Professional Documents

Culture Documents

Atlas Copco Jack Legs

Uploaded by

ÜmNitzaSchnitzerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Atlas Copco Jack Legs

Uploaded by

ÜmNitzaSchnitzerCopyright:

Available Formats

Pneumatic rock drills BBC/BBD/RH

High quality. Long lifetime. Low long-term costs.

Real value

As soon as you pick it up, youll feel the quality. Its solid,

well made. Start it up and youll notice the raw power.

But to appreciate the real advantages of an Atlas

Copco rock drill, youll have to wait. Each and every part

is made to the highest tolerances and of the very best

materials. This means that even when you replace a part,

your drill will deliver the same performance as when it

was new. Time after time. Year after year.

How long does an Atlas Copco rock drill last? Lets

just say that by the end of its service life youll be in no

doubt that its given you real value for money.

High quality for high performance

But our drills are not just a good long-term investment,

they also make money from day one. This is because

Atlas Copco rock drills are efficient. For every litre of air

you put in, youll get high impact energy out.

Why? Again, the answer is quality. And quality is no

accident. Its a question of using the right materials,

proven heat treatment methods and machining to high

tolerances. Last but not least, quality is the result of

good honest engineering: todays range is based on the

same reliable design as the Atlas Copco drills that launched the Swedish Method back in the 1940s.

Stoper

BBD 46WS/WR Falcon

Suitable for production drilling, raise driving and bolting in soft to

medium hard rock

Short stroke, good penetration rates

Large piston diameter gives high efficiency even at low air pressure

Ratchet wheel rotation mechanism

WR version with clockwise rotation for tightening nuts and roof bolting

Stoper data

Type

Part No

Hole range

Air

consumption

at 6 bar

Rock drill

Piston bore

Stroke

length

Impact rate

at 6 bar

Feed

Piston bore

Feeding

length

Length

retracted

Length

extracted

Weight

mm

l/s

mm

mm

Hz

mm

mm

mm

mm

kg

BBD 46WS-6

8311 0202 03

27-41

75

75

45

51

75

770

1435

2205

39

BBD 46WS-8

8311 0202 11

27-41

75

75

45

51

75

970

1650

2620

40

BBD 46WR-6

8311 0202 29

27-41

75

75

45

49

75

770

1435

2205

39

BBD 46WR-8

8311 0202 37

27-41

75

75

45

49

75

970

1650

2620

40

Find the right drill

BBC 16W Puma

All-round rock drill, suitable for most drilling applications in

medium to hard rock

Long stroke, good penetration rate

Robust rifle bar rotation mechanism

Pusher leg control placed in back head of the rock drill

BBC 34W Leopard

Highly efficient in medium to hard rock

Long stroke, high impact energy

Large piston diameter makes it very efficient even at low air

pressure

Powerful rifle bar rotation mechanism

Pusher leg control placed in back head of the rock drill

BBD 94W Panther

High performance rock drill for soft to hard rock

Short stroke and high impact rate makes it ideal for soft rock

Large piston diameter for high efficiency even at low air pressure

Ratchet wheel rotation mechanism

Pusher leg control is placed on the pusher leg

RH 656W

Suitable for soft to medium hard rock

Good ratio between high penetration/low air consumption

Due to low weight, it can also be used as a sinker. Supplied

with T-handle

Robust rifle bar rotation mechanism

Pusher leg control is placed on the pusher leg

Rock drill data

Type

Part No

Hole range

Air consumption

at 6 bar

Piston bore

Stroke length

Impact rate

at 6 bar

Length

mm

l/s

mm

mm

Hz

mm

kg

Weight

BBC 16W

8311 0401 10

27-41

69

70

55

39

710

26

BBC 34W

8311 0408 05

27-41

88

80

70

38

775

31

BBD 94W

8311 0206 09

27-41

97

90

45

55

670

27

RH 656W

8311 0303 45

27-41

48

65

60

34

630

22

Pusher leg data

Type

Part No

Suitable

for rock drill

Single telescope

Piston bore

Feeding length

Length retracted

Length extracted

mm

mm

mm

mm

kg

Weight

BMT 51

8321 0301 01

BBC 16W, 34W

60

1300

1658

2958

15

ALF 71

8321 0201 94

BBC 16W, 34W

70

1300

1805

3105

14

ALF 71-1

8321 0201 95

BBC 16W, 34W

70

950

1455

2405

13

ALF 72D

8321 0201 80

BBD 94W

70

1300

1970

3270

19

ALF 72D-1

8321 0201 81

BBD 94W

70

1200

1830

3030

16

BMK 62S

8321 0102 02

RH 656W

53

1300

1815

3115

17

ALF 67/80

8321 0201 85

BBC 16W, 34W

67/80

1855

1495

3350

17

ALF 67/80D

8321 0201 69

BBD 94

67/80

1855

1595

3450

19

Double telescope

Faster drilling and lower drilling costs

Tapered drilling equipment offers a long list of advantages

over integral steel. First and foremost, penetration is

faster. Over 50% faster in some rock. Tapered bits are also

easier to use: collaring is faster, drilling straight holes is

simpler and vibrations are considerably lower. And in addition to all of this, tapered equipment actually gives you

lower total drilling costs. Still not convinced? Do a test run

and judge for yourself.

Penetration rate

Service life

0%

50%

100%

150%

200%

Optional equipment/spare

Pos. Description

Part No

9030 2051 00

2 RH 656

9030 2067 00

2 BBD 94

9030 2068 00

3 Water flushing hose with

fitted couplings for BBC, BBD, RH

9030 2069 00

Intellecta 2006 07

1 BBC 16, BBC 34, BBD 46

Formalix 2005

Compressed air hose for rock drill and

feed, fitted with couplings for:

4 Lubricator for BBC, BBD, RH

BLG 30

8202 5102 05

CLG 30

8202 5102 39

5 Mandrel for 25 mm bolt

3081 0001 00

6 Socket for 37 mm hexagon nut

3081 0006 00

2005, Atlas Copco Construction Tools AB, Stockholm, Sweden

Tools for roof bolting with BBD 46WR

9800 0630 01

Use only authorized parts. Any damage or malfunction caused by the use of

unauthorized parts is not covered by Warranty or Product Liability.

www.atlascopco.com

You might also like

- 9852 1522 01b Safety Boomer 104Document43 pages9852 1522 01b Safety Boomer 104Bojan TaskovicNo ratings yet

- Atlas Copco Technical Data GA 37Document1 pageAtlas Copco Technical Data GA 37castkarthick50% (2)

- Manual Kaeser CSDX T CompressDocument170 pagesManual Kaeser CSDX T Compressverel adamNo ratings yet

- MSK CatalogueDocument14 pagesMSK CatalogueCsaba VargaNo ratings yet

- Filters Only ListDocument2 pagesFilters Only ListThane MasureikNo ratings yet

- Ny Serie Evisa Olielamel Vakuumpumper PDFDocument56 pagesNy Serie Evisa Olielamel Vakuumpumper PDFLuis Felipe ZuñigaNo ratings yet

- Catalog Donaldson EngDocument10 pagesCatalog Donaldson EngLatDatNo ratings yet

- Hertz Hgs 3 20 ManuelDocument69 pagesHertz Hgs 3 20 Manueligor_sandulenkoNo ratings yet

- Atlas Copco Roto Inject Lubricant MSDS JECDocument7 pagesAtlas Copco Roto Inject Lubricant MSDS JECMario ArzateNo ratings yet

- Ceccato DRB 30-50 Leaflet EN 6999100361 PDFDocument6 pagesCeccato DRB 30-50 Leaflet EN 6999100361 PDFmogwai71No ratings yet

- CSDX.5 100 125 (T) Ids 2018Document3 pagesCSDX.5 100 125 (T) Ids 2018IngosvaldoNo ratings yet

- Ask - 28 Keiser CompDocument138 pagesAsk - 28 Keiser CompHitesh sharmaNo ratings yet

- MC3 Sullair PartsListManual 750XHH 900XH 900XHH 1150XH TC - Sullair Reman HighlightsDocument228 pagesMC3 Sullair PartsListManual 750XHH 900XH 900XHH 1150XH TC - Sullair Reman HighlightsnNo ratings yet

- Atlas Copco Productsheet GA 7-11Document16 pagesAtlas Copco Productsheet GA 7-11Machine33No ratings yet

- Brochure XA (H, T, V, X) S 186-600C, XRHS 666C, V900, X1300, XA (T, V) S 100-1200 Cud China 2958 0961 52 EnglishDocument2 pagesBrochure XA (H, T, V, X) S 186-600C, XRHS 666C, V900, X1300, XA (T, V) S 100-1200 Cud China 2958 0961 52 EnglishMuhammad BintangNo ratings yet

- Atlas Copco PRICELIST-2014Document3 pagesAtlas Copco PRICELIST-2014Johnn Doe Srdjan JocicNo ratings yet

- Screw Compressors: Boge Air. The Air To WorkDocument40 pagesScrew Compressors: Boge Air. The Air To WorkI'an Triple SNo ratings yet

- DM30 Rotary Drill 3649Document448 pagesDM30 Rotary Drill 3649Ermilo LopezNo ratings yet

- 2365 GD Pilot VSDocument36 pages2365 GD Pilot VSandy habibiNo ratings yet

- Tyre Loads in KG/LB - Tyre Pressures in Bar/PsiDocument1 pageTyre Loads in KG/LB - Tyre Pressures in Bar/PsiThiago Lisboa GuimarãesNo ratings yet

- APF206589 Instruction Book GA 250-125 PackDocument136 pagesAPF206589 Instruction Book GA 250-125 PackEspaña U XimenaNo ratings yet

- P37 To P275 High Pressure Piston Air Compressor English Tcm795-3514985Document12 pagesP37 To P275 High Pressure Piston Air Compressor English Tcm795-3514985Jozsef MagyariNo ratings yet

- FIAC CATALOGO UK Ilovepdf Compressed Ilovepdf CompressedDocument21 pagesFIAC CATALOGO UK Ilovepdf Compressed Ilovepdf CompressedSergio MaldonadoNo ratings yet

- Sotras Cross References PDFDocument8 pagesSotras Cross References PDFStephen Lovett100% (2)

- Quincy QT Series Model QT-5Document18 pagesQuincy QT Series Model QT-5mkaukolaNo ratings yet

- Technical DataDocument3 pagesTechnical DataeddyfredyNo ratings yet

- ALMIG Spare Parts Price List 01-15 Version 2015-07-22 GBDocument192 pagesALMIG Spare Parts Price List 01-15 Version 2015-07-22 GBАлексей Галайдин100% (1)

- Compresores A TornilloDocument10 pagesCompresores A TornilloGerardo Bois100% (1)

- Quincy GA30-GA45 Compressor Parts ManualDocument43 pagesQuincy GA30-GA45 Compressor Parts ManualPorfirioDuarteZarateNo ratings yet

- 2 30 Oil Free Scroll CompressorsDocument12 pages2 30 Oil Free Scroll CompressorsMECATROKNo ratings yet

- Atlas Copco: Parts ListDocument214 pagesAtlas Copco: Parts ListСергей КолесниковNo ratings yet

- Atlas Copco Stationary Air CompressorsDocument62 pagesAtlas Copco Stationary Air Compressorsmarius virtosu65No ratings yet

- Compresores de Aire Pequeños Atlas CopcoDocument8 pagesCompresores de Aire Pequeños Atlas CopcoFernando CaffroniNo ratings yet

- Atlas Copco Snow Compressors: Snow-LE40, - 55 Snow-LF22, - 30, - 40, - 55 Snow-SF2, - 4 Instruction Book and Parts ListDocument48 pagesAtlas Copco Snow Compressors: Snow-LE40, - 55 Snow-LF22, - 30, - 40, - 55 Snow-SF2, - 4 Instruction Book and Parts ListGS OLDNo ratings yet

- China Ga18 VSD Ipm Ga22 VSD Ipm Atlas Copco Oil Injected Permanent Magnetic Screw Air Compressor - China Ga37VSD Ga45VSD Ga55VSD Ga75VSD Ga90VSD, Ga7 VSD Ipm Ga11 VSD Ipm Ga15 VSD IpmDocument8 pagesChina Ga18 VSD Ipm Ga22 VSD Ipm Atlas Copco Oil Injected Permanent Magnetic Screw Air Compressor - China Ga37VSD Ga45VSD Ga55VSD Ga75VSD Ga90VSD, Ga7 VSD Ipm Ga11 VSD Ipm Ga15 VSD IpmEduardo AyreNo ratings yet

- Monarch TT 30Document4 pagesMonarch TT 30Migue ToasaNo ratings yet

- DIAMEC 262 Spare Part Recommendations: One Shift of Operation For One RigDocument2 pagesDIAMEC 262 Spare Part Recommendations: One Shift of Operation For One RigMAURICIO CARRERO IBAÑEZ100% (1)

- D41IM-D299IM Air Dryer Operation Manual PDFDocument21 pagesD41IM-D299IM Air Dryer Operation Manual PDFIsarafil100% (3)

- OSC Oil-Water Separator Leaflet (Filtro de Los Atlas Corp)Document8 pagesOSC Oil-Water Separator Leaflet (Filtro de Los Atlas Corp)David CauichNo ratings yet

- Diagramas Hidraulicos - ElectricosDocument80 pagesDiagramas Hidraulicos - ElectricosMilu Borja CabelloNo ratings yet

- Manual SM - 1C - 1846699 - 10-000 - 00EDocument108 pagesManual SM - 1C - 1846699 - 10-000 - 00ESergei KurpishNo ratings yet

- WTD 11 130Document3 pagesWTD 11 130ray mojicaNo ratings yet

- MANEC5Document18 pagesMANEC5RC Villeda100% (1)

- 9852 3027 01a Secoroc YT29A Pusher Leg Rock Drill - Operator's Instruction and Spare Parts List - tcm572-3511855Document20 pages9852 3027 01a Secoroc YT29A Pusher Leg Rock Drill - Operator's Instruction and Spare Parts List - tcm572-3511855marioxxyNo ratings yet

- RodDocument24 pagesRodYebrail Mojica RuizNo ratings yet

- New Silver 55-75-10 HPDocument6 pagesNew Silver 55-75-10 HPEber.CVNo ratings yet

- Manual de Operación Secador D41IM-D299IM - All LanguagesDocument314 pagesManual de Operación Secador D41IM-D299IM - All LanguagesJA23410No ratings yet

- ASD-T-TriVoltage Service Manual 9 - 5721 - 06Document138 pagesASD-T-TriVoltage Service Manual 9 - 5721 - 06Mario GonzalezNo ratings yet

- Oil-Free Rotary Tooth Compressors: Atlas CopcoDocument172 pagesOil-Free Rotary Tooth Compressors: Atlas Copconugrohowijaya37No ratings yet

- Tamrotor Ceccato Kit List 2009Document2 pagesTamrotor Ceccato Kit List 2009saurabhjtNo ratings yet

- 9851 3302 01 - LDocument4 pages9851 3302 01 - Llourdes calderonNo ratings yet

- Curtis RSD150 Parts ListDocument19 pagesCurtis RSD150 Parts Listrobert100% (1)

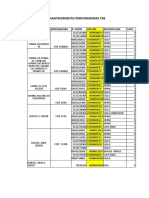

- Mantenimiento Perforadoras T38: Equipo Perforadora #Parte Cod JRC Descripccion CantDocument1 pageMantenimiento Perforadoras T38: Equipo Perforadora #Parte Cod JRC Descripccion CantPaulAldoNo ratings yet

- Ga 15-26Document110 pagesGa 15-26Hitesh sharmaNo ratings yet

- Manuel HetrzDocument128 pagesManuel HetrzHP ServicesNo ratings yet

- 5437 1Document190 pages5437 1Khateeb RehmanNo ratings yet

- ZE4 APFS902571ASLv00Document217 pagesZE4 APFS902571ASLv00MARKNo ratings yet

- Marktinfo - 17. Auflage - 2020-03-06 - InTDocument875 pagesMarktinfo - 17. Auflage - 2020-03-06 - InTOliver FrereNo ratings yet

- Atlas Copco AutomanDocument6 pagesAtlas Copco Automan19poeNo ratings yet

- FRD Product LineDocument8 pagesFRD Product Linegiapy0000No ratings yet

- Louis Vuitton Out Let On Lines LVDocument24 pagesLouis Vuitton Out Let On Lines LVLiu DehuaNo ratings yet

- Drill CollarsDocument3 pagesDrill CollarsRambabu ChNo ratings yet

- Transcript For Internal Controls For Cash and Cash Equivalents VideoDocument3 pagesTranscript For Internal Controls For Cash and Cash Equivalents VideoAsenathi SandisoNo ratings yet

- Slab Design TWO WAY at 10.2 M TOCDocument1 pageSlab Design TWO WAY at 10.2 M TOCVikalp MadhavNo ratings yet

- Ofelia L. Mendoza - Drug StudyDocument3 pagesOfelia L. Mendoza - Drug StudyMaenard JavierNo ratings yet

- Tamiya Model Magazine - November 2019Document70 pagesTamiya Model Magazine - November 2019temp userNo ratings yet

- Formatting TextsDocument3 pagesFormatting TextsCelestineNo ratings yet

- Nanyang Technological University SEMESTER 2 QUIZ 2019-2020 Ee6508 - Power QualityDocument2 pagesNanyang Technological University SEMESTER 2 QUIZ 2019-2020 Ee6508 - Power QualityYaraNo ratings yet

- IOT Practical 2021-22Document25 pagesIOT Practical 2021-22Abhi AbhiNo ratings yet

- EKNOSDocument2 pagesEKNOSBipin tiwariNo ratings yet

- Schiavi Enc Met Page023Document1 pageSchiavi Enc Met Page023Adel AdelNo ratings yet

- Youth Unemployment and Mental Health: Prevalence and Associated Factors of Depression Among Unemployed Young Adults in Gedeo Zone, Southern EthiopiaDocument11 pagesYouth Unemployment and Mental Health: Prevalence and Associated Factors of Depression Among Unemployed Young Adults in Gedeo Zone, Southern EthiopiaKindhun TegegnNo ratings yet

- Transformers: What Is An Electric Transformer?Document14 pagesTransformers: What Is An Electric Transformer?Mohamed IbrahemNo ratings yet

- Gold Prospecting in OhioDocument2 pagesGold Prospecting in OhioJannette FerreriaNo ratings yet

- Patient Experience Measurement: Presented by Anum HashmiDocument16 pagesPatient Experience Measurement: Presented by Anum HashmiAnumNo ratings yet

- Swichtgear de Media Tension Aislado Por AireDocument33 pagesSwichtgear de Media Tension Aislado Por Airetotipo10No ratings yet

- Dfsan AbilistDocument64 pagesDfsan AbilistTorNo ratings yet

- Narrative Report BLSDocument6 pagesNarrative Report BLSSoriano Armenio67% (3)

- Day Care CentersDocument16 pagesDay Care CentersAndreea RaduNo ratings yet

- Q8-Auto-JK - en PDSDocument1 pageQ8-Auto-JK - en PDSagnovNo ratings yet

- Unit 5-Elements of Costing-Financial Accounting-Nikita KeshanDocument58 pagesUnit 5-Elements of Costing-Financial Accounting-Nikita Keshanharshita bhatiaNo ratings yet

- Advt 09 - 2022 DTD 08.09.2022Document11 pagesAdvt 09 - 2022 DTD 08.09.2022Mayur Mohanji GuptaNo ratings yet

- Print - MAU JN (MAU) - AHMEDABAD JN (ADI) - 2828328577Document1 pagePrint - MAU JN (MAU) - AHMEDABAD JN (ADI) - 2828328577TATKAL TICKET SOFTWARENo ratings yet

- Tri-City Times: Doctors Are in The SchoolhouseDocument26 pagesTri-City Times: Doctors Are in The SchoolhouseWoodsNo ratings yet

- AFSCN Architecture EvolutionDocument7 pagesAFSCN Architecture Evolutionbaixiu0813No ratings yet

- Andrew Allen: 454 CR 3504 Quinlan, TX 75474 (903) 269-7874Document3 pagesAndrew Allen: 454 CR 3504 Quinlan, TX 75474 (903) 269-7874api-250314960No ratings yet

- Quaid-e-Azam (Rahmatullah) Said Very Clearly That The Rights of The - Will Be Fully Protected in PakistanDocument7 pagesQuaid-e-Azam (Rahmatullah) Said Very Clearly That The Rights of The - Will Be Fully Protected in PakistanAmna ShahzadNo ratings yet

- Final ProjectDocument80 pagesFinal ProjectMinkal PatelNo ratings yet

- MetricsDocument50 pagesMetricsArjun VaranasiNo ratings yet

- Elastic and Inelastic Collisions Lab ReportDocument16 pagesElastic and Inelastic Collisions Lab ReportDelfina FariasNo ratings yet

- Arizona, Utah & New Mexico: A Guide to the State & National ParksFrom EverandArizona, Utah & New Mexico: A Guide to the State & National ParksRating: 4 out of 5 stars4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoFrom EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoRating: 5 out of 5 stars5/5 (1)

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptFrom EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptRating: 5 out of 5 stars5/5 (1)

- The Bahamas a Taste of the Islands ExcerptFrom EverandThe Bahamas a Taste of the Islands ExcerptRating: 4 out of 5 stars4/5 (1)

- New York & New Jersey: A Guide to the State & National ParksFrom EverandNew York & New Jersey: A Guide to the State & National ParksNo ratings yet

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensFrom EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNo ratings yet