzzy2No ratings yet

- Week-5-Q1-Gen Chem-Sep-25-29-DllDocument14 pagesWeek-5-Q1-Gen Chem-Sep-25-29-DllJennette BelliotNo ratings yet

- CatalysisDocument32 pagesCatalysismanvi sharmaNo ratings yet

- Sample Problem Mod 3 CPCDocument6 pagesSample Problem Mod 3 CPCAman PratikNo ratings yet

- 3M - VHB - Structural Glazing Tapes Technical GuideDocument32 pages3M - VHB - Structural Glazing Tapes Technical GuideMahadeva PrasadNo ratings yet

- Reaction Mechanisms 1 MSDocument9 pagesReaction Mechanisms 1 MSBeatrice MoyoNo ratings yet

- Master Emaco P210Document2 pagesMaster Emaco P210Gavriel NgNo ratings yet

- Materials 13 04965Document14 pagesMaterials 13 04965paulo passeiosNo ratings yet

- Assignment 2015 1Document1 pageAssignment 2015 1manishNo ratings yet

- August 2022 Report For Dennis T MuzilaDocument11 pagesAugust 2022 Report For Dennis T MuzilaDennis MuzilaNo ratings yet

- FME-2021-0403 Proof HiDocument41 pagesFME-2021-0403 Proof HiAsif EqubalNo ratings yet

- Lecture 1Document7 pagesLecture 1Dr. Aung Ko LattNo ratings yet

- Assessment PN1096617Document14 pagesAssessment PN1096617Amr TarekNo ratings yet

- Hazardous Substance Assessment Checklist Rev 3-1Document5 pagesHazardous Substance Assessment Checklist Rev 3-1Santo WardanaNo ratings yet

- Bronze Castings For Bridges and TurntablesDocument4 pagesBronze Castings For Bridges and TurntablesmatiullahNo ratings yet

- 3rd Summative TestDocument8 pages3rd Summative TestAngelica ValdezNo ratings yet

- China's First Ministry of Machine-Building Standard for Radiography of WeldsDocument133 pagesChina's First Ministry of Machine-Building Standard for Radiography of Weldsmsiddique1No ratings yet

- Asset Preservation MethodsDocument10 pagesAsset Preservation MethodsLuck Luqe67% (3)

- Steel Member Design - Sample Calculation (AS4100)Document5 pagesSteel Member Design - Sample Calculation (AS4100)Tiam MarapeNo ratings yet

- Compact C Pump Flyer v2Document2 pagesCompact C Pump Flyer v2GonzalezElizaNo ratings yet

- Advanced Lab Course 50: PhotovoltaicsDocument18 pagesAdvanced Lab Course 50: PhotovoltaicsHamza OuerfelliNo ratings yet

- MEB Nptel Week 5 Assignment AnswersDocument4 pagesMEB Nptel Week 5 Assignment AnswersMeethiPotterNo ratings yet