Professional Documents

Culture Documents

B31.3 - Process - Piping - Course - 11 Designing With Expansion Joints

Uploaded by

abs0001Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B31.3 - Process - Piping - Course - 11 Designing With Expansion Joints

Uploaded by

abs0001Copyright:

Available Formats

ASME B31.

3 Process Piping Course

11. Designing with Expansion Joints

ASME B31.3 Process Piping

Charles Becht IV, PhD, PE

Don Frikken, PE

Instructors

Designing with Expansion Joints -

Piping Development Process

1. Establish applicable system standard(s)

2. Establish design conditions

3. Make overall piping material decisions

Pressure Class

Reliability

Materials of construction

4. Fine tune piping material decisions

Materials

Determine wall thicknesses

Valves

5. Establish preliminary piping system layout & support

configuration

6. Perform flexibility analysis

7. Finalize layout and bill of materials

8. Fabricate and install

9. Examine and test

Designing with Expansion Joints -

ASME B31.3 Process Piping Course

11. Designing with Expansion Joints

11. Designing with Expansion Joints

Types of Expansion Joints

Pressure Thrust

Installation of Expansion Joints

Metal Bellows Expansion Joints

(Hanjo)

(General Rubber)

(Hyspan)

Designing with Expansion Joints -

The Material in This Section is

Addressed by B31.3 in:

Chapter II - Design

Appendix X - Metallic Bellows Expansion

Joints

Designing with Expansion Joints -

ASME B31.3 Process Piping Course

11. Designing with Expansion Joints

Types of Expansion Joints

Slip

Ball

Rubber Bellows

Metal Bellows

Designing with Expansion Joints -

Pressure Thrust

Expansion Joint Manufacturers Association (EJMA)

Designing with Expansion Joints -

ASME B31.3 Process Piping Course

11. Designing with Expansion Joints

Pressure Thrust

(EJMA)

Which types of expansion joints have this problem?

Designing with Expansion Joints -

Pressure Thrust

For a bellows type expansion joint, the pressure

thrust force is the effective thrust area

recommended by the manufacturer times the

pressure. In the absence of this information:

F = P * * d p2

4

Where

F = pressure thrust force

P = pressure

dp = mean diameter of bellows

Designing with Expansion Joints -

ASME B31.3 Process Piping Course

11. Designing with Expansion Joints

Pressure Thrust

Net force on nozzle = PAn

Net force on vessel = 0

PAn

PAn

Designing with Expansion Joints -

Pressure Thrust

Net force on nozzle = F-PAn

Net force on vessel = F

Net force on anchor = F

PAn

dp

PAn

Designing with Expansion Joints -

10

ASME B31.3 Process Piping Course

11. Designing with Expansion Joints

Pressure Thrust Workshop

What is the

apparent change

in the weight of a

vessel caused

by increasing the

pressure by 100

psi (700 kPa)?

Rigid Support

See the

supplement,

page 52.

Weigh Cell (typ)

Designing with Expansion Joints -

11

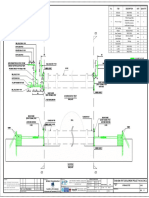

Installation of Expansion Joints

Anchors must be designed for full pressure thrust

based on maximum operating pressure.

(EJMA)

Designing with Expansion Joints -

12

ASME B31.3 Process Piping Course

11. Designing with Expansion Joints

Bellows Movement

Axial (EJMA)

Rotation (EJMA)

Designing with Expansion Joints -

13

Bellows Movement

Lateral (EJMA)

Inefficient for bellows

Bellows are not intended to

take torsional displacement.

Efficient use of bellows for

Lateral movement (EJMA)

Designing with Expansion Joints -

14

ASME B31.3 Process Piping Course

11. Designing with Expansion Joints

Universal Expansion Joint

Piping Technology & Products

(PTP)

(PTP)

Designing with Expansion Joints -

15

Universal Expansion Joint

In-plane application

(EJMA)

3-dimensional application

(EJMA)

Designing with Expansion Joints -

16

ASME B31.3 Process Piping Course

11. Designing with Expansion Joints

Hinged Expansion Joint

(EJMA)

(Adsco)

(Hae Jo Industrial)

Designing with Expansion Joints -

17

Hinged Expansion Joint

(EJMA)

(EJMA)

Designing with Expansion Joints -

18

ASME B31.3 Process Piping Course

11. Designing with Expansion Joints

Gimbal Expansion Joint

(EJMA)

(Adsco)

(Hae Jo Industrial)

Designing with Expansion Joints -

19

Gimbal Expansion Joint

(EJMA)

Designing with Expansion Joints -

20

ASME B31.3 Process Piping Course

11. Designing with Expansion Joints

Pressure Balanced Expansion Joint

Designing with Expansion Joints -

21

Pressure Balanced Expansion Joint

(EJMA)

(Hae Jo Industrial)

Designing with Expansion Joints -

22

ASME B31.3 Process Piping Course

11. Designing with Expansion Joints

Pressure Balanced Expansion Joint

(EJMA)

(EJMA)

Designing with Expansion Joints -

23

Bellows Expansion Joint Types

Type

Single

Type

Axial

Yes

Universal

(tied)

Lateral Rotation

Small

Yes

Yes

Yes

Hinged

Yes

Gimbal

Yes

Pressure

Balanced

Yes

Small

Pressure

Thrust

Yes

Yes

Designing with Expansion Joints -

24

ASME B31.3 Process Piping Course

11. Designing with Expansion Joints

Metal Bellows Expansion Joints

Bellows Shapes

Failure Modes

Designing with Expansion Joints -

25

Bellows Shapes (EJMA)

Designing with Expansion Joints -

26

ASME B31.3 Process Piping Course

11. Designing with Expansion Joints

Bellows Shapes (EJMA)

Unreinforced U

Toroidal

Reinforced U

Designing with Expansion Joints -

27

Metal Bellows Failure Modes

In-plane squirm

Column squirm

Fatigue

In-plane

squirm

(Design Factor = 2.6 on cycles)

Creep-fatigue

Burst, collapse, over

stretching

Column

squirm

(Design Factor = 3.0 on burst)

Corrosion

Designing with Expansion Joints -

28

ASME B31.3 Process Piping Course

11. Designing with Expansion Joints

Flixborough Disaster

1974 cyclohexane vapor cloud

explosion (UK)

Killed 28, injured 89, damaged 1821

homes

Caused by plant personnels failure to

recognize expansion joint pressure

thrust problem

Designing with Expansion Joints -

29

Metal Bellows Fatigue

Total Stress Range

1000000

EJMA

Unreinforced

EJMA

Reinforced

B31.3

Unreinforced

B31.3

Reinforced

100000

10000

100

1000

10000

100000

1000000

Number of Cycles

Designing with Expansion Joints -

30

You might also like

- B31.3 Process Piping Course - 11 Designing With Expansion Joints PDFDocument15 pagesB31.3 Process Piping Course - 11 Designing With Expansion Joints PDFSulist N WahyudieNo ratings yet

- B31.3 Process Piping Course - 07 Layout and SupportDocument15 pagesB31.3 Process Piping Course - 07 Layout and SupportgerrydimayugaNo ratings yet

- B31.3 Process Piping Course - 08 FlexibilityDocument23 pagesB31.3 Process Piping Course - 08 Flexibilitydalianbouri100% (1)

- Unlock-B31.3 Process Piping Course - 11 Designing With Expansion JointsDocument15 pagesUnlock-B31.3 Process Piping Course - 11 Designing With Expansion JointsProkopNo ratings yet

- B31.3 Process Piping Course - 04 Pressure Design of MetalsDocument22 pagesB31.3 Process Piping Course - 04 Pressure Design of MetalsEryl YeongNo ratings yet

- B31.3 Process Piping Course - 17 High Pressure PipingDocument12 pagesB31.3 Process Piping Course - 17 High Pressure PipingpfpmatosNo ratings yet

- Drilling Engineering - Casing DesignDocument65 pagesDrilling Engineering - Casing Designnissefar00750% (2)

- Design of Ductile Iron Pipe DIPRA PDFDocument8 pagesDesign of Ductile Iron Pipe DIPRA PDFChristian D. OrbeNo ratings yet

- C-27-2008 Thrust Block DesignDocument26 pagesC-27-2008 Thrust Block Designeagle411No ratings yet

- Thrust Restraint Design For DI PipeDocument24 pagesThrust Restraint Design For DI PipefazyroshanNo ratings yet

- ASME Code CalculationDocument12 pagesASME Code Calculationmasoud_968370957No ratings yet

- Thrust and Anchor Blocks DesignDocument26 pagesThrust and Anchor Blocks DesignShyBokx100% (4)

- Geothermal Engineering DesignDocument67 pagesGeothermal Engineering Designrichard nagilusNo ratings yet

- DIPRA - Design of Ductile Iron PipeDocument8 pagesDIPRA - Design of Ductile Iron PipeSrinivasan DeviNo ratings yet

- Aspects of Piperack DesignDocument70 pagesAspects of Piperack Designdhdahanuwala100% (3)

- 16-21Document6 pages16-21parag7676No ratings yet

- Ductile Iron Pipe vs. BCCP Pipe: Strength and ForDocument20 pagesDuctile Iron Pipe vs. BCCP Pipe: Strength and ForAnonymous kbPP3CCcNo ratings yet

- 10 Casing DesignDocument78 pages10 Casing Designمحمد سعيدNo ratings yet

- American Water Works Association Journal (American Water Works Association)Document15 pagesAmerican Water Works Association Journal (American Water Works Association)picott100% (1)

- Module 05 Piping Stress Analysis Pravin JedheDocument15 pagesModule 05 Piping Stress Analysis Pravin JedheAbdul Tayyeb100% (2)

- Selecting The Optimum Bolt Assembly Stress Influence of Flange Type On Flange Load LimitDocument7 pagesSelecting The Optimum Bolt Assembly Stress Influence of Flange Type On Flange Load LimitMohammed EljammalNo ratings yet

- The Piping Guide by David Sherwood - 1991Document267 pagesThe Piping Guide by David Sherwood - 1991bavarian_sheep100% (1)

- ProTech1Ch6 PDFDocument61 pagesProTech1Ch6 PDFweldsv100% (1)

- Introduction FlangesDocument2 pagesIntroduction FlangesArmandoZacariasAcostaNo ratings yet

- Cyclic Behavior and Seismic Design of Bolted Flange Plate Steel Moment ConnectionsDocument12 pagesCyclic Behavior and Seismic Design of Bolted Flange Plate Steel Moment ConnectionsJoaquin PalermoNo ratings yet

- Omae2011-50184 - Integral Buckle - Venu RaoDocument10 pagesOmae2011-50184 - Integral Buckle - Venu RaoD DeletarNo ratings yet

- Bolt Head Stress Concentration Factors in Cylindrical Pressure VesselsDocument6 pagesBolt Head Stress Concentration Factors in Cylindrical Pressure VesselsLeandroNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Pressure Rating PDFDocument4 pagesPressure Rating PDFMohamed AdelNo ratings yet

- B31.3 Process Piping Course - 06 Flexibility Analysis For IntroDocument10 pagesB31.3 Process Piping Course - 06 Flexibility Analysis For IntroJose BijoyNo ratings yet

- Choi 2008 Engineering-StructuresDocument10 pagesChoi 2008 Engineering-StructuresAndreea NanNo ratings yet

- Flanges General For DummiesDocument68 pagesFlanges General For DummiesditoNo ratings yet

- Thrust Restraint Design For Buried PipingDocument26 pagesThrust Restraint Design For Buried PipingSenthil Kumar SubramanianNo ratings yet

- FEM Analysis of Offshore Pipelines During Pressure Test - Multi-Objective OptimizationDocument13 pagesFEM Analysis of Offshore Pipelines During Pressure Test - Multi-Objective OptimizationLava SatNo ratings yet

- BOA Group Axial Expansion JointsDocument24 pagesBOA Group Axial Expansion JointsA_ValsamisNo ratings yet

- 1 Casing DesignDocument73 pages1 Casing DesignHasril Fauzul AziNo ratings yet

- Your Company Name: COMPRESS Pressure Vessel Design CalculationsDocument4 pagesYour Company Name: COMPRESS Pressure Vessel Design Calculationsdskr fkshNo ratings yet

- 09 Truss AnalysisDocument18 pages09 Truss Analysis0808276kNo ratings yet

- An Overview Of: Piping Material SpecificationDocument60 pagesAn Overview Of: Piping Material SpecificationNeeraj Bora100% (10)

- Es 16 417Document8 pagesEs 16 417agaricusNo ratings yet

- HDD Design and MethodologyDocument14 pagesHDD Design and MethodologyVipin Gupta100% (4)

- B31.3 Process Piping Course - 09 ReactionsDocument0 pagesB31.3 Process Piping Course - 09 ReactionsCarlos Del ToroNo ratings yet

- Pipe SupportsDocument62 pagesPipe Supportscbt_71100% (1)

- IM BSCE 4 - Steel Design Part 1Document86 pagesIM BSCE 4 - Steel Design Part 1acurvz2005No ratings yet

- Ansi B16.5 Flange PDFDocument45 pagesAnsi B16.5 Flange PDFeldaniel00067416No ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationFrom EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNo ratings yet

- Casing and Liners for Drilling and Completion: Design and ApplicationFrom EverandCasing and Liners for Drilling and Completion: Design and ApplicationRating: 5 out of 5 stars5/5 (3)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Behavior and Design of Trapezoidally Corrugated Web Girders for Bridge Construction: Recent AdvancesFrom EverandBehavior and Design of Trapezoidally Corrugated Web Girders for Bridge Construction: Recent AdvancesNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Process Heat Transfer: Principles, Applications and Rules of ThumbFrom EverandProcess Heat Transfer: Principles, Applications and Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (11)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Datasheet 1182 PDFDocument6 pagesDatasheet 1182 PDFabs0001No ratings yet

- 309-8e SKR PDFDocument56 pages309-8e SKR PDFabs0001100% (1)

- ISO Hazard Checklist WW IDM UpdateDocument6 pagesISO Hazard Checklist WW IDM Updateabs0001No ratings yet

- F7tp5a5hinob4rp PDFDocument3 pagesF7tp5a5hinob4rp PDFabs0001No ratings yet

- Metallic Casing Spacers-Isolators Designed Especially For Water and Sewer Cased PipelinesDocument8 pagesMetallic Casing Spacers-Isolators Designed Especially For Water and Sewer Cased Pipelinesabs0001No ratings yet

- MuconIDV Brochure F 1Document24 pagesMuconIDV Brochure F 1abs0001No ratings yet

- How To Cure 7 Common Tank Gauging HeadachesDocument12 pagesHow To Cure 7 Common Tank Gauging Headachesabs0001No ratings yet

- Bodinehandbook All ChaptersDocument264 pagesBodinehandbook All Chaptersabs0001No ratings yet

- BellowsTech Ebook 11-15 Vs4Document9 pagesBellowsTech Ebook 11-15 Vs4abs0001No ratings yet

- Bolts Torque CalculatorDocument2 pagesBolts Torque Calculatorabs0001No ratings yet

- Piping and Pipe Support SystemsDocument178 pagesPiping and Pipe Support Systemssaisssms9116No ratings yet

- @yard and Rack Area PipingDocument23 pages@yard and Rack Area Pipingabs0001No ratings yet

- Pump & SystemDocument84 pagesPump & Systemabs0001No ratings yet

- ChE 220 Mod 5 Flow of Incompressible Fluid 2020-2021Document73 pagesChE 220 Mod 5 Flow of Incompressible Fluid 2020-2021Claire G. MagluyanNo ratings yet

- Hydraulic PumpsDocument23 pagesHydraulic PumpsArth LubayNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument27 pagesAgitator Power Requirement and Mixing Intensity Calculation황종서100% (1)

- CVEN 3323 Weirs LabDocument5 pagesCVEN 3323 Weirs LabJJ Sean CruzNo ratings yet

- Control Valve Analysis1Document13 pagesControl Valve Analysis1Ekundayo JohnNo ratings yet

- Idlechik - 4th EditionDocument49 pagesIdlechik - 4th EditionyesrkNo ratings yet

- R4000 Series (Steel) : Operating Guidelines Product FeaturesDocument7 pagesR4000 Series (Steel) : Operating Guidelines Product FeaturesDebraj DattaNo ratings yet

- NSFMW 1992 Technical PapersDocument379 pagesNSFMW 1992 Technical Papersachmadh_2010No ratings yet

- Relief Valve (Line) - Test and Adjust - Hydraulic Hammer PDFDocument4 pagesRelief Valve (Line) - Test and Adjust - Hydraulic Hammer PDFjuan castaedaNo ratings yet

- Types 1808 and 1808A Pilot-Operated Relief Valves or Backpressure RegulatorsDocument8 pagesTypes 1808 and 1808A Pilot-Operated Relief Valves or Backpressure RegulatorsAlberto CastellanosNo ratings yet

- Pumps Identification: AKL APG ATL TPG TPR TMP TCKDocument2 pagesPumps Identification: AKL APG ATL TPG TPR TMP TCKAdi HaryadiNo ratings yet

- EBVF4103 (Chapter 4) Fluid Mechanics For Civil EngineeringDocument30 pagesEBVF4103 (Chapter 4) Fluid Mechanics For Civil EngineeringSaurabh SumanNo ratings yet

- 7733 OostlanderDocument97 pages7733 Oostlanderpich222No ratings yet

- Techlok Hubs PDFDocument6 pagesTechlok Hubs PDFG.SWAMINo ratings yet

- Hydraulic Report Mudlogging ExampleDocument1 pageHydraulic Report Mudlogging ExampleCarmen Ibeth Olivos PradaNo ratings yet

- CV of Masud Hasan - Sr. Project EngineerDocument8 pagesCV of Masud Hasan - Sr. Project Engineermasud_hasan2004No ratings yet

- Aspect Ratio (Wing)Document5 pagesAspect Ratio (Wing)MOFEEZALAMNo ratings yet

- Fluid Mechanics - Y. A. Cengel and J. M. CimbalaDocument119 pagesFluid Mechanics - Y. A. Cengel and J. M. CimbalaGilmarAranassilNo ratings yet

- Valve Literature ReviewDocument3 pagesValve Literature ReviewPratik100% (1)

- 980E-4 Hoist System Components, Operation, AdjustmentDocument30 pages980E-4 Hoist System Components, Operation, AdjustmentRonny Leido Rodriguez Bernabe100% (1)

- Control Valve (Boom Lowering)Document6 pagesControl Valve (Boom Lowering)john ayengahNo ratings yet

- Tutorial-9 PDocument1 pageTutorial-9 Ppriyanshu gangwarNo ratings yet

- Pump Head CalculationDocument22 pagesPump Head CalculationShesadri ChakrabartyNo ratings yet

- Test Kit Pressure-10002Document1 pageTest Kit Pressure-10002Thông VũNo ratings yet

- Ficha-Tecnica-10500 10502 10504 All PMDocument1 pageFicha-Tecnica-10500 10502 10504 All PMJorge Luis Sánchez MuñozNo ratings yet

- ICONE10-22763: A Complete Piping Analysis With Thermal Stratification LoadsDocument8 pagesICONE10-22763: A Complete Piping Analysis With Thermal Stratification LoadsMilton DongNo ratings yet

- Gas Lift Optimization To Improve Well PerformanceDocument11 pagesGas Lift Optimization To Improve Well Performancerante angelNo ratings yet

- Unit 4 PDFDocument23 pagesUnit 4 PDFPrathamesh LagadNo ratings yet

- Simplifed Manning Formula TableDocument4 pagesSimplifed Manning Formula TableAnonymous Of0C4dNo ratings yet

- EDL Presentation Lube Oil Blending 04 13 EngDocument27 pagesEDL Presentation Lube Oil Blending 04 13 EngMark Temitope BrownNo ratings yet