Professional Documents

Culture Documents

ActivFire In200bar Afp1262

Uploaded by

maxmorekOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ActivFire In200bar Afp1262

Uploaded by

maxmorekCopyright:

Available Formats

LISTING NUMBER

Dates:

Commonwealth Scientific and Industrial Research Organisation, Australia

Ph.: 61 3 9252 6000

Fax: 61 3 9252 6011

Web site: http://www.ActivFire.gov.au

E-mail: info@ActivFire.gov.au

afp - 1262

Registration: ........... 21-Dec-1999

Version: .. 1.8. .. 7-Dec-2006

Valid until: ........... 31-Jul-2007

Page 1 of 3

PRODUCT LISTING DATA SHEET

(Active Fire Protection Equipment)

Product designation

Ansul, Inergen 200 bar, Inert Gas Total-Flood Type Extinguishing System

(Refer to the Technical Specification section of this document for further specific detail)

Supplier

Tyco Fire & Security

Unit 1, 2-8 South Street, RYDALMERE, NSW, AUSTRALIA, 2116

Manufacturer

Ansul Incorporated

One Stanton Street, MARINETTE, WI, USA, 54143-2542

Supplier's description

The Ansul, Inergen 200 bar, Inert Gas Total-Flood Type Extinguishing System is an engineered gaseous totalflooding type fixed fire protection system which extinguishes fire by using a patented blend of inert gases to dilute

the oxygen content of the air within the risk enclosure. The inert gas blend is marketed by Tyco International Pty Ltd

as "INERGEN" (IG-541), and is a mixture of nitrogen, argon and carbon dioxide in the approximate percentages of

52, 40, and 8 respectively. As these gases occur naturally in the atmosphere, accidental and deliberate releases of

IG-541 do not contribute to global atmospheric warming or ozone depletion. IG-541 is particularly suitable for use in

occupiable areas because the recommended extinguishing concentrations result in an atmosphere within the

protected enclosure which can be breathed for a prolonged period with no risk to health and little if any discomfort.

The Ansul, Inergen 200 bar, Inert Gas Total-Flood Type Extinguishing System covered by this SSL Product

Listing Data Sheet is quite similar to the SSL-Listed ANSUL, INERGEN 150 bar system (afp - 718) except that

the IG-541 agent is stored at 200 bar, the storage cylinders, discharge valves, other control valves, and manifold

piping, being stronger than those of the 150 bar system and otherwise suitable for the higher agent pressure.

Overall design, and pipe sizing, of the agent reticulation pipework for the 200 bar system is done with the aid of a

computer software program which is similar to that for the 150 bar systems, but allows for the slightly different flow

and pressure decay performance due to use of considerably higher storage pressure. The principal reason for

development of the 200 bar ANSUL, INERGEN equipment was to reduce the number of storage cylinders

compared to using 150 bar storage pressure and hence to achieve a significantly lower installed cost and smaller

space requirement for housing the cylinders.

Conformance criteria and evaluation

The Ansul, Inergen 200 bar, Inert Gas Total-Flood Type Extinguishing System complies with the requirements of

Australian Standard AS 4214 'Gaseous fire extinguishing systems'.

Listing is subject to ActivFire Scheme terms and conditions as applicable to the designated registrant and supplier.

This product listing data sheet should be read in conjunction with the general requirements of the

terms and conditions of listing under the ActivFire Scheme.

CSIRO Australia, 2006

afp1262.lds

Listing may be subject to amendment, suspension or withdrawal at any time. Always verify current status.

Executive Officer

afp - 1262

Registration: ........... 21-Dec-1999

Version: .. 1.8... 7-Dec-2006

Valid until:..........31-Jul-2007

Page 2 of 3

Limitations/conditions of conformance

Limitations/conditions of conformance, where identified on this Product Listing Data Sheet, are derived

from qualifications within the report of the testing agency and/or other related technical documentation. It

is recommended that all details with respect to design, assembly and installation restrictions should be

checked against the designated supplier's/manufacturer's current technical manual/data sheets and the

requirements of the Authority having Jurisdiction.

The Ansul, Inergen 200 bar, Inert Gas Total-Flood Type Extinguishing System is SSL listed for use only where

the ambient temperature of the storage cylinders will be between 0C and 54C. System design and installation

shall be done strictly in accordance with the ANSUL, INERGEN System Design, Installation, Recharge and

Maintenance Manual (with Australian Addendum), Revision 1 March 1999 (ANSUL p/n 416655), and agent

reticulation pipework sizing and layout shall be designed only by use of ANSUL INERGEN 200 bar Flow

Calculation Software, Ver. 2.02, 23 Feb. 1999.

Enclosure venting shall be provided and designed to ensure that, when the system is discharged, the pressure

within the enclosure can not become harmful to the enclosure or its occupants.

Technical specification

The following details are a representative extract of the technical specification for the Ansul, Inergen

200 bar, Inert Gas Total-Flood Type Extinguishing System and may be subject to change. Complete and

current details should be determined from the designated supplier's/manufacturer's technical manual/data

sheets.

The components of the Ansul, Inergen 200 bar, Inert Gas Total-Flood Type Extinguishing System that have

been appraised by SSL and form part of this SSL's ActivFire listed system include the following:

ANSUL (Tyco)

Part No.

Description

(IGO80H)

Storage Cylinder, 80 litre WC, 300 bar T.P.

(IGVAL200)

(IGCAPCV90)

423684

423309

Discharge Valve, Australian Version (ANSUL p/n 426679)

Transport Collar, Storage Cylinder (Valve-Protection Collar)

Electric Actuator for CV-98 Discharge Valve (suits IGVAL200)

Mechanical Actuator, Local Manual Type w/- Locking Pin, for CV-98 Discharge

Valve

Mechanical Actuator, Local Manual Type w/o Locking Pin, for CV-98 Discharge

Valve

Mechanical Actuator, Remote Cable-pull Type, for CV-98 Discharge Valve

Discharge Hose Assembly c/w check (200 bar)

Stainless Steel Actuation Hose Assembly, 406 long.

Stainless Steel Actuation Hose Assembly, 508 long.

Stainless Steel Actuation Hose Assembly, 609 long.

Pressure Reducing Orifice Assembly, 25NB

Pressure Reducing Orifice Assembly, 32NB

Pressure Reducing Orifice Assembly, 40NB

Pressure Reducing Orifice Assembly, 50NB

Discharge Nozzle, 360 pattern, 15NB, ANSUL p/n 417362

Discharge Nozzle, 360 pattern, 20NB, ANSUL p/n 417364

Discharge Nozzle, 360 pattern, 32NB, ANSUL p/n 417365

Discharge Nozzle, 360 pattern, 40NB, ANSUL p/n 417366

Discharge Nozzle, 360 pattern, 50NB, ANSUL p/n 426155

Discharge Nozzle, 360 pattern, 65NB, ANSUL p/n 426156

Discharge Nozzle, 360 pattern, 80NB, ANSUL p/n 426137

Discharge Nozzle, 180 pattern, 15NB, ANSUL p/n 426140

Discharge Nozzle, 180 pattern, 25NB, ANSUL p/n 426142

Discharge Nozzle, 180 pattern, 32NB, ANSUL p/n 426143

Discharge Nozzle, 180 pattern, 40NB, ANSUL p/n 426157

Discharge Nozzle, 180 pattern, 50NB, ANSUL p/n 426144

Discharge Nozzle, 180 pattern, 65NB, ANSUL p/n 426145

Discharge Nozzle, 180 pattern, 80NB, ANSUL p/n 426146

423310

423311

423568

831809

832335

832336

(IGORIF025)

(IGORIF032)

(IGORIF040)

(IGORIF050)

(IGNOZ015)

(IGNOZ025)

(IGNOZ032)

(IGNOZ040)

(IGNOZ050)

(IGNOZ065)

(IGNOZ080)

(IGNOZS15)

(IGNOZS25)

(IGNOZS32)

(IGNOZS40)

(IGNOZS50)

(IGNOZS65)

(IGNOZS80)

afp1262.lds

Listing may be subject to amendment, suspension or withdrawal at any time. Always verify current status.

Drawing No.

(Rev.)

Mannesmann

A 0008_03(0)

426679(3)

IGCAPCV90(0)

423550(13)

423309(1)

423311(2)

423568(1)

Registration: ........... 21-Dec-1999

Version: .. 1.8... 7-Dec-2006

Valid until:..........31-Jul-2007

afp - 1262

Page 3 of 3

Technical Specification (Cont)

ANSUL (Tyco)

Part No.

417708

417714

805156

423923

840309

842175

(73AEB03177)

(73AEB03207)

416655

ANINU200

Description

Deflector Shield, Discharge Nozzle, 15NB

Deflector Shield, Discharge Nozzle, 25NB

Pressure Trip

Cylinder Pressure Test Assembly

Header Vent Plug

Pressure Bleeder Plug

Cylinder Front Bracket

Cylinder Rear Bracket

ANSUL INERGEN System Design, Installation, Recharge and Maintenance

Manual, (with Australian Addendum)

ANSUL INERGEN 200 bar Flow Calculation Software

Drawing No.

(Rev.)

Revision March

1, 1999

Ver. 2.02

23 Feb. 1999

Piping requirements:

Two types of piping shall be used in an Ansul, Inergen 200 bar, Inert Gas Total-Flood Type Extinguishing

System:

1.

High pressure piping, extending from the storage cylinders to the pressure reducing orifice. This shall be

suitable for a working pressure of at least 23.0 MPa and shall be Class 2 or 3, Pipe Grade B, in accordance with AS

4041. Minimum thickness of pipe wall shall be in accordance with BS 1600 and ANSI/ASME B36.10M. Welding

shall be by Certified Code Welders only. Welded flanges shall be to ANSI/ASME B16.5 Class 900 lb, AS 2129

Table T. Butt-welded fittings shall be to ANSI/ASME B16.9 or BS 1640 Classes 1 and 2 (Standard weight =

Schedule 40. Extra strong = Schedule 80). Screwed fittings shall be DN50 maximum, and shall be 3000 lb fittings

to BS 3799 or ANSI B16.11.

2.

Low pressure piping, extending from the pressure reducing orifice to the nozzles. This shall be suitable for

a working pressure of at least 11.5 MPa and shall be Class 2 or 3, Pipe Grade B, in accordance with AS 4041.

Minimum thickness of pipe wall shall be in accordance with BS 1600 and ANSI/ASME B36.10M. Welding shall be

by Certified Code Welders only. Welded flanges shall be to ANSI/ASME B16.5 Class 600 lb, AS 2129 Table K.

Butt welded fittings shall be to ANSI/ASME B16.9 or BS 1640 Classes 1 and 2 (Standard weight = Schedule 40;

Extra strong = Schedule 80). Screwed fittings shall be DN50 maximum, and shall be 3000 lb fittings to BS 3799 or

ANSI B16.11.

Supplementary information

Nil Supplementary Information.

afp1262.lds

Listing may be subject to amendment, suspension or withdrawal at any time. Always verify current status.

You might also like

- MVAC Testing & Commissioning Procedure - 2007Document245 pagesMVAC Testing & Commissioning Procedure - 2007spencersiu100% (6)

- Final 99Document20 pagesFinal 99Sadeep MadhushanNo ratings yet

- HVAC Design Manual CalculationDocument114 pagesHVAC Design Manual CalculationPhyu Mar Thein Kyaw0% (1)

- 00 BLANK - Hot and Cold Water LU Calculation SheetDocument17 pages00 BLANK - Hot and Cold Water LU Calculation SheetmaxmorekNo ratings yet

- Installation and Inspection of Chillers & PumpsDocument12 pagesInstallation and Inspection of Chillers & PumpsmaxmorekNo ratings yet

- Unistrut AUS 2013Document164 pagesUnistrut AUS 2013maxmorek50% (2)

- Applied Thermodynamics and Engineering Fifth Edition by T.D Eastop and A. McconkeyDocument593 pagesApplied Thermodynamics and Engineering Fifth Edition by T.D Eastop and A. McconkeyEgonPittoors100% (2)

- Fire Safety PolicyDocument27 pagesFire Safety PolicymaxmorekNo ratings yet

- Chiller Storage Tank Sizing - 2-20-9Document2 pagesChiller Storage Tank Sizing - 2-20-9RahulNo ratings yet

- AutoCAD 2012 DGN Hotfix Readme0Document3 pagesAutoCAD 2012 DGN Hotfix Readme0Kristy RobinsonNo ratings yet

- CHEMICAL Dosing InspectionDocument2 pagesCHEMICAL Dosing InspectionmaxmorekNo ratings yet

- Fire Alarm SystemsDocument34 pagesFire Alarm Systemsengamer80No ratings yet

- Estimating Fire Detection ResponseTemperature Rating (°F)165212250286360450Document41 pagesEstimating Fire Detection ResponseTemperature Rating (°F)165212250286360450maxmorekNo ratings yet

- What Is PLADocument2 pagesWhat Is PLAmaxmorekNo ratings yet

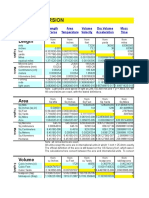

- Unit Conversion: LengthDocument35 pagesUnit Conversion: LengthAnonymous 8aj9gk7GCLNo ratings yet

- Cabstrut Price List March 2014Document48 pagesCabstrut Price List March 2014maxmorekNo ratings yet

- AutoCAD 2012 DGN Hotfix Readme0Document3 pagesAutoCAD 2012 DGN Hotfix Readme0Kristy RobinsonNo ratings yet

- Heat Load Calculation Excel SheetDocument21 pagesHeat Load Calculation Excel SheetSenthil KumarNo ratings yet

- M.01.1 Stone Clad + Steel BarsDocument1 pageM.01.1 Stone Clad + Steel BarsmaxmorekNo ratings yet

- Essential HVAC Calculations Spreadsheet for Load Estimation, Psychrometrics, Duct DesignDocument52 pagesEssential HVAC Calculations Spreadsheet for Load Estimation, Psychrometrics, Duct DesignSyed ShahbazNo ratings yet

- PIPE SIZING CALCULATION SHEETDocument9 pagesPIPE SIZING CALCULATION SHEETmaxmorekNo ratings yet

- Fume Cupboards in SchoolsDocument62 pagesFume Cupboards in SchoolsmaxmorekNo ratings yet

- The Design and Manufacture of Commercial Kitchen Extraction SystemsDocument17 pagesThe Design and Manufacture of Commercial Kitchen Extraction Systemsmaxmorek33% (3)

- BMS Systems1Document1 pageBMS Systems1maxmorekNo ratings yet

- Balancing Circuits for Optimal FlowDocument75 pagesBalancing Circuits for Optimal Flowmaxmorek100% (1)

- Cat Com Vide-UkDocument72 pagesCat Com Vide-UkmaxmorekNo ratings yet

- Safe Management of Industrial Steam and Hot Water Boilers HSEDocument10 pagesSafe Management of Industrial Steam and Hot Water Boilers HSENita IndrianiNo ratings yet

- 03 VESDA-E Pocket Guide A4 LoresDocument2 pages03 VESDA-E Pocket Guide A4 LoresmaxmorekNo ratings yet

- 00 VFT-15 Tube Length Calculator - Excel VersionDocument1 page00 VFT-15 Tube Length Calculator - Excel VersionmaxmorekNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Intake Screen For River Pump Size 24in-X-24inDocument1 pageIntake Screen For River Pump Size 24in-X-24inmoh. rusli bahtiarNo ratings yet

- ASTM F 1718 - 99Document7 pagesASTM F 1718 - 99Oh No PotatoNo ratings yet

- Mesc Spe 77-100 Oct 2012 Ball Valve To Bs 5351Document17 pagesMesc Spe 77-100 Oct 2012 Ball Valve To Bs 5351Dwayne YiiNo ratings yet

- Book FracpumpDocument7 pagesBook FracpumpMehdi MortezapourNo ratings yet

- NCDMB Cet - Flowline Construction Repairs and Replacement in Oml 17 20022023 - R2Document3 pagesNCDMB Cet - Flowline Construction Repairs and Replacement in Oml 17 20022023 - R2Peter ObueroNo ratings yet

- JF VerticalFirePumps E00636 (1) Brosur From Vendor BCUDocument6 pagesJF VerticalFirePumps E00636 (1) Brosur From Vendor BCUyoi_123No ratings yet

- ButterflyDocument43 pagesButterflyAlberico MuratoriNo ratings yet

- Design of Flange JointDocument14 pagesDesign of Flange Jointmichal_lysy100% (2)

- Ptfe TeaditDocument12 pagesPtfe TeaditDimitriNo ratings yet

- Data Sheet Highlights Submersible PumpDocument10 pagesData Sheet Highlights Submersible PumpRamón OvalleNo ratings yet

- Tube-Mac® Piping Technologies Ltd. Catalogue (Imperial Units)Document364 pagesTube-Mac® Piping Technologies Ltd. Catalogue (Imperial Units)TheAnonymousLugiaNo ratings yet

- Twistflex Pdr/Udr70, 0.6MDocument1 pageTwistflex Pdr/Udr70, 0.6MLuciano Silvério LeiteNo ratings yet

- General Bearings Part NumbersDocument93 pagesGeneral Bearings Part NumbersFaizal JamalNo ratings yet

- UmtteknikDocument85 pagesUmtteknikaaNo ratings yet

- Awwa c501-1992 铸铁闸阀Document24 pagesAwwa c501-1992 铸铁闸阀allauScribd0% (1)

- Type 6010, 6011, and Whisper Disk Inline Diffusers: Bulletin 80.1:6010Document6 pagesType 6010, 6011, and Whisper Disk Inline Diffusers: Bulletin 80.1:6010Datt NguyenNo ratings yet

- Flange Design & Bot Tightening0012Document14 pagesFlange Design & Bot Tightening0012Gulzar AliNo ratings yet

- Piston ValveDocument28 pagesPiston ValveDamien BouticourtNo ratings yet

- AVK WWE Brochure Handle Torque PDFDocument80 pagesAVK WWE Brochure Handle Torque PDFShankey JAlanNo ratings yet

- MAGNA3, Model D (I & O Instructions)Document70 pagesMAGNA3, Model D (I & O Instructions)Moshi KayandaNo ratings yet

- Process Equipment Failure FrequenciesDocument40 pagesProcess Equipment Failure FrequenciesKonstantinKot100% (6)

- Comparison of Nonmetallic Flat Gaskets in High Pressure Saturated SteamDocument6 pagesComparison of Nonmetallic Flat Gaskets in High Pressure Saturated SteamالGINIRAL FREE FIRENo ratings yet

- Basics of Steel Connections PDFDocument74 pagesBasics of Steel Connections PDFSantosh RaiNo ratings yet

- Schuf Fetterolf Drain & Sampling Valves: Ablass-Und ProbenahmeventileDocument5 pagesSchuf Fetterolf Drain & Sampling Valves: Ablass-Und ProbenahmeventilemaygomezNo ratings yet

- Instructions en 2021Document25 pagesInstructions en 2021ВадимNo ratings yet

- 00057Document31 pages00057Phanhai KakaNo ratings yet

- Escotape enDocument2 pagesEscotape enMyo Kyaw KyawNo ratings yet

- Bolt TighteningDocument13 pagesBolt Tighteningwali banNo ratings yet

- Armstrong Series L Bladder Expansion Tank Installation Instructions PDFDocument2 pagesArmstrong Series L Bladder Expansion Tank Installation Instructions PDFAngel CastNo ratings yet

- TDW 760 and Power SupplyDocument5 pagesTDW 760 and Power SupplyERICK RALPH MONTENEGRO CASTRONo ratings yet