Professional Documents

Culture Documents

1resistance of Steel Connections To Low-Cycle Fatigue

Uploaded by

Massimo LatourOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1resistance of Steel Connections To Low-Cycle Fatigue

Uploaded by

Massimo LatourCopyright:

Available Formats

11th European Conference on Earthquake Engineering 1998 Balkema, Rotterdam, ISBN 90 5410 982 3

Resistance of steel connections to low-cycle fatigue

A. Plumier & M.R.Agatino

Department of Civil Engineering, University of Liege, Belgium

A. Castellani, C.A. Castiglioni & C. Chesi

Department of Structural Engineering, Politecnico di Milano, Italy

Keywords: Earthquake, Steel, Welding, Frame, Connection, Ductility, Fatigue, Experimental Tests

ABSTRACT: following the northridge and Kobe earthquake, attention of researchers has been focused on the problem of the brittle collapse of beam to column connections in moment resisting

steel frames. large evidence has been given by the earthquake to this phenomenon which, although

not involving the frame global collapse, drastically changes the expectations about energy dissipation and ductile behaviour of connections. the paper presents an experimental testing program

which has been planned with the purpose of contributing to a deeper knowledge of the following

problems: the low cycle fatigue behaviour of welded joints and the implications of brittle failure in

welded connections on the global frame response.

1 INTRODUCTION

In the variety of cases of structural damage which were observed after the Northridge earthquake, a

most prominent one occurred in steel moment resisting frames (Bertero et al. 1994, Tremblay

1995); although not reaching collapse, this kind of frames presented brittle failures at moment connections in welded beam to column joints. The obvious relevance of this kind of behaviour has led

to a detailed mapping of such cases. Although similar failure situations had already been observed

in previous earthquakes and during laboratory experiments, the Northridge earthquake has given

special evidence to the problem of brittle failure of welded joints and to the need of clarifying the

conditions under which this kind of failure is likely to be induced by seismic actions. This implies

the study of the low cycle fatigue behaviour of beam to column connections. The same problem is

being addressed as it is of particular interest, at present, in the European Community Countries as

well, where common codes have recently been developed covering the various design fields,

among which the design of steel structures (CEN, Eurocode 3, 1994) and the design of buildings in

seismic areas (CEN, Eurocode 8, 1994). Codes are now subject to public debate and contributions

should be provided on critical design problems, like the case of welded joints subject to seismic

actions. In this context, funding has been accorded by the European Community for a wide project,

named Steelquake, which is under way at the moment and which is presented in this paper. The

Steelquake project concerns the analysis of the behaviour of civil engineering steel structures, of

the moment resisting category, under earthquake loads. The overall objective is to provide a better

insight into the actual behaviour of civil engineering steel structures, of the moment resisting category, under earthquake loads, implementing in such an analysis a quantitative reference to the failure of connections in terms of low cycle fatigue, considering the duration of the earthquake and the

corresponding number of cycles supported in dissipative (plastic) zones. The structural behaviour

factor characterising the structure (the so-called "q" factor) presently proposed in Eurocode 8, is not

related to the fatigue resistance of the potential failure zones, that is beam to column connections.

The aim is to allow the full design (weld size, thickness of components, dimensions) of steel frame

connections, taking into account the duration of the earthquake and the corresponding number of

cycles to be supported in dissipative (plastic) zones, that is to introduce q factors depending on the

considered earthquake time-history. A classification of connections, in terms of q values, is ex-

11th European Conference on Earthquake Engineering 1998 Balkema, Rotterdam, ISBN 90 5410 982 3

pected as a result of the project research. In order to achieve the above-said objective, full scale

testing of beam to column connections and testing on welds are carried out on different specimens

in Milan and Liege; shaking table tests at Athens and at ISMES Bergamo and pseudo-dynamic tests

at JRC Ispra are performed to provide complementary experimental data concerning the global behaviour of steel frames; parallel numerical analyses are performed with an aim to deeply interpret

the experimental behaviour both of the investigated single connections and steel frames.

The project has been conceived with the purpose of providing some contributions to two existing problems: 1) a clear understanding of the real behaviour of welded beam to column connections, a problem which still deserves accurate investigation despite of the work done in this area by

several researchers (Plumier 1994, Bernuzzi et al. 1997) and 2) the interpretation of the influence

of the connection failure on the global frame answer to seismic actions; in the Northridge earthquake no remarkable effect was noticed on the global frame behaviour as a consequence of joint

collapse. In this paper, only the research activities related to phase 1 is presented.

2

2.1

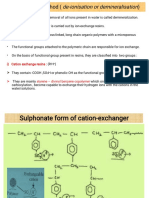

BEAM TO COLUMN CONNECTIONS AND WELDING PROCEDURES

Specimens selection and test set-up

The first part of the project, discussed here, is focused on the experimental response of welded

connections, for which the low cycle fatigue problem is investigated. The specimen selection aimed

at covering a significant variety of beam to column connections, frequently adopted in both European and American practice. Four typologies, as shown in Figure 1, were identified for this purpose, based on welded joints (type C) or partially welded joints (type A). All of these provide interesting cases; note, in particular, connection type A2, based on the concept of shifting the plastic

hinge zone away from the node, a joint design approach which has been recently proposed in the

U.S., and for which some results are already available, based on work of Ballio & Castiglioni

(1994).

Figure 1. Beam to column connection typologies without (left) and with (right) node reinforcing plate.

11th European Conference on Earthquake Engineering 1998 Balkema, Rotterdam, ISBN 90 5410 982 3

Figure 2. Different welding procedures C1 and C3: with steel backing bar; C2: with polyester backing bar.

Figure 3. Beam to column connection

full scale specimen.

Figure 4. Full scale-small size specimens

for weld size testing.

The presence of stiffening plates in the panel zone of the column is also to be investigated; for

this purpose, each of the above typologies include one additional specimen, with a node stiffening

plate. The research, however, is mainly focused on the beam-column connection behaviour; for this

reason, an external T-shaped joint has been selected for the experimental program, in which collapse is expected to occur preferably at the beam-column interface. For connection type C different

welding procedures have been considered. These include the full penetration double bevel groove

weld and the full penetration single bevel groove weld with a steel or polyester backing bar, Figure

2. A V-shaped steel backing bar is also considered (C3). Some special care has been devoted to

welding execution, which was done by competent structural steel fabricators, using certified welders.

A typical view of the full-scale specimens is shown in Figure 3. During tests, the column is kept

horizontal, hinged at both ends, and the (horizontal) loading system applied at the top of the beam.

A total of 32 specimens have been fabricated, 16 specimens (type C1, C2 and C4) to be tested in

Milan and 16 specimens of types A, B and C3 to be tested in Liege. Testing has been completed. In

addition to the beam-column joints, full-scale small size specimens have also been fabricated with

the purpose of verifying whether the weld preparation and the specimen sizes are critical parameters. The specimens (Fig. 4) incorporate welded connections representing the welded beam to column flange connection. A total of 40 specimens have been constructed and subjected to cyclic

testing.

3

11th European Conference on Earthquake Engineering 1998 Balkema, Rotterdam, ISBN 90 5410 982 3

2.2

Testing procedure

In 1986, a recommended testing procedure was proposed by ECCS for cyclic testing of steel members and joints. The ECCS recommendations (ECN, 1986) proposed to perform cyclic tests applying to the specimen cycles of increasing amplitude with at least three cycles for the same amplitude, similarly to what is proposed by ATC 24 (1992).

Since then, a number of research programs were carried out in various European countries,

adopting such ECCS recommended procedures. Tests were carried out in Italy, Germany, Belgium,

Portugal and France, on members, connections and structural subassemblages. In particular a research project was carried out with the sponsorship of Arbed Research on beam to column connections, and tests were performed at different research centers in various European countries; see, for

instance, Ballio & Chen (1993). After nearly ten years, some criticism was raised with regard to the

1986 ECCS recommendations. In particular, with regard to the Testing Procedures, it has been recognised that:

1. Repeating three cycles for each cycle amplitude and then increasing the amplitude does not

provide direct information regarding the damage accumulation and strength degradation corresponding to one particular ductility demand; in fact, at increasing amplitudes corresponds an isotropic strain hardening effect resulting in an increment of the load carrying capacity of the member,

but this effect is opposite to the strength degradation due to local buckling and low cycle fatigue,

which are directly connected to the cycle amplitude and the number of imposed cycles;

2. Sometimes tests were performed under unusually large cycle amplitudes, i.e. simulating

situations and ductility demands unlikely to occur during earthquakes.

It was then proposed by various authors both in Europe (Ballio & Castiglioni 1994, Bernuzzi et

al. 1997) and in the U.S. (Krawinkler & Zohrei 1983) to perform tests with cycles of a constant

amplitude; such procedures present, with regard to the ECCS recommended testing procedure, the

advantage of allowing a clear understanding of the damage accumulation process as well as of the

parameters governing it.

The scope of the research is the development of a cumulative damage model for assessing the

performance of structural components under arbitrary loading histories and evaluating the effects of

inelastic cycles on a limit state of acceptable behaviour. A cumulative damage model is generally

based on a damage hypothesis and includes structural performance parameters to be determined

experimentally (Bernuzzi, et al 1997, Krawinkler & Zohrei 1983). Hence a multi-specimen testing

program is required, encompassing constant amplitude loading tests on identical specimens. For

each test, a new specimen must be used, since each specimen is to be tested to failure under deformation amplitudes covering the range of performance assessment.

Cyclic tests are performed following a constant amplitude loading history in the plastic range,

after a few cycles in the elastic range. In particular, it is proposed to adopt the loading history

schematically represented in Figure 5, vy being the normal yield displacement, to be computed

theoretically by means of usual structural mechanics.

Figure 5. Schematic of the loading history.

11th European Conference on Earthquake Engineering 1998 Balkema, Rotterdam, ISBN 90 5410 982 3

Two cycles will be performed for each cycle with a displacement range v < 2 vy, while cycles

in the plastic range will be continued until complete failure of the specimen. Various values of the

maximum displacement range are considered: v = 4 vy , 6 vy , 8 vy. Experience gathered in previous testing programs, when it was assumed a cumulative damage model based on an S-N curve

approach, indicated that such procedure allows for a correct identification of low cycle fatigue

curves for each typology. To run the test, a definition of the failure of the specimen must be given

in cyclic testing, in particular when cycles of constant displacement amplitude are applied, the

failure may be very long process if a zero resistance is chosen as the definition of failure. Refering to practical applications in structures, it is clear that the structure is out of use before a zero resistance is reached. Conventionally in our testing, failure is determined by a drop in resistance of

50 % of the initial value obtained at the same displacement.

3 PRESENTATION OF LOW-CYCLE FATIGUE TEST RESULTS

The parameter characterizing high cycle fatigue is the number N of cycles at failure and the stress

tange , defined as follow for overall elastic deformations:

M P d P P d

=

=

W

W

P

W

(1)

P v

=

P

v

=

(2)

v P d

v

W

(3)

A working hypothesis is developed for low cycle fatigue. is the basic parameter characterizing

fatigue; in the dissipative zone, an equivalent stress * can be computed as:

* = E =

v Py d

vy

W

(4)

As test on each specimen are run at constant v and as Py and vy are known, it is easy to compute

* and to present the results in typical diagrams used for the presentation of high cycle fatigue

with * in ordinate and the number N of cycles to failure as abciss.

Expressed in the way, the results allow the definition of low cycles fatigue (Whler) curves

which can be compared to curves concerning the resistance to high cycle fatigue (classical). In the

presentation of the test results, reference is made to the design curves of Eurocode 3 (design of

steel structures).

Figure 6.

11th European Conference on Earthquake Engineering 1998 Balkema, Rotterdam, ISBN 90 5410 982 3

4 TEST RESULTS

All the tests in Lige and in Milan were constructed in early 1998. Some first significant results are

presented hereafter, but the analysis of the results is still going on, involving numerical evaluation

and considering experimental work still going on at the other testing sites.

4.1 Specimens type A1

Specimens A1 correspond to a rigid full strength bolted connection. The end plate of the beam is

welded with K preparation. The failure takes place in the beam: flange buckling or cracks in the

beam close to the weld. The results are presented in terms of low cycle fatigue (*, N) (Fig. 7).

Results A15 (95 mm) is situated on a higher curve than A12 (38 mm) and than A13 (57 mm). This

corresponds to two different failure modes: without apparent deformation in the flange for A12 and

A13, with buckles in the flange for A15. The result of specimen A1B2 (33 mm), which had no

double plate in the web of the column, lies higher than A12 (38 mm); this may be explained by the

existence of yielding of the panel zone that brings an increase in resistance to low cycle fatigue.

Globally, it can be concluded that connection A1, which is typical European design involving

welding at the shop and bolting on the site, has a very good behaviour. It corresponds to yielding in

the flange of the beam or to yielding in the panel zone of the column (specimen A1B).

4.2 Specimens type A2

The specimens A2 were subjected to several problems, which are not related to failure in welds:

Failure of bolts in the original design with 4 bolts in the connection (specimens A2 I , A2 II)

Lateral buckling, caused by a combination of web and flange buckling in the section where the

hunch starts (specimen A23); consequently the lateral support were increased in the testing rig

Even with increased lateral support (specimen A25, A26) the combination of local buckling of

web and flange in the section where the haunch starts remains the factor governing failure; this

can be explained by particular state of stress at this place; indeed the haunch introduces a thrust

onto the web; this was known and complete web stiffener would be needed to really prevent

the web buckling.

As a general comment on haunched beams the following can be expressed:

Putting a haunch increases the rigidity and the resistance of the beam

However, the haunch beam cost is very high because it requires much preparation of stiffeners,

a very high and thick plate and very long welds; the cost of connection A2 is about 80% higher

than the cost of A1.

The results are presented in terms of low-cycle fatigue in Figure 8.

4.3 Specimen B

Connection B is a semi rigid partial strength connection in which bolts are perpendicular to the

bended beam. The bolts are prestressed to a 9 kNm torque.

It is intended to develop energy dissipation through the ovalization of boltholes and through

friction between the web of the UPN 300 beam and the flange of the HE 300 M column. Both

mechanisms work:

- friction gives a constant resistance throughout the displacement,

- bearing resistance provides increases in resistance at both left and right side of the M - diagrams (Fig. 9).

These mechanisms are not subjected to degradation of strength up to number of cycles which can

be considered very high (over 40) in the earthquake context.

11th European Conference on Earthquake Engineering 1998 Balkema, Rotterdam, ISBN 90 5410 982 3

Figure 7. Whler curve for specimen type A1.

Figure 8. Whler curve for specimen type A2.

Figure 9. M - diagram for specimen B2.

The imposed displacements in test of specimens B have been chosen on the basis of a maximum

5 % drift of the building in which they would be present. In the range of displacements considered,

the friction force is quite constant and independent of the maximum displacement. It is around 50

kNm / (4 x 0,113 x 2) = 55 kN / bolt in both directions.

This last value is coherent for a M27 10.9 bolt with partial prestress and a friction coefficient

around 0,25. Once the bearing resistance is involved, the total resistance becomes higher, by a factor of 4 at the beginning of the cycles; this correspond to a total resistance of about 4 x 55 = 220 kN

/ bolt. This is very similar to the design resistance computed in the design of the specimens (217

kN / bolt). In reality, the phenomenon explaining the resistance of the connection is more complicated than a simple addition of "friction" and "bearing resistance", because at the 1st cycle, the

yielding realized by the ovalization of holes generates a local increase in the thickness of the web

of the UPN 300, which brings two additional factors: an increased prestress because the bolt is

forced to elongate and an increased friction because of the uneven surface produced by this "forging" phenomenon. The complete understanding of the resistance mechanism in such a connection

requires an extensive study and numerous small tests.

11th European Conference on Earthquake Engineering 1998 Balkema, Rotterdam, ISBN 90 5410 982 3

4.4 Specimen C1

Specimen type C1 were realized with a full penetration single bevel groove weld with a steel

backing bar. Figure 10 shows the hysteresis loops for test C1-50, while Figure 11 shows the hysteresis loops for C1-100 one. These specimens were tested under displacement ranges v = 50

mm and v = 100 mm. The yield displacement vy being approximately 23-25 mm, these displacement ranges resulted in ductility ranges v/ vy = 2 and 4 respectively. These specimens

are similar to those adopted for the moment resisting frame structures in which failures were reported during the Northridge Earthquake. Specimen C1-50 collapsed by failure of the beam flange

at the weld toe; this failure can be considered a brittle failure, because it took place suddenly, without noticeable deterioration in the load carrying capacity of the specimen. Only limited local buckling was evident at the end of the test in the beam flanges. Completely different was the behaviour

of specimen C1-100, which collapsed by failure of the beam flange due to large plastic deformations in the buckles, at the plastic hinge location. In the case of this specimen, the deterioration is

obvious and represents a clear warning sign of an incipient collapse. The different behaviour of the

two specimens is also evident at Figure 14, which presents the trend of the absorbed energy at each

cycle (E) normalized on the energy at the first cycle in the plastic range (E0). It can be noticed that

in the case of specimen C1-100, the ratio E/E0 shows an evident reduction during all the test duration, and before the last cycles leading to failure, it is already reduced below a value of 0.50. On the

other hand, the same ratio remains higher than 0.8 for specimen C1-50, dropping then suddenly, in

the last two cycles, below 0.2.

Figure 10. Hysteresis loops for specimen C1-50.

Figure 11. Hysteresis loops for specimen C1-100.

In addition, it should also be noticed that the conventional failure for specimen C1-50 can be

considered attained after 17 cycles in the plastic range, while that of specimen C1-100 was attained at cycle n. 12. This difference in the life of the specimens, that is very small, can be explained only by the different failure modes. From these results, it seems that cycles with a small

amplitude can lead to brittle fracture and may be more dangerous because they provide much less

visual warning about the degradation of the connection than cycles of large amplitude. These ones,

on the contrary, induce the formation of a plastic hinge with local buckling giving a very ductile

behaviour and a large energy dissipation.

4.5 Specimens C2

Specimens C2 are identical to specimen C1 but for the material of the backing bars, which is polyester. All the observation made for C1 are relevant. The distinction between two behaviours, one

brittle (C2B50, C2B75) and one ductile ( C2B100, C2B125) is even clearer (Figs. 13, 15).

8

11th European Conference on Earthquake Engineering 1998 Balkema, Rotterdam, ISBN 90 5410 982 3

Figure 12. Whler curve for specimen type C1.

Figure 13. Whler curve for specimen C2.

Figure 14. Energy absorption in Hysteresis loops

for specimens type C1-B.

Figure 15. Energy absorption in Hysteresis loops

for specimens type C2.

Figure 16. Whler curve for specimens C4.

11th European Conference on Earthquake Engineering 1998 Balkema, Rotterdam, ISBN 90 5410 982 3

4.6 Specimens C3

Specimens C3 are similar to C1, but for the shape of the backing bars which are triangular. The

backing bar tested in specimens C3 did not allow a complete butt weld to be made. Yielding was

restricted to the weld material and it did not last long: 2 or 3 cycles, to be compared for instance to

30 and 77 in specimens A1.

The high yield strength of the IPE 450A material (405 N / mm instead of the expected 300

N/mm) may also be participating to this early failure, since the weld material had not been chosen

specifically for a yield strength higher than expected.

4.7 Specimens C4

Specimens C4 correspond to a K preparation and welding from both sides of the flanges, which are

conditions for high quality welds.

Here again two different behaviours can be observed, to which two levels of Whler curves correspond, Figure 16:

- Brittle for displacement up to 50 mm

- Ductile above 50 mm

4.8 Comparison between various design

In the above table, the index of EC3 curves that would represent the behaviour of tested specimens

is given. For each specimen type two values are presented, which correspond to the two different

mechanical behaviour observed:

Low cycle fatigue excursions, no buckling, rather brittle failure

High yield excursion, buckling, progressive decrease of resistance.

Table 1. Comparison for of EC3 fatigue line (MPa) between various designs.

SPECIMEN TYPE

A1

A2

C1

C2

C3

C4

Small yield

displacement v = 2 vy

High yield

displacement v = 4 vy

42

/

21

32

10

29

50

40

56

63

18

63

5 CONCLUSIONS

The tests realized with the objective to define low cycle fatigue curves corresponding to various

design detail of connection used in moment frames allow several practical conclusions.

The results obtained set forward the validity of a quantification of cyclic tests in term of low

cycle fatigue

On that basis, the various connection design tested can be classified in terms of average of resistance, but also of scatter; in this formulation, the word design includes the many factors influencing the behaviour, like base material, weld material, groove type, welding sequence, type

of backing bar, flexibility of eventual end plates, yielding resistance of the panel zone of the

column

Two basic different behaviours have been observed, independently of the type of connection

design. One takes place when the plastic strains realized during the cyclic test are small,

10

11th European Conference on Earthquake Engineering 1998 Balkema, Rotterdam, ISBN 90 5410 982 3

around two times the yield stains, and no buckling of the beam is observed; then, the strength

degradation is small until a relatively sudden failure takes place. The other type of behaviour

happens when large plastic cyclic excursions are realized; then the resistance progressively

drops, as buckling develops.

ACKNOWLEDGEMENTS

Financial support to the project has been provided by the European Community Commission for

Environment and Climate Programme, Directorate XII, Science, Research and Development;

Contract N. ENV4-CT96-0278; Proposal N. PL950671.

REFERENCES

ATC-24 1992. Guidelines for Cyclic Seismic Testing of Components of Steel Structures, Applied Technology Council.

Ballio, G., Chen, Y. 1993. An Experimental Research on Beam Column Joints: Exterior Connections,

Giornate C.T.A., Viareggio.

Ballio, G., Castiglioni, C.A. 1994. Seismic Behaviour of Steel Sections, Journal of Constructional Steel

Research, Vol. 29, pp. 21-54.

Bernuzzi, C., Calado, L., Castiglioni, C.A. 1997. Behaviour of Steel Beam-to-Column Joints under Cyclic

Reversal Loading: an Experimental Study, SSDS, Proceedings, Nagoya, Japan.

Bernuzzi, C., Calado, L., Castiglioni, C.A. 1997. Low Cycle Fatigue of Structural Steel Components: Methods for Re-Analysis of Test Data and a Design Approach Based on Ductility, submitted for publication

on the Journal of Earthquake Engineering.

Bertero, V., Anderson, J.C., Krawinkler, H. 1994. Performance of Steel Building Structures during the

Northridge Earthquake, EERC, University of California, Berkeley, Rep. n. UCB/EERC-94/09.

European Committee for Standardization (CEN) 1994. ENV 1993-1-1 Eurocode 3: Design of Steel Structures.

European Committee for Standardization (CEN) 1994. ENV 1998 Eurocode 8: Design Provisions for Earthquake Resistance of Structures.

European Convention for Constructional Steelworks 1996. Recommended Testing Procedures for Assessing

the Behaviour of Structural Elements under Cyclic Loads, Technical Committee 1, TWG 1.3 - Seismic

Design, Publ. N. 45.

Krawinkler, H., Zohrei, M. 1983 Recommendations for Experimental Studies on the Seismic Behaviour of

Steel Components and Materials, The John Blume Earthquake Engineering Research Center, Stanford

University, Rep. n. 61.

Plumier, A. 1994. Behaviour of Connections, Journal of Constructional Steel Research, Vol. 29, N. 2, pp.

95-119.

Tremblay, R., Timler, P., Bruneau, M., Filiatrault, A. 1995. Performance of Steel Structures during the

Northridge Earthquake, Canadian Journal of Civil Engineering, Vol. 22, N. 2, April.

11

You might also like

- Effects of Semi-Rigid Connections on Steel Frame ReliabilityDocument17 pagesEffects of Semi-Rigid Connections on Steel Frame ReliabilityMassimo LatourNo ratings yet

- Vozni Red AutobusaDocument4 pagesVozni Red AutobusamiskoscribdNo ratings yet

- FVOKS 2011 Guide For Applicants Vol 2 enDocument163 pagesFVOKS 2011 Guide For Applicants Vol 2 enMassimo LatourNo ratings yet

- Freedam 04-18-2017 Load CurveDocument1 pageFreedam 04-18-2017 Load CurveMassimo LatourNo ratings yet

- A Special Reinforcing Technique To Improve Resistance of Beam-To-TubularDocument14 pagesA Special Reinforcing Technique To Improve Resistance of Beam-To-TubularMassimo LatourNo ratings yet

- Complex Machine Performance Testing: Business JustificationDocument2 pagesComplex Machine Performance Testing: Business JustificationMAFS0504No ratings yet

- Adobe Cloud ServicesDocument6 pagesAdobe Cloud ServicesaafqwreNo ratings yet

- Seismic retrofit of industrial buildings with energy dissipating dampersDocument14 pagesSeismic retrofit of industrial buildings with energy dissipating dampersMassimo LatourNo ratings yet

- Rths Chae - enDocument12 pagesRths Chae - enMassimo LatourNo ratings yet

- Abstract PDFDocument2 pagesAbstract PDFMassimo LatourNo ratings yet

- Immunization Thesis: August 2019Document66 pagesImmunization Thesis: August 2019Massimo LatourNo ratings yet

- Rths Chae - enDocument12 pagesRths Chae - enMassimo LatourNo ratings yet

- Plate Buckling in Design Codes: The Difference Between NEN 6771 and NEN-EN 1993-1-5Document106 pagesPlate Buckling in Design Codes: The Difference Between NEN 6771 and NEN-EN 1993-1-5Sandeep BhatiaNo ratings yet

- Abstract PDFDocument2 pagesAbstract PDFMassimo LatourNo ratings yet

- Tese Jose HenriquesDocument252 pagesTese Jose HenriquesMassimo LatourNo ratings yet

- BioRes 12-3-4690 Xie Shear Capacity Connector 11280Document18 pagesBioRes 12-3-4690 Xie Shear Capacity Connector 11280Massimo LatourNo ratings yet

- OpenFresco Example Manual 2.6 XPCTargetDocument17 pagesOpenFresco Example Manual 2.6 XPCTargetMassimo LatourNo ratings yet

- Rths Chae - en PDFDocument27 pagesRths Chae - en PDFMassimo LatourNo ratings yet

- An Innovative Dual System For New Structures or For The Retrofit of Precast Concrete Industrial BuildingsDocument9 pagesAn Innovative Dual System For New Structures or For The Retrofit of Precast Concrete Industrial BuildingsMassimo LatourNo ratings yet

- A Classification of Structures and Mason PDFDocument15 pagesA Classification of Structures and Mason PDFMassimo LatourNo ratings yet

- Plate Buckling in Design Codes: The Difference Between NEN 6771 and NEN-EN 1993-1-5Document106 pagesPlate Buckling in Design Codes: The Difference Between NEN 6771 and NEN-EN 1993-1-5Sandeep BhatiaNo ratings yet

- Eurosteel2014 T-StubDocument8 pagesEurosteel2014 T-StubMassimo LatourNo ratings yet

- 1 s2.0 S0143974X1730562X MainDocument19 pages1 s2.0 S0143974X1730562X MainMassimo LatourNo ratings yet

- Composite Sandwich Floor Panel Connection SystemsDocument13 pagesComposite Sandwich Floor Panel Connection SystemsMassimo LatourNo ratings yet

- Cyclic Behavior and Modeling of A Dissipative Connector For Cross Laminated Timber Panel BuildingsDocument36 pagesCyclic Behavior and Modeling of A Dissipative Connector For Cross Laminated Timber Panel BuildingsMassimo LatourNo ratings yet

- Bearing Resistance OF Bolted Connections FOR Tubular Racking StructuresDocument10 pagesBearing Resistance OF Bolted Connections FOR Tubular Racking StructuresMassimo LatourNo ratings yet

- E As 1201003Document9 pagesE As 1201003Massimo LatourNo ratings yet

- Latour - Paper SISMICA 2010Document12 pagesLatour - Paper SISMICA 2010Massimo LatourNo ratings yet

- Lateral-Torsional Buckling of Steel Beams With Open Cross SectionDocument177 pagesLateral-Torsional Buckling of Steel Beams With Open Cross Sectionp18000No ratings yet

- Connections VII Latour Piluso Rizzano Column BaseDocument12 pagesConnections VII Latour Piluso Rizzano Column BaseMassimo LatourNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Surfactant Enhanced Oil Recovery by Wettability Alteration in SandstoneDocument77 pagesSurfactant Enhanced Oil Recovery by Wettability Alteration in SandstoneSaurabhSharmaNo ratings yet

- PIP STE05121 Anchor Bolt Design Guide PDFDocument56 pagesPIP STE05121 Anchor Bolt Design Guide PDFVasan Sam100% (1)

- Synthetic ester oils for air compressorsDocument1 pageSynthetic ester oils for air compressorsironiteNo ratings yet

- Astm C78Document3 pagesAstm C78avrajan100% (3)

- Hot Dip Galvanizing Process ExplainedDocument13 pagesHot Dip Galvanizing Process ExplainedaselabollegalaNo ratings yet

- PEM - Threaded Inserts For Plastics PDFDocument20 pagesPEM - Threaded Inserts For Plastics PDFHenrique MarquesNo ratings yet

- 7 Skema Kimia K1 & K2 Trial SPM Terengganu MPP3 2019Document14 pages7 Skema Kimia K1 & K2 Trial SPM Terengganu MPP3 2019Ain MiorNo ratings yet

- 17 Samss 007Document12 pages17 Samss 007Cherukunnon Jubu0% (1)

- Clark1984 PDFDocument29 pagesClark1984 PDFMiguel HerreraNo ratings yet

- 3) Dynamic Properties and Influence of Clay Mineralogy Types On The Cyclic Strength of Mine Tailings PDFDocument13 pages3) Dynamic Properties and Influence of Clay Mineralogy Types On The Cyclic Strength of Mine Tailings PDFVgkBharadwajNo ratings yet

- Mechanical Design Engineer Interview QuestionsDocument4 pagesMechanical Design Engineer Interview QuestionssuseevNo ratings yet

- Longboard Study BoardDocument6 pagesLongboard Study BoardGiovanniTauroNo ratings yet

- Portable Hardness Testing - Principles and ApplicationsDocument8 pagesPortable Hardness Testing - Principles and ApplicationsvrapciudorianNo ratings yet

- ASTM standards for concrete specificationsDocument2 pagesASTM standards for concrete specificationsAlaaFaragAllahNo ratings yet

- Astm A-297 HPDocument2 pagesAstm A-297 HPeduardo_exsys100% (1)

- Aluminium Cookware To MinimizeDocument7 pagesAluminium Cookware To MinimizeKeep CalmNo ratings yet

- N2XSEBY cable specificationsDocument5 pagesN2XSEBY cable specificationsKiki WidyaNo ratings yet

- Ion Exchange ProcessDocument10 pagesIon Exchange Process056 Jatin GavelNo ratings yet

- PS1 Without AnswerDocument3 pagesPS1 Without Answerbrian galangNo ratings yet

- Removal of H2S in down-flow GAC biofiltration using sulfide oxidizing bacteriaDocument3 pagesRemoval of H2S in down-flow GAC biofiltration using sulfide oxidizing bacteriaมาร์ค มัธยมNo ratings yet

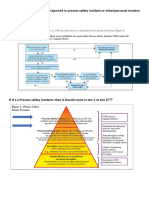

- REPORTING INCIDENTSDocument6 pagesREPORTING INCIDENTSDivyansh Singh ChauhanNo ratings yet

- Flash Point by Abel's ApparatusDocument3 pagesFlash Point by Abel's ApparatusAbhishek JoshiNo ratings yet

- Functional Biopolymers: Mohammad Abu Jafar Mazumder Heather Sheardown Amir Al-Ahmed EditorsDocument586 pagesFunctional Biopolymers: Mohammad Abu Jafar Mazumder Heather Sheardown Amir Al-Ahmed EditorsMonique BarretoNo ratings yet

- Nature Koligatif SolutionDocument28 pagesNature Koligatif SolutionDiah SukmawatiNo ratings yet

- Batch Asphalt Mixing Plants Brochure Ppb-1591-04-En 221009Document17 pagesBatch Asphalt Mixing Plants Brochure Ppb-1591-04-En 221009Mohammad Rabnawaz imamNo ratings yet

- Machined Seals: Product RangeDocument43 pagesMachined Seals: Product RangeAnonymous r3MoX2ZMTNo ratings yet

- Material Safety Data Sheet Surfaklen 395 (Long)Document3 pagesMaterial Safety Data Sheet Surfaklen 395 (Long)Fabrication PMCNo ratings yet

- BS 5950 - Worked Example 7Document9 pagesBS 5950 - Worked Example 7libanpires100% (1)

- Anaerobic Sludge DigestionDocument27 pagesAnaerobic Sludge DigestionHRK65No ratings yet

- Dektite Diverter and Retrofit Dektite Diverter: Pipe FlashingsDocument2 pagesDektite Diverter and Retrofit Dektite Diverter: Pipe FlashingscherandinhoNo ratings yet