Professional Documents

Culture Documents

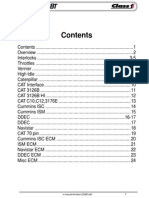

HFD Catalog IL8

Uploaded by

PartsGopher.comOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HFD Catalog IL8

Uploaded by

PartsGopher.comCopyright:

Available Formats

IL8 Series Filters - Order Today, SHIP TODAY at www.PartsGopher.

com

IL8 Series

Medium Pressure Filters

88

IL8 Series Filters - Order Today, SHIP TODAY at www.PartsGopher.com

IL8 Series

Applications

Applications for

IL8 series filters

Lube oil systems

Power generation plants

Cover

Handle

protects

indicators from

damage

Easy on, easy

off, for fast

service

Test stands

Fill Port

Prefilter the fluid,

before it gets into

the machines

system

Purge air

while filling

Primary metal equipment

Pulp & paper equipment

Offshore drilling and oil patch

Flushing skids

IL8 series filters are excellent

choices for your demanding

applications whether you require

simplex, duplex or quadplex

assemblies.

Wherever high flow or high capacity filters are required, the IL8 series

can be applied with confidence.

Air Bleed

Helps protect

bearings and

other sensitive

components from

trapped air

Indicators

You can tell

element

condition

at a glance

Both visual

and electrical

available

Filter housings have a simple yet

critical job... securely contain the

filter element with positive internal

sealing.

Bowl

Rugged cold

drawn steel

excellent fatigue

resistance

Three sizes for

any application:

Single (8),

Double (16),

and Triple (39)

Ports

SAE straight

thread or

flange face

The IL8 series filter housings are

the result of careful engineering.

High grade materials are used

to provide strength at critical stress

points.

The cover and base are annodized aluminum, the handle is nickel

plated ductile iron and the bowl is

rugged carbon steel. The result is

a reliable high performance filter for

an array of applications.

Drain Port

(not visible)

Clean and easy servicing

Lets you drain bowl of fluidbefore element changes

89

Bypass Valve

(not visible)

Soft seat design

for zero internal leakage

Located in cover assembly

IL8 Series Filters - Order Today, SHIP TODAY at www.PartsGopher.com

IL8 Series

Element Features

Ecoglass III

Replacement Elements

Reusable core

Ecoglass III represents the merging of high

performance filtration technology with

environmentally conscious engineering.

The Ecoglass III line of replacement elements

feature 100% non-metallic construction.

The design reduces solid waste and minimizes

disposal costs for industry. The non-metallic

construction means lightweight elements

(60% less weight) for easier servicing.

The Ecoglass III elements utilize the same

proprietary media design as our Microglass III

line of replacement elements.

Non-metallic Ecoglass III

element assembly

With Ecoglass III, a reusable core is installed

into the filter housing and remains in service

throughout the life of the assembly.

Microglass III

Replacement Elements

Microglass III represents a leap forward in the performance

obtainable in hydraulic and lube filter elements.

The unique multi-layer design combines high efficiencies with

exceptional dirt holding capacities for performance that is unequalled in the industry today. This performance is further enhanced in the IL8 series with the introduction of the deep pleat

design. The deep pleat element design increases the amount

of media in the element and therefore capacity.

With Microglass III you do not have to make a compromise

between efficiency and capacity, you can have both.

90

IL8 Series Filters - Order Today, SHIP TODAY at www.PartsGopher.com

IL8 Series

IL8-1 Element Performance

Efficiency

Beta Rating

10000

Efficiency %

2Q

Capacity

PSID

100

BAR

5Q

5Q

80

99.9

1000

2Q

5Q

10Q

20Q

10Q

200

60

99.5

99.0

100

20Q

5

4

3

40

20

95.0

2

20

50.0

0

12

16

20

20

40

Micron Size (c)

60

80 100 120 140 160

Capacity grams

Results typical from Multi-pass tests run per test standard ISO 16889 @ 40 gpm to 60 psid terminal - 10 mg/L BUGL

Refer to Appendix on pages 264-265 for relationship to test standard ISO 4572.

Flow vs. Pressure Loss

LPM

0

100

200

LPM

300

400

500

25

5

1.5

20

100

200

300

400

500

150SUS

Empty Housing

0.30

0.25

SAE-24

PSID

10

05Q

0.15

e

ac

eF

g

an

Fl

ce

2

e Fa

Elang

F

A

S

-2

SAE

0.5

10Q

0.20

SAE-32

20Q

30

60

90

120

150

0.0

GPM

30

60

GPM

91

90

120

150

0.10

0.05

0.0

BAR

02Q

3

BAR

1.0

PSID

15

IL8 Series Filters - Order Today, SHIP TODAY at www.PartsGopher.com

IL8 Series

IL8-2 Element Performance

Efficiency

Capacity

Beta Rating

10000

Efficiency %

2Q

BAR

PSID

60

5Q

5Q

50

2Q

5Q

10Q

20Q

99.9

1000

10Q

40

200

100

99.5

99.0

30

95.0

20

20Q

20

1

10

2

50.0

0

12

16

20

0

0

60

120 180

Micron Size (c)

240 300 360

420

Capacity grams

Results typical from Multi-pass tests run per test standard ISO 16889 @ 50 gpm to 60 psid terminal - 10 mg/L BUGL

Refer to Appendix on pages 264-265 for relationship to test standard ISO 4572.

Flow vs. Pressure Loss

LPM

0

25

200

400

LPM

600

800

1000

10

150SUS

1.5

20

200

400

600

800

1000

150SUS

Empty Housing

0.6

0.5

PSID

0.5

05Q

5

0

10Q

50

100

150

200

0.3

SA

0.4

SA

E2

10

SAE-24

0.2

0.1

20Q

250

300

0.0

GPM

50

100

150

GPM

92

200

250

300

0.0

BAR

02Q

6

BAR

1.0

PSID

15

E2

Fl

an

ge

F

Fa

lan

ce

ge

Fa

ce

SAE-32

IL8 Series Filters - Order Today, SHIP TODAY at www.PartsGopher.com

IL8 Series

IL8-3 Element Performance

Efficiency

Beta Rating

10000

Efficiency %

2Q

Capacity

PSID

60

5Q

5Q

BAR

4

2Q

5Q

10Q

20Q

50

99.9

1000

10Q

40

200

99.5

100

99.0

30

95.0

20

20Q

20

1

2

10

50.0

0

12

16

20

300

Micron Size (c)

600

900

1200

1500

Capacity grams

Results typical from Multi-pass tests run per test standard ISO 16889 @ 50 gpm to 60 psid terminal - 10 mg/L BUGL

Refer to Appendix on pages 264-265 for relationship to test standard ISO 4572.

Flow vs. Pressure Loss

LPM

10

500

1000

1500

25

150SUS

0.6

8

02Q

0.3

SAE-32

150

225

300

375

450

SAE-24

15

10

0.2

5

0.1

75

1.5

PSID

PSID

20Q

150SUS

Empty Housing

0.0

75

150

225

GPM

GPM

93

300

375

450

1.0

0.5

0.0

BAR

10Q

1500

20

BAR

0.4

05Q

1000

0.5

6

4

500

SA

SA

E2

EFla

2

ng

F

eF

la

ac

ng

e

eF

ac

e

LPM

IL8 Series Filters - Order Today, SHIP TODAY at www.PartsGopher.com

IL8 Series

Specications: IL8/LL8

Single

Pressure Ratings:

Maximum Allowable Operating Pressure

(MAOP): 500psi (34.5 bar)

Rated Fatigue Pressure: 330psi (22.8 bar)

Design Safety Factor: 3:1

Element

Removal Clearance

6.25

377.7

Double

14.87

934

Triple

36.77

Operating Temperatures:

Buna: -40oF (-40oC) to 225oF (107oC)

Fluorocarbon: -15oF (-26oC) to 275oF (135oC)

Element Collapse Rating:

150 psid (10.3 bar)

Single

Element Condition Indicators:

Visual (optional)

Electrical -heavy duty (optional)

SPDT .25 amps (resistive) MAX 5

watts 12 to 28 VDC & 110 to 175 VAC

Note: Product of switching voltage and current

must not exceed wattage rating

Double

Color Coding:

White (common)

Black (normally open)

Blue (normally closed)

Triple

4367

17.11.25

6537

25.71.25

12097

47.61.25

Materials:

Bowl: low carbon steel

Cover: anodized aluminum

Handle: nickel plated ductile iron

Base: anodized aluminum

Inlet

IL8 Outlet

33.3

1.31

Shipping Weights (approximate):

Single: 40 lbs. (18.1 kg)

Double: 50 lbs. (22.7 kg)

Triple:

75 lbs. (34 kg)

Drawings are for reference only.

Contact factory for current version.

LL8 Outlet

118.1

4.65

Linear Measure: millimeter

inch

101.6

4.0

50.8

2.0

M2

H1

H2

H3

138.2

5.44

141.7

5.58

203.2

8.00

175.3

6.90

2363

9.28.12

33.3

1.31

95.3

3.75

94

95.3

3.75

.500 - 13 UNC2B x .75 Deep

Min. Mounting

Holes, 4 Total

101.6

4.0

58.7

2.31

IL8 Series Filters - Order Today, SHIP TODAY at www.PartsGopher.com

IL8 Series

Specications: HDIL8/HQIL8

Pressure Ratings:

Maximum Allowable Operating Pressure

(MAOP): 400psi (27.6 bar)

Rated Fatigue Pressure: 330psi (22.8 bar)

Design Safety Factor: 2.5:1

Element Condition Indicators:

Visual (optional)

Electrical-heavy duty (optional)

SPDT .25 amps (resistive) MAX 5 watts

12 to 28 VDC & 110 to 175 VAC

Note: Product of switching voltage and current

must not exceed wattage rating

Operating Temperatures:

-15oF (-26oC) to 200oF (93oC)

Color Coding:

White (common)

Black (normally open)

Blue (normally closed)

Element Collapse Rating:

150 psid (10.3 bar)

Materials:

Changeover valve: steel

Bowl: low carbon steel

Cover: anodized aluminum

Cover handle: nickel plated ductile iron

Base: steel

Shipping Weights (approximate):

HDIL8-2 320 lbs. (145 kg)

HDIL8-3 375 lbs. (170 kg)

HQIL8-2 525 lbs. (238 kg)

HQIL8-3 650 lbs. (295 kg)

Linear Measure: millimeter

inch

Ansi Flange Adapter

End, Side View

22.5

7.00

177.8

Changeover Valve Flow vs. Pressure Loss

Flow LPM

500

1000

6

5

4

3

00

20

.24

lve

Va

4

US

S

0

20

e

alv

V

3

lve

Va US

3

0S

S

20

SU

.3

.2

.1

1

0

50

100

150

200

250

Flow GPM

95

300

350

400

450

500

Pressure Drop Bar

Pressure Drop PSI

1500

20

00

SU

S

4

Va

lve

IL8 Series Filters - Order Today, SHIP TODAY at www.PartsGopher.com

IL8 Series

Specications: HDIL8/HQIL8

Linear Measure: millimeter

inch

1704.5

33.55

EQUALIZING VALVE

MOUNTING HOLES

.66 DIA THRU 16 TOTAL

203.2

8.00

165.1

6.50

SAE-8 STR THD FILL PORT.

TORQUE 30-45 FT-LBS.

228.6

9.00

165.1

6.50

HDIL8

203.2

8.00

177.8

7.00

Top View

SAE-4 STR THD VENT PORT.

TORQUE 10-15 FT-LBS.

OPTIONAL ANSI

FLANGE ADAPTER

(-2)

431.8

17.0

(-3) 990.6

39.0

MINIMUM ELEMENT REMOVAL CLEARANCE

COVER

HANDLE

TORQUE:

HAND

TIGHT

H STYLE

SHOWN

TORQUE

30-45 FT-LBS

180 HANDLE

ROTATION FOR

CHANGE OVER

763.75

(-2) 30.07

HDIL8/HQIL8

Side View

M2 STYLE SHOWN

TORQUE 30-45 FT-LBS

692.7

(-2) 27.27

(-3) 1320.6

51.99

(-3) 1249.5

49.19

427.0

16.81

1 SAE-16 STR

THD DRAIN

PORT TORQUE:

85-100 FT-LBS

300

11.81

16.0

.63

65.5

2.58

STANDARD SAE PORTING

771.55

30.38

SAE-4 STR

THD VENT PORT

TORQUE 10-15

FT.-LBS.

EQUALIZING

VALVE

165.1

6.50

587.35

23.12

HQIL8

Top View

203.2

8.00

624.85

24.60

SAE-8 STR

THD FILL PORT

TORQUE

30-45 FT.-LBS.

177.8

7.00

638.85

25.15

355.60

14.00

115.9

4.56

Drawings are for reference only.

Contact factory for current version.

203.2

8.00

165.1

6.50

366.7

14.44

OPTIONAL ANSI FLANGE

ADAPTER

96

733.5

28.88

568.3

11.19

MOUNTING HOLES .66 DIA

THRU 16 TOTAL

IL8 Series Filters - Order Today, SHIP TODAY at www.PartsGopher.com

IL8 Series

Element Servicing Instructions: IL8

When servicing the IL8/LL8 filter, use

the following procedure:

Top View

1. Stop the systems power unit.

2. Relieve pressure in the filter line. Drain fluid from

housing if desired.

3. Rotate cover handle counter-clock wise.

Carefully lift and remove the cover.

4. Remove element from the housing. Discard all

disposable elements as they are not cleanable.

With Ecoglass III elements the permanent core

will remain in the housing.

5. Place new element in housing, centering it on the

element locator in the bottom of bowl.

6. Inspect cover o-ring and replace if necessary.

7. Install cover, rotate clockwise and hand tighten.

IL8

Outlet

7

Torque 3045 FTLBS

Torque 1015 FTLBS

3

Optional indicator

(Visual or Blank Only)

Location IL8, LL8

Torque 5570 FTLBS

Parts List

Nitrile

P/N

Fluorocarbon

P/N

Cover Assembly

25 psi bypass w/indicator port

50 psi bypass w/indicator port

No bypass w/indicator port

928887

928889

928891

928888

928890

928892

Cover o-ring

N72257

V72257

Indicators

P option-indicator port plug

M 225 PSI

M 250 PSI

H25 PSI

H50 PSI

H 225 PSI

H 250 PSI

H 325 PSI

H 350 PSI

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

925515

932026

932027

933053

932905

933141

933142

934164

934165

Index

1

4

not shown

6

not shown

7

Description

NOTE:

Elements

(See chart on model code page)

6

2

Bleed (vent) Plug, SAE 4

931357

931358

Fill Plug, SAE 8

908822

928628

Drain Port Plug, SAE 10

925513

928883

Base O-ring

N72262

V72262

924786

924785

924782

929313

929314

929315

926011

926010

926007

929346

929347

929348

Flange Kits (optional)

1 NPTF (w/2 flange face only)

2 NPTF (w/2 flange face only)

SAE-24 (w/2 flange face only)

2 socket weld (w/2 flange face only)

SAE-32 (w/2 flange face only)

2 NPTF (w/2 flange face only)

Handle Torque

Hand Tight

Indicator location

LL8 only

IL8/LL8 inlet

LL8 outlet

The 2 Flange Face Kits include the

minimum width SAE J518 Code 61 Flanges.

Drawings are for reference only.

Contact factory for current version.

97

IL8 Series Filters - Order Today, SHIP TODAY at www.PartsGopher.com

IL8 Series

Element Servicing Instructions: HDIL8/HQIL8

The system does not need to be shut down to service the elements.

1. Red arrow on operating handle points to on-duty

chamber(s).

2. Open off-duty vent plug(s). Do not thread out

completely.

3. Open the pressure equalizing (fill line) valve slowly to

admit fluid to the off-duty chamber(s).

4. When fluid is discharged from the off-duty vent

plug(s), close and tighten.

5. Turn the T handle, on the center valve section,

counter-clockwise 5 turns.

6. Depress the operating handle to unseat the seal

shoes, then rotate 180 and return handle upward

into the opposite slot.

7. Turn the T handle fully clockwise and hand tighten

only. This will seat the shoes.

8. Close the pressure equalizing valve.

9. Red arrow now points to the new on-duty

chamber(s).

10. Open the new off-duty vent plug(s).

11. Remove the new off-duty chamber cover(s) by

rotating counter-clockwise.

12. Remove the new off-duty drain plugs and drain

chambers to desired level.

13. Follow steps 3 - 7 on opposite page.

14. Close and tighten the vent plug(s).

Warning: You should not rotate the handle

until you equalize the pressure.

Parts List

HDIL8

HQIL8

Index

Description

Nitrile

Fluorocarbon

Nitrile

Fluorocarbon

Cover Assembly

25psi bypass w/indicator port

50psi bypass w/indicator port

No bypass w/indicator port

928887

928889

928891

928888

928890

928892

928887

928889

928891

928888

928890

928892

Cover O-ring

N72257

V72257

N72257

V72257

Indicators

P option-indicator port plug

M2 25psi

M2 50psi

H 25psi

H 50psi

H2 25psi

H2 50psi

H3 25psi

H3 50psi

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

925515

932026

932027

933053

932905

933141

933142

934164

934165

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

925515

932026

932027

933053

932905

933141

933142

934164

934165

Elements (see chart on

model code page)

Bleed (vent) Plug SAE-4

931357

931358

931357

931358

Fill Plug SAE-8

908822

928628

908822

928628

Drain Plug SAE-16

925353

928364

925353

928364

Transfer Valve

SAE 4

SAE 3

933824

933825

936123

936122

933824

933825

936123

936122

Housing Assembly

Double length

Triple length

933832

933831

933832

933831

933832

933831

933832

933831

10

5/8-11 x 3 SHCS

933928

933928

933928

933928

11

5/8 Lock Washer

933879

933879

933879

933879

12

Adapter Block Kit

(block, 3 o-rings, 12 bolts)

N/A

N/A

N/A

933833

934170

934172

934171

934173

934170

934172

934171

934173

13

Flange Adapter Kit

(flange, o-ring, 4 bolts)

3 SAE 300 lb. flange

4 SAE 300 lb. flange

14

Seal Kit Transfer Valve

Consult factory

Consult factory

15

Seal Kit Housing Assembly

Consult factory

Consult factory

16

Equalizing Valve

Consult factory

Consult factory

98

3

9

3

12

IL8 Series Filters - Order Today, SHIP TODAY at www.PartsGopher.com

IL8 Series

How to Order

BOX 1

BOX 2

BOX 3

BOX 4

BOX 5

BOX 6

BOX 7

BOX 8

BOX 9

HDIL8

20QE

HM2

25

BOX 1: SEALS

Symbols

Description

BOX 5: Element Media

Symbols

Description

BOX 7: Bypass & Indicator Setting

Symbols

Description

None

Nitrile

20QE

Ecoglass III

25

25 psid

F3

Fluorocarbon

10QE

Ecoglass III

50

50 psid

05QE

Ecoglass III

XX

02QE

Ecoglass III

No indicator and

blocked bypass

BOX 2: Basic Assembly

Symbols

Description

IL8

In-line

LL8

90o angle porting

20Q

Microglass III

HDIL8

Duplex

10Q

Microglass III

HQIL8

Quadplex

05Q

Microglass III

02Q

Microglass III

BOX 3: Basic Assembly

Symbols

Description

Single length

Double length

Note: Microglass III elements only available in

single length, and must utilize.

Triple length

Symbol

Description

Port plugged

Visual auto reset

Electrical w/ conduit

connection

Electrical w/ DIN 43650

connector

Electrical w/ 3-pin ANSI/B

93.55M connector

Electrical/Visual

(w/ NPT conduit

connection and wire

leads)

BOX 4: Core

Symbols

Description

None*

Disposable core

H2

Reusable core

H3

E

Please note the bolded options reflect

standard options with a reduced lead-time.

Consult factory on all other lead-time

options.

Description

PP

RR

YY

ZZ*

IL8/LL8

SAE-24 straight thread

SAE-32 straight thread

SAE 2 flange face

SAE 2- flange face

* Note: IL8 outlet port requires minimum

width SAE J518 code 61 flange.

BOX 6: Indicators

P

M2

H

*Single length only

BOX 8: Ports

Symbols

HDIL8/HQIL8

3 SAE flange face (code 61)

4 SAE flange face(code 61

WW

QQ

BOX 9: Option

Symbols

Description

None

11

Blocked bypass

Note: Two symbols required, first is for

housing, the second is for the cover(s).

Electrical indicators only available on the

housing

Replacement Elements

Microglass III (Fluorocarbon)

Ecoglass III (Fluorocarbon)

Media

Single

Double

Triple

Media

Single

Double

Triple

20Q

929099Q

933047Q

932875Q

20QE

N/A

933837Q

933736Q

10Q

927661Q

933046Q

932874Q

10QE

N/A

933836Q

933735Q

05Q

927861Q

933045Q

932873Q

05QE

N/A

933835Q

933612Q

02Q

927663Q

933044Q

932872Q

02QE

N/A

933834Q

933734Q

WR

929103

929109

932006

Reuseable

Core

N/A

933838

933636

Global products as identified are offered

worldwide through all Parker locations and

utilize a common ordering code.

99

You might also like

- XGQ-25F, 50F User ManualDocument46 pagesXGQ-25F, 50F User ManualNorval Santos74% (39)

- As 2601-2001 The Demolition of StructuresDocument7 pagesAs 2601-2001 The Demolition of StructuresSAI Global - APAC0% (5)

- DT-EDU-DeN60EDU0101. Virtual DataPort ArchitectureDocument23 pagesDT-EDU-DeN60EDU0101. Virtual DataPort Architecturesilent7777No ratings yet

- Automotive Air Conditioning and Climate Control SystemsFrom EverandAutomotive Air Conditioning and Climate Control SystemsRating: 4 out of 5 stars4/5 (6)

- Hil Co Master CatalogDocument88 pagesHil Co Master CatalogcolimecNo ratings yet

- SR EN 1090 2 2009 RomDocument225 pagesSR EN 1090 2 2009 RommariustudoracheNo ratings yet

- Lesson 2Document3 pagesLesson 2Jacob SwainNo ratings yet

- HFD Catalog CN PDFDocument13 pagesHFD Catalog CN PDFPartsGopher.comNo ratings yet

- Hydraulic Filter - Catalog 2300-14 - Catalog2300!14!15P - 30PDocument12 pagesHydraulic Filter - Catalog 2300-14 - Catalog2300!14!15P - 30PIgor Alberto MarkovNo ratings yet

- 15P/30P Series: High Pressure FiltersDocument12 pages15P/30P Series: High Pressure FiltersPartsGopher.comNo ratings yet

- HFD Catalog RF7Document8 pagesHFD Catalog RF7PartsGopher.comNo ratings yet

- HFD Catalog Moduflow PlusDocument16 pagesHFD Catalog Moduflow PlusPartsGopher.comNo ratings yet

- 50P Series: High Pressure FiltersDocument10 pages50P Series: High Pressure FiltersPartsGopher.comNo ratings yet

- Catalogue AIR TORQUE N° 4thG.-R-BDocument6 pagesCatalogue AIR TORQUE N° 4thG.-R-BnegrinNo ratings yet

- Torque Systems MDM Food Grade Series Product GuideDocument4 pagesTorque Systems MDM Food Grade Series Product GuideElectromateNo ratings yet

- Parker 3349112014 PGP511 Series, Pgp511a0140ab1h2vf5f3b1b1Document21 pagesParker 3349112014 PGP511 Series, Pgp511a0140ab1h2vf5f3b1b1Anonymous srN69mFE100% (1)

- จำหน่าย Parker FilterDocument14 pagesจำหน่าย Parker FilterParinpa KetarNo ratings yet

- Valves, Valve Springs, Valve Rotocoils, and LocksDocument55 pagesValves, Valve Springs, Valve Rotocoils, and Locksbetoven8437No ratings yet

- 12CS/50CS Series: Coreless Medium Pressure FiltersDocument11 pages12CS/50CS Series: Coreless Medium Pressure FiltersPartsGopher.comNo ratings yet

- Cast Aluminum BrochureDocument2 pagesCast Aluminum BrochureRomanCHubaNo ratings yet

- Il2 RF2 CF2 PDFDocument14 pagesIl2 RF2 CF2 PDFjuliocanel2009No ratings yet

- SI Industrial Washer Brochure PDFDocument4 pagesSI Industrial Washer Brochure PDFAl AdcockNo ratings yet

- 01 Excelon FiltersDocument16 pages01 Excelon Filtersalex_alfonso9407No ratings yet

- Glass Lined BrochureDocument8 pagesGlass Lined BrochureKarna2504No ratings yet

- Donaldson Visokotlačni FilteriDocument86 pagesDonaldson Visokotlačni FilteriViktor -stNo ratings yet

- EDX5-3.Miller 500 Eco PDFDocument8 pagesEDX5-3.Miller 500 Eco PDFDen BagusNo ratings yet

- Service Literature 80Mgf Series Units: Corp. 9801 L2 Revised 08 2004Document46 pagesService Literature 80Mgf Series Units: Corp. 9801 L2 Revised 08 2004askew9103No ratings yet

- PearlDocument2 pagesPearlairomaticccorpNo ratings yet

- TF4 Mar 20 06Document6 pagesTF4 Mar 20 06DANIZACHNo ratings yet

- SPEC Pulsatron E PLUS SeriesDocument2 pagesSPEC Pulsatron E PLUS SeriesAlfonso Javier Medina PernethNo ratings yet

- Lennox G26Document53 pagesLennox G26Kyle ZielinskiNo ratings yet

- Filter Bag SystemsDocument52 pagesFilter Bag SystemskategordNo ratings yet

- Stick, TIG, MIG, Flux-Cored K1653-2 Mobiflex 200-M K1741-1 Mobiflex 400-MSDocument4 pagesStick, TIG, MIG, Flux-Cored K1653-2 Mobiflex 200-M K1741-1 Mobiflex 400-MSmarioxxyNo ratings yet

- GbsDocument2 pagesGbsSuresh Kumar Mittapalli100% (1)

- Biofuge Contifuge Stratos 120 200 208 240V DualDocument103 pagesBiofuge Contifuge Stratos 120 200 208 240V DualAndrew Holmes50% (2)

- Automax Valve Automation Systems - Pneumatic Actuators and Accessories - FlowserveDocument24 pagesAutomax Valve Automation Systems - Pneumatic Actuators and Accessories - FlowserveKakoDaNo ratings yet

- pt3 4diaphragm DrumPumpsDocument29 pagespt3 4diaphragm DrumPumpsMatthew NievesNo ratings yet

- STR58U Mastepact ACBDocument74 pagesSTR58U Mastepact ACB322399mk7086No ratings yet

- Screw Pump Brochure USA LowResDocument12 pagesScrew Pump Brochure USA LowResSandeep LeeNo ratings yet

- Split Aire Acondicionado LG Ln0320ccDocument100 pagesSplit Aire Acondicionado LG Ln0320ccJuan Carlos MuñozNo ratings yet

- HFD Catalog BGT PDFDocument6 pagesHFD Catalog BGT PDFPartsGopher.comNo ratings yet

- Sorvall Centrifuges Rotor GuideDocument22 pagesSorvall Centrifuges Rotor GuideluroguitaNo ratings yet

- Toshiba Medium Voltage Motor SolutionsDocument6 pagesToshiba Medium Voltage Motor Solutionsحازم صبحى100% (1)

- Moog Servo Valves CatalogueDocument20 pagesMoog Servo Valves Cataloguemt.sasongkoNo ratings yet

- XL1100 Brochure PDFDocument8 pagesXL1100 Brochure PDFDanny Joel Espinoza CastañedaNo ratings yet

- 4530 Spec SheetDocument2 pages4530 Spec SheetLye YpNo ratings yet

- Abb Acs355 CatalogDocument24 pagesAbb Acs355 Catalogsatish734No ratings yet

- Azolla Zs 32 TdsDocument1 pageAzolla Zs 32 TdsahmetNo ratings yet

- Mobile Dual Spin-On SeriesDocument4 pagesMobile Dual Spin-On SerieseliasjrodriguezNo ratings yet

- CORRUGADODocument4 pagesCORRUGADOOwen Beni SerNo ratings yet

- GM MLT3060M Spec 10000022016 ADocument4 pagesGM MLT3060M Spec 10000022016 AEdgar ZarzaNo ratings yet

- NDT Films Guide-201510 For RTDocument1 pageNDT Films Guide-201510 For RTArbiMuratajNo ratings yet

- PT Series: Tank Top FiltersDocument14 pagesPT Series: Tank Top FiltersPartsGopher.comNo ratings yet

- G51MP Service FilesDocument53 pagesG51MP Service Files74747474No ratings yet

- Jet Pulse FilterDocument12 pagesJet Pulse FilterAkshay KadbeNo ratings yet

- Using The 8T-2700 Blowby/Air Flow Indicator (0774, 0781, 0785)Document34 pagesUsing The 8T-2700 Blowby/Air Flow Indicator (0774, 0781, 0785)Jorge Luis Cervantes Carrillo100% (1)

- MarelliMotori A4C 180 L4Document48 pagesMarelliMotori A4C 180 L4superspif100% (1)

- Tapflo CT BrochureDocument8 pagesTapflo CT BrochureСања БанковићNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Metric ClampsDocument12 pagesMetric ClampsPartsGopher.comNo ratings yet

- Hydraulic Flanges & Components & Dual Seal FlangesDocument44 pagesHydraulic Flanges & Components & Dual Seal FlangesPartsGopher.comNo ratings yet

- Warning PDFDocument1 pageWarning PDFPartsGopher.com100% (1)

- K4 BSP AdaptersDocument10 pagesK4 BSP AdaptersPartsGopher.comNo ratings yet

- ParKlamp Inch Tube Clamps PDFDocument16 pagesParKlamp Inch Tube Clamps PDFPartsGopher.comNo ratings yet

- Offer of SaleDocument2 pagesOffer of SalePartsGopher.comNo ratings yet

- EO & EO-2 Metric Bite Type FittingsDocument66 pagesEO & EO-2 Metric Bite Type FittingsPartsGopher.comNo ratings yet

- Intru-Lok Flareless Bite Type FittingsDocument8 pagesIntru-Lok Flareless Bite Type FittingsPartsGopher.comNo ratings yet

- O-Rings & SealsDocument10 pagesO-Rings & SealsPartsGopher.comNo ratings yet

- General TechnicalDocument40 pagesGeneral TechnicalPartsGopher.comNo ratings yet

- Diagnostic Orifice Bleed Adapters & Specialty FittDocument14 pagesDiagnostic Orifice Bleed Adapters & Specialty FittPartsGopher.comNo ratings yet

- Ferulok Flareless Bite Type FittingsDocument14 pagesFerulok Flareless Bite Type FittingsPartsGopher.comNo ratings yet

- Conversion AdaptersDocument6 pagesConversion AdaptersPartsGopher.comNo ratings yet

- EquipmentDocument58 pagesEquipmentPartsGopher.com100% (1)

- 3800 D SwivelDocument45 pages3800 D SwivelPartsGopher.comNo ratings yet

- 3800 E ValvesDocument24 pages3800 E ValvesPartsGopher.comNo ratings yet

- Metric TubeDocument6 pagesMetric TubePartsGopher.comNo ratings yet

- 3800 CoverDocument3 pages3800 CoverPartsGopher.comNo ratings yet

- Komatsu Style AdaptersDocument6 pagesKomatsu Style AdaptersPartsGopher.comNo ratings yet

- Actuator Products: Parker Pneumatic Section BDocument31 pagesActuator Products: Parker Pneumatic Section BPartsGopher.comNo ratings yet

- JIS FittingsDocument8 pagesJIS FittingsPartsGopher.comNo ratings yet

- PND1000-3 Automation Products PDFDocument59 pagesPND1000-3 Automation Products PDFPartsGopher.comNo ratings yet

- 3800 F DiagnosticDocument35 pages3800 F DiagnosticPartsGopher.comNo ratings yet

- PND1000-3 Tie Rod Cylinders PDFDocument82 pagesPND1000-3 Tie Rod Cylinders PDFPartsGopher.comNo ratings yet

- PND1000-3 Direct Acting Valves PDFDocument10 pagesPND1000-3 Direct Acting Valves PDFPartsGopher.comNo ratings yet

- 3800 A PneumaticDocument47 pages3800 A PneumaticPartsGopher.comNo ratings yet

- 3800 AppendicesDocument16 pages3800 AppendicesPartsGopher.comNo ratings yet

- PND1000-3 Subbase Manifold Valves PDFDocument123 pagesPND1000-3 Subbase Manifold Valves PDFPartsGopher.comNo ratings yet

- PND1000-3 Guided CylindersDocument52 pagesPND1000-3 Guided CylindersPartsGopher.comNo ratings yet

- Sokkia Grx2 GpsDocument4 pagesSokkia Grx2 GpsJuan Silver Condori TitoNo ratings yet

- Datasheet G RelaysDocument10 pagesDatasheet G RelaysthomaswangkoroNo ratings yet

- Economic of GenerationDocument3 pagesEconomic of GenerationirjuneNo ratings yet

- CQI-9 - 2a. Edicion - Ingles PDFDocument69 pagesCQI-9 - 2a. Edicion - Ingles PDFIram Chavira100% (1)

- EBCS 13 - Fire PrecautionsDocument135 pagesEBCS 13 - Fire PrecautionsGirum Menassie100% (2)

- Upgrading To HTTPS With StunnelDocument5 pagesUpgrading To HTTPS With StunnelJoxNo ratings yet

- Technical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40Document5 pagesTechnical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40mechmohsin4745No ratings yet

- Honeywell Sensing Smart Position Sensor Rotary Product Sheet 005948 2 enDocument6 pagesHoneywell Sensing Smart Position Sensor Rotary Product Sheet 005948 2 enRasigan KannanNo ratings yet

- Product Datasheet: Acti9 iC60H 3P 63A C Miniature Circuit BreakerDocument2 pagesProduct Datasheet: Acti9 iC60H 3P 63A C Miniature Circuit BreakerRaphael HoNo ratings yet

- PCI Compliance - Best Practices For Securing Credit Card DataDocument3 pagesPCI Compliance - Best Practices For Securing Credit Card Datahalock100% (3)

- Parker A-Lok Fittings PDFDocument152 pagesParker A-Lok Fittings PDFJonathan WhiteNo ratings yet

- TD 211-1-EngDocument24 pagesTD 211-1-EngElizhNo ratings yet

- Voltage Fluctuation Effect On Pumps and MotorsDocument13 pagesVoltage Fluctuation Effect On Pumps and MotorsPratik RaoNo ratings yet

- ETSI EG 201 013 - Human Factors (HF) Definitions, Abbreviations and SymbolsDocument15 pagesETSI EG 201 013 - Human Factors (HF) Definitions, Abbreviations and SymbolsTamer El-TonsyNo ratings yet

- Reference GuideDocument24 pagesReference GuideasadiqbalansariNo ratings yet

- HwrasgvdzsgDocument2 pagesHwrasgvdzsgMohamed SelimNo ratings yet

- 15 Years of EIA in BangladeshDocument30 pages15 Years of EIA in BangladeshShahriar ShuvaNo ratings yet

- Saep 311Document29 pagesSaep 311Sunny Thundil100% (1)

- Information SecurityDocument22 pagesInformation Securitydebleena mondalNo ratings yet

- LZ4 Streaming FormatDocument12 pagesLZ4 Streaming FormatLữ Tấn HoàNo ratings yet

- Steering Column: Section 6EDocument16 pagesSteering Column: Section 6Efrancisca19No ratings yet

- Donaldson, ToritGeneralBrochure PDFDocument16 pagesDonaldson, ToritGeneralBrochure PDFKuganesh SankaranNo ratings yet

- Congestion ControlDocument16 pagesCongestion ControlRenjithNo ratings yet

- Gujarat Power Engineering and Research Institute: B.E. Computer Engineering VIII Semester PROJECT-II Report FormatDocument3 pagesGujarat Power Engineering and Research Institute: B.E. Computer Engineering VIII Semester PROJECT-II Report Formaturwashi pal0% (1)

- Jackson CookbookDocument14 pagesJackson CookbookvevaradhNo ratings yet