Professional Documents

Culture Documents

Rexroth Re29564 XN 102 b2 - 2010 05

Uploaded by

boilerqwerty81Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rexroth Re29564 XN 102 b2 - 2010 05

Uploaded by

boilerqwerty81Copyright:

Available Formats

1/12

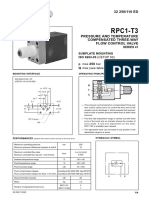

4/3 directional servo-valve

with mechanical position feedback

RE 29564-XN-102-B2/05.10

Replaces: 02.09

Type 4WS2EM 6...XN...-102

Size 6

Component series 2X

Maximum operating pressure 315 bar

Maximum flow 48 l/min

H5994

ATEX units

For explosive areas

Part II

Technical data sheet

Information on explosion protection:

Range of application in accordance with the Explosion Protection Directive 94/9/EC

II3G: Type of protection Ex nA II T5X according to

EN 60079-0:2006 / EN 60079-15:2005

II3D: Type of protection Ex tD A22 IP 65 TX according to

EN 61241-0:2006 / EN 61241-1:2004

What you need to know about these operating instructions

These operating instructions apply to the explosion-proof version of Rexroth valves and consist of

the following three parts:

Part I

Part II

Part III

General information RE 07010-X-B1

Technical data sheet RE 29564-XN-102-B2

Product-specific instructions RE 29564-XN-102-B3

RE 29564-XN-102-B0

You can find further information on the correct handling of Rexroth hydraulic products

in our publication "General product information on hydraulic products" RE 07008.

2/12

Bosch Rexroth AG

Hydraulics

4WS2EM 6...XN...-102

Table of contents

Content

Page

Features

Ordering code and scope of delivery

Symbol

Function, section

Technical data

5, 6

Information on explosion protection

External control electronics

Mating connector

Electrical connection

Characteristic curves

8, 9

Unit dimensions

10

Flushing plate

11

Features

Directional servo-valve for proper use in explosive areas of

zone 2 and 22

Valve to control position, force, pressure or velocity

2-stage servo valve with mechanical feedback

1st stage as nozzle flapper plate amplifier

For subplate mounting,

porting pattern according to ISO 4401-03-02-0-05

subplates available in FE/ZN version (see page 10)

Dry control motor, no contamination of the solenoid gaps by

the hydraulic fluid

Can also be used as 3-way version

Wear-free spool feedback element

Control:

External control electronics in Eurocard format or in modular design (separate order), see page 6

Valve is adjusted and tested

Pressure chambers at the control sleeve with gap seal,

therefore no wear of the seal ring

Filter for 1st stage freely accessible from the outside

RE 29564-XN-102-B2

RE 29564-XN-102-B2

4WS2EM 6...XN...-102

Hydraulics

Bosch Rexroth AG

3/12

Ordering code and scope of delivery

4WS2EM

6 2X

B 11 XN ET

K17

V 102

Electrically actuated

2-stage servo valve in

4/3 directional design with

mechanical feedback for

external control electronics

Size 6

102 =

Seal material

V=

FKM seals,

suitable for mineral oil (HL, HLP)

according to DIN 51524

=6

Component series 20 to 29

= 2X

(20 to 29: unchanged installation and

connection dimensions)

Rated flow 1)

2 l/min

5 l/min

10 l/min

15 l/min

20 l/min

25 l/min

Characteristic curves, see page 8

(observe tolerance field of flow

signal function)

special number 6)

E=

D=

C=

K17 =

=2

=5

= 10

= 15

= 20

= 25

Spool overlap 5)

0 0.5 % negative

0 0.5 % positive

3 5 % positive

electrical connection

via connector

Order mating connector separately,

see page 7

Inlet pressure range 4)

10 to 210 bar

10 to 315 bar

210 =

315 =

ET = internal pilot oil supply and return3)

Valve for external control electronics

coil no. 11 (30 mA/85 per coil) 2)

= 11

XN =

explosion protection "type nA

For details see information on the explosion protection, page 6

Included in the delivery:

Valve operating instructions with declaration of conformity in part III

1)

4)

Rated flow

The rated flow refers to a 100% command value signal

at 70 bar valve pressure differential (35 bar per control

edge). The valve pressure differential must be regarded as

reference. Other values result in the flow being changed. A

possible rated flow tolerance of 10% must be taken into

account (see flow signal function page 8).

2)

3)

Care should be taken that the system pressure is as constant as possible.

With regard to the dynamics, the frequency response dependency must be observed within the admissible pressure

range of 10 ... 210 bar and/or 10 ...315 bar.

5)

External control electronics

The actuating signal must be formed by a current controlled

output stage. Control electronics (servo amplifier) see page 6.

Pilot oil

The valve is only delivered with internal pilot oil supply

and return.

Symbol

A B

a, b

P T

Inlet pressure range

Spool overlap

The spool overlap is specified in % of the control spool

stroke.

6)

Special number "102"

Without actuation (de-energized condition), channels P A

and B T are open for 10% of the nominal quantity.

4/12

Bosch Rexroth AG

Hydraulics

4WS2EM 6...XN...-102

RE 29564-XN-102-B2

Function, section

4WS2EM 6-2X/...XN...-102

Valves of this type are electrically actuated, 2-stage

directional servo-valves with porting pattern according to

ISO 4401-03-02-0-05. They are mainly used to control position, force, pressure or velocity.

These valves are made of an electro-mechanical converter

(torque motor) (1), a hydraulic amplifier (principle: nozzle flapper plate) (2) and a control spool (3) in a bushing (2nd stage)

which is connected with the torque motor via a mechanical

feedback.

An electrical input signal at the coils (4) of the torque motor

generates a force by means of a permanent magnet which

acts on the armature (5), and in connection with a torque tube

(6) results in a torque. This causes the flapper plate (7) which

is connected to the torque tube (6) via a pin to move from the

central position between the two control nozzles (8), and a

pressure differential is created across the front faces of the

control spool (3). The pressure differential results in the spool

changing its position, which results in the pressure port being connected to one actuator port and, at the same time, the

other actuator port being connected to the return flow port.

The control spool is connected to the flapper plate or the

torque motor by means of a bending spring (mechanical feedback) (9). The position of the spool is changed until the feedback torque across the bending spring and the electro-magnetic torque of the torque motor are balanced and the pressure differential at the nozzle flapper plate system becomes

zero.

The stroke of the control spool and consequently the flow of

the servo valve are controlled in proportion to the electrical input signal. It must be noted that the flow depends on the valve

pressure drop.

External control electronics (separate order)

External control electronics (servo amplifier) serve the actuation of the valve, amplifying an analog input signal (command

value) so that with the output signal, the servo valve is actuated in a flow-controlled form.

Type 4WS2EM 6-2X/...XN...-102

1

4

5

6

7

8

2

3

(T)

P

RE 29564-XN-102-B2

4WS2EM 6...XN...-102

Hydraulics

Bosch Rexroth AG

Technical data

general

Porting pattern

ISO 4401-03-02-0-05

Installation position

Any

Surface protection

(Ensure that upon system start-up, the valve is

supplied with enough pressure (10 bar)! )

Valve body, cover, filter screw

Nitro-carburated

Cap

Anodized

Storage temperature range

C 20 +80

Ambient temperature range

C 30 +80

Weight

kg 1.1

hydraulic (measured with HLP 32, oil = 40C 5C)

Operating pressure

Ports P, A, B

bar 10 210 or 10 315

Return flow pressure

Port T

bar Pressure peaks < 100, static < 10

Hydraulic fluid

Mineral oil (HL, HLP) according to DIN 51524,

ignition temperature > 150 C

Hydraulic fluid temperature range

C -15 ... +80; preferably +40 ... +50

mm2/s 15 ... 380; preferably 30 ... 45

Viscosity range

Maximum admissible degree of contamination of the hydraulic fluid cleanliness class according to ISO 4406 (c)

Zero flow qV,L 2)

with spool overlap E

measured without dither signal

Rated flows qv rated 3), tolerance 10 %

with valve pressure differential p = 70 bar

Max. control spool stroke possible with

mechanical end position (in case of error)

related to nominal stroke

Class 18/16/131)

l/min

pP / 70 bar (0.4 l/min + 0.02 qV rated) 3); 4)

l/min

2; 5; 10; 15; 20; 25

% 120 170

Feedback system

Mechanical

Hysteresis (dither-optimized)

% 1.5

Range of inversion (dither-optimized)

% 0.2

Response sensitivity (dither-optimized)

% 0.2

Pressure gain with 1 % spool stroke change

(from the hydraulic zero point)

% of pP 4) 50

Zero adjustment flow over the entire

operating pressure range

% 3, long-term 5

Zero shift upon change of:

Hydraulic fluid temperature

% / 20 1

Ambient temperature

% / 20 1

Operating pressure 80 120 % of pP 4)

% / 100 bar 2

Return flow pressure 0 10 % of pP 4)

1)

% / bar 1

The cleanliness classes specified for the components must

be adhered to in hydraulic systems. Effective filtration prevents faults and at the same time increases the service life

of the components.

For the selection of filters, see technical data sheets

RE 50070, RE 50076 and RE 50081.

2)

qV,L

3)

qv rated = Rated flow in l/min

4)

pP

= Zero flow in l/min

= Operating pressure in bar

5/12

6/12

Bosch Rexroth AG

Hydraulics

4WS2EM 6...XN...-102

RE 29564-XN-102-B2

Technical data

electric

Protection class according to EN 60529:1991+A1:2000

IP 65 with mating connector correctly mounted and locked

Type of signal

analog

Rated current per coil

mA 30

Resistance per coil

85

Inductivity with 60 Hz

and 100% rated current

Connection in series

H 1.0

Connection in parallel

H 0.25

In case of actuation using non-Rexroth amplifiers, we recommend a superimposed dither signal

Information on explosion protection

Range of application as per directive 94/9/EC

II 3 G; II 3 D

Type of protection according to EN 60079-0:2006 /

EN 60079-15:2005

Ex nA II T5X

Type of protection according to EN 61241-0:2006 /

EN 61241-1:2004

Ex tD A22 IP 65 TX

Maximum surface temperature

C 100

Ambient temperature range

C 30 +80

Hydraulic fluid temperature range

C 15 +80

Max. admissible operating voltage of the servo amplifier

Conditions for use in zone 2 and 22

V 32 (DC)

The valve may only be used in explosive zones of device

group II, category 3, with "low" risk of mechanical hazards

according to the harmonized standards EN 60079-0:2006,

section 26.4.2 and EN 61241-0:2006, section 23.4.2.1.

If used in zones with a "high" risk of mechanical load according to these standards , the user must take measures with a

"low" risk of mechanical load.

External control electronics

Servo amplifier

(separate order)

Eurocard format

Analog Type VT-SR2-1X/.60 according to technical data sheet

RE 29980

Modular design

Analog Type VT 11021 according to technical data sheet RE 29743

The coils of the valve may only be connected to these amplifiers in parallel!

WARNING Risk of explosion

The external servo amplifier must be operated outside the explosive area!

RE 29564-XN-102-B2

4WS2EM 6...XN...-102

Hydraulics

Bosch Rexroth AG

7/12

Mating connector

4,5... 7,0

The servo valve may only be supplied through this mating

connector. Separate order, material no. R901043330

21,6

58

Connection:

Contact bushings with connection cross-section

for litz wires 0.4 0.75 mm2 are supplied unpacked.

The connection of the litz wires to the contact bushings is possible by crimping or soldering.

A list of the required tools for crimping connection is

available in the assembly instructions which are supplied with the mating connector.

Lock screw

Electrical connection (example of parallel connection)

Non-explosive area

Explosive area

Valve: Coils

Control electronics

Mating connector

A

C

B

D

E

F

The coils are connected in parallel in the mating connector

or at the amplifier (see figure).

In case of serial connection, contacts B and C must be

connected.

The E-F bridge can be used for the electrical determination

of the correct connection of the plug-in connector and/or for

the identification of cable break.

The electrical actuation from A (+) to D () causes flow direction from P A and B T. The reverse electrical actuation causes flow direction from P B and A T.

8/12

Bosch Rexroth AG

Hydraulics

4WS2EM 6...XN...-102

RE 29564-XN-102-B2

Characteristic curves (measured with HLP 32, oil = 40C 5C)

Flow/load function (tolerance 10 %) with 100 % command value signal

Note:

Observe flow values in the max. command value range (see tolerance field

of the flow/signal function)

50

40

6

5

30

25

20

Ordering

code

Rated flow

Curve

2 l/min

5 l/min

10

10 l/min

15

15 l/min

20

20 l/min

25

25 l/min

Flow in l/min

15

2

10

8

6

5

4

3

2

1

20

30

40

50 60

70 80 100

200

300

Valve pressure differential in bar

Tolerance field of flow/signal function

at constant valve pressure difference p

P A; B T

110

Flow in % 100

80

60

40

20

100 80 60

40

Tolerance field

20 10

Typical

flow curve

20

20

40

60

80

P B; A T

100

110

40

60

80

100

Command value in %

p = Valve pressure differential

(inlet pressure pP

minus load pressure pL

minus return flow pressure pT)

RE 29564-XN-102-B2

4WS2EM 6...XN...-102

Hydraulics

Bosch Rexroth AG

9/12

Characteristic curves (measured with HLP 32, oil = 40C 5C)

Transition function with pressure rating 315 bar, step response without flow

40 bar

Spool stroke in %

100

70 bar

140 bar

80

210 bar

60

315 bar

40

20

0

4

6

8

Time in ms

10

12

315

5 %

270

25 %

3

5

225

100 %

10

180

15

135

20

90

25

45

30

10

Phase angle in

Amplitude ratio in dB

Frequency response with pressure rating 315 bar, stroke frequency without flow

Measured at

pilot pressure pST = 315 bar

0

20

30

50

100

200 300

500

1000

Frequency in Hz

Dependency of the frequency f at 90 on the operating pressure p and the inlet amplitude

100

40 bar

90

70 bar

Inlet amplitude in %

80

140 bar

70

The output signal corresponds to the spool stroke

with flow and without load

pressure

210 bar

60

315 bar

50

40

30

1)

20

25 l/min

20 l/min

15 l/min

10 l/min

5 l/min

2 l/min

10

0

100

150

200

250

300

Frequency with phase angle 90 in Hz 1)

350

Correction factors at q V rated:

1.00

1.00

0.95

0.90

0.85

0.80

10/12

Bosch Rexroth AG

Hydraulics

4WS2EM 6...XN...-102

RE 29564-XN-102-B2

Unit dimensions (dimensions in mm)

2

52,5

45

58

80

35

64

A P(T) B

M5

80

66

40,5

14

9

0,01/100

0,75

Rzmax 4

31

46

31,75

Required

surface quality of the

valve mounting face

A

4,57,0

B

P

15

137

8 Filter

9 Plug screw

10 Machined valve mounting face,

porting pattern according to

ISO 4401-03-02-0-05

Deviating from the standard:

Locating pin not available (G)

Subplates

G341/01 FE/ZN (G1/4)

G342/01 FE/ZN (G3/8)

G502/01 FE/ZN (G1/2)

10

80

19

47

1 Required space for the removal of mating connectors, additionally observe

the bending radius of the connection

line

2 Cap

3 Valve mounting screws

For reasons of stability, exclusively the

following valve mounting screws may

be used:

4 hexagon socket head cap screws

ISO 4762-M5x50-10.9-flZn-240h-L

(Friction coefficient 0.09 0.14

according to VDA 235-101)

(included in the delivery)

4 Identical seal rings for ports P, A, B

and T

5 Name plate

6 Mating connector (order separately,

see page 7)

7 Connection line, further

information on page 7

F1

A

F4

F2

B

G

F3

with dimensions as in the technical

data sheet RE 45052

(must be ordered separately)

Note:

Subplates are no components in the sense of directive 94/9/EC and can be used

after the manufacturer of the overall system has assessed the risk of ignition.

The G...FE/ZN versions are free from aluminum and/or magnesium and galvanized.

RE 29564-XN-102-B2

4WS2EM 6...XN...-102

Hydraulics

Bosch Rexroth AG

11/12

Flushing plate with porting pattern according to ISO 4401-03-02-0-05 (dimensions in mm)

Symbol

P

Weight: 0.6 kg

Identical seal rings for ports P, A, B and T

Mounting screws

For reasons of stability, exclusively the following

mounting screws may be used:

4 hexagon socket head cap screws

ISO 4762-M5x40-10.9-flZn-240h-L

(Friction coefficient 0.09 - 0.14 according to

VDA 235-101) (included in the delivery)

Note

Before the assembly, observe the information in the

product-specific instructions RE 29564-XN-102-B3,

section 3.2.

9,5

Material number: R900936049

30,5

35,5

Ordering code and more information

12/12

Bosch Rexroth AG

Hydraulics

4WS2EM 6...XN...-102

RE 29564-XN-102-B2

Notes

Bosch Rexroth AG

Hydraulics

Zum Eisengieer 1

97816 Lohr am Main, Germany

Phone +49 (0) 93 52 / 18-0

Fax

+49 (0) 93 52 / 18-23 58

documentation@boschrexroth.de

www.boschrexroth.de

This document, as well as the data, specifications and other information set forth in it, are the exclusive property of Bosch Rexroth AG. It may

not be reproduced or given to third parties without its consent.

The data specified above only serve to describe the product. No statements concerning a certain condition or suitability for a certain application can be derived from our information. The information given does not

release the user from the obligation of own judgment and verification. It

must be remembered that our products are subject to a natural process

of wear and aging.

You might also like

- CDL Test AnswersDocument13 pagesCDL Test AnswersRichard Tod Gould100% (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Rexroth 4WE6D6X-G24 Directional ValveDocument12 pagesRexroth 4WE6D6X-G24 Directional ValveCosma Petru-RaulNo ratings yet

- Rexroth 4we10 Data SheetDocument10 pagesRexroth 4we10 Data SheetOrlando Arias100% (1)

- RT-flex-Introduction May13 Rev1Document96 pagesRT-flex-Introduction May13 Rev1NAGENDRA KUMAR D100% (1)

- Ellingsen 1761 Local Control Panel GuideDocument35 pagesEllingsen 1761 Local Control Panel GuidesalamrefighNo ratings yet

- 4wre 6-10 Sew1xDocument12 pages4wre 6-10 Sew1x2267airportNo ratings yet

- Weld Capacity CalculationDocument6 pagesWeld Capacity CalculationjaineranaNo ratings yet

- A6 VDocument40 pagesA6 VWesame Shnoda100% (1)

- Proportional Reducing ValveDocument8 pagesProportional Reducing ValvediabalziabNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Proportional Pressure Control Valves Series P2 & 4VP01Document12 pagesProportional Pressure Control Valves Series P2 & 4VP01abuzer1981No ratings yet

- 3-En2200-B - 4VP01Document15 pages3-En2200-B - 4VP01najafali1No ratings yet

- Re 92012Document12 pagesRe 92012Ahmed Abd Elhakeem100% (1)

- Axial Variable Duoble PumpDocument40 pagesAxial Variable Duoble Pumpveljeg100% (1)

- Proportional Control Valves with Integrated 24 Volt ElectronicsDocument24 pagesProportional Control Valves with Integrated 24 Volt ElectronicsLuis Alberto RamosNo ratings yet

- Hydraulic TechnologyDocument76 pagesHydraulic TechnologyOgulcan CafNo ratings yet

- Stamping (Metalworking)Document5 pagesStamping (Metalworking)Odebiyi StephenNo ratings yet

- Advanced Control Using MatlabDocument541 pagesAdvanced Control Using Matlabboilerqwerty81100% (2)

- Axial Piston Compact Unit A10CODocument8 pagesAxial Piston Compact Unit A10COJohn SimmondsNo ratings yet

- D631 Series Servo Control Valves ISO 4401 Size 05Document12 pagesD631 Series Servo Control Valves ISO 4401 Size 05José OlaveNo ratings yet

- Proportional Control Valves ISO 4401 Size 05Document8 pagesProportional Control Valves ISO 4401 Size 05Devendra BangarNo ratings yet

- A11vo - Re 92 500 - PDFDocument60 pagesA11vo - Re 92 500 - PDFSyed Azhar Hussain50% (2)

- 36 PneumaticDocument50 pages36 PneumaticduythienddtNo ratings yet

- 4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XDocument8 pages4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XlizbethdiosesNo ratings yet

- 4WS2EM 6-2X servo directional valve technical documentationDocument12 pages4WS2EM 6-2X servo directional valve technical documentationIbrahim MoamenNo ratings yet

- Re29564 2007-011Document12 pagesRe29564 2007-011engineer86No ratings yet

- Servo Bending TPM Ra - 29646Document10 pagesServo Bending TPM Ra - 29646Fajar Wahyu Nugroho JapraksNo ratings yet

- Re29583 2011-05Document20 pagesRe29583 2011-05Fajar Wahyu Nugroho JapraksNo ratings yet

- Rexroth电磁阀手册Document12 pagesRexroth电磁阀手册davidwang85120% (1)

- Flow Control, 3 Way, PR & Temp Compensated, NG6, Type RPC1-T3Document4 pagesFlow Control, 3 Way, PR & Temp Compensated, NG6, Type RPC1-T3LibinNo ratings yet

- Proportional Pressure Relief Valve R4V DENISONDocument15 pagesProportional Pressure Relief Valve R4V DENISONBerenice Bautista BelmontesNo ratings yet

- 4RP01Document12 pages4RP01Margaret DaughertyNo ratings yet

- 62 Series Servovalves Technical OverviewDocument8 pages62 Series Servovalves Technical OverviewDevendra BangarNo ratings yet

- Condenserless Liquid ChillersDocument12 pagesCondenserless Liquid ChillersBader ShrbajiNo ratings yet

- 2-Way Flow Control Bosch-RexrothDocument12 pages2-Way Flow Control Bosch-RexrothKemal GokovicNo ratings yet

- Bomba Hidrailica A10VSODocument44 pagesBomba Hidrailica A10VSOkiarabenitezparejaNo ratings yet

- Re 28163Document12 pagesRe 28163ShortcutterNo ratings yet

- Rexroth Bomba HidraulicaDocument52 pagesRexroth Bomba HidraulicaHernan LopezNo ratings yet

- Catalago PDFDocument12 pagesCatalago PDFGregory StewartNo ratings yet

- Proportional Throttle Valves Technical SpecificationsDocument15 pagesProportional Throttle Valves Technical Specificationsabuzer1981No ratings yet

- Valvula Placa RexrothDocument36 pagesValvula Placa RexrothRafael Koppe100% (1)

- Re92711 2012-01Document48 pagesRe92711 2012-01Edson Huarachi FloresNo ratings yet

- Válvula Rexroth STW 0195 Size 6 - Papelera San FranciscoDocument20 pagesVálvula Rexroth STW 0195 Size 6 - Papelera San FranciscoJose FloresNo ratings yet

- Kalorimetar Data Sheet UH50 - UH106 101kDocument15 pagesKalorimetar Data Sheet UH50 - UH106 101kbobesponjakockaloneNo ratings yet

- Bronkhorst Folder El FlowDocument4 pagesBronkhorst Folder El FlowPankaj GargNo ratings yet

- Ael6 PDFDocument9 pagesAel6 PDFCarlos Rafael Pereyra SegoviaNo ratings yet

- Functional Description: HA 5115 8/2005 Proportional Directional Control ValvesDocument19 pagesFunctional Description: HA 5115 8/2005 Proportional Directional Control ValvesgatodeftoneNo ratings yet

- A10VSO18 Bomba HidraulicaDocument16 pagesA10VSO18 Bomba HidraulicaGuilherme RodriguesNo ratings yet

- 200711111524631291Document16 pages200711111524631291Navneet GuptaNo ratings yet

- Rexroth A2VK Series PDFDocument12 pagesRexroth A2VK Series PDFMomo-Princess Peanut-buttercupNo ratings yet

- Series 10 Subplate Mounting ISO 4401-03 (CETOP 03) P Max: Bar Max (See Performances Table)Document4 pagesSeries 10 Subplate Mounting ISO 4401-03 (CETOP 03) P Max: Bar Max (See Performances Table)chekit9No ratings yet

- 5-EN 4050-A (Dig) - 2F1CDocument9 pages5-EN 4050-A (Dig) - 2F1Cabuzer1981No ratings yet

- Components For Pneumatic Automation: Five ONEDocument26 pagesComponents For Pneumatic Automation: Five ONEamNo ratings yet

- Proportionala Bosch REPDocument16 pagesProportionala Bosch REPMihaiNo ratings yet

- SC-600 - Electro-Pneumatic - Devices - Pressure Control Valves REXROTHDocument60 pagesSC-600 - Electro-Pneumatic - Devices - Pressure Control Valves REXROTHadrianahoukiNo ratings yet

- Directional Valve Spec SheetDocument4 pagesDirectional Valve Spec SheetRFIGUEROACNo ratings yet

- Samson - Proportional ControllerDocument12 pagesSamson - Proportional ControllerzamburittiNo ratings yet

- Re26892 2003-02Document10 pagesRe26892 2003-02DANIZACHNo ratings yet

- IUPUI ECE 602 Midterm 1Document9 pagesIUPUI ECE 602 Midterm 1boilerqwerty81No ratings yet

- Subversion IntroductionDocument23 pagesSubversion Introductionboilerqwerty81No ratings yet

- Pole Placement 1Document8 pagesPole Placement 1Ruchit PathakNo ratings yet

- Servo Valves TechnicalDocument24 pagesServo Valves Technicalobvert100% (2)

- Bolted Connection CalcDocument1 pageBolted Connection Calcboilerqwerty81No ratings yet

- QAP For Conical StrainerDocument2 pagesQAP For Conical StrainersatishchidrewarNo ratings yet

- (MINI) Manual de Despiece Mini InglesDocument247 pages(MINI) Manual de Despiece Mini InglesNahir ProtasioNo ratings yet

- Unit I MCQ SD IiiDocument18 pagesUnit I MCQ SD IiiKiran BandeNo ratings yet

- 08 PDFDocument23 pages08 PDFRakesh7770No ratings yet

- Advanced Numerical Methods for Process Safety AssessmentsDocument13 pagesAdvanced Numerical Methods for Process Safety Assessmentsandi suntoroNo ratings yet

- RK-2001E2 English TraductionDocument2 pagesRK-2001E2 English TraductionwxcvbnnbvcxwNo ratings yet

- .Catálogo PRESSOSTATO SUCO 2Document10 pages.Catálogo PRESSOSTATO SUCO 2Fernando MoraesNo ratings yet

- ARTESIAN VFD DRIVES FOR CENTRIFUGAL PUMPSDocument1 pageARTESIAN VFD DRIVES FOR CENTRIFUGAL PUMPScristobal_tl2277No ratings yet

- A Review On Effect of Preheating and orDocument3 pagesA Review On Effect of Preheating and orKing SabiNo ratings yet

- Manual Termostato Digitall t6812 FancoilDocument4 pagesManual Termostato Digitall t6812 FancoilaarroyofNo ratings yet

- P4. Fungsi Keadaan Dan Diferensial EksakDocument8 pagesP4. Fungsi Keadaan Dan Diferensial EksakAnis AnisaNo ratings yet

- Therm-O-Disc Bimetal-60t-Section-En-Us-5469064Document14 pagesTherm-O-Disc Bimetal-60t-Section-En-Us-5469064Phạm Thiên TrườngNo ratings yet

- Comparison of Effective Width Method, Pigeaud's Theory and Westergaad's Method With SAP2000 Fem ModelDocument14 pagesComparison of Effective Width Method, Pigeaud's Theory and Westergaad's Method With SAP2000 Fem ModelAkarshGowdaNo ratings yet

- Nonlinear Model Predictive Extended Eco-Cruise Control For Battery Electric VehiclesDocument6 pagesNonlinear Model Predictive Extended Eco-Cruise Control For Battery Electric VehiclesJade MarabellaNo ratings yet

- Fluid Mechanics-Fluid Dynamics PDFDocument3 pagesFluid Mechanics-Fluid Dynamics PDFCristian OmacNo ratings yet

- SBS Fluidized Bath Operating ManualDocument14 pagesSBS Fluidized Bath Operating Manualcraigorio616No ratings yet

- PROBLEM 9.31: SolutionDocument10 pagesPROBLEM 9.31: Solutionjuan felipeNo ratings yet

- Powerex Bombas de Vacio Vane Montado en Tanque ManualDocument64 pagesPowerex Bombas de Vacio Vane Montado en Tanque ManualHugovillarruelNo ratings yet

- Mechanical Engineer Interview Question ListDocument14 pagesMechanical Engineer Interview Question ListRj SakthiNo ratings yet

- Pneumatic Circuit TrainerDocument5 pagesPneumatic Circuit Trainerdipsankar chatterjeeNo ratings yet

- Four Month Industrial TrainingDocument54 pagesFour Month Industrial Trainingsurbhi sharmaNo ratings yet

- Numerical Methods HW2Document6 pagesNumerical Methods HW2Shaisone Shoop100% (2)

- 2017 - Aquaflair Chillers Brochure PDFDocument76 pages2017 - Aquaflair Chillers Brochure PDFJeffNo ratings yet

- Week 1 Lect. 2 - ViscosityDocument17 pagesWeek 1 Lect. 2 - ViscosityAhmad RazaNo ratings yet

- Plate and Frame Heat Exchanger SizingDocument13 pagesPlate and Frame Heat Exchanger SizingUtsav PatelNo ratings yet