Professional Documents

Culture Documents

Die Steel OHNS - Saaj Steel

Uploaded by

Harsha PrasadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Die Steel OHNS - Saaj Steel

Uploaded by

Harsha PrasadCopyright:

Available Formats

05/03/2015

DieSteelOHNS|SaajSteel

JOIN US

HOME

ABOUT US

OUR PRODUCTS

PROPERTIES

INFRASTRUCTURE

SERVICES

CLIENTELE

CONTACT US

Die Steel Grade OHNS

Alloy Steel

En Series Steel

Carbon Steel

Forging Steel

Case Hardening Steel

Die Steel

Die Steel EN31

Die Steel D2

Oil Hardening Non Shrinking Die Steel

Die Steel D3

Blanking and stamping dies, Punches, Rotary shear blades, Thread cutting tools,

Die Steel SAE/AISI 52100

Milling cutters, Reamers, Measuring tools, Gauging tools, Wood working tools,

Broaches, Chasers.

An ideal type oil-hardened steel which is economical and dependable for

gauging, cutting and blanking tools as well as can be relied for hardness and

good cutting performance.

O1 Tool Steel is an electric-furnace melted, oil-hardened, non-shrinking, generalpurpose tool steel. It is chemically composed of approximately 0.95 percent

carbon, 1.1 percent manganese, 0.6 percent chromium, 0.6 percent tungsten and

0.1 percent vanadium. The hardening temperature of O1 tool steel is between

790 degrees Celsius and 820 degrees Celsius.

Die Steel SKD-11

Die Steel CW-1

Die Steel HCHCR

Die Steel OHNS

Die Steel H 13

Die Steel H 11

Tool Steel

HIgh Speed Steel

Hot Die Steel

High Carbon High Chromium Steel

Plastic Mould Steel

Die Block Steel

Spring Steel

Cold Work Tool Steel

Hot Work Tool Steel

Uses

http://saajsteel.com/?page_id=1055

Free Cutting Steel

1/4

05/03/2015

DieSteelOHNS|SaajSteel

O1 Tool Steel is not easily abraded, has high surface hardness post tempering,

Our Products

does not deform during hardening and can be machined well. Further, it also has

a low hardening temperature (and, therefore, can be heat treated in homes and

shops), and does not lose shape during quenching. It is inexpensive and readily

available. O1 Tool Steel is ideal for making tools and knives,

as it can be easily

C35

EN 24

EN 47

sharpened.

EN 8D

Properties

Metric

Imperial

Density

7.85 g/cc

0.284 lb/in3

16MNCR5

Strength and Hardness

Strength of a metal determines the extent to which it may deform when load is

applied on it. Strength can be measured based on various parameters, such as

the maximum ability to take strain, resistance to wear and tear, impact handling,

or how the material performs when subjected to frequently changing load

conditions. Strength generally increases as the carbon and manganese content

increases. Given the high percentage of both of those, O1 Tool Steel is strong.

Hardness of a material indicates its resistance to get indented that is not

temporary (i.e.; it persists even after the load conditions are removed, as

opposed to the strength that is an indication of its performance only when the

load is applied), and carbon is also the primary hardening element in steel. The

Rockwell method measures the hardness of O1 Tool Steel to be in the range of

64 RC to 58 RC (this is the most commonly used measurement technique).

Application

All press cutting tools & punching tools for thinner materials. Small tools of

complicated design for reforming, bending & drawing. Small plastic & rubber

moulds.

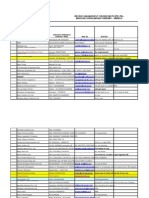

Forming

Bending, raising, drawing, rim rolling,

56 - 62

spinning and flow forming

Small coining dies

56 - 60

Guide bushes, ejector pins, high duty,

58 - 60

small/medium drills and taps Small gear wheels, pistons,nozzles,cams

Physical Properties

The following table shows the physical properties of P20 tool steels.

Max Hardness

60 - 64

Heat Resistance

Low

http://saajsteel.com/?page_id=1055

2/4

05/03/2015

DieSteelOHNS|SaajSteel

Wear Resiatance

Medium

Machinability

Good

Deformation During Hardening

Medium

Hardening Temperature

760 - 870 C

Resistance to Decarburization

Good

Micro Hardness

280 Vhn

Density

8670 kg/M3

Emissivity

0.8

Toughness and Brittleness

Toughness of a material determines

whether it can be subjected to shock

conditions, and the extent to which it

may undergo deformity in shape but

still not snap. If subjected to a proper

treatment process, O1 Tool Steel tends

to be very tough. As opposed to

toughness, brittleness measures

whether a material will snap instead of

getting deformed, when load is

applied. Alloy steels like O1 Tool Steel

are less brittle than cast or pig iron

because of the presence of

magnesium.

Home

Testimonials

About Us

Our Products

Properties

Infrastructure

Services

Clientele

Contact Us

Shop Address

Warehouse

No.23 / 81 Mugapair Road,

Old No.85,New No.64,Shed

Mannurpet, Padi,

II,

Most competitive prices for variety of

Chennai

- 600 050

products and our stock range is

our

Plot 6A,Galaxy Road,

main strength. We can supply flat

Ph:+91 92821 01942,

material (Black Bar) from min thickness

+91 92832 10628

Ponniamman Nagar,

6mm to 500mm and width min from

Chennai-600 095

044-2624 7076, 044-

Ph:+91 92821 01942,

26259635.

+91 92831 82727,

E-mail:

Telephone:044-64547076

20mm to 2000mm in all grades

Kilayanambakkam,

Telephone:

saajsteel@gmail.com

Website:

www.saajsteel.com

Copyrights 2014 - All Rights Reserved

http://saajsteel.com/?page_id=1055

3/4

05/03/2015

http://saajsteel.com/?page_id=1055

DieSteelOHNS|SaajSteel

4/4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Substructure Taking OffDocument4 pagesSubstructure Taking Offlutos2100% (5)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Drill Bit Speed ChartDocument1 pageDrill Bit Speed Chartterrymo2No ratings yet

- f1 Track Design and SafetyDocument10 pagesf1 Track Design and SafetyHarsha Prasad100% (1)

- Bultaco Swingarm Needle Roller Conversion Installation Guide R1Document6 pagesBultaco Swingarm Needle Roller Conversion Installation Guide R1Steve NewmanNo ratings yet

- 7 11 JapanDocument27 pages7 11 JapanMuhammad Mazhar HussainNo ratings yet

- DM Manual For - ReferenceDocument240 pagesDM Manual For - ReferenceDao Phu100% (1)

- Ergonomics Guidebook For Manual Production SystemsDocument16 pagesErgonomics Guidebook For Manual Production SystemsHarsha PrasadNo ratings yet

- Bimba Ref HandbookDocument47 pagesBimba Ref HandbookRico AriezonaNo ratings yet

- How To Get (VTU, BE) Consolidated Marks Card of Individual Semester - Explained - Sureshjonna PDFDocument66 pagesHow To Get (VTU, BE) Consolidated Marks Card of Individual Semester - Explained - Sureshjonna PDFHarsha Prasad100% (2)

- bREAK dOWN bOARD tEMPLATEDocument1 pagebREAK dOWN bOARD tEMPLATEHarsha PrasadNo ratings yet

- TPM BasicDocument175 pagesTPM BasicHarsha PrasadNo ratings yet

- LT5SReport Feng ShuiDocument7 pagesLT5SReport Feng ShuiAnonymous LhmiGjO67% (3)

- Plantrun Oee CalculatorDocument2 pagesPlantrun Oee CalculatorYogesh SharmaNo ratings yet

- Doosan Heavy Industries Vietnam Haipong CoDocument42 pagesDoosan Heavy Industries Vietnam Haipong CoUhrinImreNo ratings yet

- BD ReportDocument14 pagesBD Reportsunitha_05100% (2)

- Jayesh Hingorani: Exports / Logistics / Supply Chain ManagementDocument4 pagesJayesh Hingorani: Exports / Logistics / Supply Chain ManagementNikesh ShahNo ratings yet

- 1998 Q1-SasDocument3 pages1998 Q1-SastlnrsNo ratings yet

- MMD Brochure CompressedDocument13 pagesMMD Brochure Compressedapi-254065454100% (1)

- Problem and Answer in Iron and Steel Making ProcessDocument32 pagesProblem and Answer in Iron and Steel Making ProcessIndera Pradana0% (2)

- D/Stream Pipeline Corrosion Defects & Remedy: Pipeline & Storage Tanks Integrity Assessment WorkshopDocument45 pagesD/Stream Pipeline Corrosion Defects & Remedy: Pipeline & Storage Tanks Integrity Assessment Workshopshakirhamid6687No ratings yet

- Problem Ariana GrandeDocument24 pagesProblem Ariana GrandeMochammad YogaswaraNo ratings yet

- LovableDocument1 pageLovableKushal Akbari100% (1)

- Huntsman Tooling BoardDocument3 pagesHuntsman Tooling BoardGaurav GuptaNo ratings yet

- Contingency Procedures NAT RegionDocument4 pagesContingency Procedures NAT RegionflyspannerrNo ratings yet

- Golden Gate Reading CompDocument3 pagesGolden Gate Reading CompJonathan SmithNo ratings yet

- JaipurreportDocument46 pagesJaipurreportLokeshSharmaNo ratings yet

- H2 Folding Hatch Covers - Original - 30544 PDFDocument8 pagesH2 Folding Hatch Covers - Original - 30544 PDFGILL2013No ratings yet

- National Water Supply & Drainage Board: S R I L A N K ADocument5 pagesNational Water Supply & Drainage Board: S R I L A N K AbissauNo ratings yet

- AttaDocument10 pagesAttaAkshay KhatriNo ratings yet

- Astm A530Document2 pagesAstm A530Thiruvengadam75% (4)

- 專業術語Document21 pages專業術語Tsun-Wu LiuNo ratings yet

- 191cDocument0 pages191cSahaya GrinspanNo ratings yet

- Hydrocarbon Eng Feb 2017Document24 pagesHydrocarbon Eng Feb 2017jcarbajal2013No ratings yet

- AFRICA218Document9 pagesAFRICA218Raj Moily100% (1)

- Anordica Steel Wire Fibres En02 LowDocument4 pagesAnordica Steel Wire Fibres En02 Lowadc26No ratings yet

- Akzo Nobel NDocument3 pagesAkzo Nobel NAnulekha AtriNo ratings yet

- Logistics in International MarketingDocument211 pagesLogistics in International Marketingmonish1760% (1)

- How To Perform Tack Welding SuccessfullyDocument2 pagesHow To Perform Tack Welding SuccessfullyLucaRoldoNo ratings yet