Professional Documents

Culture Documents

Metrology Lab w2014

Uploaded by

ObaidCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metrology Lab w2014

Uploaded by

ObaidCopyright:

Available Formats

RYERSON UNIVERSITY

DEPARTMENT OF MECHANICAL & INDUSTRIAL ENGINEERING

MEC322 Manufacturing Fundamentals

INSTRUCTIONS FOR THE PREPARATION OF MANUFACTURING/METROLOGY

LABORATORY REPORTS

The report may be divided into five sections;

1) Introduction and Procedure

2) Results

3) Analysis of Results

4) Conclusions and Discussions

5) Answer to Questions

Title Page download the lab report cover page from www.mie.ryerson.ca and have you and your lab

partners sign.

Introduction and Procedure

A brief outline of how the experiment was carried out, and the instruments and accessories used in each

section.

Results

All the data leading to the results as well as the results themselves should be included in this section.

The individual gauge block sizes used, vernier height gauge readings, etc. (raw data) leading to the final

results should all be included. The reported measurements must indicate the resolution of the

measurement device. For example a a length measured using a vernier caliper with resoultion of 0.001

should be reported as 10.124 0.0005.

Analysis of Results

The results of each part of the experiment should be queried to determine sources of error relating to

environment, instrument, component or operator. In many cases it will be possible to pinpoint the limits

of accuracy which may be expected due to the method used. Any difficulties which are found in using

the instruments should also be defined.

Conclusions

Include in this section any trends, or highlights resulting from the experiment. Industrial applications

should be discussed.

Answer to Questions

Most laboratory sheets have questions attached to them. These should be answered separately at the

end of the report.

Ryerson University

Department of Mechanical and Industrial Engineering

MEC 322 Manufacturing Fundamentals

Measuring Instruments Lab

Purpose: To familiarize students with the construction and use of line gradated and micrometer

type instruments and transfer tools

Measurement Exercises: See the attached data sheets, measure the required dimensions, record the

measurement directly on them. Attach these sheets to the report.

Questions:

1. Discuss the term Parallax Error associated with steel scale measurements.

2. A micrometer type instrument achieves magnification by two basic principles. Explain these.

3. Describe possible errors when measuring outside diameter of a part using a vernier caliper.

4. Are these errors random or systematic? How would you reduce these errors?

5. What does Traceability mean when applied to measuring instruments?

Ryerson University

Department of Mechanical and Industrial Engineering

MEC 322 Manufacturing Fundamentals

Measurement by comparison and Dial Indictor Lab

Purpose: Understanding the principles of measurement by comparison and learning how to setup and

use different types of comparators and dial indicators.

Part A

Measurement Exercises:

1. Setup the Sheffield pneumatic column gauge with the

master ring gauge set provided and measure the inside

diameters of the parts using the highest magnification

possible ( record all settings and measurements).

2. Setup and adjust the Sigma pressure drop pneumatic

comparator using the 12.74 mm. set, then measure the

parts provided.

3. Use Sigma mechanical comparator to inspect the

height of the cylindrical part. Use a gage block stack

equal to nominal size.

Questions Part A:

1 . What advantages do electronic comparators have over mechanical comparators?

2. State one advantage, one disadvantage of the air gauge compared to other principles of

magnification.

3. In your own words, define resolution" as applicable. Does Sigma mechanical Comparator have

enough resolution for measuring the cylinder in part 3? Explain why or why not.

Part B: Inspecting parallelism Tolerance

Measure the deviation from parallelism for the part shown in Figure 1

using the mandrel provided (Figure 2)

Part C: Inspecting Runout and Total Runout Tolerances

Measure the runout on section X of the shaft in Figure 3.

Measure the total runout on section Y of the shaft.

0.010 -A-

0.002 -A-

Figure 3

Part D: Inspecting Angularity Tolerance

Measure the angularity tolerance for the specimen shown in Figure 4 by using the setup in Figure 5.

Hint : Use a gage block stack to setup the sine bar equal to nominal angle.

0.007 -A-

Figure 4

Figure 5

Questions Part B, C and D:

1. Describe the procedure for calibrating a dial indicator?

2. What are some of the sources of systematic error when using dial indicators?

3. Describe sources of random error when using dial indicators.

Ryerson University

Department of Mechanical and Industrial Engineering

MEC 322 Manufacturing Fundamentals

Optical metrology Lab

Purpose: To familiarize students with measuring tools that use optical methods

Part A: Optical Projector

1. Check the zero of the vernier protractor on the screen.

First set the protractor scale on zero. Then, using the test in

gauge on the table, project the image (shadow) of the

vertical pin on the screen and adjust the table vertically until

the tip of the shadow just contacts the horizontal cross line.

Traverse the table horizontally using the micrometer and

note if the shadow moves in contact with the cross line,

adjust if screen position if necessary.

2. Determine system magnification by measuring:

a) magnified pin diameter. b) actual pin diameter.

3. Setup the given tap between centers and measuring

directly from the screen determine the following screw

thread dimensions:

a) Major diameter

b) Minor diameter

c) Average Pitch (use 4 pitches)

Note: Dimensions measured directly off the screen are

affected by system magnification.

4. For the same tap, this time using the micrometers on the projector measure:

a) the pitch

b) the pitch diameter

c) calculate the lead angle

Part B: Toolmakers Microscope

1.Check and set, if necessary, the zero of the eyepiece vernier

protractor as follows:

Set the protractor scale at zero as shown in Fig. I. Then verify that

the horizontal cross line is parallel to the cross travel of the stage.

To do this, rotate the side micrometer knob and note that any

object viewed thru the eyepiece runs parallel to the cross line.

2. Setup the watch plate (Fig II) such that the pins centre line is

parallel to the horizontal cross line on the eye piece, then take

measurements to determine the centre distance of the pins.

Record the measurements to four decimal places.

3. Measure the diameter of the hole on the watch plate.

Figure I

Figure II

Part C: Measurement Using Optical Flats

In the Figure A (highly exaggerated) height of the gage-block stack is 0.9420 in. The other

dimensions are as given . Use a monochromatic helium light source (=23.2 in.), to measure the

diameter of the cylindrical plug gage within the resolution provided by this setup.

Figure A

Questions:

1. Describe possible errors when measuring major diameter of the screw. Are these errors random or

systemic? How would you reduce these errors?

2. Describe possible errors when measuring the pin using the toolmakers microscope. Are these errors

random or systemic? How would you reduce these errors?

3. Suggest the reason why the cross lines on optical projector and the microscope are broken lines and

not solid lines

What is the resolution of the measurement using optical flat.

Ryerson University

Department of Mechanical and Industrial Engineering

MEC 322 Manufacturing Fundamentals

Coordinate Measuring Machine

Measurement & Reverse Engineering

This lab will illustrate the application of a coordinate measuring machine (CMM) for quality

control in industry and as a measuring tool for a parts dimensions

Equipment:

Brown & Sharp Micro-Hite CMM with pcDMIS software.

TesaSTAR Touch trigger ball probe.

Rectangular part to be measured.

1 pair clamps.

USB key to save your files student to supply

Experimental Setup:

Before measurements can be taken, the probe must be calibrated and the part coordinate

system (datum) must be defined. To calibrate the probe, a minimum of 5 hits must be taken on the

reference sphere. The Precision Reference Sphere is 0.7500 inches in diameter and is calibrated to

0.00002 inches. Usually, it is mounted on the CMM table at a location that does not interfere with the

normal movements of the probe during part measurement. The axis of the part must now be defined

relative to the machines axis. The part should be placed on the table so that its axis lines up

approximately with the axis of the machine (within 30). The axis of the part is defined by taking several

hits on the part surface. During measurement, the computer will make the necessary calculations to

compensate for the misalignment between the part and machine axis and for the radius of the probe

ball.

To measure with the ball probe, firmly hold the probe as close as possible to the end of the arm

and gently make contact with the surface of the part. Be sure there are no vibrations or bouncing and

that the probe has come completely to rest against the part. Be careful not to slide the probe on the

part surface. Make sure you move away perpendicular to the surface being measured. BE VERY

CAREFUL AS THE TOUCH PROBE IS VERY FRAGILE! Make sure you lock all the axis when you are not

moving the CMM.

Part A - Calibration and Alignment Setup

1)

2)

3)

Make sure that your USB key is in the computer

From the computers desktop, select the pcDMIS icon (looks like a blue globe)

Once up, we will tell pcDMIS save the data files to your USB key:

a. EDIT SET SEARCH PATH enter the path to your USB key

Note: you must do this for both:

Default Part Program Directory

Probe Directory

4)

FILE NEW PART NAME name your file

Select inches radio button and hit OK.

5)

Probe Calibration

VIEW OTHER QUICK START

A new window will pop up first we will define the probe by selecting

the icon on the left that looks like a probe.

CALIBRATE PROBE find the PROBE_TESASTAR from the list

TIP#1 find the TIP3BY12mm for the 3mm tip from the list

MEASURE hit that button for a new window to pop up

NUMBER OF HITS

5 and click the MANUAL radio button.

Hit the MEASURE button now a new pop up window will tell

you to Take Hit 1 of 5

Once youve taken 5 hits on the calibration ball, click CONTINUE

You are now ready for the part alignment.

ASIDE Shortcut Keys

CTRL-W - to turn on the live co-ordinates.

CTRL-N - move cursor to end of the program.

CTRL-E - to redo a whole measurement entity in the edit window

ALT- minus

- to delete the last measurement hit.

END or CMM scroll wheel button

- to finish a series of measurements

F9

- change parameters of an entity in the EDIT window

F5

- set up menu

6)

Setting the part alignment and origin

From the QUICK START window select ALIGNEMENT PLANE/LINE/LINE

1

3

2

6

4

The origin and axis alignment will be defined by the intersection of a plane on the top of the part

(touch pts. 1-3 on the part top and hit END) and a line across the front of the part (pts. 4-5 and

hit END) and a line up the left side (pts. 6-7 on the lower step edge and hit END). You may need

to scroll down your quick start menu to see the entities that you are measuring.

7)

Your origin should now be placed in the lower right hand corner of your part. To verify, you can

move the CMM probe over that point and see the X and Y go to zero. You can now close your

quick start menu.

Part B Measurement Exercise and Manual Reverse Engineering

You will be required to record the measurements listed on Table 1. Use your measurements to

finish reverse engineering the part (incomplete drawing shown under table, you are to redraw this in

Solidworks with your actual measurements).

Simple Entities to measure a simple entity, select the correct one from the measurement toolbar

(point, line, circle, plane, etc) and then collect the points with the touch probe. Press END after you

have collected your points for that entity. ie. POINT min 1 pts., LINE min of 2 pts., CIRCLE and PLANE

min of 3 pts. After you hit END, you will see the data show up on the EDIT window on the left hand side.

For example, to measure the thickness of the part, measure a POINT on the CMM table.

Measurement for simple measurements such as (1) from Table 1, measure a point on the CMM table.

This is now PNT2. Select the [+] button on the GD&T toolbar. A pop up window will now show all the

entities. To calculate the distance, select PLN1 and PNT2, select the appropriate axis, and whether its

parallel or perpendicular. Click CREATE, and CLOSE to close the pop-up window.

Creating a CMM Report WINDOW REPORTS WINDOW will create a cmm report on the right hand

side of the screen. It will create a line of data for every GD&T Measurement entity. Youll need to hit

the REFRESH icon each time [looks like a broom]. To go back to your graphical screen WINDOW

GRAPHICAL. For example, if you hit REFRESH is should create a line for the measurement between PNT2

and PLN1 from the paragraph above.

Constructions Sometimes, certain measurements must be constructed from other measurement

entities. For example, (4) from Table 1 is the intersection of a cone with the top surface. First measure

the cone using the CONE icon. (For a CONE: take 3 hits in a circle inside the cone, move the z-axis

further down and take another 3 hits in a circle) Go to INSERT FEATURE CONSTRUCT and select

CIRCLE. Now select your cone, and the top plane (if you have the graphical screen up, it turns red) and

select INTERSECTION radio button and hit CREATE (then CLOSE). It will now create a circle in the EDIT

window. You will need to use the [+] icon in the GD&T toolbar and select your newly created circle to

add the measurement to your CMM report.

For GD&T you will need 2 entities for measurement (12) in Table 1, parallelism. First, measure a line

along the top of the part. Then select the [//] from the GD&T toolbar. In the pop-up window, select

DATUM DEFINITIONS and define your A and B datums as in the drawing. Select CREATE and then CLOSE.

Now select the line feature you just created, and change the feature control box as per the drawing.

(note: youll need to remove the symbol in this case)

PDF of your CMM report FILE PRINTING REPORT WINDOW PRINT_SETUP. Make sure FILE is

checked and select PDF. Now go to FILE PRINTING REPORT WINDOW PRINT, and a CMM report

will be written to your USB Key.

Part C Geometric Dimensioning and Tolerancing

One of the great advantages to the CMM is its ability to measure a variety of GD&T with ease.

Using the CMM, check measurements 7-12.

Extra Lab Report Requirements

In addition to the normal Metrology lab report requirements the following extra Questions are also

expected:

Part B

Table 1 with your measurements (hand written) and the CMM report. Label the corresponding

measurements on your CMM report with the measurement number on Table 1.

Comment on how the measurements can be used to finish the reverse engineering of the part.

Re-draw the part to scale fully dimensioned in Solidworks with the ACTUAL DIMENSIONS that you

gathered with the CMM, label the GD&T with the appropriate feature control frames.

Part C

Comment on measurements 7 through 12 and whether and by how much they satisfy the GD & T

If they do not satisfy GD&T, how can the part be modified such that they can pass inspection.

Also consider the following positional GD&T. Do your measurements indicate that the part meets

the tolerance? By how much? Show any calculations. (bonus tolerance, etc.)

Circle

Distance

Distance

Tolerance

GD & T

from Afrom BCIR 5

1.000

3.000

1.000

0.990

CIR 6

6.000

3.300

0.700

0.750

CIR 7

4.500

2.000

2.000

1.995

Table 1 - Data record sheet for Part B:

Feature Description

1

Thickness of block

2

Height of block

Position and diameter

of hole CIR 5

Position and diameter

of cone CIR 6 at the top

surface.

Position and diameter

of hole CIR 7

Angle-upper left corner

Flatness of top surface

Concentricity

CIR7 to CIR8

Straightness of Surface

B

Roundness of CIR7

9

10

11

12

Perpendicularity of

Surface A to Surface B

Parallelism of Surface B

to Top Surface

X=

Y=

D=

X=

Y=

D=

X=

Y=

D=

Degrees =

Measured Value

You might also like

- MIL-PRF-23377 Rev. KDocument19 pagesMIL-PRF-23377 Rev. KRoban BieberNo ratings yet

- Static Pressure Concept 1Document8 pagesStatic Pressure Concept 1bharath477No ratings yet

- Steel Connections: Connection Name: MF-I24-02 Connection ID: 1 Design Code: AISC 360-2005 LRFDDocument12 pagesSteel Connections: Connection Name: MF-I24-02 Connection ID: 1 Design Code: AISC 360-2005 LRFDmalikasalNo ratings yet

- Structural Calculation For Directly Welded Flange FR Moment Connection (Beam-To-Column Flange)Document10 pagesStructural Calculation For Directly Welded Flange FR Moment Connection (Beam-To-Column Flange)danieldumapitNo ratings yet

- Part 1 (Final 2022-11-21)Document28 pagesPart 1 (Final 2022-11-21)saraNo ratings yet

- ISO 3834purchasedocumentDocument8 pagesISO 3834purchasedocumenthector-salomonNo ratings yet

- Shear Wave PDFDocument6 pagesShear Wave PDFcutefrenzyNo ratings yet

- Section 2 - Thread - BasicsDocument27 pagesSection 2 - Thread - BasicsChris MedeirosNo ratings yet

- Y14 43Document1 pageY14 43Adrian JoelNo ratings yet

- Result Summary - Overall: Moment Connection - Beam Splice Code AISC 360-16 LRFDDocument6 pagesResult Summary - Overall: Moment Connection - Beam Splice Code AISC 360-16 LRFDMichenerparkNo ratings yet

- Engineering DrawingDocument157 pagesEngineering DrawingLab Thermo100% (1)

- Lecture 6 Surface Roughness I IDocument23 pagesLecture 6 Surface Roughness I IilincastNo ratings yet

- Skeletal System: - Composed of The Body's Bones and Associated Ligaments, Tendons, and Cartilages. - FunctionsDocument66 pagesSkeletal System: - Composed of The Body's Bones and Associated Ligaments, Tendons, and Cartilages. - FunctionsDenver TanhuanNo ratings yet

- Engineering Drawing Notes BDocument50 pagesEngineering Drawing Notes BAchinNo ratings yet

- AISC steel connection design documentDocument17 pagesAISC steel connection design documentSh MNNo ratings yet

- Geometrical TolerancingDocument12 pagesGeometrical TolerancingItalo Venegas100% (1)

- ISO 898-6-1994, OCR Mechanical Properties of Fasteners-2nd EdDocument12 pagesISO 898-6-1994, OCR Mechanical Properties of Fasteners-2nd EdRenatoGolinNo ratings yet

- New Microsoft Office Word DocumentDocument9 pagesNew Microsoft Office Word DocumentKhalid PerwezNo ratings yet

- JDN 179Document11 pagesJDN 179X800XLNo ratings yet

- Chevron ConnectionDocument35 pagesChevron ConnectionAbdelrahman YoussefNo ratings yet

- GSNH Science Lessons on ElectricityDocument4 pagesGSNH Science Lessons on ElectricityMaám Rosemary B. LandanNo ratings yet

- WELD DESIGN CHECK FOR ANCHOR SUPPORTDocument8 pagesWELD DESIGN CHECK FOR ANCHOR SUPPORTUmer AziqNo ratings yet

- RT Standards NotesDocument4 pagesRT Standards NotesprabhuNo ratings yet

- Simboluri SudareDocument8 pagesSimboluri SudarecornelutsNo ratings yet

- Stud Application QualificationDocument1 pageStud Application QualificationPatrick DominguezNo ratings yet

- Reliability Based DesignDocument11 pagesReliability Based DesigntohemaNo ratings yet

- Shotcrete Support Load CalculationsDocument6 pagesShotcrete Support Load Calculationsanon_160157252No ratings yet

- Basic Review CardDocument6 pagesBasic Review CardSheena LeavittNo ratings yet

- Aspen Plus DEPG ModelDocument23 pagesAspen Plus DEPG ModelAmir JoonNo ratings yet

- GD&T: Theory To Reality: Mission StatementDocument67 pagesGD&T: Theory To Reality: Mission StatementCharlie Tej100% (1)

- Engg - Drawing 1st Year LMDocument167 pagesEngg - Drawing 1st Year LMPRIYABRATA JENANo ratings yet

- AWS Catalog 2017 Winter SpringDocument52 pagesAWS Catalog 2017 Winter SpringPilar Medrano MenaNo ratings yet

- Engineering Drawing Notes BDocument50 pagesEngineering Drawing Notes BsrchougulaNo ratings yet

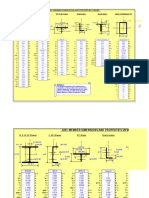

- AISC Properties MM GPP 2017Document87 pagesAISC Properties MM GPP 2017Pablo García PeñaNo ratings yet

- AWS Weld Symbol BasicsDocument3 pagesAWS Weld Symbol Basicschairul anwarNo ratings yet

- How To Read Welding GaugesDocument8 pagesHow To Read Welding GaugeshemnNo ratings yet

- Welder Qualification Test Log: Engineering Standards Manual OST220-03-01-ESM Chapter 13, WeldingDocument1 pageWelder Qualification Test Log: Engineering Standards Manual OST220-03-01-ESM Chapter 13, WeldingReza100% (1)

- A Review of The Application of Weld Symbols On Drawings - Part 2 - Job Knowledge 65Document5 pagesA Review of The Application of Weld Symbols On Drawings - Part 2 - Job Knowledge 65tuanNo ratings yet

- B1-10M Edtn 2004 PDFDocument26 pagesB1-10M Edtn 2004 PDFCarlitosNo ratings yet

- Indian Standard: General Technical Delivery Requirements FOR Steel and Steel ProductsDocument17 pagesIndian Standard: General Technical Delivery Requirements FOR Steel and Steel ProductsPermeshwara Nand Bhatt100% (1)

- Daytime Colorimetric Properties of Fluorescent Retroreflective Sheeting and Marking Materials For High Visibility Traffic Control and Personal Safety Applications Using 45°:normal GeometryDocument6 pagesDaytime Colorimetric Properties of Fluorescent Retroreflective Sheeting and Marking Materials For High Visibility Traffic Control and Personal Safety Applications Using 45°:normal GeometryEnriqueVeNo ratings yet

- Resistance Welding Electrodes: Tips With Tapered Shanks Nose Types A, B, C, D, E & FDocument9 pagesResistance Welding Electrodes: Tips With Tapered Shanks Nose Types A, B, C, D, E & FreachfsrNo ratings yet

- Duties of Welding ManagerDocument3 pagesDuties of Welding ManagerBalkishan DyavanapellyNo ratings yet

- M793Document29 pagesM793Hossam AliNo ratings yet

- Welding SymbolsDocument78 pagesWelding Symbolsuttamtm100% (1)

- Applicable ASTM Specifications For Structural Fasteners: Table 3.8 Anchor RodsDocument1 pageApplicable ASTM Specifications For Structural Fasteners: Table 3.8 Anchor Rodsivan bolañosNo ratings yet

- Surface Roughness TesterDocument6 pagesSurface Roughness TesterLingga SetiawanNo ratings yet

- Introduction To Non-Destructive TestingDocument34 pagesIntroduction To Non-Destructive Testingegy pure100% (1)

- MSFC-SPEC-3679 - Process Specification Welding Aerospace HardwareDocument102 pagesMSFC-SPEC-3679 - Process Specification Welding Aerospace HardwareXto PeregrinNo ratings yet

- EW 512 6 Nondestructive TestingDocument37 pagesEW 512 6 Nondestructive TestingHarun HodžićNo ratings yet

- Source: Https://assist - Dla.mil - Downloaded: 2017-12-05T21:08Z Check The Source To Verify That This Is The Current Version Before UseDocument6 pagesSource: Https://assist - Dla.mil - Downloaded: 2017-12-05T21:08Z Check The Source To Verify That This Is The Current Version Before UseJoey ThomannNo ratings yet

- ASTM D 1054-91 - Resillence Using A Rebound PendulumDocument4 pagesASTM D 1054-91 - Resillence Using A Rebound PendulumBatNo ratings yet

- Standard Test Method For Radioscopic Examination of WeldmentsDocument5 pagesStandard Test Method For Radioscopic Examination of WeldmentsWagner Renato AraújoNo ratings yet

- Lab Manual: Machining Processes and Metrology Lab (MEE211L)Document27 pagesLab Manual: Machining Processes and Metrology Lab (MEE211L)Agnivesh SharmaNo ratings yet

- Measure diameters and thicknesses with Vernier calipers and micrometersDocument12 pagesMeasure diameters and thicknesses with Vernier calipers and micrometersvdnsitNo ratings yet

- Me 8513 MM Lab ScetDocument34 pagesMe 8513 MM Lab ScetSatheesh Kumar50% (4)

- Subject Name:-Inspection and Quality Control Paper Code: - 121762/031762 Branch/Sem.: - Mechanical Engg./6thDocument30 pagesSubject Name:-Inspection and Quality Control Paper Code: - 121762/031762 Branch/Sem.: - Mechanical Engg./6thKaran KushwahaNo ratings yet

- 3 5 A AppliedstatisticsDocument3 pages3 5 A Appliedstatisticsapi-310705480No ratings yet

- Measurement and InspectionDocument33 pagesMeasurement and InspectionSri RNo ratings yet

- Faculty Orientation Programme-2017 SAE, Mechanical Department, Kondhwa, PuneDocument57 pagesFaculty Orientation Programme-2017 SAE, Mechanical Department, Kondhwa, Puneraghav maskeNo ratings yet

- Lecture 1 MeasurementDocument30 pagesLecture 1 Measurementakash258456No ratings yet

- Metrology ReportDocument11 pagesMetrology ReportRahimin RashidNo ratings yet

- Me8513 MMDocument2 pagesMe8513 MMSiva RamanNo ratings yet

- 5.EMM Lab ManualDocument38 pages5.EMM Lab ManualRakeshkumarcegNo ratings yet

- Mid Term InformationDocument5 pagesMid Term InformationObaidNo ratings yet

- A Scientific Study On Dickload Measurement: Dr. Miller Candalf Gingey Ty Dye Tranny January 17, 2015Document1 pageA Scientific Study On Dickload Measurement: Dr. Miller Candalf Gingey Ty Dye Tranny January 17, 2015ObaidNo ratings yet

- Secret BankingDocument8 pagesSecret BankingberryberryNo ratings yet

- Chapter 38Document14 pagesChapter 38Obaid0% (1)

- Davis Langdon Cost Models: Office RefurbishmentDocument14 pagesDavis Langdon Cost Models: Office RefurbishmentcsharpplusNo ratings yet

- Short Manual: Vision Sensor With Built-In Touch ScreenDocument65 pagesShort Manual: Vision Sensor With Built-In Touch ScreenJavier AyzaNo ratings yet

- Math 54 Le5Document1 pageMath 54 Le5Lester Jason T. ChengNo ratings yet

- AFU 19740100 APRO Bulletin January-FebruaryDocument11 pagesAFU 19740100 APRO Bulletin January-Februaryratatu100% (1)

- INChO2012 Solution of Previous Year Question Papers of Indian National Chemistry Olympiad (INChO)Document9 pagesINChO2012 Solution of Previous Year Question Papers of Indian National Chemistry Olympiad (INChO)Akshay PandeyNo ratings yet

- Introduction to Structural AnalysisDocument2 pagesIntroduction to Structural AnalysisMelvin EsguerraNo ratings yet

- Bohring Bot Narayana Co Super Chaina 8 Gta Mocks Full SyllabusDocument207 pagesBohring Bot Narayana Co Super Chaina 8 Gta Mocks Full Syllabussknoushad126No ratings yet

- Eartquake Books Central LibraryDocument430 pagesEartquake Books Central Librarytejaswini100% (1)

- Introduction and Basic Concepts: Fluid Mechanics: Fundamentals and ApplicationsDocument21 pagesIntroduction and Basic Concepts: Fluid Mechanics: Fundamentals and ApplicationsAhmedalaal LotfyNo ratings yet

- The Inertial Lift On A Spherical Particle in A Plane Poiseuille Flow at Large Channel Reynolds NumberDocument25 pagesThe Inertial Lift On A Spherical Particle in A Plane Poiseuille Flow at Large Channel Reynolds Numberจักรพงศ์ กิ่วแก้วNo ratings yet

- 31-XX29-6Document1 page31-XX29-6rohitkush100% (1)

- Mahesh CP 506Document25 pagesMahesh CP 506GURUDEEP PNo ratings yet

- 525d Manual Instalare Detector Paradox Cu MicroundeDocument2 pages525d Manual Instalare Detector Paradox Cu MicroundeGheorghiescu AndreiNo ratings yet

- Deno, Deso, and Co Removal Technology For Power PlantDocument5 pagesDeno, Deso, and Co Removal Technology For Power PlantcumiiNo ratings yet

- Numerical Problem-Solar Air HeaterDocument15 pagesNumerical Problem-Solar Air HeaterBrutalNo ratings yet

- Appendix: 12.1 Inventory of DistributionsDocument6 pagesAppendix: 12.1 Inventory of DistributionsAhmed Kadem ArabNo ratings yet

- 1 Syringe Siliconisation Trends Methods Analysis Procedures PDFDocument6 pages1 Syringe Siliconisation Trends Methods Analysis Procedures PDFSofiaProtopsaltiNo ratings yet

- Structures: Complex Stresses and DeflectionsDocument17 pagesStructures: Complex Stresses and Deflectionswsjouri2510No ratings yet

- Suong V. Hoa - Design and Manufacturing of Composites-CRC Press (1998)Document248 pagesSuong V. Hoa - Design and Manufacturing of Composites-CRC Press (1998)joereisNo ratings yet

- 5 Longitudinal and Transverse VibrationsDocument4 pages5 Longitudinal and Transverse Vibrationsenggsantu0% (1)

- Instant Download Ebook PDF Finite Element Analysis Theory and Application With Ansys 4th Edition PDF ScribdDocument41 pagesInstant Download Ebook PDF Finite Element Analysis Theory and Application With Ansys 4th Edition PDF Scribdlouise.kolar628100% (42)

- TLC Analysis of Siling Labuyo Extract ComponentsDocument3 pagesTLC Analysis of Siling Labuyo Extract ComponentsJan Eric Balete0% (1)

- CEMKS3 E7 GM4 1 ItDocument3 pagesCEMKS3 E7 GM4 1 ItHan Yuan YapNo ratings yet

- National Engineering Handbook Chapter 3Document35 pagesNational Engineering Handbook Chapter 3bb8585528No ratings yet

- Light and Optics Chapter SummaryDocument83 pagesLight and Optics Chapter SummaryWhye Jun CheongNo ratings yet