Professional Documents

Culture Documents

07 Z.A. Rahman - Marine Clay

Uploaded by

Jayson TeeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

07 Z.A. Rahman - Marine Clay

Uploaded by

Jayson TeeCopyright:

Available Formats

Sains Malaysiana 42(8)(2013): 10811089

Geotechnical Characterisation of Marine Clay

As Potential Liner Material

(Pencirian Geoteknik Lempung Marin

Sebagai Potensi Bahan Pelapik)

Z.A. RAHMAN*, W.Z.W. YAACOB, S.A. RAHIM, T. LIHAN, W.M.R. IDRIS

& W.N.F. MOHD SANI

ABSTRACT

Natural clay is commonly used as a liner material to contain landfill leachate from contaminating the environment. A

key characteristic of liner material is its hydraulic conductivity. It is recommended that the hydraulic conductivity of the

potential liner material should be of 110-9 m/s or less. This paper presents the geotechnical characteristics of marine

clay that may be used as landfill liner material. The tests were consistency index, compaction behaviour, compressibility

and hydraulic conductivity. The marine clay was dominated by finer fraction of silt and clay (78%-88%) followed by

sand (12%-22%). The clay minerals commonly present were montmorillonite, kaolinite and illite as well as quartz as the

non-clay mineral. The consistency index for the liquid limit, wL and plastic limit, wP were 56.6%-80.5% and 36%-45%,

respectively. The plastic index, Ip of the marine clay samples ranged from 19% to 37%. The permeability test indicated

that the hydraulic conductivity of the samples ranged between 1.10 10-9 and 2.44 10-9 m/s. The very low permeability

showed by the marine clay can be related to the presence of high content of finer fraction. Compaction of marine clay

samples resulted in maximum dry density, dmax that ranged between 1.5 and 1.6 g/cm3 and optimum moisture content, wopt

that ranged between 18.2% and 25%. During the consolidation of the marine clay, the hydraulic conductivity decreased

within the recommended permeability for landfill liners. This study showed that some geotechnical characteristics of

the studied marine clay were in favour of being used as landfill liner material.

Keywords: Consistency index; landfill; liner; marine clay; shear strength

ABSTRAK

Lempung semula jadi sering digunakan sebagai bahan pelapik untuk menghalang pencemaran cecair larut resap tapak

pelupusan ke persekitaran. Ciri utama bahan pelapik adalah sifat ketelapannya. Kekonduksian hidraulik yang disarankan

bagi bahan berpotensi sebagai pelapik seharusnya 110-9 m/s atau kurang. Kertas ini menunjukkan ciri geoteknik

lempung marin yang mungkin dapat digunakan sebagai bahan pelapik tapak pelupusan. Ujian yang dilakukan adalah

indeks ketekalan, sifat pemadatan dan kekonduksian hidraulik. Lempung marin didominasi oleh fraksi halus bersaiz

lodak dan lempung (78%-88%) diikuti oleh pasir (12%-22%). Mineral lempung yang sering hadir adalah monmorilonit,

kaolinit dan ilit serta kuarza sebagai mineral bukan lempung. Indeks kekonsistensi bagi had cecair, wL dan had plastik, wp

masing-masing adalah 56.6%-80.5% dan 36%-45%. Indeks keplastikan, IP sampel lempung marin berjulat daripada 19

hingga 37%. Ujian ketelapan menunjukkan kekonduksian hidraulik sampel berjulat antara 1.10 10-9 dan 2.44 10-9 m/s.

Nilai ketelapan yang sangat rendah yang ditunjukkan oleh lempung marin boleh dikaitkan dengan kehadiran kandungan

fraksi halus yang tinggi. Pemadatan sampel lempung marin menghasilkan ketumpatan kering maksimum, dmax berjulat

1.5 - 1.6 g/cm3 dan kandungan optimum lembapan, wopt berjulat antara 18.2% dan 25%. Semasa pengukuhan lempung

marin, kekonduksian hidraulik menurun dalam kebolehtelapan yang disyorkan bagi bahan pelapik tapak pelupusan.

Kajian ini menunjukkan ciri geoteknik lempung marin yang dikaji memihak sebagai bahan pelapik tapak pelupusan.

Kata kunci: Indeks ketekalan; kekuatan ricih; lempung marin; pelapik; tapak pelupusan

INTRODUCTION

Rapid development has increased the quantity of solid

waste that has to be safely disposed and handled by

landfill operators at effective cost (Arasan & Yetimoglu

2006). The presence of heavy metals such as lead,

cadmium, zinc, nickel and chromium are commonly

associated with industrial waste and considered noxious

to human health (Yong & Phadungchewit 1993). A

common natural earth material such as clayey soil is

widely used for containment of landfill leachate from

migrating to the environment. Geosynthetic Clay Liner

(GCL) is one of the advanced synthetic material that

has been widely used in construction of impermeable

liner material in modern landfills. The uncertainty of its

1082

performance over a period and its expensive cost have

made this product unfavourable (Arasan 2010). Finding

natural earth materials can be an advantage economically

to landfill operators as long as the material provides

suitable characteristics (e.g. permeability, strength

and shrinkage). However, these earth materials should

comply with the recommended criteria to ensure their

effectiveness as impermeable liners.

Marine clay is characterised by low permeability

and has the capability in attenuation of inorganic

contaminants. This sediment is mainly deposited

along the coastal areas of Peninsular Malaysia. It is

microcrystalline in nature and consists of clay minerals

such as chlorite, montmorillonite, kaolinite and illite

(Basack & Purkayastha 2009; Bjerrum 1973). Some

common non-clay minerals are also present such as

quartz and feldspar. It has been found that the strength

and stiffness characteristics of marine clay deposits are

subjected to wave induced cyclic stresses (Dias & Alves

2009; Hyde et al. 1993; Long & Menkiti 2007).

Previous studies showed that the properties of marine

clay have advantages over the lateritic soils as permeable

liners (Chalermyanont et al. 2008; Du & Hayashi 2004;

Kamon & Katsumi 2001). Clay minerals have high

metal absorption capability and are characterised by

low hydraulic conductivity. The hydraulic conductivity

of an effective liner material should be equal or less

than 1 10-9 m/sec (Jones et al. 1993). The engineering

behaviour of marine clay has been studied by many

researchers (Chew et al. 2004; Chung et al. 2007; Rao

et al. 2011; Suneel et al. 2008). Benson and Trast (1995)

performed hydraulic conductivity tests on thirteen

compacted clay samples under controlled conditions.

They found that the k value decreased with an increase

in clay content. In addition, compaction of clayey soils

at initial saturation in excess of 85% could decrease the

hydraulic conductivities down to 10-10 m/s. Itakura et

al. (2005) examined the consistency limit and hydraulic

conductivity of Londonderry Clay deposit for industrial

liquid waste containment material.

This paper presents the geotechnical characteristics

of marine clay that may be used as liner material to contain

the migration of landfill leachate to the environment. The

geotechnical characterisation conducted on the marine

clay samples were consistency index, compaction

behaviour, compressibility, hydraulic conductivity and

shear strength.

MATERIALS AND METHODS

SAMPLE COLLECTION AND PREPARATION

The collection of the marine clay samples was performed

at three locations along the coastal area of Kuala Muda,

Kedah (Figure 1). At each station, three sub-samples

were collected for sample replication. This soft marine

clay deposit was developed under the shallow coastal

saline water conditions. On-hand sample, marine clay

found to be greenish or bluish in colour with fine stripes

of organic matter. It was common to find a lot of small

fragments of shells. The grey colour was possibly

developed because of the oxidation of sulphur and iron

in the clay as a result of being exposed to the atmosphere

(Taha et al. 2000). The sample collection was performed

using shallow open trench excavation (0.5 m depth from

ground surface) approach during low tide. Undisturbed

samples were taken for oedometer tests. A block sampler

of 300 mm cubical with a 20o outside angle cutting edge

was pushed vertically into the marine clay deposit and a

scoop was carefully used to dig out the sample. Extreme

precautions were imposed during sampling to keep the

clay in its natural water conditions. Sufficient amount of

disturbed marine clay samples, weighing about 30 kg for

each station, was also taken from the same trench and

then transferred for laboratory experiments. Undisturbed

samples were used to determine the value of their natural

compression index. Meanwhile, bulk samples were

air-dried at room temperature for a week. Aggregates

of dried samples were manually crushed by pestle and

mortar to individual grain. The prepared samples were

used to determine the mineralogical and geotechnical

characteristics. The studied characteristics were particle

size distribution, clay mineralogy, specific gravity, pH,

consistency index, compaction behaviour, compression

index and hydraulic conductivity.

EXPERIMENTAL PROCEDURES

The technique adopted to determine the particle size

distribution was dry-sieving and hydrometer (size

passing sieve number 200) techniques. Identification of

clay and non-clay minerals was determined by the X-ray

diffraction (XRD) technique. A Philip X-ray diffractometer

equipped with Ni-filtered CuK radiation generated at

30 kV and 30 mA with a scan speed of 42 min-1 was

used. Prior to analysis, samples had to be pulverized

into powder state. In this study, the samples tested for

X-ray diffraction had particle size of less than 2 m.

Quantitative estimation of clay minerals was carried out

based on peak areas and peak height for non-clay minerals

(Pierce & Siegel 1969). Determination of the specific

gravity of the marine clay samples was established by

using the pyknometer bottle technique. Consistency

index is usually used to correlate the water contents of

cohesive soil into empirical boundaries namely nonplastic, plastic and viscous liquid (Dias & Alves 2009).

It is widely known as the Atterberg limits of liquid limit,

wL and plastic limit, wP. Liquid limit is used to classify

particular soil and to estimate its moisture content at

which the shear strength is virtually zero. Liquid limit

can be determined by using the Casagrande method

where the V-groove cut in the soil paste is subjected to

shallow drop of the cup. The plastic limit is determined

by rolling the soil thread into a 3 mm diameter without

crumbling. The plasticity, Ip index is defined as the

difference between the liquid limit and the plastic limit.

1083

FIGURE

1. The location of the sampling points for the marine clay

Soil with difference in Ip value tends to be clay, silt or

non-plastic material. The ratio of the difference between

natural water content, plastic limit and plasticity index

is known as the liquidity index, IL. The IL value can be

correlated to the shear strength of the soil (Dias & Alves

2009; Yilmaz 2000). As value IL equal to 1.0, the soil

achieves its liquid limit and becomes a plastic limit if IL

equal to 0. A reliable correlation between IL value and

degree of consolidation of clayey soil was presented by

Rominger and Rutledge (1952) and Means and Parcher

(1963). The values of the liquid limit and plasticity index

of the marine clay samples were then plotted onto the

Casagrande Chart. The chart is usually used to classify

the soil based on its different behaviour. Compaction

characteristic tests were performed using 2.5 kg standard

proctor (also known BS Light). Sample was compacted

in three equal layers using a rammer where each layer

experienced 27 blows that were evenly distributed over

the mould area. The maximum dry density, dmax and

optimum moisture content, wopt can be achieved from

the compaction curve. Meanwhile, the permeability tests

performed adopted a falling head permeameter method.

The compression index, Cc of the samples was determined

using the oedometer test. A further explanation of the

methods applied for particle size distribution, specific

gravity, consistency limits, 1-dimension compression,

compaction and permeability tests for soil can be referred

to the British Standard Institution 1377 (1990(a), 1990(b),

1990(c), 1990(d)) Parts 2, 4, 5 and 7.

RESULTS AND DISCUSSION

PARTICLE SIZE DISTRIBUTION AND MINERALOGY

The particle size distribution curves for the three clay

samples collected at different locations with three

replications for each sample are shown in Figure 2. These

samples can be classified as clayey silt. The mean values

for sand, silt and clay fractions are shown in Table 1. It

shows that the marine clay samples are dominated by silt

fraction (54.3%-58.3%) followed by clay fraction (23.7%

29.7%). Sand fraction in marine clay samples ranged

between 12% and 22%. The sand fraction at stations L1

and L2 showed a higher content, namely 19.2% and 22%,

respectively. Shell fragments were also commonly found

in the marine clay samples. The presence of higher silt

and clay fractions is a characteristic of the typical muddy

coastal beach of Kuala Muda, Kedah. An appreciable

content of fines is desirable in soil that is to be used as the

hydraulic barrier (Belloo 2012). Jones et al. (1993) cited

that the suitable material for liners should contain clay of

greater than 10%. EPA (1990) recommended that soils used

as liner material should have at least 20% fines (fine silt

and clay size particles) to achieve hydraulic conductivity

values of or less than 1 107 m/s. It is difficult to achieve

the recommended hydraulic conductivity for soil with less

clayey content. Hydraulic conductivity usually decreases

with the increase of the content of fine particles (Alamgir

et al. 2005).

1084

FIGURE

2. Particle distribution curves for the marine clay samples

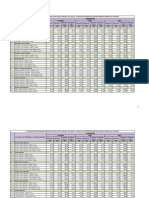

TABLE

Material Properties

Particle size distribution, %

Sand

Silt

Clay

Fines fraction,

Organic cont., %

Natural moisture cont., w%

XRD

Analysis

Specific gravity, Gs

pH

L1

19.2

56.5

24.3

80.8

2.13

56.7

Montmorillonite,

kaolinite, illite,

quartz, halite

2.6

7.7

Sample No.

Mean

L2

L3

22.0

54.3

23.7

78.0

12.0

58.3

29.7

88.0

17.8

56.4

25.9

82.3

67.6

65.9

1.96

73.5

Quartz, halite,

montmorillonite,

kaolinite

2.4

7.7

1.83

Montmorillonite,

kaolinite, illite,

quartz, halite

1.97

2.6

2.6

7.6

7.7

CEC, meq/100g

25.24

25.82

27.09

26.05

Liquid limit, wL

Plastic limit, wP

Plastic index, IP

Liquidity index, IL

Ratio wP/wL

72.0

42.0

30.0

0.5

0.6

70.0

42.0

28.0

1.3

0.6

79.0

44.0

35.0

0.7

0.4

73.0

47.0

30.0

0.8

0.5

1.6

18.2

1.5

25.0

1.5

23.8

1.5

22.3

65-58kPa

0.576-0.611

14-53kPa

1.674-1.032

60-59kPa

0.849-0.900

Atterberg limit, %

Permeability, k: (x10-9) m/s

Compaction test

Max. dry density, dmax: g/cm3

Opt. moisture content, wopt: %

Pre-consolidation stress, Pc

Compression index, Cc

1-D Compression test

1. Summary of the marine clay characteristics

- in descending order of intensity value

3 - applied confining pressure

1.10

2.44

1.77

1.77

1085

X-ray diffraction (XRD) is a common technique used

to determine mineral content in sediments. It is important

to establish the types of minerals present in order to assess

the behaviour of soil toward pollutants. Yong et al. (1998)

mentioned that every mineral has particular surface and

structure characteristics that determine its capability to

confine heavy metals. Identification of mineral is based

on the characteristics of diffraction when the photon

X-ray is radiated to the samples. The results from the

XRD analysis indicated that the studied clay samples were

composed of montmorillonite, kaolinite and illite (Table

1). Each mineral has different mineral concentration as

reflected from the intensity of the XRD. For sample L1, the

presence of peak at 15.52 and 5.01 was identified as

montmorillonite. Kaolinite was detected from the peak at

7.22 and 3.58 while illite at peak of 10.10 and 3.55

. Sample L2 indicated the presence of montmorillonite

from the peak at 15.17 and 4.48 followed by kaolinite

at peak of 7.17 and 3.57 . The presence of both minerals

in L2 were lesser than the sample of L1. In sample L3,

montmorillonite showed the strongest peak at 15.29

and 5.01 , followed by kaolinite at peak of 7.16 and

3.57 . Illite was detected at peak of 5.01 and 3.34 .

Other minerals detected were quartz and halite. The ratio

between plastic limit, wP and liquid limit, wL of the samples

ranged between 0.4 and 0.6; these values typically reflect

marine clay from around the world (Dias & Alves 2009;

Sridharan et al. 2004).

SPECIFIC GRAVITY, PH AND ORGANIC MATTER

The mean value for specific gravity, Gs of the marine

clay was 2.6 and no significant difference was found in

the result of the test. The value of Gs ranged between 2.4

and 2.6 (Table 1). The pH test showed that the samples

were slightly alkaline with values ranging from 7.6 to 7.7.

Similarly, no clear difference was found from the samples

collected at the three locations (Table 1). These values of

Gs and pH were also similar to the marine clay deposit

studied by Rao et al. (2009) and Tan et al. (2002). Loss on

ignition value for organic content in marine clay samples

was low, ranging from 1.83 to 2.13% with a mean value of

less than 2%. It was also reported that the organic matter

from Singapore marine clay is less than 1% (Ohtsubo et

al. 2012). Tan et al. (2002) also stated that the organic

content of marine clay composed of sedimentary deposit

is around 3%, with moderate contents of kaolinite, illite,

chloride and smectite.

ATTERBERG LIMITS AND PERMEABILITY TESTS

The values of the liquid limit, wL and plastic limit, wP

are shown in Table 1. The wL values ranged from 70 to

79% while the wP values were between 42 and 44% with

mean values of 73 and 43%, respectively. The values

of each Atterberg limit are remarkably uniform. The

plastic index, IP ranged from 28 to 35 with a mean value

of 30. The recommended materials for landfill liners are

those clays that have wL and IP less than 90% and 65%,

respectively, with clay fraction of greater than 10%

(Jones et al. 1993). These criteria should be followed in

order to avoid instability, deformation and compaction in

earthworks (Department of Transport 1991).

According to Benson and Trast (1995), the liquid

limit wL and plastic limit wP values are directly related

to mineralogy and clay content. The presence of high

content of clay, especially active clay minerals generally

corresponds to a decrease in the size of microscale pores

that subsequently lower the hydraulic conductivity of the

soil. The liquidity index of the studied clay ranged from

0.5 to 1.3 with a mean value of 0.8. The mean value of IL

indicated that the studied clay fall within the cohesive soil

deposit and can be categorised as normally consolidated

clay based on the classification scheme introduced by

Means and Parchers (1963).

The plotted results of IP and wL of all the clay subsamples on the Cassagande Chart are shown in Figure 3.

All samples lie below the A-line, representing silt with

high to very high plasticity. It is clearly seen in Figure

3 that even though the samples collected from L2 and

L3 are below the A-line, these samples are distributed

slightly further up in comparison to the samples of L1.

Jones et al. (1993) stated that such material that falls

below the A-line is classified as material unsuitable as a

liner. However, they also added that materials classified

as silt based on plasticity can achieve the required

low permeability if adequately compacted within an

acceptable range of moisture content. Studies showed that

compaction can decrease void ratio that resulted in low

hydraulic conductivity of soils (Ahn & Jo 2009; Bagchi

2004; Kooistra & Tovey 1994).

The permeability of earth materials for liners should

be investigated in order to establish their capability in

confining or eliminating the movement of leachate from

being seeped into the surrounding environment (Van

Imple 1998). Murray et al. (1992) recommended that

the permeability of a liner for high-technology landfill

should be 110-9m/s. The permeability of the studied

clay was generally very low; it ranged from 1.10 to

2.44 10-9 ms-1 with a mean value of 1.77 10-9 m/s

(Table 1). The low permeability value was due to the

higher content of finer fraction of silt and clay. The low

permeability values of the marine clay samples were

within the requirement for liner material. The differences

in the hydraulic conductivity were related to the different

content of fine and clay minerals (Table 1). Higher content

of finer fraction can be associated with high CEC value in

marine clay (Chalermyanont et al. 2008). This resulted

in a thicker double layer during hydration in which the

capacity of the water flow path decreases, subsequently

lowering the hydraulic conductivity (Mitchell 1993).

COMPACTION AND CONSOLIDATION TESTS

The purpose of compaction is to densify the soil mass by

bringing down the air voids. Islam et al. (2008) presented

results showing the effect of compaction on the hydraulic

1086

FIGURE

3. Plasticity chart for the marine clay samples

curves for sample L1 is located above those of samples

L2 and L3. Sample L1 achieved higher dmax at lower

moisture content when compared with that of samples

L2 and L3. The study carried out by Islam et al. (2008)

on Khulna clay deposit indicated that the compacted soil

at maximum dry density, dmax at 20% optimum moisture

content, wopt could achieve hydraulic conductivity close

to 2.5 10-10 m/s.

The consolidation behaviour was studied using

oedometer test. This test provides information related

to the amount of loads that clay can withstand once the

Dry density, dmax: g/cm3

conductivity. In this study, compaction tests of 2.5 kg

(BS Light) standard proctor compactive efforts were

performed on the marine clay samples.

The results of the maximum dry density, dmax and

optimum moisture content, wopt are shown in Table 1.

Figure 4 illustrates the compaction curves of the marine

clay samples. The maximum dry density, dmax values

ranged from 1.5 to 1.6 g/cm3 with a mean value of 1.5 g/

cm3. Meanwhile, the values of optimum moisture content,

wopt ranged between 18.2% and 25% with a mean value of

22.3%. It can be seen from Figure 4 that the compaction

Moisture content, w: %

FIGURE

4. Compaction curves for the collected marine clay samples

1087

liners are in operation. However, the overburden pressure

was released during sampling that resulted in a lower

value of maximum effective stress compared to the

value of field condition. The 1-dimension consolidation

tests were performed on the marine clay samples. The

preconsolidation stress, pc is the effective stress that

denotes the boundary between soft and stiff deformation

response of soil to loading (Terghazi et al. 1996). The

pc values were obtained from the void ratio; e log pc

curves gave values ranging from 58-65kPa for sample

L1, 14-53kPa for L2 and 60-59kPa for L3 (Table 1).

Figure 5(a) shows the consolidation curves for two

clay samples in e log pc space. The consolidation curves

FIGURE

of e log pc illustrated a slight concave upon reaching

the virgin compression line. This typical behaviour was

also reported by Taha et al. (2000). The Cc is described

by the change of the void ratio, e and the change of the

effective stress, plotted to the log scale. It is clearly

seen that the initial void ratio of L1 was lower than L2

and L3 (Figure 5(a)). The compression index, Cc values

for samples L1, L2 and L3 ranged from 0.576 to 0.611,

1.674 to 1.032 and 0.849 to 0.900, respectively. The

change in hydraulic conductivity during consolidation

of the samples is shown in Figure 5(b). It indicated

that the marine clay could achieve very low hydraulic

conductivity value of equal or less than 10-10 m/s.

5. (a) Consolidation curves for marine clay samples plotted on e log pc space and

(b ) Hydraulic conductivity, k plotted against log pc

1088

CONCLUSION

Geotechnical characterisation of marine clay deposit

was investigated for possible use as liner material. The

marine clay samples were classified as clayey silt with low

organic content. The fraction of the finer ranged between

78% and 88%, indicating appreciable quantity of fines

that are suitable for achieving the targeted low hydraulic

conductivity for liners. The XRD analysis showed the

presence of clay minerals of montmorillonite, kaolinite

and illite. The liquid and plastic limit ranged from 70%

to 79% and 42% and 44%, respectively. The plasticity

index ranged from 28 to 35 and these values are within

the recommended values for landfill liner materials.

Based on the Cassagrande chart, all marine clay samples

were classified as silt of high to very high plasticity. Even

samples were categorised below A-line, the required

permeability can be achieved if adequate compaction

effort is applied. The marine clays presented very low

permeability that ranged from 1.10 - 2.44 10-9 m/s which

corresponded with higher content of finer fraction of silt

and clay. Compaction of the marine clay samples achieved

maximum dry density ranging from 1.5 - 1.6 g/cm3 with

optimum moisture content that ranged from 18.2% 25%. The hydraulic conductivity of the marine clays also

dropped within the desired permeability of landfill liners

during consolidation. The results of this study showed that

the geotechnical characteristics of the studied marine clay

can potentially be used as landfill liner material.

ACKNOWLEDGEMENTS

The authors would like to thank Universiti Kebangsaan

Malaysia for the financial support under the research grants

UKM-GUP-2011-188 and UKM-ST-07-FRGS0022-2010.

The authors would also like to express their gratitude to the

laboratory staff at the School of Environmental and Natural

Resource Sciences, Faculty of Science and Technology,

UKM for sample preparation and testing.

REFERENCES

Ahn, H.S. & Jo, H.Y. 2009. Influence of exchangeable cations

on hydraulic conductivity of compacted-bentonite. Applied

Clay Science 44: 144-150.

Alamgir, M., McDonald, Ch., Roehl, K.E. & Ahsan, A. 2005.

Integrated management and safe disposal of municipal solid

waste in least developed Asian countries. A feasibility study.

Khulna University of Engineering and Technology, Khulna,

Bangladesh. p. 83.

Arasan, S. & Yetimoglu, T. 2006. Effect of leachate components

on the consistency limits of clay liners. 11th National Soil

Mechanic and Foundation Engineering Congress, Trabzon,

Turkey. pp. 439-445.

Arasan, S. 2010. Effect of chemicals on geotechnical properties of

clay liners: A review. Research Journal of Applied Sciences,

Engineering and Technology 2(8): 765-775.

Bagchi, A.C. 2004. Design of landfills and integrated solid waste

management. In Landfill Design. 3rd ed. United States of

America: Wiley and Sons.

Basack, S. & Purkayastha, R.D. 2009. Engineering properties

of marine clays from the eastern coast of India. Journal of

Engineering and Technology Research 1(6): 109-114.

Belloo, A.A. 2012. Geotechnical evaluation of reddish brown

tropical soils. Geotechnical and Geology Engineering

Journal 30: 481-498.

Benson, C.H. & Trast, J.M. 1995. Hydraulic conductivity of

thirteen compacted clays. Clays and Clay Minerals 43(6):

669-681.

Bjerrum, L. 1973. Problems of soil mechanics and construction

on soft clays: state of the art report. Proceedings 8th

International Conference on Soil Mechanics and Foundation

Engineering. Moscow, Russia

British Standard Institution 1377. 1990(a). Methods of Test for

Soil for Civil Engineering Purposes-Part 2: Classification

Tests. BS1377, London.

British Standard Institution 1377. 1990(b). Methods of Test for

Soil for Civil Engineering Purposes-Part 4: CompactionRelated Tests. BS1377, London.

British Standard Institution 1377. 1990(c). Methods of Test for

Soil for Civil Engineering Purposes-Part 5: Compressibility,

Permeability and Durability Tests. BS1377, London.

British Standard Institution 1377. 1990(d). Methods of Test for

Soil for Civil Engineering Purposes-Part 7: Shear Strength

Tests (Total Stress). BS1377, London.

Chalermyanont, T., Arrykul, S. & Charoenhaisong, N. 2008.

Potential use of lateritic and marine clay soils as landfill

liners to retain heavy metals. Waste Management 29: 117-127.

Chew, S.H., Kamrazzuman, H.M. & Lee, F.H. 2004.

Physicochemical and engineering behavior of cement

treated clays. Journal of Geotechnical and Geoenvironmental

Engineering ASCE 130(7): 696-706.

Chung, S.G., Ryu, C.K., Jo, K.Y. & Huh, D.Y. 2007. Geological

and geotechnical characteristics of marine clays at the Busan

new port. Marine Georesources and Geotechnology 23(3):

235-251.

Du, Y.J. & Hayashi, S. 2004. Some factors controlling the

adsorption of potassium ions on clayey soils. Applied Clays

Science 27: 209-231.

Department of Transport 1991. Specification for Highway Works.

HMSO, London.

Dias, C.R.R. & Alves, A.M.L. 2009. Geotechnical properties

of the Cassino Beach mud. Continental Shelf Research 29:

589-596.

EPA. 1990. Compilation of Information on Alternative Barriers

for Liner and Cover Systems. EPA600-R-91-002. Prepared

by Daniel, D.E. & Estornell, P.M. for Office of Research and

Development, Washington, DC.

Hyde, A.L., Yasuhara, K. & Hirao, K. 1993. Stability criteria

for marine clay under one-way cyclic loading. Journal of

Geotechnical Engineering ASCE 119(11): 1771-1789.

Islam, M.R., Alamgir, M., Mohiuddin, K.M. & Hasan, K.M.M.

2008. Investigation of physical properties of a selected soil to

use as a clay liner in sanitary landfill. Proceedings of National

Seminar on Solid Waste Management-WasteSafe. pp.167-174.

Itakura, T., Airey, D.W. & Dobrolot, J.Y.M. 2005. Geotechnical

characterisation of alluvial soils used to contain industrial

liquid wastes. Bulletin of Engineering Geology and

Environments 64: 273-285.

Jones, R.M., Murray, E.J. & Rix, D.W. 1993. Selection of clays for

use as landfill liners. Waste Disposal by Landfill. Proceedings

Symposium Green 93. pp. 433-438.

Kamon, M. & Katsumi, T. 2001. Clay liners for waste landfill. In

Clay Science for Engineering, edited by Adachi, K. & Fukue,

M. & Balkema, A.A. pp. 29-46.

Kooistra, J.M. & Tovey, N.K. 1994. Effects of compaction on

soil microstructure. In Soil Compaction in Crop Poduction.

Soane, B.D. & van Quwerkerk, C. Elsevier. pp. 91-111.

Long, M. & Menkiti, C.O. 2007. Geotecnical properties of Dublin

Boulder clay. Geotechnique 57(7): 595-611.

Means, R.E. & Parchers, J.V. 1963. Physical Properties of Soils.

Ihio: Merrill Book Inc. Columbus.

Mitchell, J.K. 1993. Fundamentals of Soil Behavior. 2nd ed. New

York: John Wiley & Sons.

Murray, E.J., Rix, D.W. & Humphrey, R.D. 1992. Clay lining

to landfill sites. Quarterly Journal of Engineering Geology

25(4): 371-376.

Ohtsubo, M., Egashira, K., Tanaka, H. & Mishima, O. 2002.

Clay minerals and geotechnical index properties of marine

clays in East Asia. Marine Georesources & Geotechnology

20(4): 223-235.

Pierce, J.W. & Siegel, F.R. 1969. Quantification in clay minerals

studies of sediment and sedimentary rock. Journal of

Sediment Petrology 9: 187-193.

Rao, D.K., Raju, R.P., Sowjanya, C. & Rao, P. 2009. Laboratory

studies on the properties of stabilised marine clay from

Kakinada Sea, Coast India. International Journal of

Engineering Science and Technology 3(1): 422-428.

Rao, D.K., Raju, R.P. & Kumar, R.A. 2011. Consolidation

characteristics of treated marine clay for foundation bed soils.

International Journal of Engineering Science and Technology

3(2): 788-796.

Rominger, J.F. & Rutledge, P.C. 1952. Use of soil mechanics data

in correlation and interpretation of Lake Aggassiz sediments.

Journal of Geology 60(2): 160-180.

Sridharan, A., Rao, P.R. & Miura, N. 2004. Characterization

of Ariake and other marine clays. In Proceedings of

International Symposium of Lowland Technology 1: 53-58.

Suneel, M., Park, L.K. & Im, J.C. 2008. Compressibility

characteristics of Korean marine clay. Marine Georesources

& Geotechnology 26(2): 111-127.

1089

Taha, M.T., Ahmed, J. & Asmirza, S. 2000. One-dimensional

consolidation of Kelang clay. Pertanika Journal Science &

Technology 8(1): 19-29.

Tan, T.S., Goh, T.L. & Yong, K.Y. 2002. Properties of Singapore

marine clay improved by cement mixing. Geotechnical

Testing Journal 25(4): 1-11.

Terzaghi, K., Peck, R. & Mesri, G. 1996. Soil Mechanics in

Engineering Practice. 3rd ed. New York: Wiley-Interscience,

John Wiley and Sons, Inc.

Van Imple, W.F. 1998. Environmental Geotechnics: ITC5

Activities-State of Art. In Proceedings of the 3rd International

Congress on Enviromental Geotechnics pp.1163-1187.

Yilmaz, I. 2000. Evaluation of shear strength of clayey soils by

using their liquidity index. Bulletin of Engineering. Geology

and Environments 59: 227229.

Yong, R.N., Tan, B.K., Bently, S.P., Thomas, H.R., Yaacob,

W.Z.W. & Hashim, A. 1998. Assessment of attenuational

capability of two clay soils via leaching column test.

In: Proceedings of the 3 rd International Congress on

Enviromental Geotechnics. 503-308.

Yong, R.N. & Phadungchewit, Y. 1993. pH influence on

selectively and retention of heavy metals in some clay soils.

Canadian Geotechnical Journal 30: 821-833.

School Environmental & Natural Resource Sciences

Faculty of Science and Technology

Universiti Kebangsaan Malaysia

Bangi 43600 Selangor D.E.

Malaysia

*Corresponding author; email: zarah1970@ukm.my

Received: 18 July 2012

Accepted: 22 February 2013

You might also like

- Reservoir Characterization of Tight Gas Sandstones: Exploration and DevelopmentFrom EverandReservoir Characterization of Tight Gas Sandstones: Exploration and DevelopmentNo ratings yet

- Utilization of Lime For Stabilizing Soft Clay Soil of High Organic ContentDocument25 pagesUtilization of Lime For Stabilizing Soft Clay Soil of High Organic ContentLarisa ChindrișNo ratings yet

- Soil Physical Measurement and Interpretation for Land EvaluationFrom EverandSoil Physical Measurement and Interpretation for Land EvaluationNo ratings yet

- 1 s2.0 S0038080620316693 MainDocument11 pages1 s2.0 S0038080620316693 MainInácio RibeiroNo ratings yet

- 05 R. ZulfahmiDocument10 pages05 R. ZulfahmiIvit SulastriNo ratings yet

- Geotechnical Characteristics of Coal Mine Spoil - FityusDocument10 pagesGeotechnical Characteristics of Coal Mine Spoil - FityusCharlie YoungNo ratings yet

- Experimental Investigations of The Wettability of Clays and ShalesDocument11 pagesExperimental Investigations of The Wettability of Clays and Shalesadib wahyuNo ratings yet

- Hydrodynamic Evaluation of A Filter Bed of Porous Material From Stratified Sedimentary Rocks For The Removal of Turbidity in Surface WatersDocument9 pagesHydrodynamic Evaluation of A Filter Bed of Porous Material From Stratified Sedimentary Rocks For The Removal of Turbidity in Surface WatersjcbobedaNo ratings yet

- Engineering Characteristics of Sand-Clay Mixtures Used For Clay Cores of Earth-Fill DamsDocument8 pagesEngineering Characteristics of Sand-Clay Mixtures Used For Clay Cores of Earth-Fill DamsKarwan AhmedNo ratings yet

- Mallick-Mishra2017 Article EvaluationOfClinkerStabilizedFDocument16 pagesMallick-Mishra2017 Article EvaluationOfClinkerStabilizedFCHRISTIAN ARIZA GOMEZNo ratings yet

- Dynamic Characteristics of Lime-Treated Expansive Soil Under Cyclic LoadingDocument8 pagesDynamic Characteristics of Lime-Treated Expansive Soil Under Cyclic LoadingDhiraj BarpandaNo ratings yet

- An Empirical Model For Predicting Hydraulic ConducDocument9 pagesAn Empirical Model For Predicting Hydraulic ConducFernando Andrés Ortega JiménezNo ratings yet

- Assessment of Beach Sand As Lateritic Soil StabilizerDocument11 pagesAssessment of Beach Sand As Lateritic Soil StabilizerElaMazlanNo ratings yet

- Evaluation of Clinker Stabilized Fly AshDocument18 pagesEvaluation of Clinker Stabilized Fly AshManoj Kumar MishraNo ratings yet

- Characterization and Viability of Clay Soils From Metro Manila As Lanfill Liners - Acebedo, PerdonDocument5 pagesCharacterization and Viability of Clay Soils From Metro Manila As Lanfill Liners - Acebedo, PerdonRalph100% (2)

- Partial Replacement of River Sand With Volcanic Pyroclastics As Fine Aggregates in Concrete ProductionDocument5 pagesPartial Replacement of River Sand With Volcanic Pyroclastics As Fine Aggregates in Concrete ProductionJeriel PacerNo ratings yet

- Frankincense ProjectDocument15 pagesFrankincense ProjectOkpalannebuaku Augustine EkeneNo ratings yet

- Applied Clay Science: Abdulrahman Aldaood, Marwen Bouasker, Muzahim Al-MukhtarDocument11 pagesApplied Clay Science: Abdulrahman Aldaood, Marwen Bouasker, Muzahim Al-MukhtarGonçalo SonaglioNo ratings yet

- Taghvaei2018 Article ExperimentalAndNumericalModeliDocument8 pagesTaghvaei2018 Article ExperimentalAndNumericalModeliPriya RajanNo ratings yet

- AP Building Rules-2017Document12 pagesAP Building Rules-2017Somesh KurellaNo ratings yet

- A Review On The Geotechnical and Engineering Characteristics 1ini0ym8mqDocument7 pagesA Review On The Geotechnical and Engineering Characteristics 1ini0ym8mqYi Sun ShinNo ratings yet

- Chapter 2 Fyp Nur HanimDocument11 pagesChapter 2 Fyp Nur HanimNUR HANIM SURAYA BINTI MIANNo ratings yet

- A Review On The Geotechnical and Engineering Characteristics of Marine Clay and The Modern Methods of ImprovementsDocument8 pagesA Review On The Geotechnical and Engineering Characteristics of Marine Clay and The Modern Methods of ImprovementsATHIRA K RAJANNo ratings yet

- Geotechnical and Environmental Evaluation of Lime-CementDocument12 pagesGeotechnical and Environmental Evaluation of Lime-CementferraNo ratings yet

- CONFERENCE Direct Shear Strength Properties of Limestone-Blended PDFDocument6 pagesCONFERENCE Direct Shear Strength Properties of Limestone-Blended PDFbagus yosan setiawanNo ratings yet

- Characterization Study On The Influence of Limestone and Shell Lime As A Fine Aggregate Substitute A Traditional Approach On Lime Plaster RestorationDocument8 pagesCharacterization Study On The Influence of Limestone and Shell Lime As A Fine Aggregate Substitute A Traditional Approach On Lime Plaster Restorationelmer cervantesNo ratings yet

- Efects of Inhibitor KCL On Hydration SwellingDocument8 pagesEfects of Inhibitor KCL On Hydration SwellingMoustafa AbdouNo ratings yet

- Suction Swell Relationship of Stabilized Expansive Soil IJERTV8IS110137Document10 pagesSuction Swell Relationship of Stabilized Expansive Soil IJERTV8IS110137saleh hashishNo ratings yet

- Aop 3815Document8 pagesAop 3815UshaNo ratings yet

- The Retention Characteristics of Heavy Metals in Natural Soils Using Soil Column ExperimentDocument8 pagesThe Retention Characteristics of Heavy Metals in Natural Soils Using Soil Column ExperimentGloria YongNo ratings yet

- Compressibility and Collapsibility of Dune Soil in Tikrit CityDocument8 pagesCompressibility and Collapsibility of Dune Soil in Tikrit Cityal.baidhani7471No ratings yet

- Effects of Soldier-Ant Mound On The Strength of Lateritic Clay SoilsDocument12 pagesEffects of Soldier-Ant Mound On The Strength of Lateritic Clay SoilsADEYEMI ADEBOJENo ratings yet

- Diavik Waste Rock Project: Unsaturated Water FlowDocument10 pagesDiavik Waste Rock Project: Unsaturated Water FlowEduardo Alemany PerretNo ratings yet

- RTR CriteriaDocument11 pagesRTR CriteriaHunegnaw AynalemNo ratings yet

- Pindan Sand Properties StudyDocument15 pagesPindan Sand Properties Studyganguly147147No ratings yet

- A Review On The Geotechnical and Engineering Characteristics of Marine Clay and The Modern Methods of ImprovementsDocument8 pagesA Review On The Geotechnical and Engineering Characteristics of Marine Clay and The Modern Methods of ImprovementsOrozco DairoNo ratings yet

- Applied Clay Science: Abdulrahman Aldaood, Marwen Bouasker, Muzahim Al-MukhtarDocument11 pagesApplied Clay Science: Abdulrahman Aldaood, Marwen Bouasker, Muzahim Al-MukhtarIzuara BeckmannNo ratings yet

- Engineering Properties of Marine Clays From The Ea PDFDocument7 pagesEngineering Properties of Marine Clays From The Ea PDFOrozco DairoNo ratings yet

- Engineering Properties of Marine Clays From The EaDocument7 pagesEngineering Properties of Marine Clays From The EaOrozco DairoNo ratings yet

- 10.1007@s12517 020 05287 WDocument11 pages10.1007@s12517 020 05287 WArunavNo ratings yet

- Cement and Lime Stabilization of A NigerianDocument9 pagesCement and Lime Stabilization of A NigerianVidhu KrishnanNo ratings yet

- Characterization and Origin of Weathering Crusts On Kylin Carved-Stone, Kylin Countryside, Nanjing - A Case StudyDocument5 pagesCharacterization and Origin of Weathering Crusts On Kylin Carved-Stone, Kylin Countryside, Nanjing - A Case StudyIS AANo ratings yet

- Geochemical and Geotechnical Appraisal of The Regolith Along Ado-Ilawe Road, Ekiti State, Nigeria For Engineering ConstructionDocument8 pagesGeochemical and Geotechnical Appraisal of The Regolith Along Ado-Ilawe Road, Ekiti State, Nigeria For Engineering ConstructionIJASRETNo ratings yet

- Meador, Layher - Unknown - Instream Sand and Gravel Mining Environmental Issues and Regulatory Process in The United StatesDocument8 pagesMeador, Layher - Unknown - Instream Sand and Gravel Mining Environmental Issues and Regulatory Process in The United StatesClaudio Esteban GodoyNo ratings yet

- Black Cotton Soil Stabilization by Using Fly Ash - Kota Stone Slurry MixDocument7 pagesBlack Cotton Soil Stabilization by Using Fly Ash - Kota Stone Slurry MixIJRASETPublicationsNo ratings yet

- 10 1016@j Matpr 2020 01 384Document8 pages10 1016@j Matpr 2020 01 384Geeta JiraliNo ratings yet

- 2015.10.24, Rock Durability Tests (DMI TEST Etc) PDFDocument31 pages2015.10.24, Rock Durability Tests (DMI TEST Etc) PDFkyuguNo ratings yet

- Assessment of Critical State Shear Strength Properties of Copper TailingsDocument7 pagesAssessment of Critical State Shear Strength Properties of Copper TailingsBrahian Roman CabreraNo ratings yet

- Chapter 2 (Pre-Final)Document10 pagesChapter 2 (Pre-Final)Nathanniel Pogado GonzalesNo ratings yet

- Toll, D.G. - Soil-water-retention-behaviour-for-an-instrumented-embankmentConference-Paper - 2016Document4 pagesToll, D.G. - Soil-water-retention-behaviour-for-an-instrumented-embankmentConference-Paper - 2016Avishek NepbloodNo ratings yet

- 2006 Andrina BCDocument15 pages2006 Andrina BCRodrigo Alarcón VásquezNo ratings yet

- 3 Thusyanthan World Conference 2004Document14 pages3 Thusyanthan World Conference 2004Dr I ThusyanthanNo ratings yet

- Geotechnical and Mineralogical Characteristics of Marl Deposits in JordanDocument8 pagesGeotechnical and Mineralogical Characteristics of Marl Deposits in Jordanali jamiilNo ratings yet

- Niger Delta Case StudyDocument6 pagesNiger Delta Case Studymmmd.krmv.00No ratings yet

- Petrology and Diamonds 1996Document1 pagePetrology and Diamonds 1996Johana Paola GrandeNo ratings yet

- Science of The Total EnvironmentDocument9 pagesScience of The Total Environmenttayour007No ratings yet

- Effect of Compaction Conditions On The Hydraulic and Compressibility Behaviour of Fly Ash - Bentonite MixturesDocument28 pagesEffect of Compaction Conditions On The Hydraulic and Compressibility Behaviour of Fly Ash - Bentonite MixturesIOSRjournalNo ratings yet

- Compaction Behaviour of Lateritic Soil-Calcium Chloride MixturesDocument20 pagesCompaction Behaviour of Lateritic Soil-Calcium Chloride Mixturesbakhtiar Al-BarzinjiNo ratings yet

- Shear Strength, Collapsibility and Compressibility Characteristics of Compacted Baiji Dune SoilsDocument13 pagesShear Strength, Collapsibility and Compressibility Characteristics of Compacted Baiji Dune SoilsIshak GoudjilNo ratings yet

- Case StudyDocument12 pagesCase StudyAlexNo ratings yet

- KAPOW Consulting AgreementDocument11 pagesKAPOW Consulting AgreementJayson TeeNo ratings yet

- Loveless City WL 3k ClubDocument1 pageLoveless City WL 3k ClubJayson TeeNo ratings yet

- Onlysnipers Final WL - Sheet1Document31 pagesOnlysnipers Final WL - Sheet1Jayson TeeNo ratings yet

- Sweep The Floor Challenge 9 Feb 2022Document4 pagesSweep The Floor Challenge 9 Feb 2022Jayson TeeNo ratings yet

- Copy of Copy of Whitelist Platoon DAO ResponsesDocument8 pagesCopy of Copy of Whitelist Platoon DAO ResponsesJayson TeeNo ratings yet

- Aki Story Whitepaper v1Document9 pagesAki Story Whitepaper v1Jayson TeeNo ratings yet

- Phase 1 Mint WalletsDocument5 pagesPhase 1 Mint WalletsJayson TeeNo ratings yet

- Aluminum 6063Document1 pageAluminum 6063이영준No ratings yet

- Price List: Jadual Kadar Sewa Loji 2003Document9 pagesPrice List: Jadual Kadar Sewa Loji 2003nik arif100% (3)

- Company Profile: Kenwa-Micom SDN BHDDocument3 pagesCompany Profile: Kenwa-Micom SDN BHDJayson TeeNo ratings yet

- TS 75 VDocument1 pageTS 75 Vmercab15No ratings yet

- Edm24nii 30nii CatalogDocument6 pagesEdm24nii 30nii CatalogJayson TeeNo ratings yet

- FWCMS Equota - Document List - Ver1.3Document1 pageFWCMS Equota - Document List - Ver1.3Jayson TeeNo ratings yet

- Chapter3 - Basic StructureDocument26 pagesChapter3 - Basic StructureJayson TeeNo ratings yet

- Load CalculationDocument108 pagesLoad Calculationvpshreekanth71% (14)

- USF-Fab (Floor Access Panel)Document92 pagesUSF-Fab (Floor Access Panel)Jayson TeeNo ratings yet

- PTFE Resin CoatingDocument2 pagesPTFE Resin CoatingJayson TeeNo ratings yet

- PWD ContractDocument54 pagesPWD ContractRajesh NagarajanNo ratings yet

- Access Panels & Floor DoorDocument12 pagesAccess Panels & Floor DoorJayson TeeNo ratings yet

- Upah Machine OperatorDocument2 pagesUpah Machine OperatorNia ZainorinNo ratings yet

- What Are Preliminaries and How To Evaluate ThemDocument11 pagesWhat Are Preliminaries and How To Evaluate Themplanning5No ratings yet

- Malaysia Green Building Technologies - Perspective & InitiativesDocument14 pagesMalaysia Green Building Technologies - Perspective & InitiativesAsrul Azhar Abd RahmanNo ratings yet

- UpahMachineOperatorjan12 SemenanjungDocument2 pagesUpahMachineOperatorjan12 SemenanjungNurul HusnaNo ratings yet

- Summary Average Price Sabah Ok T 09Document12 pagesSummary Average Price Sabah Ok T 09Jayson TeeNo ratings yet

- Average Price of M&E Component For M&E Works: MARCH 2011Document25 pagesAverage Price of M&E Component For M&E Works: MARCH 2011Jayson TeeNo ratings yet

- Upah Machine Operator Jan 12 - SarawakuploadDocument2 pagesUpah Machine Operator Jan 12 - SarawakuploadRipalo CalNo ratings yet

- Upah Machine Operator Jan 12 - SemenanjunguploadDocument8 pagesUpah Machine Operator Jan 12 - SemenanjunguploadJayson TeeNo ratings yet

- Upah Machine Operator Jan 12 - SabahuploadDocument2 pagesUpah Machine Operator Jan 12 - SabahuploadJayson TeeNo ratings yet

- Summary Average Prices M Jan 09Document16 pagesSummary Average Prices M Jan 09Nyu123456No ratings yet

- JANUARY 2011: Average Price of M&E Component For M&E WorksDocument25 pagesJANUARY 2011: Average Price of M&E Component For M&E WorksJayson TeeNo ratings yet

- 5.FDR BookletDocument80 pages5.FDR BookletSourabh PalNo ratings yet

- Cruciform Construction ManualDocument37 pagesCruciform Construction ManualDipak BorsaikiaNo ratings yet

- New Microsoft Word DocumentDocument4 pagesNew Microsoft Word DocumentVinothan VasavanNo ratings yet

- Analysis and Design of Box Culverts: Unllje8Sity LibraryDocument113 pagesAnalysis and Design of Box Culverts: Unllje8Sity LibraryAhmed AjelNo ratings yet

- Parámetros en GeotecniaDocument20 pagesParámetros en Geotecniahad18052010No ratings yet

- Wyong Road Enviro Factors Appendix PDocument314 pagesWyong Road Enviro Factors Appendix PAniculaesi MirceaNo ratings yet

- Planning Document - Bhavnagar Chimney (Revised)Document40 pagesPlanning Document - Bhavnagar Chimney (Revised)Anand Yatri100% (1)

- Stability Properties of Uncured Lime-Treated Fine-Grained SoilsDocument7 pagesStability Properties of Uncured Lime-Treated Fine-Grained SoilsRahaf GcNo ratings yet

- Utilization of Recycled Concrete Aggregates For Light-Stabilization of Clay SoilsDocument11 pagesUtilization of Recycled Concrete Aggregates For Light-Stabilization of Clay SoilsApoorva AgarwalNo ratings yet

- Chapter 4: Soil CompactionDocument16 pagesChapter 4: Soil Compactionحسين عمران محيسنNo ratings yet

- A Review of The Code of Practice For Laying Precast Concrete Paving Blocks and Clay Pavers For Flexible Pavements BS 7533-3 2003Document9 pagesA Review of The Code of Practice For Laying Precast Concrete Paving Blocks and Clay Pavers For Flexible Pavements BS 7533-3 2003Bolanle OlaawoNo ratings yet

- c7-10 Construction of Estate Roads, Driveways and FootwaysDocument22 pagesc7-10 Construction of Estate Roads, Driveways and FootwaysJacky TiongNo ratings yet

- Roads 1Document42 pagesRoads 1Musiime AlvinNo ratings yet

- FYP 1 Interim ReportDocument29 pagesFYP 1 Interim ReportOdu Paul DukuNo ratings yet

- DSR Book Vol 2 2016 (English Version) FinalDocument8 pagesDSR Book Vol 2 2016 (English Version) Finalamit singhNo ratings yet

- Stabilization of Colombian Lateritic Soil With A Hydrophobic Compound (Organosilane)Document8 pagesStabilization of Colombian Lateritic Soil With A Hydrophobic Compound (Organosilane)Mohammad Asad FirdausNo ratings yet

- Density TestDocument41 pagesDensity TestAlbyNo ratings yet

- Earthworks PDFDocument8 pagesEarthworks PDFخـޢޢـطـޢޢـ آحـޢޢـمـޢޢـرNo ratings yet

- Application of The Rapid Impact Compaction TechniqueDocument13 pagesApplication of The Rapid Impact Compaction TechniqueuygarkoprucuNo ratings yet

- Agglomeration Handbook PDFDocument52 pagesAgglomeration Handbook PDFSARAVANANNo ratings yet

- Asphalt Institute MS2 - 6th Edition PDFDocument147 pagesAsphalt Institute MS2 - 6th Edition PDFDeven Patle75% (4)

- 10 Prediction of Resilient Modulus From Soil Index PropertiesDocument71 pages10 Prediction of Resilient Modulus From Soil Index PropertiesAynup IrahtakNo ratings yet

- 2-MS For Soft Ground TreatmentDocument18 pages2-MS For Soft Ground TreatmentsurangaNo ratings yet

- CH 5 Earthwork and QuantificationDocument43 pagesCH 5 Earthwork and QuantificationZeleke Taimu0% (1)

- Lessons Learned From Wall Failure - Ts1097Document2 pagesLessons Learned From Wall Failure - Ts109718926119No ratings yet

- Rapid Impact CompactorDocument10 pagesRapid Impact CompactorSuneel MatchalaNo ratings yet

- Pile FoundationsDocument8 pagesPile FoundationsOtep TimusNo ratings yet

- Embankment & Sub-Grade LayerDocument9 pagesEmbankment & Sub-Grade LayerPathankot MandiNo ratings yet

- Geotech Practice-Problems CE2024Document7 pagesGeotech Practice-Problems CE2024Zina CabreraNo ratings yet

- Chapter 1 Part 1 EarthworkDocument50 pagesChapter 1 Part 1 EarthworknnsNo ratings yet

- The Age of Magical Overthinking: Notes on Modern IrrationalityFrom EverandThe Age of Magical Overthinking: Notes on Modern IrrationalityRating: 4 out of 5 stars4/5 (29)

- ADHD is Awesome: A Guide to (Mostly) Thriving with ADHDFrom EverandADHD is Awesome: A Guide to (Mostly) Thriving with ADHDRating: 5 out of 5 stars5/5 (2)

- By the Time You Read This: The Space between Cheslie's Smile and Mental Illness—Her Story in Her Own WordsFrom EverandBy the Time You Read This: The Space between Cheslie's Smile and Mental Illness—Her Story in Her Own WordsNo ratings yet

- LIT: Life Ignition Tools: Use Nature's Playbook to Energize Your Brain, Spark Ideas, and Ignite ActionFrom EverandLIT: Life Ignition Tools: Use Nature's Playbook to Energize Your Brain, Spark Ideas, and Ignite ActionRating: 4 out of 5 stars4/5 (404)

- Summary: The Psychology of Money: Timeless Lessons on Wealth, Greed, and Happiness by Morgan Housel: Key Takeaways, Summary & Analysis IncludedFrom EverandSummary: The Psychology of Money: Timeless Lessons on Wealth, Greed, and Happiness by Morgan Housel: Key Takeaways, Summary & Analysis IncludedRating: 5 out of 5 stars5/5 (81)

- The Ritual Effect: From Habit to Ritual, Harness the Surprising Power of Everyday ActionsFrom EverandThe Ritual Effect: From Habit to Ritual, Harness the Surprising Power of Everyday ActionsRating: 3.5 out of 5 stars3.5/5 (3)

- Raising Good Humans: A Mindful Guide to Breaking the Cycle of Reactive Parenting and Raising Kind, Confident KidsFrom EverandRaising Good Humans: A Mindful Guide to Breaking the Cycle of Reactive Parenting and Raising Kind, Confident KidsRating: 4.5 out of 5 stars4.5/5 (170)

- Love Life: How to Raise Your Standards, Find Your Person, and Live Happily (No Matter What)From EverandLove Life: How to Raise Your Standards, Find Your Person, and Live Happily (No Matter What)No ratings yet

- The Obesity Code: Unlocking the Secrets of Weight LossFrom EverandThe Obesity Code: Unlocking the Secrets of Weight LossRating: 4 out of 5 stars4/5 (6)

- Raising Mentally Strong Kids: How to Combine the Power of Neuroscience with Love and Logic to Grow Confident, Kind, Responsible, and Resilient Children and Young AdultsFrom EverandRaising Mentally Strong Kids: How to Combine the Power of Neuroscience with Love and Logic to Grow Confident, Kind, Responsible, and Resilient Children and Young AdultsRating: 5 out of 5 stars5/5 (1)

- Think This, Not That: 12 Mindshifts to Breakthrough Limiting Beliefs and Become Who You Were Born to BeFrom EverandThink This, Not That: 12 Mindshifts to Breakthrough Limiting Beliefs and Become Who You Were Born to BeRating: 2 out of 5 stars2/5 (1)

- Summary: Outlive: The Science and Art of Longevity by Peter Attia MD, With Bill Gifford: Key Takeaways, Summary & AnalysisFrom EverandSummary: Outlive: The Science and Art of Longevity by Peter Attia MD, With Bill Gifford: Key Takeaways, Summary & AnalysisRating: 4.5 out of 5 stars4.5/5 (42)

- Mindset by Carol S. Dweck - Book Summary: The New Psychology of SuccessFrom EverandMindset by Carol S. Dweck - Book Summary: The New Psychology of SuccessRating: 4.5 out of 5 stars4.5/5 (328)

- Outlive: The Science and Art of Longevity by Peter Attia: Key Takeaways, Summary & AnalysisFrom EverandOutlive: The Science and Art of Longevity by Peter Attia: Key Takeaways, Summary & AnalysisRating: 4 out of 5 stars4/5 (1)

- Why We Die: The New Science of Aging and the Quest for ImmortalityFrom EverandWhy We Die: The New Science of Aging and the Quest for ImmortalityRating: 4 out of 5 stars4/5 (5)

- Dark Psychology & Manipulation: Discover How To Analyze People and Master Human Behaviour Using Emotional Influence Techniques, Body Language Secrets, Covert NLP, Speed Reading, and Hypnosis.From EverandDark Psychology & Manipulation: Discover How To Analyze People and Master Human Behaviour Using Emotional Influence Techniques, Body Language Secrets, Covert NLP, Speed Reading, and Hypnosis.Rating: 4.5 out of 5 stars4.5/5 (110)

- Summary: Limitless: Upgrade Your Brain, Learn Anything Faster, and Unlock Your Exceptional Life By Jim Kwik: Key Takeaways, Summary and AnalysisFrom EverandSummary: Limitless: Upgrade Your Brain, Learn Anything Faster, and Unlock Your Exceptional Life By Jim Kwik: Key Takeaways, Summary and AnalysisRating: 5 out of 5 stars5/5 (8)

- To Explain the World: The Discovery of Modern ScienceFrom EverandTo Explain the World: The Discovery of Modern ScienceRating: 3.5 out of 5 stars3.5/5 (51)

- When the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisFrom EverandWhen the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisRating: 3.5 out of 5 stars3.5/5 (2)

- The Body Keeps the Score by Bessel Van der Kolk, M.D. - Book Summary: Brain, Mind, and Body in the Healing of TraumaFrom EverandThe Body Keeps the Score by Bessel Van der Kolk, M.D. - Book Summary: Brain, Mind, and Body in the Healing of TraumaRating: 4.5 out of 5 stars4.5/5 (266)

- The Marshmallow Test: Mastering Self-ControlFrom EverandThe Marshmallow Test: Mastering Self-ControlRating: 4.5 out of 5 stars4.5/5 (58)

- Cult, A Love Story: Ten Years Inside a Canadian Cult and the Subsequent Long Road of RecoveryFrom EverandCult, A Love Story: Ten Years Inside a Canadian Cult and the Subsequent Long Road of RecoveryRating: 4 out of 5 stars4/5 (45)

- The Courage Habit: How to Accept Your Fears, Release the Past, and Live Your Courageous LifeFrom EverandThe Courage Habit: How to Accept Your Fears, Release the Past, and Live Your Courageous LifeRating: 4.5 out of 5 stars4.5/5 (253)