Professional Documents

Culture Documents

Beam Design

Uploaded by

Arnel DodongCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Beam Design

Uploaded by

Arnel DodongCopyright:

Available Formats

Project Control No.

SD-PLW&FH

Detailed Structural Design of Proposed Linemen's Warehouse & Function Hall

Brgy. Colo, Molave, Zamboanga del Sur

Date :

Client :

Subject :

Reference

Jan-15

Zamboanga del Sur Electric Coop. Inc.

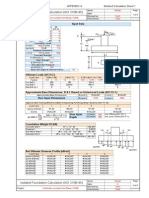

Design of Torsional Reinforcement

A.

411.8.4.3

B.

411.7.3.6

411.7.3.1

411.7.3.1

Engr. Keflin Lagura

Engr. Keflin Lagura

Engr. Keflin Lagura

Remarks

Analysis and Design Calculations

BEAM MARK:

B-1

All dimensions are in Newtons or millimeters unless otherwise indicated

409.4.2.3

411.7.1

411.7.1

411.7.1

Calculate by :

Checked by :

Approved by :

Design Input

Torsional Moment

Reduction factor, t

Angle of compression diagonals in truss analogy for torsion,

Modification Factor,

Provided torsional stirrup spacing , S

Longitudinal Reinforcement, f

Stirrup bar diameter, s

Number of Stirrup Legs, Nlegs

Beam over all depth, h

Beam overall width, b

Effective Depth, d

Concrete cover, cc

Concrete compressive strength, fc'

Steel Yield Strength, fy

Secondary Yield Strength, fyt

Shear provided by concrete, Vc

Shear provided by stirrup, Vs

Shear Demand , Vu

Analysis and Design Calculations

Area enclosed by outside perimeter, Acp = b*h =

Outside perimeter of the conc., pcp = 2*(h + b) =

Check if torsional analysis is needed, **sqrt(fc')/12 * (Acp2/pcp) =

Gross area enclosed by shear, Aoh = (b - 2*(cc + s/2))*(d-2*(cc + s/2) =

Gross area enclosed by shear flow, Ao = 0.85*Aoh =

Per. Of centerline outermost closed transverse torsional reinforcement,ph

ph = ((b - 2*(cc + s/2)) + (d-2*(cc + s/2) ) *2 =

Check for crushing of concrete or adequacy of section :

t*(Vc/b*d + (2/3)*sqrt(fc')) =

sqrt( (Vu/b*d)2 + (Tu*ph / 1.7*Aoh2)2 ) =

8.97

0.75

45

1.0

75.0

12.0

10.0

3.0

400

300

344

40

21.00

414.00

276.00

80.40

149.14

58.51

120000

1400

2.95

65100.0

55335.0

KN.m

mm

mm

mm

legs

mm

mm

mm

mm

Mpa

Mpa

Mpa

KN

KN

KN

mm2

mm

KN.m

mm2

mm2

Needed

1040.0 mm

2.876 Mpa

1.880 Mpa

Compliant

Calculation for stirrup area req'd for torsion :

411.7.3.5

Calculation for torsional nominal moment, Tn = Tu / t =

411.7.3.6

At/s = (Tn/2*Ao*fyt)*(cot )

11.964 KN.m

2

0.392 mm /mm

Calculation for stirrup area req'd for shear :

411.6.7.2

Av/s = Vs /fyt*d

2

1.571 mm /mm

Calculation for required torsional stirrups area

(Av + t)/s = Av/s + 2At/s

Calculate Area of torsional bar, Abar = Nleg*PI()*(s)2/4

2

2.354 mm /mm

2

235.62 mm

2

Calculation for area provided, Aprovided = Abar/S

3.14 mm /mm

Therefore, the provided torsional confinement is adequate to carry combined shear & torsion.

411.7.5.2

411.7.5.2

2

Check for minimum torsional area req'd, 0.062*sqrt(fc')*b/fyt

0.309 mm /mm

2

0.35*b/fyt

0.380 mm /mm

2

Therefore adopt min. torsional area req'd, (Av + 2*At)/s = larger above

0.380 mm /mm

Therefore, the provided torsional confinement is compliant for minimum requirement.

411.7.6.1

411.7.6.1

Check for maximum spacing, ph/8

130.00 mm

or 300 mm

300 mm

Thefore adopt maximum spacing, Smax

130.000 mm

Therefore, the torsional confinement spacing is compliant for code requirement.

411.7.3.7

411.7.5.3

411.7.5.3

411.6.6.2

411.6.6.2

Additional longitudinal reinforcement required for torsion,

Al = ph*(At/s)*(fyt/fy)*(cot)2

Check for minimum required longitudinal reinfircement for torsion,

Check for, 0.175*b/fyt

Therefore adopt, At/s

Check for required min. required area,

Almin = 5*sqrt(fc')*Acp/12*fy - (At/s)*fyt/fy*ph

Therefore adopt required longitudinal reinf, Al

Compliant

2

271.569 mm

2

0.19 mm /mm

2

0.392 mm /mm

2

281.88 mm

2

281.88 mm

As per NSCP Section.411.7.6.2 state that " The longitudinal reinforcement required for torsion shall be

distributed around the perimeter of the close stirrups with a maximum spacing of 300mm.The longitudinal bars

or tendons shall be inside the stirrups. There shall be at least one longitudinal bar or tendon in each corner of

the stirrups. Longitudinal bars shall have a diameter at least 1/24 of the stirrups spacings but not less than

10mm.

To satisfy above condition : ( At Left Support)

Minimum required torsional bar dia. (1/24)*S but should not be less than 10mm

Provided torsional reinf. bar diameter, t

Provided torsional reinf. area, Ator = PI()*(t2)/4

10.00 mm

12.0 mm

2

113.10 mm

Compliant

Total number of torsional reinf. provided, Nt = Al/Ator

411.6.6.2

Required number of bars, Nreq'd

Therefore, adopt number of torsional bars, N =

Distribute around the perimeter of stirrups, @ Top bars

@ Mid bars

@ Bot bars

Area of reinf. per layer, @ Top bars = Astop

@ Mid bars = Asmid

@ Bot bars = Asbot

Required flexural area @ tension side, Asten

Required reinf. area @ comp. side, Ascomp = 2*PI()*f2/4

Final Reinforcement Lay-out :

@ Top bars = Asten + Astop

Provided diameter :

Area provided, Apro = PI()*f2/4

12 mm

Total number of top bar, Ntop

@ Mid bars = Asmid

Provided diameter :

12 mm

Area. provided, Apro = PI()*t2/4

Total number of mid bar, Nmid

@Bot bars = Ascomp + Asbot

Provided diameter :

12 mm

Area provided, Apro = PI()*f2/4

Total number of bot bar, Nbot

411.6.6.2

To satisfy above condition : ( At Midspan)

Minimum required torsional bar dia. (1/24)*S but should not be less than 10mm

Provided torsional reinf. bar diameter, t

Provided torsional reinf. area, Ator =

PI()*(t2)/4

Total number of torsional reinf. provided, Nt = Al/Ator

411.6.6.2

Required number of bars, Nreq'd

Therefore, adopt number of torsional bars, N =

Distribute around the perimeter of stirrups, @ Top bars

@ Mid bars

@ Bot bars

Area of reinf. per layer, @ Top bars = Astop

@ Mid bars = Asmid

@ Bot bars = Asbot

Required flexural area @ tension side, Asten

Required reinf. area @ comp. side, Ascomp = 2*PI()*f2/4

Final Reinforcement Lay-out :

@ Top bars = Ascomp + Astop

Provided diameter :

Area provided, Apro = PI()*f2/4

12 mm

Total number of top bar, Ntop

@ Mid bars = Asmid

Provided diameter :

12 mm

Area. provided, Apro = PI()*t2/4

Total number of mid bar, Nmid

@ Bot bars = Asten + Asbot

Provided diameter :

12 mm

Area provided, Apro = PI()*f2/4

Total number of bot bar, Nbot

411.6.6.2

To satisfy above condition : ( At Right Support)

Minimum required torsional bar dia. (1/24)*S but should not be less than 10mm

Provided torsional reinf. bar diameter, t

Provided torsional reinf. area, Ator = PI()*(t2)/4

Total number of torsional reinf. provided, Nt = Al/Ator

411.6.6.2

Required number of bars, Nreq'd

Therefore, adopt number of torsional bars, N =

Distribute around the perimeter of stirrups, @ Top bars

@ Mid bars

@ Bot bars

Area of reinf. per layer, @ Top bars = Astop

@ Mid bars= Asmid

@ Bot bars = Asbot

Required flexural area @ tension side, Asten

Required reinf. area @ comp. side, Ascomp = 2*PI()*f2/4

Final Reinforcement Lay-out :

@ Top bars = Asten + Astop

Provided diameter :

Area provided, Apro = PI()*f2/4

12 mm

Total number of top bar, Ntop

@ Mid bars = Asmid

Provided diameter :

12 mm

Area. provided, Apro = PI()*t2/4

Total number of mid bar, Nmid

Provided diameter :

12 mm

3.00 pcs

6.0

6.0

2.0

2.0

2.0

226.19

pcs

pcs

pcs

pcs

pcs

mm2

2

226.19 mm

2

226.19 mm

2

339.29 mm

2

226.19 mm

2

565.49 mm

2

mm

113.10

5.0 pcs

2

226.19 mm

2

113.10 mm

2.0 pcs

2

452.39 mm

2

113.10 mm

4.0 pcs

10.00 mm

12 mm

2

113.10 mm

Compliant

3.0 pcs

6.0

6.0

2.0

2.0

2.0

226.19

pcs

pcs

pcs

pcs

pcs

mm2

2

226.19 mm

2

226.19 mm

2

339.29 mm

2

226.19 mm

2

452.39 mm

2

113.10 mm

4.0 pcs

2

226.19 mm

2

113.10 mm

2.0 pcs

2

565.49 mm

2

113.10 mm

5.0 pcs

10.00 mm

12 mm

2

113.10 mm

3.0 pcs

6.0

6.0

2.0

2.0

2.0

226.19

pcs

pcs

pcs

pcs

pcs

mm2

2

226.19 mm

2

226.19 mm

2

339.29 mm

2

226.19 mm

2

565.49 mm

2

113.10 mm

5.0 pcs

2

226.19 mm

2

113.10 mm

2.0 pcs

@Bot bars = Ascomp + Asbot

452.39

Area provided, Apro = PI()*f2/4

Total number of bot bar, Nbot

113.10

4.0 pcs

Compliant

You might also like

- Design of Floor (Slab 4) : La LBDocument10 pagesDesign of Floor (Slab 4) : La LBAyreesh Mey SpntNo ratings yet

- Concrete Beam DesignDocument3 pagesConcrete Beam DesignArnel DodongNo ratings yet

- One Way Slab Design: Ref: Nilson-13Th Edition-418 Page ExampleDocument4 pagesOne Way Slab Design: Ref: Nilson-13Th Edition-418 Page Examplerasedul islamNo ratings yet

- One Way Slab DesignDocument4 pagesOne Way Slab DesignMario FeghaliNo ratings yet

- Structural Design StepsDocument4 pagesStructural Design StepsAnonymous ciKyr0tNo ratings yet

- Two Way Slab Design PDFDocument12 pagesTwo Way Slab Design PDFAnand Kumar Pandiri100% (1)

- Part F FoundationsDocument90 pagesPart F Foundationsmedian27No ratings yet

- Earthquake Lateral ForcesDocument10 pagesEarthquake Lateral ForcesOnurUmanNo ratings yet

- Slab DesignDocument4 pagesSlab DesignAie BantuganNo ratings yet

- Sample Beam DesignDocument12 pagesSample Beam DesignmokalnganNo ratings yet

- Two Way Slab Design (DRAFT)Document72 pagesTwo Way Slab Design (DRAFT)ابو عمر الأسمريNo ratings yet

- Design of Beam (Internal) at Midspan: Solution (Using NSCP 7th Edition)Document9 pagesDesign of Beam (Internal) at Midspan: Solution (Using NSCP 7th Edition)Nico Paulo RuzNo ratings yet

- Mechanical Columns Buckling FailureDocument19 pagesMechanical Columns Buckling FailurePraful Patil100% (1)

- KANDING Loadings - NSCP 2015 - 2 Storey Residential Concrete StructureDocument23 pagesKANDING Loadings - NSCP 2015 - 2 Storey Residential Concrete StructureNikka FerrerNo ratings yet

- Slab Design One-WayDocument8 pagesSlab Design One-WayEmil ParangueNo ratings yet

- Design of One-Way Slab for Case 9Document3 pagesDesign of One-Way Slab for Case 9Ayreesh Mey SpntNo ratings yet

- DESIGN OF TWO-WAY SLAB REINFORCEMENT FOR FLOOR LEVELS 2-5Document180 pagesDESIGN OF TWO-WAY SLAB REINFORCEMENT FOR FLOOR LEVELS 2-5Gino Paolo ObsiomaNo ratings yet

- Slab Design ACI With Reinforcment (Sketch)Document7 pagesSlab Design ACI With Reinforcment (Sketch)chemtahir100% (1)

- Design Recommendations For Steel Deck Floor SlabsDocument32 pagesDesign Recommendations For Steel Deck Floor Slabswayzane100% (1)

- 1m X 1m Single Cell Box CulvDocument6 pages1m X 1m Single Cell Box CulvKush Deka100% (1)

- Double RC Beam (WSD)Document15 pagesDouble RC Beam (WSD)api-19753598No ratings yet

- Engineers: My Notes StructuralDocument14 pagesEngineers: My Notes StructuralGladies Mhay Binay SandovalNo ratings yet

- S2 - Floor / Roof: Design of Two - Way Slab With Provision For Torsion at CornersDocument2 pagesS2 - Floor / Roof: Design of Two - Way Slab With Provision For Torsion at CornersMuhammed Sabah100% (1)

- Roof SlabDocument2 pagesRoof SlabnoneNo ratings yet

- Concrete slab and beam design calculationsDocument16 pagesConcrete slab and beam design calculationsGing LimjocoNo ratings yet

- RCD-DeSIGN Engr. Mark ChristianDocument9 pagesRCD-DeSIGN Engr. Mark ChristianTaki TachibanaNo ratings yet

- Proposed Two Storey Aparment Building Struct AnalysisDocument26 pagesProposed Two Storey Aparment Building Struct AnalysisIver Ace BihisNo ratings yet

- Super Composite ColumnDocument2 pagesSuper Composite ColumnCheng Por EngNo ratings yet

- Seismic Analysis of Multi-Story RC BuildingsDocument15 pagesSeismic Analysis of Multi-Story RC BuildingsPrakash Channappagoudar100% (1)

- Slab 1 DesignDocument1 pageSlab 1 DesignJoseph Cloyd LamberteNo ratings yet

- 2 M High Free Standing WallDocument20 pages2 M High Free Standing WallAnonymous ciKyr0tNo ratings yet

- TWO WAY SLAB SEISMIC ANALYSISDocument20 pagesTWO WAY SLAB SEISMIC ANALYSISKent BasigaNo ratings yet

- BEAM DESIGN & Column DesignDocument3 pagesBEAM DESIGN & Column DesignVea Anne Austria GirayNo ratings yet

- Design of One Way SlabDocument4 pagesDesign of One Way SlabSherwin PonsNo ratings yet

- Cant FTGDocument1 pageCant FTGrbalmodalNo ratings yet

- Slab Design Slab C8Document1 pageSlab Design Slab C8Mark Christian Esguerra100% (1)

- Isolated Foundation Calculation (ACI 318M-95) : Input DataDocument5 pagesIsolated Foundation Calculation (ACI 318M-95) : Input DataJuan CarlosNo ratings yet

- 1 To 2: A To: Proposed Hostel CompexDocument4 pages1 To 2: A To: Proposed Hostel Compexanon_577049076No ratings yet

- Design of isolated footingDocument366 pagesDesign of isolated footingkarthiksampNo ratings yet

- Appendix 6.2-G - Fire Pump Engine SpecsDocument9 pagesAppendix 6.2-G - Fire Pump Engine Specs050678No ratings yet

- Design of ColumnDocument6 pagesDesign of ColumnShivsagar YadavNo ratings yet

- Design of Beam (Internal) at Midspan: Solution (Using NSCP 6th Edition)Document12 pagesDesign of Beam (Internal) at Midspan: Solution (Using NSCP 6th Edition)Nico Paulo RuzNo ratings yet

- Design rectangular beam reinforced for tensionDocument8 pagesDesign rectangular beam reinforced for tensionaltavanoarNo ratings yet

- One Way Slab DesignDocument19 pagesOne Way Slab DesignWinston Advincula100% (1)

- Slab On Metal Deck AnalysisDocument5 pagesSlab On Metal Deck Analysismaris_sasecNo ratings yet

- Design of Two Way Slab: 2nd/3rd Floor Slab S1Document14 pagesDesign of Two Way Slab: 2nd/3rd Floor Slab S1John Paul Hilary EspejoNo ratings yet

- Design of roof slab, beam and column for houseDocument18 pagesDesign of roof slab, beam and column for housekkhan_451062No ratings yet

- Structural Computation: Prepared byDocument7 pagesStructural Computation: Prepared byJing JingNo ratings yet

- Steel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiDocument6 pagesSteel Frame Structure Modeling by Staad-Pro (Example - 2) by Prof. Dr. Nabeel Al-BayatiProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (1)

- Design of Doubly Reinforced BeamDocument7 pagesDesign of Doubly Reinforced BeamAmrutha SivaramanNo ratings yet

- IBC 2006 Response SpectrumDocument5 pagesIBC 2006 Response SpectrumprabhuNo ratings yet

- Design of Isolated Mat FootingDocument5 pagesDesign of Isolated Mat FootingYAROFENo ratings yet

- Drop Panel CalculationDocument2 pagesDrop Panel Calculationsandiok86No ratings yet

- Column-Footing Size 3Document8 pagesColumn-Footing Size 3Anonymous HJ7hmihhNo ratings yet

- Protection WorkDocument1 pageProtection Workrajivkannan100% (1)

- Column Design Subjected To Axial and BendingDocument4 pagesColumn Design Subjected To Axial and BendingArnel Dodong0% (1)

- BASE PLATE DESIGN OPTIMIZATIONDocument45 pagesBASE PLATE DESIGN OPTIMIZATIONMuhammed Ali60% (5)

- Final Design of Angle Members For 4leged Single Angle TowersDocument65 pagesFinal Design of Angle Members For 4leged Single Angle Towersks_raghuveerNo ratings yet

- Design of Beam Ledge Reinforcement as per ACI 318M95Document2 pagesDesign of Beam Ledge Reinforcement as per ACI 318M95auatipu100% (1)

- 2010 Lysaght Product Catalogue 15 Dec 09Document88 pages2010 Lysaght Product Catalogue 15 Dec 09Arnel DodongNo ratings yet

- CCAC PreconstructionMeetingGuideDocument7 pagesCCAC PreconstructionMeetingGuideArnel DodongNo ratings yet

- Concrete Crack Repair ManualDocument62 pagesConcrete Crack Repair ManualShamsul Bahrin Sulaiman100% (1)

- Project Sheets 1Document1 pageProject Sheets 1Arnel DodongNo ratings yet

- 6032a4a PDFDocument2 pages6032a4a PDFArnel DodongNo ratings yet

- Ocean Wave Forecasting at Ecmwf Version 201402Document58 pagesOcean Wave Forecasting at Ecmwf Version 201402Arnel DodongNo ratings yet

- DCP TestDocument10 pagesDCP TestRicardo Alfaro100% (1)

- SikaLoadflex PdsDocument2 pagesSikaLoadflex PdsArnel DodongNo ratings yet

- Brainard Retaining Wall Design SpecsDocument4 pagesBrainard Retaining Wall Design SpecsArnel DodongNo ratings yet

- 2010 Lysaght Product Catalogue 15 Dec 09Document88 pages2010 Lysaght Product Catalogue 15 Dec 09Arnel DodongNo ratings yet

- Asok Fence Final DraftDocument14 pagesAsok Fence Final DraftArnel DodongNo ratings yet

- TAP Marrickville Geotechnical-Investigation Apr 2013Document22 pagesTAP Marrickville Geotechnical-Investigation Apr 2013Arnel DodongNo ratings yet

- SR187Document37 pagesSR187Arnel DodongNo ratings yet

- Technical Standard Ts 35-31-26 50 - Fixed Type Private Jetties On Water Way BanksDocument20 pagesTechnical Standard Ts 35-31-26 50 - Fixed Type Private Jetties On Water Way BanksArnel DodongNo ratings yet

- Hot Rolled Sheet PileDocument52 pagesHot Rolled Sheet Pileswarup_datta03100% (1)

- NZTIF Specifying TimberDocument9 pagesNZTIF Specifying TimberArnel DodongNo ratings yet

- Building Code - Contents, Preface & IntroductionDocument17 pagesBuilding Code - Contents, Preface & IntroductionArnel DodongNo ratings yet

- Scope of Services - Revised 30 Nov 15Document2 pagesScope of Services - Revised 30 Nov 15Arnel DodongNo ratings yet

- SECTION B - Structural Provisions and DemolitionDocument15 pagesSECTION B - Structural Provisions and DemolitionArnel DodongNo ratings yet

- SECTION de - Dwellings and Outbuildings - Services & EquipmentDocument13 pagesSECTION de - Dwellings and Outbuildings - Services & EquipmentArnel DodongNo ratings yet

- Drumaheglis Canoe JettyDocument10 pagesDrumaheglis Canoe JettyArnel DodongNo ratings yet

- SECTION A - All BuildingsDocument32 pagesSECTION A - All BuildingsArnel DodongNo ratings yet

- Guide to Installing Timber Roof TrussesDocument32 pagesGuide to Installing Timber Roof TrussesArnel DodongNo ratings yet

- SECTION DD - Dwellings and Outbuildings - Access & EgressDocument8 pagesSECTION DD - Dwellings and Outbuildings - Access & EgressArnel DodongNo ratings yet

- SPECIFICATION A2.4 - Early Fire Hazard TestDocument2 pagesSPECIFICATION A2.4 - Early Fire Hazard TestArnel DodongNo ratings yet

- SPECIFICATION A1.3 - Standards Adopted by ReferenceDocument7 pagesSPECIFICATION A1.3 - Standards Adopted by ReferenceArnel DodongNo ratings yet

- SPECIFICATION A2.3 - Fire Resistance of Building ElementsDocument28 pagesSPECIFICATION A2.3 - Fire Resistance of Building ElementsArnel DodongNo ratings yet

- Proposed Site Survey and Soil TestingDocument6 pagesProposed Site Survey and Soil TestingArnel DodongNo ratings yet

- CCECC 28-Aug-15Document5 pagesCCECC 28-Aug-15Arnel DodongNo ratings yet

- Solution of Homework 4Document4 pagesSolution of Homework 4Kamalakar Reddy100% (2)

- SRM Institute of Science and Technology Department of Mathematics Probability and Queueing Theory Tutorial Sheet I2Document1 pageSRM Institute of Science and Technology Department of Mathematics Probability and Queueing Theory Tutorial Sheet I2Cooldude 69No ratings yet

- Seksioni I Kabllos Per Rrymat e Lidhjes Se ShkurteDocument1 pageSeksioni I Kabllos Per Rrymat e Lidhjes Se ShkurteDukagjin Ramqaj100% (1)

- VRV A 12 PDFDocument1 pageVRV A 12 PDFMoe Thiri ZunNo ratings yet

- Pipeline Corrosion Assessment MethodsDocument21 pagesPipeline Corrosion Assessment MethodsGilletNo ratings yet

- Goniophotometer T1: OxytechDocument6 pagesGoniophotometer T1: OxytechGustavo CeccopieriNo ratings yet

- VLSI Design: Introduction & Motivation Introduction & MotivationDocument33 pagesVLSI Design: Introduction & Motivation Introduction & MotivationPriyanka SharmaNo ratings yet

- Tunnel DamperDocument8 pagesTunnel DamperIvanNo ratings yet

- The Professional DesktopDocument318 pagesThe Professional Desktopalintuta2No ratings yet

- PM Master Data Template v1Document72 pagesPM Master Data Template v1Naseer SultanNo ratings yet

- FDocument1 pageFDiego PorrasNo ratings yet

- h6541 Drive Sparing Symmetrix Vmax WPDocument19 pagesh6541 Drive Sparing Symmetrix Vmax WPsantoshNo ratings yet

- Comparative Study Between Vyatra 3 and Vyatra 4 WBMDocument9 pagesComparative Study Between Vyatra 3 and Vyatra 4 WBMFatih RakaNo ratings yet

- Power Cable Installation ManualDocument50 pagesPower Cable Installation ManualAnn DodsonNo ratings yet

- Tech Note 14Document2 pagesTech Note 14meteohrNo ratings yet

- Analisis Pengaruh Profitabilitas, Strategi Diversifikasi, Dan Good Corporate Governance Terhadap Nilai PerusahaanDocument16 pagesAnalisis Pengaruh Profitabilitas, Strategi Diversifikasi, Dan Good Corporate Governance Terhadap Nilai PerusahaanEra ZsannabelaNo ratings yet

- PF-CIS-Fall 2022 LABDocument4 pagesPF-CIS-Fall 2022 LABMuhammad FaisalNo ratings yet

- GenEd Mathematics LLL PDFDocument32 pagesGenEd Mathematics LLL PDFArmely NiedoNo ratings yet

- Climate Change: The Fork at The End of NowDocument28 pagesClimate Change: The Fork at The End of NowMomentum Press100% (1)

- Lsantos - Reflecting Writing For Optimization ProjectDocument2 pagesLsantos - Reflecting Writing For Optimization Projectapi-341418797No ratings yet

- Fans Reference GuideDocument160 pagesFans Reference Guidekarthikraja21100% (13)

- Data Warehousing: Modern Database ManagementDocument49 pagesData Warehousing: Modern Database ManagementNgọc TrâmNo ratings yet

- NewsDocument26 pagesNewsMaria Jose Soliz OportoNo ratings yet

- 3RP15 05-1aDocument3 pages3RP15 05-1atycristinaNo ratings yet

- Answers To Chemistry Homework 5.1 From Particles To Solutions P. 178 # 8,9,10Document6 pagesAnswers To Chemistry Homework 5.1 From Particles To Solutions P. 178 # 8,9,10fantasy373No ratings yet

- Valve Actuator Data SheetDocument1 pageValve Actuator Data SheetRob StorrowNo ratings yet

- Water Reducing - Retarding AdmixturesDocument17 pagesWater Reducing - Retarding AdmixturesAbdullah PathanNo ratings yet

- Hot Rolled Sheet Pile SHZ Catalogue PDFDocument2 pagesHot Rolled Sheet Pile SHZ Catalogue PDFkiet eelNo ratings yet

- Excel Gantt Chart Template: Enter Your Project Details HereDocument14 pagesExcel Gantt Chart Template: Enter Your Project Details HereBarselaNo ratings yet

- Unit-3 BioinformaticsDocument15 pagesUnit-3 Bioinformaticsp vmuraliNo ratings yet

- University of Chicago Press Fall 2009 CatalogueFrom EverandUniversity of Chicago Press Fall 2009 CatalogueRating: 5 out of 5 stars5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesFrom EverandUniversity of Chicago Press Fall 2009 Distributed TitlesRating: 1 out of 5 stars1/5 (1)