Professional Documents

Culture Documents

Panasonic Inverter PDF

Uploaded by

Dario GalanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Panasonic Inverter PDF

Uploaded by

Dario GalanCopyright:

Available Formats

ORDER NO.

PHAMOS1003027C3

E1

Microwave Oven

NN-SF550M

RPH (MEXICO & LATIN AMERICA)

Panasonic Home Appliances Microwave Oven

(Shanghai) Co., Ltd. 2010.

NN-SF550M

NN-SF550M

NN-SF550M

CONTENTS

Page

Page

1 FEATURE CHART

7.4. Inverter power supply (U)

16

2 CONTROL PANEL

7.5. Temperature thermistor

16

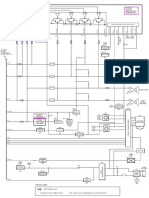

3 SCHEMATIC DIAGRAM

4 DESCRIPTION OF OPERATING SEQUENCE

4.1. Variable power cooking control

4.2. Inverter power supply circuit

4.3. Inverter defrost

8 MEASUREMENTS AND ADJUSTMENTS

17

8.1. Adjustment of primary latch switch, secondary latch switch

and monitor interlock switch.

8.2. Measurement of microwave output

17

17

9 PROCEDURE FOR MEASURING MICROWAVE ENERGY

5 CAUTIONS TO BE OBSERVED WHEN TROUBLESHOOTING 8

LEAKAGE

18

5.1. Check the grounding

9.1. Equipment

18

5.2. Inverter warnings

9.2. Procedure for measuring radiation leakage

18

5.3. Part replacement.

9.3. Record keeping and notification after measurement

18

5.4. When the 20A fuse is blown due to the malfunction of the

10 TROUBLESHOOTING GUIDE

monitor interlock switch:

19

10.1. (Troubleshooting) Oven stops operation during cooking 19

5.5. Avoid inserting nails, wire etc. through any holes in the

10.2. (Troubleshooting) Other problems

20

10.3. Troubleshooting of inverter circuit (U) and magnetron

21

5.6. Verification after repair

10.4. Trouble related to Digital Programmer Circuit

22

5.7. Sharp edges

10.5. SIMPLE WAY OF H.V. INVERTER/MAGNETRON

unit during operation.

6 DISASSEMBLY AND PARTS REPLACEMENT PROCEDURE 10

6.1. Inverter power supply

10

6.2. Magnetron

11

TROUBLESHOOTING

23

10.6. H.V.INVERTER BOARD MAIN PARTS LIST

(F606Y8X00AP)

6.3. Digital programmer circuit (D.P.C) & Membrane Switch 11

23

10.7. How to check the semiconductors using an OHM meter 24

6.4. Low voltage transformer and/or power relays (RY1, RY2)

11 EXPLODED VIEW AND PARTS LIST

25

13

11.1. EXPLODED VIEW

25

6.5. Fan motor

13

11.2. PARTS LIST

26

6.6. Door assembly

14

11.3. ESCUTCHEON BASE ASSEMBLY

27

6.7. Stirrer motor

14

11.4. DOOR ASSEMBLY

28

15

11.5. WIRING MATERIALS

29

11.6. PACKING AND ACCESSORIES

30

7 COMPONENT TEST PROCEDURE

7.1. Primary, Secondary Latch Switch interlocks & Power

15

12 DIGITAL PROGRAMMER CIRCUIT

31

7.2. Monitor Interlock Switch

15

12.1. SCHEMATIC DIAGRAM

31

7.3. Magnetron

15

12.2. PARTS LIST

33

Relay RY1

NN-SF550M

1 FEATURE CHART

2 CONTROL PANEL

NN-SF550M

3 SCHEMATIC DIAGRAM

NN-SF550M

4 DESCRIPTION OF OPERATING SEQUENCE

4.1.

Variable power cooking

control

4.3.

When the Auto Control feature is selected and the Start pad is

tapped:

High Voltage Inverter Power Supply (U) controls output power

by the signal from Digital Programmer Circuit (DPC). Power

relay always stay on, but PWM (Pulse Width Modulation) signal

controls microwave output power.

1. The digital programer circuit determines the power level and

cooking time to complete cooking and indicates the

operating state in the display window. Table shows the

corresponding cooking times for respective serving by

categories.

NOTE:

The ON/OFF time ratio does not correspond with the

percentage of microwave power since approximately 2

seconds are required for heating of magnetron

filament.

Inverter Turbo Defrost

SELECTED WEIGHT

COOKING TIME

1.0 LB

5 min.35 sec.

2. When cooking time in the display window has elapsed, the

oven turns off automatically by a control signal from the

digital programmer circuit.

Variable Power Cooking

POWER SETTING

OUTPUT

MANUAL MICROWAVE

POWER(%)

DUTY

APPROX.

ON(SEC)

OFF(SEC)

HIGH

P10

100%

22

0

P9

90%

22

0

P8

80%

22

0

MEDIUM-HIGH

P7

70%

22

0

MEDIUM

P6

60%

22

0

P5

50%

22

0

P4

40%

22

0

MEDIUM-LOW

P3

30%

22

0

P2

20%

15

7

P1

10%

8

14

DEFROST

P3

30%

22

0

4.2.

Inverter defrost

Inverter power supply circuit

The Inverter Power Supply circuit powered from the line

voltage, 120V 60Hz AC input supplies 4,000V DC to the

magnetron tube, and functions in place of the H.V. transformer,

the H.V. capacitor and H.V. diode.

1. The AC input voltage 120V 60Hz is rectified to DC voltage

immediately.

2. DC voltage will be supplied to the switching devices called

IGBT. These devices are switched ON-OFF by the 20 to 40

kHz PWM (pulse width modulation) signal from the

microcomputer in the DPC.

3. This drives the High voltage transformer to increase voltage

up to 2,000V AC.

4. Then the half-wave doubler voltage rectifier circuit,

consisting of the H.V. diodes and capacitors, generates the

necessary 4,000V DC needed for the magnetron.

5. Output power of the magnetron tube is always monitored by

the signal output from the current transformer built into the

inverter circuit.

6. This signal is fed back to the microcomputer in the DPC to

determine operating conditions and output necessary to

control PWM signal to the Inverter Power Supply for control

of the output power.

NN-SF550M

5 CAUTIONS TO BE OBSERVED WHEN

TROUBLESHOOTING

Unlike many other appliances, the microwave oven is a high

voltage, high current device. Though it is free from danger in

ordinary use, extreme care should be taken during repair.

CAUTION

Servicemen should remove their watches and rings

whenever working close to or replacing the magnetron.

5.1.

Check the grounding

Do not operate on a two wire extension cord. The microwave

oven is designed to be grounded when used. It is imperative,

therefore, to ensure the appliance is properly grounded before

beginning repair work.

5.2.

Inverter warnings

WARNING HIGH VOLTAGE AND HIGHTEMPERATURE

(HOT/LIVE) OF THE INVERTERPOWER SUPPLY (U)

The High Voltage Inverter Power Supply generates very

high voltage and current for the magnetron tube. Though it

is free from danger in ordinary use, extreme care should be

taken during repair.

Grounding of the inverter circuit board

WARNING

CAPACITORS

The aluminum heat sink is also energized with high voltage

(HOT), do not touch when the AC input terminals are

energized. The power device Collector is directly connected

to the aluminum heat sink.

DISCHARGE

THE

HIGH

VOLATGE

For about 30 seconds after the oven is turned off, an

electric charge remains in the high voltage capacitors of the

Inverter Power Supply circuit board.

When replacing or checking parts, remove the power plug

from the outlet and short the inverter output terminal of the

magnetron filament terminals to the chassis ground with an

insulated handle screwdriver to discharge. Please be sure

to contact the chassis ground side first and then short to the

output terminal.

The aluminum heat sink may be HOT due to heat energy,

therefore, extreme care should be taken during servicing.

H.V. Inverter warning

WARNING FOR INVERTER POWER SUPPLY (U)

GROUNDING

Check the High Voltage Inverter Power Supply circuit

grounding. The high voltage inverter power supply circuit

board must have a proper chassis ground. The inverter

grounding plate must be connected to the chassis. If the

inverter board is not grounded it will expose the user to very

high voltages and cause extreme DANGER! Be sure that

the inverter circuit is properly grounded via the inverter

grounding plate.

NN-SF550M

5.6.

Discharging the high voltage capacitors

WARNING

1. After repair or replacement of parts, make sure that the

screws of the oven, etc. are neither loosen or missing.

Microwave energy might leak if screws are not properly

tightened.

There is high voltage present with high current capabilities

in the circuits of the primary and secondary windings, choke

coil and heat sink of the inverter. It is extremely dangerous

to work on or near these circuits with the oven energized.

DO NOT measure the voltage in the high voltage circuit

including the filament voltage of the magnetron.

2. Make sure that all electrical connections are tight before

inserting the plug into the wall outlet.

3. Check for microwave energy leakage. (Refer to procedure

for measuring microwave energy leakage).

WARNING

Never touch any circuit wiring with your hand or with an

insulated tool during operation.

5.3.

CAUTION OF MICROWAVE RADIATION LEAKAGE

USE CAUTION NOT TO BECOME EXPOSED TO

RADIATION FROM THE MICROWAVE MAGNETRON OR

OTHER PARTS CONDUCTING MICROWAVE ENERGY.

Part replacement.

When troubleshooting any part or component is to be replaced,

always ensure that the power cord is unplugged from the wall

outlet.

5.4.

IMPORTANT NOTICE

1. The following components have potentials above 2000V

while the appliance is operated.

When the 20A fuse is blown

due to the malfunction of the

monitor interlock switch:

Magnetron

High voltage transformer (Located on inverter (U))

High voltage diodes (Located on inverter (U))

High voltage capacitors (Located on inverter (U))

WARNING

Pay special attention to these areas.

When the 20A 120V fuse is blown due to the malfunction of

the monitor interlock switch, replace all of the components

(primary latch switch, monitor interlock switch and power

relay RY1).

2. When the appliance is operated with the door hinges or

magnetron installed incorrectly, the microwave leakage

can exceed more than 5mW/cm 2. After repair or

exchange, it is very important to check if the magnetron

and the door hinges are correctly installed.

1. This is mandatory. Refer to measurements and

adjustments for the location of these switches.

5.7.

2. When replacing the fuse, confirm that it has the

appropriate rating for these models.

Sharp edges

CAUTION

3. When replacing faulty switches, be sure the mounting

tabs are not bent, broken or deficient in their ability to

hold the switches.

5.5.

Verification after repair

Please use caution when disassembling or reassembling

internal parts. Some exposed edges may be sharp to the

touch and can cause injury if not handled with care.

Avoid inserting nails, wire etc.

through any holes in the unit

during operation.

Never insert a wire, nail or any other metal object through the

lamp holes on the cavity or any holes or gaps, because such

objects may work as an antenna and cause microwave

leakage.

NN-SF550M

6 DISASSEMBLY AND PARTS REPLACEMENT

PROCEDURE

6.1.

Inverter power supply

6. Release locking tabs connecting inverter air guide with

inverter bracket.

CAUTIONS

7. Remove 1 screw holding H.V.Inverter to Inverter bracket.

1. Always leave the grounding plate in place.

2. Always securely tighten the ground screw through the bottom of the

chassis (base).

3. Securely connect 3 lead wire connectors.

4. Make sure the heat sink has enough space (gap) from the oven.

Take special care not to dress any lead wire over the aluminum heat

sink because it is hot.

1. Discharge high voltage remaining in high voltage capacitor.

2. Disconnect 2 high voltage lead wires from magnetron

filament terminals.

3. Disconnect connector CN701 & CN702 from H.V. Inverter

board.

4. Disconnect 1 connector from inverter reinforcement bracket

A.

5. Remove 4 screws holding inverter reinforcement bracket A

on right heater panel & base plate respectively.

8. Remove 1 screw holding grounding plate to H.V. Inverter.

10

NN-SF550M

6.2.

6.3.

Magnetron

1. Steps same as disassembly of H.V. Inverter step 1 to step

5.

Digital programmer circuit

(D.P.C) & Membrane Switch

NOTE:

2. Remove 1 screw holding thermistor on magnetron.

Be sure to ground any static electric charge built up on

your body before handling the D.P.C.

1. Remove 1 screw holding reinforcement bracket and

escutcheon base on front plate.

3. Remove 4 screws holding the magnetron.

2. Disconnect 1 grounding lead wire from front plate.

NOTE:

3. Disconnect all connectors from D.P.C. board.

After replacement of the magnetron, tighten mounting

screws properly in an x pattern, making sure there is no

gap between the waveguide and the magnetron to

prevent microwave leakage.

CAUTION

When replacing the magnetron, be sure the antenna gasket is in

place.

11

NN-SF550M

4. Disconnect connector CN701 from H.V. Inverter board.

8. Use tools such as kinfe etc. to lift the edge of membrane

sheet and peel off escutcheon sheet & key board

membrane completely from escutcheon base.

5. Remove 5 screws holding D.P.C. board on escutcheon

base.

NOTE:

a. The membrane key board is attached to the

escutcheon base with double faced adhesive tape.

Therefore, applying hot air such as using a hair dryer

is recommended for smoother removal.

b. When installing the new key board membrane, make

sure that the surface of escutcheon base is clean to

prevent a malfunction or shorted contacts.

6. Separate D.P.C board from tabs on the escutcheon base

and remove D.P.C board.

To replace membrane key board

7. Remove 1 screw.

12

NN-SF550M

6.4.

Low voltage transformer

and/or power relays (RY1,

RY2)

6.5.

Fan motor

1. Disconnect 2 lead wires from fan motor terminals.

2. Remove 4 screws holding inverter reinforcement bracket A

on right heater panel & base plate respectively.

NOTE:

Be sure to ground any static electric charge built up on

your body before handling the D.P.C.

1. Disconnect all connectors from D.P.C. board.

2. Remove 6 screws holding D.P.C. board on escutcheon

base.

3. Replace D.P.C. board.

(A) Using solder wick or a desoldering tool and 30W

soldering iron carefully remove all solder from the terminal

pins of the low voltage transformer and/or power relays.

NOTE:

Do not use a soldering iron or desoldering tool of

more than 30 watts on D.P.C. contacts.

(B) With all the terminal pins cleaned and separated from

D.P.C. contacts, remove the defective transformer/power

relays, Replace components making sure all terminal pins

are inserted completely resolder all terminal contacts

carefully.

3. Remove 2 screws holding fan moter on oven assembly.

4. Remove fan blade from the fan motor shaft by pulling it

straight out.

13

NN-SF550M

6.6.

Door assembly

6.7.

1. Remove door C from door E by carefully pulling outward,

starting from upper right hand corner using a flat blade

screwdriver.

Stirrer motor

1. Remove the motor cover by breaking off at the 8 spots

indicated by arrows with a cutter or the like.

2. Separate door E from tabs on door A and remove door A

(U).

3. Open Door E at the opening angle of approximately

10(Note: The door cannot be removed if the opening

angle is greater than 10).

4. Remove the door E from its hinges by pushing the door E

upward and out.

5. Remove door key and door key spring.

To re-install components:

1. Place the doors lower hinge pin into the bottom hinge

hole.

2. Use your left index finger to support the doors lower

hinge pin while guiding the doors upper hinge pin into

the top hinge hole.

NOTE:

3. Lower your finger to seat the door onto the hinges.

After removing the motor cover, be sure that cut

portions are properly trimmed or bent to the inside

so that no sharp edges will be exposed to outside.

4. Replace other components.

NOTE:

2. Disconnect 2 lead wires connected to the stirrer motor.

Adjust so that the upper portion of the door will

touch firmly to the oven cavity front plate, without

pushing the door. If the door assembly is not

mounted properly, microwave power may leak from

the clearance between the door and oven.

3. Remove the stirrer motor by removing screw.

NOTE:

Always

perform

the

microwave

leakage

measurement test after installation and adjustment

of door assembly.

NOTE:

After reinstalling the new stirrer motor and

reconnecting the 2 lead wires, reinstall the motor

cover by rotating it around 180, tucking the 2 tabs

under the base in the 2 provided slots, then screw

the single tab to the base using a 4mm 6mm

screw.

14

NN-SF550M

7 COMPONENT TEST PROCEDURE

7.3.

WARNING

1. High voltage is present at the output terminals of the High Voltage

Inverter (U) including aluminum heat sink during any cook cycle.

2. It is neither necessary nor advisable to attempt measurement of the

high voltage.

3. Before touching any oven components, or wiring, always unplug

the power cord and discharge the high voltage capacitors (see page

8).

7.1.

Continuity checks can only indicate an open filament or a

shorted magnetron. To diagnose for an open filament or

shorted magnetron.

1. Isolate magnetron from the circuit by disconnecting the

leads.

2. A continuity check across magnetron filament terminals

should indicate one ohm or less.

Primary, Secondary Latch

Switch interlocks & Power

Relay RY1

3. A continuity check between each filament terminal and

magnetron case should read open.

1. Unplug lead connectors to Power Relay RY1 and verify

open circuit of the Power Relay RY1 1-2 terminals.

2. Unplug lead connectors to Primary Latch Switch and

Secondary Latch Switch.

3. Test the continuity of switches at door opened and closed

positions with ohm meter (low scale).

Normal continuity readings should be as follows.

Primary Latch Switch

Secondary Latch Switch

Power Relay RY1

7.2.

Door Closed

0 (Close)

0 (Close)

(Open)

Door Opened

(Open)

(Open)

(Open)

Monitor Interlock Switch

1. Unplug lead wires from Inverter Power Supply (U) primary

terminals.

2. Connect test probes of ohm meter to the disconnected

leads that were connected to Inverter Power Supply (U).

3. Test the continuity of Monitor Interlock Switch with door

opened and closed positions using lowest scale of the ohm

meter.

Normal continuity readings should be as follows.

Door Opened

0 (Close)

Magnetron

Door Closed

(Open)

15

NN-SF550M

7.4.

Inverter power supply (U)

5. Program oven at High power for 1 minute and press [Start]

pad.

DO NOT try to REPAIR H.V. Inverter power supply (U).

Replace complete H.V. Inverter(U) Unit.

a. After approximately 3 seconds, oven stops operating.

b. During oven operation,

approximately 0.4A.

Unplug CN701

the

INPUT CURRENT

0.4A

input

current

is

FAILURE CODE

Oven stops in 3

seconds after started.

If both a and b check OK, the Inverter Power Supply (U) can be

determined to be OK.

7.5.

Temperature thermistor

These sensor monitors the heat produced by the heater circuit

and maintains the magnetron temperature which user had

selected. Normal room temperature 10C to 30C, the reading

across the temperature thermistor should be from 35K to 110

K.

If the resistance reading is out of the range stated here, the

thermistor is detective and must be replaced.

It is also possible to display thermistor level by taking the

following steps.

WARNING: HIGH VOLTAGE

1. Program the DPC into TEST MODE (Plug-in oven press

Clock pad once press Timer pad once press

Start pad once press Power Level pad once).

Test if failure codes H95, H97 or H98 appear when performing

the following procedure. It is recommended to use an AC line

input current ammeter for testing.

2. Program oven at Standing Time for 1 minute and press

[Start] pad.

Test 1

3. Press Power Level once, the thermistor level reading will

shown on the display.

1. With the oven units AC power supply cord is unplugged

from the wall outlet, unplug the 2 pin H.V. connector CN703

from the magnetron tube.

The normal reading should be in the range of 16-230.

2. Place 1 liter of water load into oven cavity.

3. Plug in the ovens AC power supply cord into outlet.

4. Program DPC.

a. Press Clock

pad once.

b. Press Timer

pad once.

c. Press Start

pad once.

d. Press Power Level

pad once.

5. Program oven at High power for 1 minute and press [Start]

pad.

a. After approximately 23 seconds, oven stops operating.

b. During oven operation, the input current is

approximately 0.5 to 1A. If both a and b are OK,

proceed to test 2.

Unplug CN703

INPUT CURRENT

0.5 to 1A

FAILURE CODE

Oven stops in 23

seconds after started.

Test 2

Continued from Test 1

1. Unplug the ovens AC power supply cord from outlet.

2. Unplug 3 pin connector CN701. CN703 remains unplugged.

3. Plug in the ovens AC power supply cord into outlet.

4. Program DPC.

a. Press Clock

pad once.

b. Press Timer

pad once.

c. Press Start

pad once.

d. Press Power Level

pad once.

16

NN-SF550M

8 MEASUREMENTS AND ADJUSTMENTS

8.1.

Adjustment of primary latch

switch, secondary latch switch

and monitor interlock switch.

1. Mount the Primary latch switch, the Secondary latch switch

and the Monitor interlock switch to the door hook assembly

as shown in illustration.

NOTE:

8.2.

No

specific

individual

adjustments

during

installation of the Primary latch switch, Secondary

latch switch or Monitor interlock switch to the door

hook are required.

Measurement of microwave

output

The output power of the magnetron can be determined by

performing IEC standard test procedures. However,due to the

complexity of IEC test procedures, it is recommended to test

the magnetron using the simple method outlined below.

2. When mounting the door hook assembly to the oven

assembly, adjust the door hook assembly by moving it in

the direction of the arrows in the illustration so that the oven

door will not have any play in it. Check for play in the door

by pulling the door assembly. Make sure that the latch keys

move smoothly after adjustment is completed. Completely

tighten the screws holding the door hook assembly to the

oven assembly.

Necessary Equipment:

*1 liter beaker *Glass thermometer

*Wrist watch or stopwatch

NOTE:

Check the line voltage under load.Low voltage will

lower the magnetron output. Take the temperature

readings and heating time as accurately as possible.

3. Reconnect the monitor interlock switch and check the

continuity of the monitor circuit and all latch switches again

by following the component test procedures.

1. Fill the beaker with exactly one liter of tap water.Stir the

water using the thermometer and record the waters

temperature. (recorded as T1).

2. Place the beaker on the center of glass tray.

Set the oven for High power and heat it for exactly one

minute.

3. Stir the water again and read the temperature of the water.

(recorded as T2).

4. The normal temperature rise at High power level for each

model is as shown in table.

TABLE (1L-1min. test)

RATED OUTPUT

TEMPERATURE RISE

1000W

Min. 15.4F(8.6C)

17

NN-SF550M

9 PROCEDURE FOR MEASURING MICROWAVE ENERGY

LEAKAGE

9.2.1.

WARNING

Check for radiation leakage after every servicing. After repairing or

replacing any radiation safety device, keep a written record for future

reference. This requirement must be strictly observed. In addition, the

leakage reading must be recorded on the service repair ticket while in

the customers home.

9.1.

Whenever you replace the magnetron, measure for radiation

leakage before the outer panel is installed and after all

necessary components are replaced or adjusted. Special care

should be taken in measuring around the magnetron.

Equipment

WARNING

Do not touch any high voltage parts.

Doing so can lead to personal injury or death.

Electromagnatic radiation monitor

Glass thermometer 212F or 100C

600cc glass beaker

9.2.

Measurement with the outer panel

removed.

9.2.2.

Procedure for measuring

radiation leakage

Measurements with a fully

assembled oven.

After all components, including outer panel are fully assembled,

measure for radiation leakage around the door periphery, the

door viewing window, the exhaust opening, control panel and

air inlet openings.

Note before measuring:

Do not exceed meter full scale deflection. Leakage monitor

should initially be set to the highest scale.

9.3.

To prevent false readings, the test probe should be held by

the grip portion of the handle only and moved along the

shaded area in Figure no faster than 1 inch/sec

(2.5cm/sec).

Record keeping and

notification after measurement

After any adjustment or repair to a microwave oven, a

leakage reading must be taken. Record this leakage

reading on the repair ticket even if it is zero.

Leakage with the outer panel removed: less than 5mW/cm 2.

Leakage for a fully assembled oven with door normally

closed: less than 2mW/cm 2.

A copy of this repair ticket and the microwave leakage

reading should be kept by repair facility.

Leakage for a fully assembled oven [Before the latch switch

(primary) is interrupted] while pulling the door: less than

2mW/cm 2.

Should the radiation leakage be more than 2 mW/cm 2 after

determining that all parts are in good condition, functioning

properly, and genuine replacement parts as listed in this

manual have been used.

1. Pour 275 15cc (9ozss 1/2oz) of 20C 5C (68 9F)

water in a beaker which is graduated to 600cc, and place in

the center of the oven.

2. Set the radiation monitor to 2450MHz and use it following

the manufacturers recommended test procedure to assure

correct results.

3. When measuring the leakage, always use the 2 inch (5cm)

spacer supplied with the probe.

4. Tap the start button or set the timer and with the magnetron

oscillating, measure the leakage by holding the probe

perpendicular to the surface being measured.

18

NN-SF550M

10 TROUBLESHOOTING GUIDE

DANGER: HIGH VOLTAGES

1. DO NOT RE-ADJUST PRESET CONTROL on the H.V.Inverter (U). It is very dangerous to repair or adjust without proper test equipment

because this circuit generates very large current and high voltage. Operating a misaligned inverter circuit is dangerous.

2. Ensure proper grounding before troubleshooting.

3. Be careful of the high voltage circuitry, taking necessary precautions when troubleshooting.

4. Discharge high voltage remaining in the H.V.Inverter (U).

5. When checking the continuity of the switches or the H.V.Inverter, disconnect one lead wire from these parts and then check continuity with the

AC plug removed. Doing otherwise may result in a false reading or damage to your meter. When disconnecting a plastic connector from a

terminal, you must hold the plastic connector instead of the lead wire and then disconnect it, otherwise lead wire may be damaged or the

connector cannot be removed.

6. Do not touch any parts of the circuitry on the digital programmer circuit, since static electric discharge may damage this control panel. Always

touch ground while working on this panel to discharge any static charge in your body.

7. 120V AC is present on the digital programmer circuit (Terminals of power relays and primary circuit of Digital Programmer Circuit). When

troubleshooting, be cautious of possible electrical shock hazard.

Before troubleshooting, operate the microwave oven following the correct operating procedures in the instruction manual in order

to find the exact cause of any trouble, since operator error may be mistaken for the ovens malfunction.

10.1. (Troubleshooting) Oven stops operation during cooking

SYMPTOM

1. Oven stops in 3 seconds

pressing [Start] pad

CAUSE

CORRECTIONS

after No 120V AC is supplied to H.V.Inverter (U) CN702 1. Latch Switch

terminals

2. Power relay RY1

3. Loose lead wire connector CN701, CN702

4. H.V. Inverter (U)

Oven stops in 23 seconds after H.V.Inverter (U) operates by the control signals 1. Magnetron

pressing [Start] pad

from DPC but magnetron is not oscillating

2. Loose lead wire connector CN703

3. H.V. Inverter (U)

2. No display and no operation at all.

Most probably loose connection of connectors, or 1. Allign door, Door Latch Switches

Fuse is blown.

door latch mechanism is not adjusted properly

2. Loose wiring connectors

19

NN-SF550M

10.2. (Troubleshooting) Other problems

SYMPTOM

1. Oven is dead.

Fuse is OK.

No display and no operation at all.

2. No display and no operation at all.

Fuse is blown.

3. Oven does not accept key input

(Program)

4. Fan motor turns on when oven is

plugged in with door closed.

5. Timer starts count down but no

microwave oscillation.

(No heat while oven lamp and fan

motor turn on)

1.

2.

3.

4.

1.

2.

3.

4.

1.

2.

3.

4.

1.

2.

3.

1.

2.

3.

6. Oven can program but timer does not

start countdown.

7. Microwave output is low. Oven takes

longer time to cook food.

8. Fan motor turns on and stirrer motor

rotates when door is opened.

9. Oven does not operate and return to

plugged in mode as soon as [Start]

pad is pressed.

10. Loud buzzing noise can be heard.

11. Stirrer motor does not rotate.

12. Oven stops operation during cooking.

4.

5.

6.

1.

2.

3.

1.

2.

3.

1.

CAUSE

CORRECTIONS

Open or loose lead wire harness

Open thermal cutout / thermistor

Check thermal cutout is defective.

Open low voltage transformer

Defective DPC

Shorted lead wire harness

Check adjustment of primary, secondary latch

switch and monitor interlock switch including

Defective primary latch switch (NOTE 1)

door.

Defective monitor interlock switch (NOTE 1)

Defective Inverter Power Supply (U)

NOTE 1:

All of these switches must be replaced at the same time.

Check continuity of power relay RY1 contacts (between 1 and 2) and if it has continuity, replace

power relay RY1 also.

Key input is not in proper sequence

Refer to operation procedure.

Open or loose connection of membrane key

pad to DPC (Flat cable)

Shorted or open membrane key board

Defective DPC

Refer to DPC troubleshooting.

Misadjustment or loose wiring of secondary

Adjust door and latch switches.

latch switch

Defective secondary latch switch

Door switch CN4

Off-alignment of primary latch switch

Adjust door and latch switches.

Open or loose connection of high voltage

circuit especially magnetron filament circuit

NOTE:

Large contact resistance will cause lower

magnetron filament voltage and cause

magnetron to have lower output and/or be

intermittent.

Defective high voltage component

Check high voltage component according to

H.V. Inverter Power Supply (U)

component test procedure and replace if it is

Magnetron

defective.

Open or loose wiring of power relay RY1

Defective primary latch switch

Defective DPC or power relay RY1

Refer to DPC troubleshooting

Open or loose wiring of secondary latch switch

Off-alignment of secondary latch switch

Defective secondary latch switch

Decrease in power source voltage

Consult electrician

Open or loose wiring of magnetron filament

circuit.(Intermittent oscillation)

Aging change of magnetron

Low voltage transformer on DPC.

1. Defective DPC

Check grounding connector on escutcheon

base.

1.

1.

2.

1.

Loose fan and fan motor

Open or loose wiring of stirrer motor

Defective stirrer motor

Open or loose wiring of primary and

secondary latch switch

2. Operation of thermal cutout

20

Adjust door and latch switches.

NN-SF550M

10.3. Troubleshooting of inverter circuit (U) and magnetron

This oven is programmed with a self diagnostics failure code system which will help for troubleshooting. H95, H97, H98 and H99

are the provided failure codes to indicate magnetron and inverter circuit problem areas. This section explains failure codes of H95,

H97, H98 and H99. First, you must program the DPC into TEST MODE, press Clock pad once press Timer pad once

Press Start pad once press Power Level pad once. Program unit for operation. H95, H97, H98, H99 appears in display

window a short time after [Start] pad is pressed and there is no microwave oscillation.

Alternate way to troubleshoot oven with AC Ampere meter used

H95, H97, H98, H99 appears in display window a short time after [Start] pad is pressed and no microwave oscillation with AC

Ampere meter used for troubleshooting.

21

NN-SF550M

10.4. Trouble related to Digital Programmer Circuit

SYMPTOM

No display when oven is first plugged

in

STEP

CHECK

1

Fuse pattern of D.P.C.

2

3

No key input

No beep sound

Power relay RY2 does not turn on

even though the program had been set

and the Start pad is tapped

No microwave oscillation at any power

RESULT

Normal

CAUSE/CORRECTIONS

Step2

Open

Replace D.P.C. or Fuse

Pattern

L.V.T.

Step3

Q10, ZD10, Q11, ZD11

IC1, CX320, Display

Membrane switch

IC1

IC1

BZ210, Q210

IC1

Step2

Q223

RY2

IC1

Step2

Q220 and/or Q221, Q222,

Q225

Step3

RY1

Q220 and/or Q221, Q222,

Q225

Display

IC1

IC1

Display

1. Latch Switch

2. D.P.C. /Power Relay

Step2

D.P.C.

Magnetron

Low voltage transforment (L.V.T.)

secondary voltage

Abnormal 0V

Normal

IC1 pin 23 voltage

Abnormal

Normal=3.3V

Membrane switch continuity

Abnormal

Normal

IC1 pin 1 voltage

Abnormal

Normal=3.3V

IC1 pin 2 voltage while operation

Abnormal

Normal=3.3V

Collector of Q223 voltage

Abnormal

Normal 0.7V

IC1 pin 20 voltages while operation at high Abnormal

power

Normal=3.3V

Collector of Q220 voltage

Abnormal

Short circuit between collector of Q220

and emitter of Q225

Dark or unclear display

Replace display and check operation

Missing or lighting of unnecessary

segment

Replace IC1 and check operation

H95/H97/H98 appears in window and

oven stops operation.Program High

power for 1 minute and conduct

following test quickly, unless

H95/H97/H98 appears and oven stops

Unplug CN702 (2 pin) connector and

measure voltage between terminals

Unplug CN701 (3 pin) connector and

measure pin1 voltage

22

Normal 0.7V

Still not turn on

RY1 turns on

Normal

Abnormal

Normal

Abnormal

Abnormal=0V

Normal=120V

Abnormal=0V

Approx. AC 3V

NN-SF550M

10.5. SIMPLE WAY OF H.V. INVERTER/MAGNETRON TROUBLESHOOTING

Purpose:

Simple way (3/23 seconds rule) of identifying whether its Magnetron, Inverter or others.

Set-up:

The unit under question is connected through the Ammeter as shown below.

Procedure:

Follow the matrix table below to identify the problem source.

Note:

Do not replace both Inverter board and Magnetron simultaneously and automatically without going through this

procedure.

Power will:

Ammeter reading is:

Shut off in 23 seconds 1. Between 0.5A and 1.0A.

after Start.

2. Between 1.0A and 2.0A.

To do:

Remedy:

Check and repair open magnetron circuit Open magnetron wiring between Inverter

and magnetron terminal.

Check continuity of D702 in Inverter PCB.

Shut off in 3 seconds 1. Less than 0.5A

after Start

1. D702 shorted

Replace H.V.Inverter(F606Y8X00AP)

2. D702 is OK

Replace magnetron

Check open circuit: Latch Switch, DPC, Replace defective component(s), or

Power Relay and CN701

correct switch, cables and connectors.

10.6. H.V.INVERTER BOARD MAIN PARTS LIST (F606Y8X00AP)

Ref. No.

DB701

L701

Q701

T701

C701

C702

Part No.

B0FBBQ000007

F5020W100AP

B1JAGV000015

A609A8X00AP

F0C2H284A012

F0C2E455A246

Part Name & Description

BRIDGE DIODE

CHOKE COIL

TRANSISTOR SI

H.V. TRANSFORMER

CAPACITOR

CAPACITOR

23

Pcs/Set

1

1

1

1

1

1

Remarks

20A,600V

1000V

0.28F/500VDC

4.5F/250VDC

NN-SF550M

10.7. How to check the semiconductors using an OHM meter

24

NN-SF550M

11 EXPLODED VIEW AND PARTS LIST

11.1. EXPLODED VIEW

25

NN-SF550M

11.2. PARTS LIST

NOTE:

1. When ordering replacement part(s), please use part number(s) shown in this part list.

Do not use description of the part.

2. Important safety notice:

Components identified by

mark have special characteristics important for safety.

When replacing any of these components, use only manufactures specified parts.

Ref. No.

1

2

3

4

5

Part No.

F00079Q30SRP

F10019Q30AP

F1008-1L40BS

F10099Q30SAP

F200A9Q30AP

Part Name & Description

NAME PLATE

BASE

RUBBER FOOT

CABINET BODY

OVEN

Pcs/Set

1

1

4

1

1

6

7

8

9

10

F010T9L40HP

F202K7R00BP

F20199Q30AP

F30206G30AP

F31366G30AP

FLAT TABLE (U)

ANTENNA STIRRER (U)

ANTENNA BRACKET

DOOR HOOK

HOOK LEVER A

1

1

3

1

1

11

12

13

14

F31376G30AP

F31386G30AP

F400A9Q30AP

F4008-1L70

HOOK LEVER B

HOOK LEVER C

FAN MOTOR

FAN BLADE

1

1

1

1

19

20

F41449L00RP

F4146-1P00

UPPER ORIFICE

LOWER ORIFICE

1

1

21

22

23

24

25

F612E5Y30AP

J61415G10XN

F61415U30XN

F61459L00XP

F61785U30XN

INCANDESCENT LAMP (U)

MICRO SWITCH

MICRO SWITCH

THERMAL CUTOUT

MICRO SWITCH

1

1

1

1

1

26

2M236-M42J7P

MAGNETRON

31

32

34

35

F62308F00AP

F62315G10XN

F61449Q30AP

F900C9Q30RP

FUSE

FUSE HOLDER

STIRRER MOTOR

AC CORD W/PLUG

1

1

1

1

36

37

40

F00069660AP

F00338F00RP

F11404J60XN

CAUTION LABEL

FUSE LABEL

STOPPER

1

1

1

41

42

45

F1161-1P00

F1165-1P00

F10529L10XP

INVERTER REINFORCEMENT BRACKET A

INVERTER REINFORCEMENT BRACKET B

STOPPER

1

1

2

46

47

48

50

F20999L70XP

XTWBFE4+8D

XTT4+8RDN

F22369Q30AP

REINFORCEMENT BRACKET D

SCREW

SCREW

RIGHT HEATER PANEL

1

4

4

1

51

52

53

54

55

F40279M60BP

F606Y8X00AP

F60749L00XP

F65859L00XP

MKPX2335K

INVERTER AIR GUIDE

H.V.INVERTER (U)

INCANDESCENT LAMP BRACKET

INVERTER BRACKET

CAPACITOR

1

1

1

1

1

58

F03349Q30RP

MENU LABEL

26

Remarks

(PRIMARY LATCH SWITCH)

(SECONDARY LATCH SWITCH)

(MONITOR INTERLOCK SWITCH)

20A

FOR CABINET BODY

FOR MAGNETRON

NN-SF550M

11.3. ESCUTCHEON BASE ASSEMBLY

Ref. No.

E1

E4

E5

Part No.

F603L9Q30RP

F630Y9Q30KRP

F80349Q30SAP

Part Name & Description

D.P.CIRCUIT (AU)

MEMBRANE SWITCH (U)

ESCUTCHEON BASE

E6

E7

E8

E9

F891P9L60KXP

F80375K00AP

F82569M60BP

F80579M60BBP

DOOR OPENING BUTTON (U)

COOK BUTTON SPRING

DOOR OPENING LEVER

ESCUTCHEON BASE B

Pcs/Set

1

1

1

1

1

1

1

27

Remarks

NN-SF550M

11.4. DOOR ASSEMBLY

Ref. No.

D1

D2

D3

D4

D5

Part No.

F30186P40AG

F302A9Q30SRP

F302K9Q30AP

F30215G10XN

F30859Q30AP

Part Name & Description

DOOR KEY A

DOOR A (U)

DOOR E (U)

DOOR KEY SPRING

DOOR C

D6

D9

F31459L70XP

F02459660AP

DOOR SCREEN A

DHHS LABEL

Pcs/Set

1

1

1

1

1

1

1

28

Remarks

NN-SF550M

11.5. WIRING MATERIALS

Ref. No.

W1

W2

W3

Part No.

F030A9Q30RP

F030E-1P00

F03539L00XP

Part Name & Description

LEAD WIRE HARNESS

H.V.LEAD WIRE

THERMISTOR HARNESS

Pcs/Set

1

1

1

29

Remarks

NN-SF550M

11.6. PACKING AND ACCESSORIES

Ref. No.

P1

P2

P3

P4

P5

Part No.

F00039Q30RP

F01029Q30SRP

F01049Q30AP

F01059Q30AP

F01064W00AP

Part Name & Description

INSTRUCTION MANUAL

PACKING CASE, PAPER

UPPER FILLER

LOWER FILLER

P.E.BAG

P6

P9

P10

F01078100XN

F01089L00XP

F0138-1M60

DOOR SHEET

RACK PACKING

SHEET

Pcs/Set

1

1

1

1

1

1

1

1

30

Remarks

NN-SF550M

12 DIGITAL PROGRAMMER CIRCUIT

12.1. SCHEMATIC DIAGRAM

31

NN-SF550M

32

NN-SF550M

12.2. PARTS LIST

Ref. No.

BZ210

C10

C13,C16

CX320

DISP110

DISP1 HOLDER

D10-D13

D220-D223,D227,D228

D40

D25

D26,D27

IC1

IC350

Q10,Q180

R11

R225

R211

R228,R352

RY1

RY2

T10

ZD10

ZD11

VZ490

Part No.

L0DDEA000014

F2A1V471B281

F2A1C220B624

H2B800400007

L5AYAYY00059

F67529L60XP

F66179L60XP

B0EAKT000025

B0AACK000004

B0JAAE000001

D4EAY271A036

D4EAY112A036

MN101C78AFN

C0EBE0000401

B1BAAJ000003

D0AE472JA155

D0AE470JA155

D0AE102JA155

D0AE104JA155

AEBGJQC25F18

K6B1AZA00010

G4C2AAD00005

B0BA5R600016

B0BA4R400002

D3CA6103A017

Part Name & Description

BUZZER

AL CHEM CAPACITOR

AL CHEM CAPACITOR

CERAMIC RESONATOR

LCD

DIFFUSION SHEET

LCD HOLDER

DIODE

DIODE

DIODE

ZENER RESISTOR

ZENER RESISTOR

L.S.I.

IC

TRANSISTOR

CARBON FILM RESISTOR

CARBON FILM RESISTOR

CARBON FILM RESISTOR

CARBON FILM RESISTOR

POWER RELAY

POWER RELAY

LOW VOLTAGE TRANSFORMER

ZENER DIODE

ZENER DIODE

VARISTOR

33

Pcs/Set

1

1

2

1

1

1

1

4

6

1

1

2

1

1

2

1

1

1

2

1

1

1

1

1

1

Remarks

2.0KHz

470F/35V

22F/16V

8.00MHz

270V

1100V

4.7K,1/4W,5%

47,1/4W,5%

1K,1/4W,5%

100K,1/4W,5%

10K

03/10

S-9Q3

Printed in China

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- HS8108Document8 pagesHS8108Miloš ZorićNo ratings yet

- f66fbdd3-58a5-4558-bf4a-ffaeea4fed36Document14 pagesf66fbdd3-58a5-4558-bf4a-ffaeea4fed36Chafik AlbadraouiNo ratings yet

- Panasonic - tc-p42xt50x Service ManualDocument7 pagesPanasonic - tc-p42xt50x Service ManualsesotoNo ratings yet

- KSGER 96W 24V 5A Electric Power Supply Unit For STM32 STC OLED T12 Digital DIY Soldering Station ControllerDocument1 pageKSGER 96W 24V 5A Electric Power Supply Unit For STM32 STC OLED T12 Digital DIY Soldering Station ControllerTom Tom100% (3)

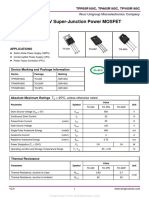

- 650V Super-Junction Power MOSFET: FeaturesDocument9 pages650V Super-Junction Power MOSFET: FeaturesAdalbertoRoque100% (1)

- RSN311W64B PDocument1 pageRSN311W64B Pmiguel angel jaramilloNo ratings yet

- Color TV Horizontal Deflection Output Applications: Data SheetDocument4 pagesColor TV Horizontal Deflection Output Applications: Data SheetJesus Wladimir RondonNo ratings yet

- Fa5695 (SPC7011F)Document21 pagesFa5695 (SPC7011F)ies837100% (1)

- TDA7296 70V - 60W DMOS Audio AmplifierDocument13 pagesTDA7296 70V - 60W DMOS Audio AmplifierGokayAkayNo ratings yet

- 32LC818 Lcd26v88amDocument53 pages32LC818 Lcd26v88amDaniel AvecillaNo ratings yet

- 69-206 Nte29Document2 pages69-206 Nte29Ulises XutucNo ratings yet

- Panasonic TV Service ModesDocument5 pagesPanasonic TV Service ModesAlfredo Valencia RodriguezNo ratings yet

- 6.2 Ka3525 Pulse Width ModulatorDocument4 pages6.2 Ka3525 Pulse Width ModulatorKarthik DmNo ratings yet

- Manual Lavadora Secadora White-WestinghouseDocument14 pagesManual Lavadora Secadora White-Westinghousecaracas293345No ratings yet

- Esquematico YEZZ 5EDocument32 pagesEsquematico YEZZ 5EJose LunarNo ratings yet

- Bd9397efv e PDFDocument30 pagesBd9397efv e PDFshafiuddin7326No ratings yet

- 5MO365R Datasheet 234274 - DSDocument21 pages5MO365R Datasheet 234274 - DSjoaocarlos1705No ratings yet

- Oscilador de TV Plasma Samsung MC34067P - MC33067PDocument17 pagesOscilador de TV Plasma Samsung MC34067P - MC33067PAntonio ChavezNo ratings yet

- TCL LD24D50 - Chassis MS09A-LA - (TKLE2413D) - Manual de Servicio PDFDocument41 pagesTCL LD24D50 - Chassis MS09A-LA - (TKLE2413D) - Manual de Servicio PDFFabian OrtuzarNo ratings yet

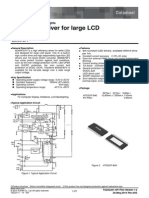

- Tps 65171Document46 pagesTps 65171deo57ar100% (2)

- Kenwood KDCMP 245 U Service Manual PDFDocument46 pagesKenwood KDCMP 245 U Service Manual PDFelmoyNo ratings yet

- MS39 Series TV Chip Training ManualDocument73 pagesMS39 Series TV Chip Training ManualMohamed SalahNo ratings yet

- Diagrama Electrico TVs Lider 8823-5VA42Document1 pageDiagrama Electrico TVs Lider 8823-5VA42jotas2525No ratings yet

- LG Chassis MC 049a RT 29fd15Document31 pagesLG Chassis MC 049a RT 29fd15Alana Clark100% (2)

- (2m246 - ( - 277 - 317 - 274 - 272 - ) .XLS) - B0ADBCB1C7FCDocument6 pages(2m246 - ( - 277 - 317 - 274 - 272 - ) .XLS) - B0ADBCB1C7FCCesarS100% (1)

- AOZ1948AIDocument13 pagesAOZ1948AIfox7878No ratings yet

- General Description Product Summary: Bvdss Rdson IDDocument4 pagesGeneral Description Product Summary: Bvdss Rdson IDDavid BarriosNo ratings yet

- Esquema TV LG Cp-29q54p 25q22 - Chassis Mc-005aDocument3 pagesEsquema TV LG Cp-29q54p 25q22 - Chassis Mc-005aAndres CamachoiNo ratings yet

- LCD Philips 32pfl3506 f7 32pfl3000 f8 Chassis Pl11.0 SMDocument89 pagesLCD Philips 32pfl3506 f7 32pfl3000 f8 Chassis Pl11.0 SMMario Contreras100% (2)

- 3-Channel 80W Audio Power ICDocument12 pages3-Channel 80W Audio Power ICTecmicro Gonzalez100% (1)

- LG LCS500UN Manual Servicio PDFDocument47 pagesLG LCS500UN Manual Servicio PDFaldo0% (1)

- Max 17126Document34 pagesMax 17126918329078250% (2)

- Power interface and backlight control circuitDocument4 pagesPower interface and backlight control circuitStoneAge1No ratings yet

- Integrados 6 TerminalesDocument9 pagesIntegrados 6 TerminalesTitán SotoNo ratings yet

- L6599ADDocument35 pagesL6599ADjuliojuder100% (1)

- HCD GT555Document118 pagesHCD GT555rgbelectronics0% (1)

- CM6800 Design GuideDocument34 pagesCM6800 Design GuidedkelicNo ratings yet

- Ne2180 Ne3280 PDFDocument43 pagesNe2180 Ne3280 PDFCarlos Castillo UrrunagaNo ratings yet

- TVC Hyundai HF-2004 Chassis CH-16CA PDFDocument45 pagesTVC Hyundai HF-2004 Chassis CH-16CA PDFJosé BenavidesNo ratings yet

- 32PC5RV Manual de ServiçoDocument38 pages32PC5RV Manual de ServiçoJose Santana100% (1)

- Stormshield SN510: Business Continuity in Complex ArchitecturesDocument4 pagesStormshield SN510: Business Continuity in Complex ArchitecturesT AnnapooraniNo ratings yet

- Sta 540 SaDocument19 pagesSta 540 Satarzan20140% (1)

- Service Manual: 8M48A ChassisDocument97 pagesService Manual: 8M48A ChassisSaidfa FaNo ratings yet

- Silicon PNP Power Transistor: INCHANGE Semiconductor Product SpecificationDocument2 pagesSilicon PNP Power Transistor: INCHANGE Semiconductor Product SpecificationElton De Souza CouraNo ratings yet

- DC 6-40v Carregador de Bateria DescarregadorDocument5 pagesDC 6-40v Carregador de Bateria DescarregadorNemesio FilhoNo ratings yet

- Nec1153 PDFDocument43 pagesNec1153 PDFCarlos Castillo UrrunagaNo ratings yet

- Panasonic NN Cs596a NN Cs596sDocument64 pagesPanasonic NN Cs596a NN Cs596sAsrulNo ratings yet

- Panasonic+Nn St557m, W+inverterDocument16 pagesPanasonic+Nn St557m, W+inverterCarlos Alberto Bandeira SoaresNo ratings yet

- Samsung MO1650xx Service ManualDocument29 pagesSamsung MO1650xx Service ManualBrent SmithNo ratings yet

- Samsung m1712n Silver SMDocument23 pagesSamsung m1712n Silver SMdieselroarmt875bNo ratings yet

- Panasonic Nn-Cs596a nn-cs596s PDFDocument64 pagesPanasonic Nn-Cs596a nn-cs596s PDFfreeschematicsNo ratings yet

- Service Manual: Specifications For APHDocument36 pagesService Manual: Specifications For APHAnonymous AsIbqUNo ratings yet

- Samsung CE1279 KSEDocument36 pagesSamsung CE1279 KSEDaniela NikolovaNo ratings yet

- SMH7159WC SAMSUNGMWlDocument33 pagesSMH7159WC SAMSUNGMWldreamyson1983No ratings yet

- Micro Onde KOT-150SOA S-MDocument72 pagesMicro Onde KOT-150SOA S-MJack BilyNo ratings yet

- SHARP Service ManualDocument44 pagesSHARP Service ManualcubewormNo ratings yet

- Horno de Microondas Sharp r209fpDocument16 pagesHorno de Microondas Sharp r209fpErick RodriguezNo ratings yet

- NN-ST657 Service ManualDocument27 pagesNN-ST657 Service ManualMarcos Yanez100% (1)

- E2 Adjustable Speed Driver Microprocessor Controlled IGBT Drive Inverter Motor Speed Regulator Operating ManualDocument63 pagesE2 Adjustable Speed Driver Microprocessor Controlled IGBT Drive Inverter Motor Speed Regulator Operating Manualel.ambiguo0% (1)

- HJC X2 Durable Film Capacitor THB Heavy DutyDocument22 pagesHJC X2 Durable Film Capacitor THB Heavy DutySignal AgulNo ratings yet

- Elng 417 Power System ProtectionDocument112 pagesElng 417 Power System ProtectionQuophi Click Lyftted100% (1)

- Sahl stock list document with parts numbers and descriptionsDocument123 pagesSahl stock list document with parts numbers and descriptionsAnonymous t8U6sKtYSNo ratings yet

- Lect 04 Diodes and Applications - Part1Document71 pagesLect 04 Diodes and Applications - Part1Sebastian GilNo ratings yet

- Introduction To Amplifier DesignDocument6 pagesIntroduction To Amplifier DesignJuanNo ratings yet

- Fused Silica DatasheetDocument2 pagesFused Silica Datasheetkats2404No ratings yet

- Rrrintel 3Document2 pagesRrrintel 3meghna vNo ratings yet

- SemiconductorDocument69 pagesSemiconductorSatheshNo ratings yet

- Power Electronics, Smart Grid and Renewable Energy SystemsDocument8 pagesPower Electronics, Smart Grid and Renewable Energy SystemsLuis Angel Garcia ReyesNo ratings yet

- Business PlanDocument25 pagesBusiness PlanMahesan SinthujanNo ratings yet

- BTech ECE 2021Document84 pagesBTech ECE 2021StiLL The BesTNo ratings yet

- Solar Panel: Solar PV Modules Mounted On A RooftopDocument17 pagesSolar Panel: Solar PV Modules Mounted On A RooftopMaria Sweetlin DNo ratings yet

- CT Saturation TutorialDocument44 pagesCT Saturation TutorialRajesh Bodduna100% (1)

- FIFO Chip Design ExampleDocument79 pagesFIFO Chip Design ExampleramachandraNo ratings yet

- 0620 s11 QP 21 PDFDocument16 pages0620 s11 QP 21 PDFArasiveluNo ratings yet

- VLSI Exam Questions on Crystal Growth, Photolithography and Oxidation ProcessesDocument2 pagesVLSI Exam Questions on Crystal Growth, Photolithography and Oxidation ProcessesAnjanaNo ratings yet

- Project Report ON and Gate: Mandi GobindgarhDocument11 pagesProject Report ON and Gate: Mandi GobindgarhAnonymous D5g37JjpGBNo ratings yet

- Optical Characterisation of La0 7Sr0 3MnDocument5 pagesOptical Characterisation of La0 7Sr0 3MnbjsimardNo ratings yet

- How To Repair CFL BulbDocument7 pagesHow To Repair CFL Bulbhernandezacevedo_jNo ratings yet

- Mini Bike LightDocument2 pagesMini Bike LightperacNo ratings yet

- Feedback Docu ProjectDocument35 pagesFeedback Docu ProjectAnonymous rgNIr9SYNo ratings yet

- Bill of Material For PCUDocument2 pagesBill of Material For PCUIqraSaeedNo ratings yet

- Bab 3 - Operational AmplifierDocument90 pagesBab 3 - Operational AmplifierAryu MitaNo ratings yet

- EDC 2 MarksDocument16 pagesEDC 2 Marksdr mbaluNo ratings yet

- P120 Application GuideDocument64 pagesP120 Application Guidevn_zoomNo ratings yet

- Cascode Amplifier: Exp - No: 5 Date: 20-9-2021Document9 pagesCascode Amplifier: Exp - No: 5 Date: 20-9-2021annambaka satishNo ratings yet

- Irf9540n PDFDocument9 pagesIrf9540n PDFKrista TranNo ratings yet

- ADC0808Document15 pagesADC0808Ketan SalviNo ratings yet

- Quanta Bd3a r3c SchematicsDocument44 pagesQuanta Bd3a r3c SchematicsKostas AthanasiadisNo ratings yet

- Simply A Logic CircuitDocument72 pagesSimply A Logic CircuitIbenk MyraldiNo ratings yet

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 5 out of 5 stars5/5 (8)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (542)

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsFrom EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsRating: 4 out of 5 stars4/5 (1)

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- C++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingFrom EverandC++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingRating: 4 out of 5 stars4/5 (1)

- Off-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemFrom EverandOff-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemNo ratings yet

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4 out of 5 stars4/5 (331)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- 8051 Microcontroller: An Applications Based IntroductionFrom Everand8051 Microcontroller: An Applications Based IntroductionRating: 5 out of 5 stars5/5 (6)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesFrom EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesRating: 5 out of 5 stars5/5 (1)

- Lithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsFrom EverandLithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsRating: 5 out of 5 stars5/5 (2)

- Ramblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowFrom EverandRamblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowNo ratings yet

- Current Interruption Transients CalculationFrom EverandCurrent Interruption Transients CalculationRating: 4 out of 5 stars4/5 (1)

- The Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026From EverandThe Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Rating: 5 out of 5 stars5/5 (1)

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- The Graphene Revolution: The Weird Science of the Ultra-thinFrom EverandThe Graphene Revolution: The Weird Science of the Ultra-thinRating: 4.5 out of 5 stars4.5/5 (4)

- Beginner's Guide to Reading Schematics, Fourth EditionFrom EverandBeginner's Guide to Reading Schematics, Fourth EditionRating: 3.5 out of 5 stars3.5/5 (10)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Digital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsFrom EverandDigital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsRating: 5 out of 5 stars5/5 (3)

- Electrical Principles and Technology for EngineeringFrom EverandElectrical Principles and Technology for EngineeringRating: 4 out of 5 stars4/5 (4)