Professional Documents

Culture Documents

Health Hazard of Welding

Uploaded by

ajuhaseenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Health Hazard of Welding

Uploaded by

ajuhaseenCopyright:

Available Formats

Health Hazards Of Welding

GENERAL

Welding joins pieces of metal by the use of heat,

pressure, or both. Brazing, or soldering, involves a

filler metal or alloy (a combination of metals) which has

a lower melting point than the metal pieces to be

joined.

Many farms have maintenance shops where welding

may be performed.

There are many different types of welding and

associated processes. Some of the most common types

of welding include: arc welding, which includes "stick",

or shielded metal arc welding (SMAW), the gasshielded methods of metal inert gas (MIG) and

tungsten inert gas (TIG), plasma arc welding (PAW),

and submerged arc welding (SAW). Other welding

processes may use oxy-acetylene gas, electrical

current, lasers, electron beams, friction, ultrasonic

sound, chemical reactions, heat from fuel gas, and

robots.

one micron or smaller, and may join together to form

larger particles. The adverse health effects of

overexposure to welding fumes and gases include

chronic or acute systemic poisoning, metal fume fever

(a short-term painful ailment with symptoms of fever

and chills), pneumoconiosis (lung disease due to

accumulation of mineral or metallic particles), and

irritation of the respiratory tract. Generally, welding

fumes and gases come from:

The base material being welded or the filler material

that is used;

Coatings and paints on the metal being welded, or

coatings covering the electrode;

Shielding gases supplied from cylinders;

Chemical reactions which result by the action of

ultraviolet light from the arc, and heat;

Process and consumables used; and contaminants

Welding, thermal cutting, and associated processes

may produce airborne contaminants, such as fumes,

gases, vapors, dust, mists, and physical hazards such

as radiant energy, heat, and noise.

HEALTH HAZARDS

SOURCES OF EXPOSURE

Chemical Hazards

The potential hazards of welding operations include

metal fumes, toxic gases, and ultraviolet and infrared

radiation. Fume particles are formed from vaporization

of molten metal. They are very fine in size, generally

The welding fumes produced at welding operations

depend primarily on the composition of the metals

being welded and the welding rods. When the base

metal is iron or steel, with welding rods of similar

composition the main component of the fume will be

iron oxide. When welding on stainless steel, fumes

containing nickel and chromium may be produced.

Welding on plated, galvanized, or painted metals may

generate fumes containing cadmium, zinc oxide, or

lead. In addition, welding rods can generate fluoride in

the fume as well as free silica, depending on the

composition of the welding rod coating. In summary,

The Experienced

Workers

Compensation

Specialist

in the air, for example vapors from cleaners and

degreasers.

RM129AG 1

welding processes may generate many different metal

fumes and other toxic components. It is important that

the hazards of a welding operation be evaluated

properly. Toxic gases that arise in welding include

carbon monoxide, nitrogen dioxides, and ozone. If

welding or cutting operations are conducted in the

presence of chlorinated hydrocarbons (solvents) either

on the metals or in the air, hazardous concentrations of

phosgene and hydrogen chloride, which are highly

toxic irritant gases, may be produced. The health

effects of welding exposures are specific to the

materials used and created during the welding process.

Some common metals and other chemicals are listed

on the tables at the end of this document.

PHYSICAL HAZARDS

Heat - Excessive exposure to heat can result in heat

stress or heat stroke. Symptoms include fatigue,

dizziness, loss of appetite, nausea, abdominal pain, and

irritability. Ventilation, shielding, rest breaks, and

frequent drinks will protect against heat-related

hazards. For information on heat stress, see RMB #11,

Preventing Heat Stress.

Ultraviolet radiation - Exposure to ultraviolet light

can cause skin burns similar to sunburn, and increase

the welder's risk of skin cancer.

Noise - Exposure to loud noise can permanently

damage welders' hearing. Noise also causes stress and

increased blood pressure, and may contribute to heart

disease. Working in a noisy environment for long

periods of time can make workers tired, nervous, and

irritable. For information on noise, see RMB #7,

Occupational Noise Exposure.

SPECIAL HAZARDS HAZARDS OF WELDING IN

CONFINED SPACES

A confined space is a small or crowded area with

limited access and little or no air flow or ventilation.

Adequate ventilation is essential for working in

confined spaces. Dangerous concentrations of toxic

fumes and gases can build up very quickly in a small

space. Unconsciousness or death from suffocation can

occur rapidly because welding processes can use up or

displace oxygen in the air. High concentrations of some

fumes and gases can also be very explosive.

All workers who may enter confined spaces either on a

regular basis or in an emergency situation should be

trained in appropriate confined space entry procedures,

and should work within the requirements of a written

confined space entry program.

WORKPLACE CONTROLS

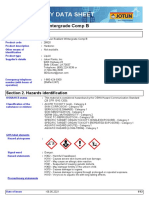

Before beginning a welding job, it is important to

identify the hazards for that particular welding

operation. The hazards will depend on the type of

welding, the materials (base metals, surface coatings,

electrodes) to be welded, and the environmental

conditions (outside or in a confined space, for

instance). The material safety data sheets (MSDSs)

will identify the hazardous materials used in welding

and cutting products, and the fumes that may be

generated. After identifying the hazard, appropriate

control methods can be implemented.

ENGINEERING CONTROLS

Ventilation should be used to remove harmful fumes

and gases. Local exhaust ventilation, which removes

the fumes and gases at their source, is the most

effective method. This can be provided by a partial

enclosure, such as a ventilated work bench, or by

hoods positioned as close to the point of welding as

possible. Mobile ventilation units are useful for welding

jobs which are not at a fixed location. General

ventilation, which uses roof vents, open doors and

windows, roof fans, or floor fans to move air through

the entire work area is not as effective as local exhaust

ventilation, and may simply spread chemicals around

the workplace. General ventilation is often helpful,

however, when used to supplement local ventilation.

Substitution of hazardous materials for less hazardous

materials, e.g., use of cadmium-free silver solders is

also an effective control method.

WORK PRACTICES

Modification of the work process and following safe

work practices can eliminate or reduce health hazards.

RM129AG 2

For example:

Avoid welding on painted or coated parts by

removing all surface coatings before welding.

Take a position while welding or cutting so that the

head is not in the fumes.

Minimize the production of welding fumes by using

the lowest acceptable amperage and holding the

electrode perpendicular and as close to the work

surface and possible.

Avoid arc welding within 200 feet of degreasing

equipment or solvents.

PERSONAL PROTECTIVE EQUIPMENT (PPE)

Personal protective equipment should always be used

along with, but never instead of, engineering controls

and safe work practices. PPE commonly used in

welding operations include:

Welding helmets, goggles, or other eye protectors

must contain special filter plates or lenses for

workers exposed to arc welding or cutting

processes, oxyfuel gas welding, brazing, or cutting.

general ventilation must be provided to keep exposure

to toxic fumes, gases, or dusts less than the

established exposure limits.

Exposure limits specified by OSHA are regulatory, but

other non-regulatory exposure limits are set by other

organizations, such as the American Conference of

Governmental Industrial Hygienists (ACGIH) Threshold

Limit Value (TLV) and the National Institute for

Occupational Safety and Health (NIOSH)

Recommended Exposure Limit (REL). Although the

non-regulatory limits are not required by law, they are

generally accepted as reflective of current research on

levels necessary to prevent illness.

The National Institute for Occupational Safety and

Health (NIOSH) has concluded that welders may be

harmed by welding fume even when the concentrations

of the individual components are less than workplace

exposure limits.

NIOSH recommends that welding emissions be reduced

to the lowest feasible concentrations using state-ofthe-art engineering controls and work practices. Air

monitoring can be conducted to determine whether

levels of any materials present a health hazard.

For further information or assistance, contact your

Zenith Safety & Health Consultant.

Hearing protectors (ear plugs or ear muffs) should

be used during noisy operations such as air arcing

and grinding.

Respiratory protection should be used when

engineering and work practice controls are not enough

to reduce exposure. To be effective, a respiratory

protection program should be in place and followed.

For information on respiratory protection, see RMB

#110, Establishing A Respirator Program.

WORKPLACE EXPOSURE LIMITS

There are no exposure limits for total welding fume,

but limits for the individual components of the fume

and for associated gases are available. Local exhaust or

RM129AG 3

Where Found

Health Hazards

Aluminum component of some alloys, e.g.,

Inconels, copper, zinc, steel, magnesium,

brass

Hardening agent found in copper,

magnesium, aluminum alloys and electrical

contacts

Silver solders, rust preventive coatings,

alloying element

Most stainless steel and high-alloy

materials, welding rods, plating material

Respiratory irritant

Alloys such as Monel, brass, bronze;

welding rods

Main component in all steel

Irritation of eyes and upper respiratory

system; metal fume fever

Siderosis, a benign lung disease. Acute

effects include irritation of nasal passages

and lungs, clears up when exposure stops.

Lead

Solder, brass and bronze alloys, coatings

on steel

Manganese

Alloying element in steel, especially high

tensile steels

Nickel

Stainless steel, Inconel, Monel and other

high-alloy materials, welding rods and

plated steel

Chronic effects to central nervous system,

circulatory system, reproductive system,

kidneys, and muscles

Central nervous system effects

(Parkinsons-like symptoms); metal fume

fever

Irritation of eyes, nose, throat, allergic

asthma, pneumonitis, sensitization

dermatitis; potential carcinogen.

Galvanized steel, brass, painted metals

Metal fume fever

Material

Metals

Aluminum

Beryllium

Cadmium

Chromium

Copper

Iron

Zinc

Damage to respiratory tract; a carcinogen

Severe lung irritation, pulmonary edema;

potential carcinogen

Irritation of eyes and respiratory system;

perforation of nasal septum; skin irritation

or ulceration; increased risk of lung cancer.

RM129AG 4

Where Found

Health Hazards

Carbon

monoxide

Created during incomplete combustion of

fuels, such as acetylene gas, or breakdown

of carbon dioxide shielding gas

Chlorinated

hydrocarbon

solvents

Fluorine

compounds

Nitrogen

oxides

Degreasing or cleaning operations.

Decomposition by ultraviolet radiation

forms phosgene

Component of some fluxes or rod coatings

Absorbed into bloodstream, causing

pounding of heart, headache, dizziness.

High concentrations may result in

unconsciousness or death

See phosgene

Material

Gases

Ozone

Phosgene

Created by decomposition of air from

ultraviolet radiation and nitrogen shielding

gas

Created by decomposition of air from

ultraviolet radiation

Created by decomposition of chlorinated

solvents (nearby degreasing operations) by

ultraviolet radiation

Irritation of eyes, nose and throat; bone

damage

Irritation of eyes, nose and throat,

pulmonary edema

Irritation of mucous membranes,

pulmonary edema

Severe irritant to eyes, nose and

respiratory system

RM129AG 5

Zenith Insurance Company/ ZNAT Insurance Company. 21255 Califa Street. Woodland Hills, CA 91367 2009 Zenith Insurance Company. All Rights Reserved. Zenith

and TheZenith are registered US service marks. Zenith Insurance Company (Zenith) assists employers in evaluating workplace safety exposures. Surveys and related

services may not reveal every hazard, exposure and/or violation of safety practices. Inspections by Zenith do not result in any warranty that the workplace, operations,

machinery, appliances or equipment are safe or in compliance with applicable regulations. Any recommendations and related services are not and should not be construed

as legal advice or be used as a substitute for legal advice. Employee protection is ultimately the responsibility of the employer. Policy coverage is not contingent upon the

provision, efficacy or sufficiency of these services.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Untitled Extract Pages 9Document1 pageUntitled Extract Pages 9ajuhaseenNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Untitled Extract PagesDocument1 pageUntitled Extract PagesajuhaseenNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Section 4. First Aid Measures: See Toxicological Information (Section 11)Document1 pageSection 4. First Aid Measures: See Toxicological Information (Section 11)ajuhaseenNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Section 8. Exposure Controls/Personal Protection: Sealion Resilient Wintergrade Comp BDocument1 pageSection 8. Exposure Controls/Personal Protection: Sealion Resilient Wintergrade Comp BajuhaseenNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Section 7. Handling and Storage: Sealion Resilient Wintergrade Comp BDocument1 pageSection 7. Handling and Storage: Sealion Resilient Wintergrade Comp BajuhaseenNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Untitled Extract Pages8Document1 pageUntitled Extract Pages8ajuhaseenNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Foundations of Professional Teaching, Which Is The Entry Level Teacher Education Course Required For AllDocument17 pagesFoundations of Professional Teaching, Which Is The Entry Level Teacher Education Course Required For AllajuhaseenNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Section 4. First Aid Measures: See Toxicological Information (Section 11)Document1 pageSection 4. First Aid Measures: See Toxicological Information (Section 11)ajuhaseenNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Safety Data Sheet: Sealion Resilient Wintergrade Comp BDocument1 pageSafety Data Sheet: Sealion Resilient Wintergrade Comp BajuhaseenNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Pyrolite 15 PDS PDFDocument5 pagesPyrolite 15 PDS PDFbhavesh solankiNo ratings yet

- Msds 3Document1 pageMsds 3ajuhaseenNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- C05 02 Consumer Fibre Broadband Service 30julyDocument21 pagesC05 02 Consumer Fibre Broadband Service 30julyajuhaseenNo ratings yet

- Section 2. Hazards Identification: Sealion Resilient Wintergrade Comp BDocument1 pageSection 2. Hazards Identification: Sealion Resilient Wintergrade Comp BajuhaseenNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Photo RequirementsDocument1 pagePhoto RequirementsajuhaseenNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Pump Package PerformanceDocument2 pagesPump Package PerformanceajuhaseenNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Pettit Tie Coat PrimerDocument2 pagesPettit Tie Coat PrimerajuhaseenNo ratings yet

- Tiecoat 100 Conb-ADocument9 pagesTiecoat 100 Conb-AajuhaseenNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 2015 Maintenance Section - Non-Turbo - PDF Montero PDFDocument17 pages2015 Maintenance Section - Non-Turbo - PDF Montero PDFdonlynNo ratings yet

- AG Penguard Universal GB English ProtectiveDocument14 pagesAG Penguard Universal GB English ProtectiveajuhaseenNo ratings yet

- Batch Certificate SampleDocument1 pageBatch Certificate SampleajuhaseenNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- TestDocument4 pagesTestajuhaseenNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- OptimizeBlastEquipment FinalDocument28 pagesOptimizeBlastEquipment FinalajuhaseenNo ratings yet

- 3M Lens Cover - 6000SDocument2 pages3M Lens Cover - 6000SajuhaseenNo ratings yet

- Paint SpecDocument8 pagesPaint SpecSreedhar Patnaik.MNo ratings yet

- PDS Hempacore One 43600 en-GBDocument2 pagesPDS Hempacore One 43600 en-GBajuhaseenNo ratings yet

- TDS Penguard Universal GB English ProtectiveDocument5 pagesTDS Penguard Universal GB English ProtectiveajuhaseenNo ratings yet

- CAFCO® 300 DatasheetDocument6 pagesCAFCO® 300 DatasheetTanmay GorNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Verified Log Book Will Become Mandatory For Renewal From January 2017Document1 pageThe Verified Log Book Will Become Mandatory For Renewal From January 2017vijay rajputNo ratings yet

- AG Penguard Universal GB English ProtectiveDocument14 pagesAG Penguard Universal GB English ProtectiveajuhaseenNo ratings yet

- TDS Penguard Universal GB English ProtectiveDocument5 pagesTDS Penguard Universal GB English ProtectiveajuhaseenNo ratings yet

- LNG EconomicsDocument19 pagesLNG EconomicsCal67% (3)

- DSR Unit 1Document69 pagesDSR Unit 1hujefaNo ratings yet

- USP-NF Atorvastatin CalciumDocument8 pagesUSP-NF Atorvastatin CalciumPhạm Đức LộcNo ratings yet

- Calcium-Magnesium by EDTA TitrationDocument5 pagesCalcium-Magnesium by EDTA TitrationnisscriNo ratings yet

- Light Dependent ResistorDocument4 pagesLight Dependent ResistorantonerajNo ratings yet

- Separating Corn Starch From CornDocument3 pagesSeparating Corn Starch From CornJagna LannaoNo ratings yet

- Metabolisme KarbohidratDocument56 pagesMetabolisme KarbohidratAnonymous QCMhA4wNgBNo ratings yet

- Phys 1241Document4 pagesPhys 1241ChrisNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Adiabatic Vs Isothermal ProcessDocument2 pagesAdiabatic Vs Isothermal ProcessRyanNo ratings yet

- Compressor AM2Document3 pagesCompressor AM2Hendra KurniawanNo ratings yet

- 41 Assigment 4 Chapter 6-9Document1 page41 Assigment 4 Chapter 6-9Rishi KumarNo ratings yet

- NCNA PatentDocument36 pagesNCNA PatentCharles GrossNo ratings yet

- Notes Lecture No 3 Cell Injury and MechanismDocument5 pagesNotes Lecture No 3 Cell Injury and MechanismDr-Rukhshanda RamzanNo ratings yet

- 2.0 Performance Evaluation of Mineral OperationsDocument35 pages2.0 Performance Evaluation of Mineral OperationsVitu Verctor ViyuyiNo ratings yet

- An 31.2 Care and Maintenance of Hot Dip GalvanizingDocument4 pagesAn 31.2 Care and Maintenance of Hot Dip GalvanizingnarmathaNo ratings yet

- Plate Girders - I: ©teaching Resource in Design of Steel Structures IIT Madras, SERC Madras, Anna Univ., INSDAGDocument38 pagesPlate Girders - I: ©teaching Resource in Design of Steel Structures IIT Madras, SERC Madras, Anna Univ., INSDAGArnoldo OlivaNo ratings yet

- BNR Process BendigoDocument6 pagesBNR Process Bendigobansa79No ratings yet

- Session1 Kroeger Beth PresDocument83 pagesSession1 Kroeger Beth PresMahesh GavasaneNo ratings yet

- DOT Pipeline RepairsDocument18 pagesDOT Pipeline RepairsSeng HeangNo ratings yet

- Sika Loadflex Polyurea Product Data 322187Document2 pagesSika Loadflex Polyurea Product Data 322187quaeNo ratings yet

- Overview of Part 2 Failure AnalysisDocument12 pagesOverview of Part 2 Failure AnalysisAnonymous S9qBDVkyNo ratings yet

- Toggle Structure and ClassificationDocument9 pagesToggle Structure and ClassificationRobin TimkangNo ratings yet

- Electrolysis ProcessesDocument180 pagesElectrolysis ProcessesEngineering Office Shahrak100% (1)

- Dimond Structural Systems Manual Aug2016Document272 pagesDimond Structural Systems Manual Aug2016Erwin Mars UyNo ratings yet

- Suncroma: Organic and Inorganic PigmentsDocument12 pagesSuncroma: Organic and Inorganic PigmentsKetav Patel100% (1)

- DRRG Equipmentlist 29032022 RDocument49 pagesDRRG Equipmentlist 29032022 RjayapalNo ratings yet

- Process For The Preparation of Amorphous Atorvastatin Calcium From Crystalline Atorvastatin CalciumDocument7 pagesProcess For The Preparation of Amorphous Atorvastatin Calcium From Crystalline Atorvastatin CalciumDrkrishnasarma pathyNo ratings yet

- Keep 512Document17 pagesKeep 512rajaijahNo ratings yet

- Rser D 16 02436R1Document88 pagesRser D 16 02436R1Jitender KaushalNo ratings yet

- Ammonia Piping Handbook PDFDocument55 pagesAmmonia Piping Handbook PDFadh3ckNo ratings yet