Professional Documents

Culture Documents

Disawas Experimental Investigation On The Performance of The Refrigeration Cycle Using A Two Phase Ejector As An Expansion Device 2004

Uploaded by

Mohamed HassanainOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Disawas Experimental Investigation On The Performance of The Refrigeration Cycle Using A Two Phase Ejector As An Expansion Device 2004

Uploaded by

Mohamed HassanainCopyright:

Available Formats

International Journal of Refrigeration 27 (2004) 587594

www.elsevier.com/locate/ijrefrig

Experimental investigation on the performance of the refrigeration

cycle using a two-phase ejector as an expansion device

Somjin Disawas, Somchai Wongwises*

Fluid Mechanics, Thermal Engineering and Multiphase Flow Research Lab. (FUTURE), Department of Mechanical Engineering,

King Mongkuts University of Technology Thonburi, Bangmod, Bangkok 10140, Thailand

Received 9 September 2003; received in revised form 25 March 2004; accepted 1 April 2004

Abstract

In the present study, new experimental data on the performance of a never before seen two-phase ejector refrigeration cycle

(TPERC) is presented. In this cycle, a two-phase ejector is used as an expansion device. The TPERC enables the evaporator to

operate as in a liquid-recirculation system. The results are compared with those of the conventional refrigeration cycle (CRC).

The effects of external parameters, i.e., heat sink and heat source temperatures on the system performance are discussed. The

results show that the coefficient of performance of the TPERC is higher than that of the CRC over the whole range of

experimental conditions. This is due to a higher refrigerant-side heat transfer coefficient in the evaporator, resulting from the

higher refrigerant mass flow rate passing through the evaporator. However, the increase becomes relatively smaller as the heat

sink temperature increases.

q 2004 Elsevier Ltd and IIR. All rights reserved.

Keywords: Refrigerator system; Experiment; Expansion; Ejector; COP; R-12; R-134a

Etude experimentale sur la performance dun cycle frigorifique

employant un ejecteur en tant que detendeur

Mots-cles: Syste`me frigorifique; Experimentation; Detente; Ejecteur; COP; R-12; R-134a

1. Introduction

Throttling loss in the expansion device, through which

the refrigerant is expanded from the condenser pressure to

the evaporator pressure, is one of the thermodynamic losses

in a conventional vapor compression refrigeration cycle.

This expansion results during the isenthalpic process in

which the kinetic energy developed as the refrigerant

pressure decrease is dissipated to the refrigerant as friction

heat. The isenthalpic process causes the larger amount of the

* Corresponding author. Tel.: 662-470-9115; fax: 662-4709111.

E-mail address: somchai.won@kmutt.ac.th (S. Wongwises).

refrigerant to flash into a vapor than in the isentropic

process. As a result, the refrigerating effect of the cycle is

reduced.

In order to recover the potential kinetic energy in the

expansion process, various researchers have attempted to

use other expanders rather than the expansion engine. Due to

the low cost, no moving parts and ability to handle twophase flow without damage, an ejector is an attractive

alternative for the expansion device in the refrigeration

system.

To the best of the authors knowledge, relatively little

information is currently available on the application of the

ejector as an expansion device in a refrigeration cycle. The

most productive studies have been continuously carried out

0140-7007/$ - see front matter q 2004 Elsevier Ltd and IIR. All rights reserved.

doi:10.1016/j.ijrefrig.2004.04.002

588

S. Disawas, S. Wongwises / International Journal of Refrigeration 27 (2004) 587594

Nomenclature

COP

cp

coefficient of performance

specific heat at constant pressure

(kJ kg21 K21)

m

_

mass flow rate (kg s21)

n

circulation ratio

P

power (kW)

Q

cooling capacity (kW)

T

temperature (8C)

Subscripts

comp

compressor

e

evaporize

evap

evaporator

hw

hot water

in

inlet section

out

outlet section

p

primary or motive

s

suction

by Kornhauser [1], Harrell and Kornhauser [2] and Manegay

and Kornhauser [3].

Kornhauser [1] analyzed the thermodynamic performance of the ejector expansion refrigeration cycle. He found a

theoretical COP improvement of up to 21% over the

standard cycle under standard conditions, 2 15 and 30 8C

for evaporator and condensor temperatures, respectively.

This result is based on ideal cycle components and constant

mixing pressure in the ejector, using R-12 as a refrigerant.

Harrell et al. [2] tested a two-phase ejector and used its

performance obtained from the test rig to estimate the COP of

the refrigeration cycle. It was found that the COP improvement ranged from 3.9 to 7.6% with R-134a as a refrigerant.

Menegay et al. [3] developed a bubbly flow tube to reduce the

thermodynamic non-equilibrium in the motive nozzle. This

device was installed upstream of the motive nozzle. An

ejector using the bubbly flow tube improved up to 3.8% of the

COP over the conventional cycle under standard conditions

with R-12 as the refrigerant. However, this result is not as

good as was expected. Therefore, study of the ejector

expansion refrigeration cycle should be extended. Domanski

[4] found that the theoretical COP of the ejector expansion

refrigeration cycle was very sensitive to the ejector

efficiency. Nakagawa et al. [5] showed that the longer the

length of the divergent part of the motive nozzle, the higher

the motive nozzle efficiency could be achieved. This was

likely caused because the longer divergent part provided a

longer period of time for the two-phase flow to achieve

equilibrium.

The published papers mentioned above focus on using

the two-phase ejector as an expansion device operating with

a dry-expansion evaporator in that they still use an

expansion valve installed downstream of the liquid vapor

separator. However, the purpose of the ejector is to replace

the throttling valve. Therefore, any throttling device in the

system should be avoided.

The main concern of this work is to experimentally

investigate the performance of the refrigeration cycle using

a two-phase ejector as an expansion device. The evaporator

is therefore flooded with refrigerant and becomes a liquidrecirculation system, in which, in addition to serving as an

expansion device, the ejector also acts as a refrigerant pump

for the low-pressure side of the system. The effects of

relevant parameters are discussed. The overall performance

between the TPERC and CRC is compared.

2. Experimental apparatus

The schematic diagram of the experimental apparatus is

shown in Fig. 1. The system consists of three main loops: the

refrigerant loop, the cold-water loop, and the hot-water loop.

The refrigerant loop is designed in order to operate in

both the conventional refrigeration cycle (CRC) and the

two-phase ejector refrigeration cycle (TPERC). It consists

of the vapor compression cycle components: compressor,

condenser, expansion valve and evaporator, and other

accessory parts-the oil separator, liquid receiver, filter/drier,

sight glass and the accumulator. The operating conditions of

the apparatus are similar to those of a typical airconditioning application. The principal modifications from

the standard refrigeration system are the addition of a

Fig. 1. Schematic diagram of experimental apparatus.

S. Disawas, S. Wongwises / International Journal of Refrigeration 27 (2004) 587594

589

two-phase ejector and a liquid vapor separator. A commercial R-134a is used as the working fluid.

Refrigerant is discharged by a two-cylinder single stage

reciprocating compressor (Bitzer, Model III), driven by an

electric motor. The speed of the motor is varied to regulate

the refrigerant flowing through the motive nozzle by an

inverter (Yaskawa, CIMR-G5A47P5). Compact plate heat

exchangers (SWEP, CBE-B8-24/C) are used for condenser

and evaporators. The evaporator referred to in this paper is

the main evaporator as shown in Fig. 1. A filter/drier, placed

downstream of the receiver, is provided to keep the

circulating refrigerant free from harmful substances:

moisture and foreign particles that might remain in the

system. An oil separator is used to keep the oil content in the

refrigerant to a minimum.

The motive and the suction mass flow rates are measured

by volumetric flow meters (Bailey F and P, 10A3225)

located downstream of the sight glass and of the liquid

vapor separator, respectively. All flow meters are specially

calibrated for R-134a from the manufacturer (Bailey F and

P). The total capacity of all refrigerant flow meters is 0.3 to

3.3 LPM. The manufacturers listed accuracy is 0.1% of the

full scale. The temperatures are measured by T-type

thermocouples having accuracy of 0.1 8C. All the temperature-measuring devices are well calibrated in a controlled

temperature bath using standard precision mercury glass

thermometers. Bourdon gauges, calibrated against the dead

weight test, are used to measure the pressures. All static

pressure taps are mounted flush in the tube wall.

In order to collect data at various conditions, the heat

load to the evaporator is supplied by using the hot-water

loop. The water in the tank is heated with a 4.5 kW electric

heater and supplied through the evaporator by the circulating pump. The condenser rejects heat to the water coming

from a cold water tank. The water is cooled by a separated

refrigeration system using R-22 as refrigerant. The separated refrigeration system consists of a condensing unit with

a capacity of approximately 2.6 ton of refrigeration, a

capillary tube, filter/drier, sight glass and a helical copper

tube coil immersed in water being cooled in an insulated

tank. The test runs are done at the cooling load ranging

between 1.7 and 3.0 kW.

The two-phase ejector, shown in Fig. 2, is designed in

three main parts: the motive nozzle, the suction chamber,

and the mixing chamber with diffuser. The motive nozzle

throat area is designed according to the Henry and Fauske

model [6]. This model is used because it considers the

metastable effect of the expansion of saturated liquid into

the liquid vapor mixture region. The remaining crosssectional areas of the ejector are designed according to the

homogeneous equilibrium model (HEM) [1,7]. HEM is

based on the assumption that vapor and liquid are in thermal

and mechanical equilibrium. Furthermore, the mixing

process is assumed to occur at constant pressure. The

other dimensions, including the lengths of each section and

the convergent and divergent angles, are based on

recommendations from the ASHRAE Handbook [8] and

from Nakagawa et al. [5]. The detailed drawing of the tested

motive nozzle is shown in Fig. 3.

Brass is used as material for the ejector. The three main

parts of the ejector are connected by fine screws. Three orings, as shown in Fig. 2, are used to prevent refrigerant

leakage.

A comparison of the cycle performance for the two

modes of operation, TPERC and CRC, can be made by two

approaches. The first one is based on internal parameters,

i.e., evaporating and condensing temperatures. This method

requires the different modes to be compared at the same

evaporating and condensing temperatures. The second one

is based on external parameters such as the inlet temperature

and the flow rate of the heat transfer fluid (HTF) [9,10]. This

method allows each mode of operation to operate under the

same external conditions. In this paper, the comparison

between the TPERC and the CRC is based on the second

method. This method is selected because it is more likely in

real life [10]. Water is used as the heat transfer fluid. Hot

water acts as a heat source while cold water acts as a heat

sink of the system.

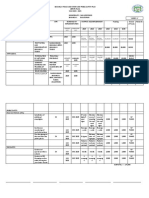

According to the experimental conditions in Table 1, the

test runs are done at heat sink temperatures ranging between

27 and 37 8C while the volume flow rate of cold water is

kept constant at 14 LPM. Each value of heat sink

temperature is tested at varying heat source temperatures

of 8, 10, 12, 14 and 16 8C. The volumetric flow rate of hot

water is fixed at 12 LPM. These volumetric flow rates of

cold water and hot water are employed to prevent water

Fig. 2. Ejector assembly.

Fig. 3. Motive nozzle.

590

S. Disawas, S. Wongwises / International Journal of Refrigeration 27 (2004) 587594

Table 1

Experimental conditions

Parameters

Heat sink

Temperature (8C)

Volumetric flow rate (LPM)

Heat source

Temperature (8C)

Volumetric flow rate (LPM)

Compressor

Speed (rpm)

Refrigerant

Heat transfer fluid

Table 3

Range of uncertainties of calculated parameters

Range

Parameters

Range of uncertainties (%)

2737 with a 2.5 8C increment

14

Pressure ratio

Circulation ratio

Cooling capacity

COP

^1.16

^4.47

^3.21

^9.16

816 with a 2.0 8C increment

12

450

R-134a

Water

from freezing on the surface of equipment. The compressor

speed is maintained at 450 rpm by controlling the inverter

frequency. It should be noted that this speed is appropriate

for this experimental set up. This speed is employed after

problems were encountered at several different speeds used

in previous experiments. It has been found that if the

compressor speeds of over 450 rpm are used, the pressure in

the liquid vapor separator decreases. This enables the

liquid in the separator to become increasingly vaporized and

finally result in the increase of the vapor temperature. This

high temperature vapor probably causes the compressor to

become damaged. Also if the compressor speeds of lower

than 450 rpm are used, the amount of liquid in the separator

gradually increases. Finally, the liquid refrigerant floods the

outlet of the separator (see Fig. 1) and flows to the

compressor. This results in compressor failure. The water

temperatures are kept constant at the required values in both

the hot and the cold water tanks. They are then circulated

through the condenser and evaporator at constant temperatures and constant volume flow rates by the circulating

pumps. The experiments are performed for both the TPERC

and the CRC systems. Experimental uncertainties in the

measured quantities are estimated according to Holman

[11]. The method is based on a combining of all the

uncertainties in the various primary experimental measurements. The uncertainties of measured quanties and calculated parameters are shown in Tables 2 and 3, respectively.

^ 1.32

^ 4.75

^ 3.88

^ 10.65

3. Results and discussion

The experimental apparatus presented in the previous

section was tested in order to determine the effects of the

heat sink and heat source temperatures on the relevant

parameters, the cooling capacity, coefficient of performance, mass flow rate, average evaporator pressure, compressor pressure ratio, and the discharge temperature. All

parameters are plotted for comparative purposes. Thermodynamic properties of R-134a were evaluated by using

REFPROP [12].

Fig. 4 shows the variation of the measured mass flow rate

of refrigerant with heat sink temperature in the TPERC and

in the CRC for the different heat source temperatures of 8,

12 and 16 8C. In fact, the refrigerant mass flow rate in the

CRC is constant throughout the system whereas the TPERC

has a different mass flow rate for high-pressure and lowpressure sides. In this paper, the high-pressure side mass

flow rate refers to the flow rate through the motive nozzle

m

_ p for the TPERC, and through the expansion device for

the CRC, while the low-pressure side mass flow rate to that

flowing through the evaporator m

_ s for both modes of

operation. Considering the mass flow rate through the

expansion device, it is found that at lower heat sink

temperature, the CRC has a higher mass flow rate than the

TPERC. It can also be seen that the mass flow rate of the

TPERC increases with increasing heat sink temperature and

Table 2

Uncertainties of measured quantities

Parameters

Uncertainty

Unit

Temperature

Pressure (low-side)

Pressure (high-side)

Flow rate (refrigerant)

Flow rate (water)

Compressor speed

^0.1

^0.5(^3.45)

^1.0 (^6.90)

^0.02

^0.2

^5

8C

Psi (kPa)

Psi (kPa)

LPM

LPM

rpm

Fig. 4. Comparison of the mass flow rate of the TPERC and the CRC

as a function of heat sink temperature for various heat source

temperatures.

S. Disawas, S. Wongwises / International Journal of Refrigeration 27 (2004) 587594

is almost constant for all heat source temperatures. Ejector is

a fixed-area device working under choked flow condition at

motive nozzle. The mass flow rate of refrigerant flowing

through the motive nozzle depends on pressure at the inlet of

the motive nozzle (upstream pressure). This upstream

pressure also depends directly on the heat sink temperature.

For the same subcooling at the inlet, the mass flow rate of

refrigerant flowing through motive nozzle at higher

upstream pressure (higher heat sink temperature) is higher

than that at lower upstream pressure (lower heat sink

temperature).

In contrast, in case of expansion valve, at specific heat

source temperature, the mass flow rate of the CRC tends to

decrease with increasing heat sink temperature. This is

because expansion valve is a kind of variable area devices

controlling the flow of liquid refrigerant to the evaporator.

For example, if the cooling load decreases, pressure at the

inlet of expansion valve decreases and thereby repositions

the valve closing to allow a smaller amount of liquid

refrigerant to enter the evaporator. In the present work, the

experimental results show that Qevap decrease with increasing heat sink temperature. Therefore, it can be concluded

that for the CRC, the increasing heat sink temperature

causes the refrigerant mass flow rate to decrease. Moreover,

at the same heat sink temperature, the mass flow rates at

higher heat source temperature are higher than at lower ones

across the range of heat sink temperatures.

Fig. 4 also shows that the evaporator mass flow rate of

the TPERC increases with increasing heat sink temperature.

The increase of the evaporator mass flow rate of the TPERC

leads to an increase in the heat transfer coefficient. However,

this also results in an increase of pressure drop across the

evaporator, leading to an increase in the specific work of the

compressor.

For the TPERC, as in the liquid-recirculation system, the

refrigerant is fed at a higher mass flow rate than is required

for evaporation. The ratio between refrigerant mass flow

Fig. 5. Variation of the circulation ratio with heat sink temperature

of the TPERC.

591

rate delivered to the evaporator m

_ s and flow rate of the

vaporized refrigerant m

_ e is called the recirculation number

or circulation ratio n [13], and can be written as:

n

m

_s

m

_e

Fig. 5 shows the variation of the circulation ratio with heat

sink temperature in the TPERC for the different heat source

temperatures of 8, 10, 12, 14 and 16 8C. It can be clearly

seen from the figure that at a specific heat source

temperature, as the heat sink temperature increases, the

circulation ratio also increases. And at the same heat sink

temperature, the circulation ratios at a higher heat source

temperature are lower than at lower ones across the range of

heat sink temperatures. The reason for this, is that when the

evaporator pressure or the heat source temperature

increases, the cooling capacity Qevap increases, while the

latent heat of vaporization hfg decreases, therefore causing

the flow rate of vaporized refrigerant m

_ e to increase. From

the result shown in Fig. 4, the refrigerant mass flow rate

delivered to the evaporator m

_ s is almost constant at various

heat source temperatures. Therefore, it can be clearly seen

that at a specific heat sink temperature, when the heat source

temperature increases, circulation ratio will decrease.

Again, from Fig. 4 it is found that both motive and

suction flows are almost independent of the heat source

temperature. This leads to the conclusion that the ejector can

be used as an expansion device in a vapor compression

refrigeration cycle with a wide range of cooling load

variations.

As the load for the evaporator increases, the evaporator

pressure increases, and the amount of refrigerant required to

accommodate the increased load also increases. In other

words, while the load decreases, the pressure and mass flow

rate at the evaporator also decrease. From Fig. 5, it is found

that the system can provide enough refrigerant to the

Fig. 6. Comparison of the average evaporator pressure between the

TPERC and the CRC as a function of heat source temperature for

various heat sink temperatures.

592

S. Disawas, S. Wongwises / International Journal of Refrigeration 27 (2004) 587594

evaporator as long as the circulation ratio is larger than one.

Therefore, although the ejector is a fixed-flow-area device, it

can provide refrigerant to the evaporator under a variation of

cooling loads, regardless of the evaporator pressure.

Fig. 6 shows the variation of the average evaporator

pressure with heat source temperature for superheating at

the compressor inlet ranging between 4 and 8 8C for

different heat sink temperatures of 27, 32, and 37 8C. Fig.

6 also compares the average evaporator pressure obtained

from the TPERC with that obtained from the CRC. The

graph shows that the TPERC has a higher evaporator

pressure than the CRC. The flooding refrigerant in the

evaporator in the TPERC is the subcooled and two-phase

mixture, while that in CRC is the two-phase mixture and

superheated vapour. This results in the higher heat transfer

rate in TPERC causing the average evaporator pressure to be

higher than that in the CRC. This means that the

corresponding evaporator temperature of the TPERC is

also higher than that of the CRC, resulting in a small

temperature difference between the refrigerant and the heat

transfer fluid (water). This is desirable from a thermodynamic point of view in that the system should be run at as high

an evaporator pressure as possible in order to obtain the

highest possible COP.

Figs. 7 and 8 present the variations of the compressor

pressure ratio and the discharge temperature with the heat

source temperatures, respectively. It can be clearly seen

from Fig. 7 that the pressure ratio of the TPERC is lower

than that of the CRC at the same heat sink temperature.

Considering Fig. 8, at a specific heat sink temperature, the

discharge temperature of the TPERC slightly decreases

while the heat source temperature increases. At the same

heat source temperature, the discharge temperature at higher

heat sink temperature is higher than at lower heat sink

temperature across the range of heat source temperatures.

The experimental results obtained from the CRC show a

where m

_ hw is the mass flow rate of the hot water (kg s21).

cp;hw is the specific heat at constant pressure of hot water

Fig. 7. Comparison of the pressure ratio between the TPERC and the

CRC as a function of heat source temperature for various heat sink

temperatures.

Fig. 9. Comparison of the cooling capacity between the TPERC and

the CRC as a function of heat source temperature for various heat

sink temperatures.

Fig. 8. Comparison of the discharge temperature between the

TPERC and the CRC as a function of heat source temperature for

various heat sink temperatures.

similar trend. However, at the same heat source and heat

sink temperature, the discharge temperature of the CRC is

higher than that of the TPERC. Due to the fact that the

evaporator pressure in the CRC is lower than that in the

TPERC (while the condenser pressure of both systems is

nearly the same), the pressure ratio and the discharge

temperature of the CRC are higher than those of the TPERC.

A lower pressure ratio and lower discharge temperature

enable the compressor to have better lubrication and a

longer lifespan.

The cooling capacity can be calculated according to the

following equation:

_ hw cp;hw Thw;in 2 Thw;out

Qevap m

S. Disawas, S. Wongwises / International Journal of Refrigeration 27 (2004) 587594

(kJ kg21 K21). Thw;in is the hot water temperature at the inlet

of the evaporator (8C). Thw;out is the hot water temperature at

the outlet of the evaporator (8C).

Fig. 9 shows the variation of the cooling capacity with

the heat source temperature for superheating at the

compressor inlet ranging between 4 and 8 8C for the

different heat sink temperatures of 27, 32, and 37 8C.

It can be seen from the figure that as the heat source

temperature increases, the cooling capacity for both modes

of operation also increases. This is because the temperature

difference between the refrigerant and the water used as the

heat transfer fluid, increases with increasing evaporator

pressure.

For the CRC, increasing of the heat source temperature

causes the cooling capacity to increase. This results from the

increasing evaporator temperature which also affects

the refrigerating effect. Furthermore, the increase of the

refrigerant density at the evaporator outlet leads to an

increase of the mass flow rate drawn by the compressor

which results in the increase of the cooling capacity. For the

TPERC, although the temperature difference between the

refrigerant and the water in the evaporator is lower,

the cooling capacity is higher than that of the CRC. This

behavior can be explained in that the overall heat transfer

coefficient of the evaporator in the TPERC is higher than

that of the CRC under the same area of the heat exchanger.

This is because of increases of the wetted area and mass flow

rate in the evaporator and the fact that the evaporator of the

CRC loses some area at the outlet for superheating, while

the evaporator outlet in the TPERC is in a liquid vapor

mixture condition.

The system COP is defined as the ratio between the

cooling capacity and the electrical power supplied to the

Fig. 10. Comparison of the COP between the TPERC and the CRC

as a function of heat sink temperature for various heat source

temperatures.

593

compressor and can be written as:

COP

Qevap

Pcomp

where Pcomp is the electrical power input to the motor of the

compressor. The power is directly obtained from the built-in

function of the inverter.

Fig. 10 shows the variation of the coefficient of

performance with the heat sink temperature for superheating

at the compressor inlet ranging between 4 and 8 8C for the

different heat source temperatures of 8, 12 and 16 8C. It can

be found that as the heat source temperature increases, the

COP also increases for both modes of operation. The heat

transfer rate in the evaporator of the TPERC is higher than

that of the CRC. This causes the COP of the TPERC to be

higher than that of the CRC over the whole range of

experimental conditions. However, the graph demonstrates

that the decreasing rate of COP in the TPERC is greater than

that of the CRC as the heat sink temperature increases. In

other words, the improvement in COP diminishes as the heat

sink temperature increases. This is mainly because of the

increment of the mass flow rate in the motive nozzle,

causing a higher power input. The COP of the TPERC

becomes increasingly higher compared to that of the CRC as

the temperature of the heat sink temperature decreases. This

shows the advantage of part-load conditions resulting from a

lower ambient temperature, which is frequently encountered

in real life situation.

4. Conclusions

This paper provides new data on the performance of the

refrigeration system using a two-phase ejector as an

expansion device. The two-phase ejector refrigeration

cycle (TPERC) enables the evaporator to operate as in a

liquid recirculation system. However, in the present work,

the effect of geometric parameters on the data is not studied

and the results are valid only with the ejector used in the

present study. Application range of the test results is shown

in Table 1. The performance of the TPERC is then compared

with that of the conventional refrigeration cycle (CRC)

using a thermostatic expansion valve as an expansion device

at the same external conditions. The following conclusions

from this study are:

1. The motive mass flow rate of the ejector is highly

dependent on the heat sink temperature and independent

of the heat source temperature. This is due to the fact that

choked flow occurs at the motive nozzle, and the

upstream condition has a significant effect on the mass

flow rate.

2. The heat source and heat sink temperatures have a

significant effect on the cooling capacity. The use of the

two-phase ejector as an expansion device enables the

594

S. Disawas, S. Wongwises / International Journal of Refrigeration 27 (2004) 587594

evaporator to be flooded by refrigerant. This leads to a

better heat transfer in the evaporator of the TPERC than

that of the CRC.

3. The TPERC shows an improvement in the COP during

low heat sink temperature. However, the improvement

becomes relatively less as the heat sink temperature

increases.

4. The compressor pressure ratio and the discharge

temperature of the TPERC are lower than those of the

CRC. This results in better lubrication and an increased

lifespan.

[4]

[5]

[6]

[7]

Acknowledgements

The authors would like to express their appreciation to

the Joint Graduate School of Energy and Environment

(JGSEE) and the Thailand Research Fund (TRF) for

providing financial support in this study. The authors also

wish to acknowledge Mr. Atikom Plertplaipan, Mr.

Kanongsak Clusintragul and Mr. Nipon Poorpromyod for

their assistance in some of the experimental work.

[8]

[9]

[10]

References

[1] Kornhauser AA. The use of an ejector as a refrigerant

expander. Proceedings of the 1990 USNC/IIR-Purdue

Refrigeration Conference; 1990, p. 10 19.

[2] Harrell GS, Kornhauser AA. Performance tests of a two-phase

ejector. Proceedings of the 30th Intersociety Energy Conversion Engineering Conference. Orlando, FL; 1995, p. 49 53.

[3] Menegay P, Kornhauser AA. Improvements to the ejector

expansion refrigeration cycle. Proceedings of the 31th

[11]

[12]

[13]

Intersociety Energy Conversion Engineering Conference.

Washington, DC; 1996, p. 702 706.

Domanski PA. Theoretical evaluation of the vapor compression cycle with a liquid-line/suction-line heat exchanger,

economizer, and ejector. Nistir-5606, National Institute of

Standards and Technology; March, 1995.

Nakagawa M, Takeuchi H. Performance of two-phase ejector

in refrigeration cycle. Proceedings of the Third International

Conference on Multiphase flow. Lyon, France; 812 June

1998, p. 18.

Henry RE, Fauske HK. The two-phase critical flow of onecomponent mixtures in nozzles, orifices, and short tubes.

ASME Trans J Heat Transfer 1971;May:179 87.

Sherif SA, Lear WE, Steadham JM, Hunt PL, Holladay JB.

Analysis and modeling of a two-phase jet pump of a thermal

management system for aerospace applications. Int J Mech Sci

2000;42:18598.

ASHRAE, ASHRAE handbookguide and data book.

American Society of Heating, Refrigerating and Air Conditioning Engineering; 1969. Chapter 13, p. 151 158.

Hoegberg M, Vamling L, Berntsson T. Calculation methods

for comparing the performance of pure and mixed working

fluids in heat pump applications. Int J Refrigeration 1993;

16(6):40313.

Giuliani G, Hewitt NJ, Marchesi Donati F, Polonara F.

Composition shift in liquid-recirculation refrigeration systems: an experimental investigation for the pure fluid R134a

and the mixture R32/134a. Int J Refrigeration 1999;22(6):

486 98.

Holman JP. Experimental methods for engineers, McGrawHill; 1987.

REFPROP, Thermodynamic properties of refrigerant and

refrigerant mixtures, version 6.01, Gaithersburg MD. National

Institute of Standards and Technology; 1998.

Stoecker WF. Industrial refrigeration handbook. McGrawHill; 1998.

You might also like

- Ts-3 Experimental Study On R-134a Refrigeration System Using A Two-Phase Ejector As An Expansion DeviceDocument11 pagesTs-3 Experimental Study On R-134a Refrigeration System Using A Two-Phase Ejector As An Expansion DevicepavannotinNo ratings yet

- Water (R718) Turbo Compressor and Ejector Refrigeration / Heat Pump TechnologyFrom EverandWater (R718) Turbo Compressor and Ejector Refrigeration / Heat Pump TechnologyNo ratings yet

- Engineering Journal::Experimental Investigation To Develop The Refrigeration System With Two Phases Condensing Ejector Along With Energy SavingDocument5 pagesEngineering Journal::Experimental Investigation To Develop The Refrigeration System With Two Phases Condensing Ejector Along With Energy SavingEngineering JournalNo ratings yet

- The University of The South Pacific: School of Engineering and PhysicsDocument4 pagesThe University of The South Pacific: School of Engineering and PhysicsRoshiv SharmaNo ratings yet

- Thermodynamics Lap 11 FinalDocument8 pagesThermodynamics Lap 11 Finalaquib14125No ratings yet

- Utf 8''sdarticle14Document9 pagesUtf 8''sdarticle14mohd_mexplore3049No ratings yet

- Ac 2013 FinDocument15 pagesAc 2013 FinRay WangNo ratings yet

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Lab Manual - Refrigeration & Air CONDITIONING (2161908) : January 2018Document47 pagesLab Manual - Refrigeration & Air CONDITIONING (2161908) : January 2018Getachew TikueNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Applied Thermal WngineeringDocument31 pagesApplied Thermal WngineeringrobinNo ratings yet

- Understanding Process Equipment for Operators and EngineersFrom EverandUnderstanding Process Equipment for Operators and EngineersRating: 4.5 out of 5 stars4.5/5 (3)

- The Effect of Capillary Tube Length On The Performance of Vapour Compression Refrigeration SystemDocument7 pagesThe Effect of Capillary Tube Length On The Performance of Vapour Compression Refrigeration SystemmahmudNo ratings yet

- Am 318385Document3 pagesAm 318385IJMERNo ratings yet

- EjectorDocument9 pagesEjectorManuel Gallegos CalderónNo ratings yet

- Osintsev 2020 IOP Conf. Ser. Earth Environ. Sci. 579 012109Document5 pagesOsintsev 2020 IOP Conf. Ser. Earth Environ. Sci. 579 012109Pooja ChughNo ratings yet

- Vapor Jet RefrigeratorDocument11 pagesVapor Jet RefrigeratorAlyan YousafNo ratings yet

- Control of Air-Cooled Chiller Condenser Fans Using Clustering Neural NetworksDocument19 pagesControl of Air-Cooled Chiller Condenser Fans Using Clustering Neural NetworksBeatrice ManolachiNo ratings yet

- Performance Improvement of The Vapour Compression Refrigeration Cycle by A Two-Phase Constant Area EjectorDocument12 pagesPerformance Improvement of The Vapour Compression Refrigeration Cycle by A Two-Phase Constant Area EjectornajeeullahNo ratings yet

- Investigating The Malfunction of A Hydro-Generator'S Cooling-SystemDocument4 pagesInvestigating The Malfunction of A Hydro-Generator'S Cooling-SystemWalter JosephNo ratings yet

- Design and Setup of The Micro-Turboexpander Transcritical CO2 SysDocument8 pagesDesign and Setup of The Micro-Turboexpander Transcritical CO2 SysRiddhesh PatelNo ratings yet

- Refrigerant UnitDocument33 pagesRefrigerant UnitSiti ZulaihaNo ratings yet

- RacDocument26 pagesRacgurunakhale123No ratings yet

- Energy and Exergy Efficiencies of Different Configurations of The Ejector-Based Co Refrigeration SystemsDocument12 pagesEnergy and Exergy Efficiencies of Different Configurations of The Ejector-Based Co Refrigeration SystemsVerma AbhiNo ratings yet

- Jurnal Teknologi: T P M E A C CDocument6 pagesJurnal Teknologi: T P M E A C CmhdmkNo ratings yet

- Thermosyphon Design for Cooling a Pentium 4 CPUCondenserOutletAmbient35.441.446.353.355.558.435.841.846.853.856.058.930.030.030.030.030.030.00.3120.3750.4180.4620.5000.525Document10 pagesThermosyphon Design for Cooling a Pentium 4 CPUCondenserOutletAmbient35.441.446.353.355.558.435.841.846.853.856.058.930.030.030.030.030.030.00.3120.3750.4180.4620.5000.525Pit_mkluNo ratings yet

- Cal U Mechanical Engineering Lab Experiment on Refrigeration CyclesDocument12 pagesCal U Mechanical Engineering Lab Experiment on Refrigeration CyclesMohamad FaizNo ratings yet

- Air Conditioning Systems Experiment: ProposalDocument16 pagesAir Conditioning Systems Experiment: ProposalShaktivell Letchumanan100% (1)

- Mcquay Chiller FundamentalsDocument20 pagesMcquay Chiller FundamentalsSajith MenonNo ratings yet

- Experimental Research and Operation Optimization of An Air-Source Heat Pumpwater HeaterDocument11 pagesExperimental Research and Operation Optimization of An Air-Source Heat Pumpwater HeaterAnderson TrindadeNo ratings yet

- 2011 - Experimental Analysis On Vortex Tube Energy Separation PerformanceDocument8 pages2011 - Experimental Analysis On Vortex Tube Energy Separation Performanceemir123456No ratings yet

- Barta - Et - Al - 2018 - Experimental Analysis and Design Improvements On Combined Viper Expansion Work Recovery Turbine and Flow Phase Separation Device in R410ADocument10 pagesBarta - Et - Al - 2018 - Experimental Analysis and Design Improvements On Combined Viper Expansion Work Recovery Turbine and Flow Phase Separation Device in R410AAmmarNo ratings yet

- Helical Coil Heat Exchanger DesignDocument4 pagesHelical Coil Heat Exchanger DesignSumit Lakde100% (1)

- Design and Performance Analysis of Water PDFDocument7 pagesDesign and Performance Analysis of Water PDFDiyar NezarNo ratings yet

- Ministory of Education: West Yangon Technological University Department of Mechanical EngineeringDocument23 pagesMinistory of Education: West Yangon Technological University Department of Mechanical EngineeringThaungShanHtet PalatarNo ratings yet

- Ijet V2i6p2Document6 pagesIjet V2i6p2International Journal of Engineering and TechniquesNo ratings yet

- Entropy: Exergy Analysis of A Subcritical Refrigeration Cycle With An Improved Impulse Turbo ExpanderDocument16 pagesEntropy: Exergy Analysis of A Subcritical Refrigeration Cycle With An Improved Impulse Turbo Expanderคงเดช คํานึกNo ratings yet

- AJES Vol.6 No.1 January June 2017 pp.18 22Document5 pagesAJES Vol.6 No.1 January June 2017 pp.18 22Design isotechplNo ratings yet

- Entropy 16-04392Document16 pagesEntropy 16-04392Wilson FigueiraNo ratings yet

- Analysis of Multiple Evaporator Refrigeration SystemDocument3 pagesAnalysis of Multiple Evaporator Refrigeration SystemInternational Jpurnal Of Technical Research And Applications0% (1)

- Dynamic Simulation LNG ProcessesDocument4 pagesDynamic Simulation LNG ProcessessppramNo ratings yet

- EN 317 - Sanidhya Anad - All Parts CombinedDocument22 pagesEN 317 - Sanidhya Anad - All Parts CombinedAtharva ChodankarNo ratings yet

- Steam Jet Refrigeration System SeminarDocument16 pagesSteam Jet Refrigeration System SeminarAmit Prakash100% (2)

- Analysis of Small Scale Ice Plant Model COPDocument23 pagesAnalysis of Small Scale Ice Plant Model COPThaungShanHtet PalatarNo ratings yet

- Value Analysis of Advanced Heat Rejection Systems For Geothermal Power PlantsDocument4 pagesValue Analysis of Advanced Heat Rejection Systems For Geothermal Power PlantsYanan CamarazaNo ratings yet

- Simulation and Validation of A Two-Stage Flash Tank Cycle Ysing R410a As A RefrigerantDocument9 pagesSimulation and Validation of A Two-Stage Flash Tank Cycle Ysing R410a As A RefrigerantYang LeechinNo ratings yet

- ModellingDocument10 pagesModellingalmadhagiNo ratings yet

- Air Conditioning Lab Final1Document20 pagesAir Conditioning Lab Final1haziqNo ratings yet

- Conjugate Heat Transfer in AirtoRefrigerant Airfoil Heat ExchangersDocument12 pagesConjugate Heat Transfer in AirtoRefrigerant Airfoil Heat ExchangersMohammed AshiqueNo ratings yet

- Experimental Investigation of Forced Draft Counter Flow Cooling Tower With Twisted Tape Insert Horizontal & VerticalDocument4 pagesExperimental Investigation of Forced Draft Counter Flow Cooling Tower With Twisted Tape Insert Horizontal & VerticalEditor IJRITCCNo ratings yet

- Thermal Performance of A Direct Expansion Solar-Assisted Heat PumpDocument8 pagesThermal Performance of A Direct Expansion Solar-Assisted Heat PumpJessica SilvaNo ratings yet

- Vol-1, Issue-5Document7 pagesVol-1, Issue-5Ijrei JournalNo ratings yet

- An Experimental Investigation of An Ejector Operating With R245faDocument6 pagesAn Experimental Investigation of An Ejector Operating With R245famhdmkNo ratings yet

- Heat Pump vs Mechanical Steam Compression DryersDocument8 pagesHeat Pump vs Mechanical Steam Compression DryersMuhammad AhmadNo ratings yet

- Black Book VCCDocument50 pagesBlack Book VCCRahul Pawar100% (2)

- Code Practice Refrigerant Leak DetectionDocument29 pagesCode Practice Refrigerant Leak DetectionArun AbNo ratings yet

- AbsorptionDocument10 pagesAbsorptionMohamed HassanainNo ratings yet

- Experimental Evaluation of HCFC-22 Replacement by The Drop-In Fluids HFC-422A and HFC-417B For Low Temperature Refrigeration ApplicationsDocument9 pagesExperimental Evaluation of HCFC-22 Replacement by The Drop-In Fluids HFC-422A and HFC-417B For Low Temperature Refrigeration ApplicationsMohamed HassanainNo ratings yet

- Air Cycle Refrigeration Systems (Indian Institute of Technology Kharagpur)Document15 pagesAir Cycle Refrigeration Systems (Indian Institute of Technology Kharagpur)emawz21No ratings yet

- Thermo 5th Chap01P001 PDFDocument33 pagesThermo 5th Chap01P001 PDFHasan ÖzdemNo ratings yet

- Refrigeration CycleDocument8 pagesRefrigeration CycleMohamed HassanainNo ratings yet

- Dynamic Viscosity and Thermal Conductivity Prediction of RefrigerDocument11 pagesDynamic Viscosity and Thermal Conductivity Prediction of RefrigerMohamed HassanainNo ratings yet

- R40 FS - Ts0027uk03Document24 pagesR40 FS - Ts0027uk03Mohamed HassanainNo ratings yet

- ST35.8/I and 3.2mmDocument1 pageST35.8/I and 3.2mmMohamed HassanainNo ratings yet

- Electric Vehicle BatteryDocument15 pagesElectric Vehicle BatteryTotal Acess100% (1)

- Cholinergic DrugsDocument29 pagesCholinergic DrugsKiranNo ratings yet

- Microeconomics 5th Edition Hubbard Solutions Manual 1Document23 pagesMicroeconomics 5th Edition Hubbard Solutions Manual 1christina100% (48)

- Plant and Animal Cells Crossword Puzzle: FreebieDocument5 pagesPlant and Animal Cells Crossword Puzzle: FreebieAref DahabrahNo ratings yet

- 310 Ta PDFDocument8 pages310 Ta PDFVincent GomuliaNo ratings yet

- F 204 (AutoRecovered)Document27 pagesF 204 (AutoRecovered)safiqulislam100% (1)

- CASE Study PTBDocument53 pagesCASE Study PTBmeleanaquino94% (16)

- Abel Rosario Marte Resume1Document2 pagesAbel Rosario Marte Resume1abelNo ratings yet

- Barangay Peace and Order and Public Safety Plan Bpops Annex ADocument3 pagesBarangay Peace and Order and Public Safety Plan Bpops Annex AImee CorreaNo ratings yet

- Environmental Stewardship - Sustainability Assignment - Ethan GabrielDocument3 pagesEnvironmental Stewardship - Sustainability Assignment - Ethan GabrielEthan GabrielNo ratings yet

- Mitsubishi v500 VFD IB NA 0600065-F FR-V500-NA Instruction Manual-DetailedDocument221 pagesMitsubishi v500 VFD IB NA 0600065-F FR-V500-NA Instruction Manual-DetailedMROstop.comNo ratings yet

- Interest RatesDocument207 pagesInterest RatesBenjamin RogersNo ratings yet

- Drug Study Pre OpDocument6 pagesDrug Study Pre OpgiaNo ratings yet

- Will BrinkDocument10 pagesWill BrinkJoao TorresNo ratings yet

- Literature Review On Female InfertilityDocument7 pagesLiterature Review On Female Infertilityea68afje100% (1)

- Examples: Inability To Sit Still, Pacing, Wringing of Hands, or Pulling of ClothingDocument14 pagesExamples: Inability To Sit Still, Pacing, Wringing of Hands, or Pulling of ClothingFaith Dianasas RequinaNo ratings yet

- Polymer MaterialsDocument31 pagesPolymer MaterialsDaithi Mac DomhnaillNo ratings yet

- MicrosystemDocument5 pagesMicrosystembabalalaNo ratings yet

- embragues-INTORK KBK14800 Erhsa2013 PDFDocument56 pagesembragues-INTORK KBK14800 Erhsa2013 PDFPablo RuizNo ratings yet

- Osteo Book Final 2014Document51 pagesOsteo Book Final 2014hyanandNo ratings yet

- DaloDocument2 pagesDalojosua tuisawauNo ratings yet

- Technical Bulletins Miglow Underwater12Document1 pageTechnical Bulletins Miglow Underwater12Arnaud PoliNo ratings yet

- Science 6-Q1-M6Document14 pagesScience 6-Q1-M6John Philip LegaspiNo ratings yet

- Physical Security Audit Checklist PDFDocument3 pagesPhysical Security Audit Checklist PDFHendrawan StbNo ratings yet

- Escala de Violencia e Índice de SeveridadDocument11 pagesEscala de Violencia e Índice de SeveridadpsiserviciosprofesioNo ratings yet

- Nursing Philosophy ReflectionDocument7 pagesNursing Philosophy Reflectionapi-480790431No ratings yet

- Louise L HAY AffirmationsDocument10 pagesLouise L HAY AffirmationsEvi Kutasi100% (2)

- BSN-2D 1st Semester ScheduleDocument2 pagesBSN-2D 1st Semester ScheduleReyjan ApolonioNo ratings yet

- Chemical Process Safety Toxicology Dose Response Data AnalysisDocument8 pagesChemical Process Safety Toxicology Dose Response Data AnalysisMuhammad Noor WaliNo ratings yet

- 16 Point Msds Format As Per ISO-DIS11014 PDFDocument8 pages16 Point Msds Format As Per ISO-DIS11014 PDFAntony JebarajNo ratings yet

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Quantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationFrom EverandQuantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationRating: 1 out of 5 stars1/5 (1)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Introduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandIntroduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 2.5 out of 5 stars2.5/5 (3)

- Control of Power Electronic Converters and Systems: Volume 1From EverandControl of Power Electronic Converters and Systems: Volume 1Rating: 5 out of 5 stars5/5 (1)

- Machinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeFrom EverandMachinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeRating: 3.5 out of 5 stars3.5/5 (4)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Design of Foundations for Offshore Wind TurbinesFrom EverandDesign of Foundations for Offshore Wind TurbinesRating: 5 out of 5 stars5/5 (3)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Three Laws of Nature: A Little Book on ThermodynamicsFrom EverandThree Laws of Nature: A Little Book on ThermodynamicsRating: 4.5 out of 5 stars4.5/5 (10)