Professional Documents

Culture Documents

SPE-112924-MS-P Identification of Wells With High CO2-Leakage Potential in Mature Oil Fields Developed For CO2-Enhanced Oil Recovery

Uploaded by

JohnSmithOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SPE-112924-MS-P Identification of Wells With High CO2-Leakage Potential in Mature Oil Fields Developed For CO2-Enhanced Oil Recovery

Uploaded by

JohnSmithCopyright:

Available Formats

SPE 112924

Identification of Wells with High CO2-Leakage Potential in Mature Oil Fields

Developed for CO2-Enhanced Oil Recovery

T.L. Watson, SPE, T.L. Watson & Associates Inc.; S. Bachu, Alberta Energy Resource Conservation Board

Copyright 2008, Society of Petroleum Engineers

This paper was prepared for presentation at the 2008 SPE/DOE Improved Oil Recovery Symposium held in Tulsa, Oklahoma, U.S.A., 1923 April 2008.

This paper was selected for presentation by an SPE program committee following review of information contained in an abstract submitted by the author(s). Contents of the paper have not been

reviewed by the Society of Petroleum Engineers and are subject to correction by the author(s). The material does not necessarily reflect any position of the Society of Petroleum Engineers, its

officers, or members. Electronic reproduction, distribution, or storage of any part of this paper without the written consent of the Society of Petroleum Engineers is prohibited. Permission to

reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of SPE copyright.

Abstract

Previous work, presented in SPE 106817, Evaluation of the Potential for Gas and CO2 Leakage along Wellbores, described

a method to predict the potential for wellbore leakage which primarily occurs in the shallow areas of a wellbore.

The work presented here focuses on the potential for leakage to occur from the deep regions of a wellbore, particularly

from viable oil reservoirs. The potential for wellbore leakage where CO2 emhanced oil recovery (EOR) or sequestration is or

may be conducted is specifically investigated.

The Alberta Energy Resources Conservation Board collects and maintains data regarding cement types used in primary

cementing of casing strings, stimulation information and abandonment data. These data were used to determine the potential

for deep wellbore leakage in the presence of CO2. This deep wellbore leakage potential is then coupled with shallow wellbore

leakage potential to predict which wells may leak to other reservoirs, potable groundwater aquifers or to the atmosphere in a

CO2 sequestration or EOR project.

Cements with additives such as bentonite have been shown to be particularly susceptible to CO2 attack. Wells were

screened for cement blends placed in the deeper sections of the wellbore during primary cementing. This information is

useful in predicting if a wellbore will remain leak free if CO2 is placed in the reservoir and the wellbore is contacted.

The stimulation method was evaluated to determine if injected CO2 may break through to existing wellbores prior to full

reservoir sweep, thus decreasing the time that the wellbore could remain leak free. Stimulations such as hydraulic fracture,

perforating and acidizing with pressure were deemed to increase the likelihood that wellbores would leak due to cement

sheath cracking coupled with CO2 attack of cement and casing.

The abandonment method was also evaluated. In Alberta the primary form of zonal abandonment utilizes a mechanical

bridge plug capped with cement. The bridge plug material is expected to fail in the presence of CO2 due to CO2 attack on

elastomers and cast iron.

Two large field evaluations are presented as case studies.

Figure 1: Shallow and deep

Introduction

Several client studies have been conducted to date in Alberta, Canada, to determine factors which

may affect wellbore leakage. The findings of these studies were presented previously (Bachu and

Watson, 2006; Watson and Bachu, 2007). These papers, particularly SPE 106817, presented an

analysis of the factors that affect the leakage potential in the shallow part of a well, and a

decision-tree type model which enables ranking of a wells potential to leak based on factors

determined in the client studies.

The original ranking system generally focused on leaks from the shallower regions of the well

(Figure 1). These leaks typically manifest themselves at surface as annular pressure (surface

casing vent flow-SCVF, known also as sustained casing pressure) or soil gas migration. This

ranking system did not take into account the potential for a native or injected fluid or gas to

create or increase the potential for a well to leak.

In Alberta several reservoirs are currently being evaluated for CO2 enhanced oil recovery

(EOR), while more than 30 depleted oil and gas reservoirs and deep saline aquifers are used for

acid gas (CO2 and H2S) disposal. In an attempt to determine the potential for a well penetrating

one of these reservoirs or aquifers to leak CO2 or acid gas from the target reservoir, a computerbased tool was developed. This tool uses the data available in electronic form from the Alberta

areas of the wellbore.

SPE 112924

Energy Resources Conservation Board (ERCB) to create a score for each wellbore. This score indicates the leakage potential

from both the shallow and deep regions of the wellbore as depicted in Figure 1. Data were also compiled to allow for the

future evaluation of possible consequences of a leaking wellbore.

The shallow leakage factors have been determined by analysing known leakage in the field and determining the most

prevalent factors that lead to annular pressure and soil gas migration (Bachu and Watson, 2006; Watson and Bachu, 2007).

The deep leakage factors, however, have been determined from theoretical deduction and laboratory results.

Shallow Leakage

Factors previously determined to have an effect on shallow wellbore leakage (Bachu and Watson, 2006; Watson and Bachu,

2007) were assigned values which reflected the influence that a particular factor has on shallow wellbore leakage. Table 1

indicates these factors, the criteria and default values assigned based on these criteria. These values are then multiplied to

determine a wells Shallow Leakage Potential (SLP) score. Table 2 summarizes scores into general leakage-potential

categories.

Table 1: Shallow leakage factors.

Factor

Criterion

Spud Date

Abandonment Date

Surface Casing Size

Well Type

Geographic Location

1965-1990

<1995

244.5 mm

Cased

Special Test

Area

>2500 m

1.2-1.8

No

Unknown

No

Unknown

Well Total Depth

Well Deviation

Cement to Surface

Cement to Surface

Additional Plug

Additional Plug

Table 2: Shallow leak potential.

Meets

Criterion

Value

3

5

1.5

8

3

Default

Value

1

1

1

1

1

1.5

1.5

5

4

2

1.5

Shallow Leak Potential (SLP)

Low

Medium

High

Extreme

Score

<50

50-200

200-400

>400

1

1

1

1

1

1

In general the analysis is based on the potential for a well to have a leakage pathway along the wellbore and does not

depend on the fluid or gas source that may be leaking.

Deep Wellbore Leakage

Three factors were used to evaluate the Deep Leakage Potential (DLP) for a wellbore in CO2 sequestration, acid gas disposal

and CO2-EOR. Deep leakage was evaluated based on the presence of CO2 or acid gas and the impact this acidic environment

would have on wellbore construction and abandonment materials such as cement, steel and elastomers. Table 3 indicates the

factors, criteria and assigned values used to determine the possibility that deep leakage would occur. These factors are then

multiplied to obtain the wells overall DLP. Table 4 summarizes the product score values into general categories.

Table 4: Deep leak potential.

Table 3: Deep leakage factors.

Factor

Criterion

Fracture

Fracture

Acid

Acid

Acid

Perforations

Abandonment type

Abandonment type

count =1

count >1

count=1

count=2

count>2

count>1

Bridge Plug

Not abandoned

Meets

Criterion

Value

1.5

2

1.1

1.2

1.5

2

3

2

Default

Value

1

1

1

1

1

1

1

1

Deep Leak Potential (DLP)

Low

Medium

High

Extreme

Score

<2

2-6

6-10

>10

Cement Type

Several studies have been conducted to determine the effect of CO2 on the quality of cements used in wellbore

construction (Browning, 1984; Onan, 1984; Bruckdorfer, 1986; Krilov et al., 2000; Duguid et al., 2004; Kutchko et al.,

2007). Most of these studies indicate that cement will not withstand CO2 attack and will fail to provide a seal in the

casing/hole annulus when CO2 is introduced (Nelson and Guillot, 2006a). Recent laboratory work suggests, however, that

cements with low free water ratios may not be as susceptible to CO2 attack due to the formation of an impermeable barrier on

the cement sheath that halts further deterioration as shown in Figures 2 and 3 (Kutchko et al., 2007a). These studies also

suggest that the inclusion of additives, such as bentonite, which increase the free water ratio, increases the potential for

SPE 112924

cement break down in the presence of CO2 (Kutchko et al., 2007a). Since no such studies exist for the effect of acid gas on

well cements, it is assumed that the conclusions and results for CO2 would apply to acid gas as well since the reactions are

due to the acidic nature of the fluid (Kutchko et al., 2007a).

Figure 2: Kinetic results for the penetration

rate of CO2 -saturated brine of the cement.

(Kutchko et al., 2007b). (Graph courtesy of B.

Kutchko, U.S. Department of Energy.)

Bentonite, commonly referred to as gel, is the most

common additive to cement. This additive is used as an

extender to increase the yield of the cement, decrease the

cement density and decrease the fluid loss (Nelson and Guillot,

2006b). The addition of bentonite increases the set cement

porosity, increasing the cement susceptibility to corrosion due

to acidic formation fluids (Nelson and Guillot, 2006a). Cement

blends which include bentonite are often used as filler

cements to reduce the cost of cementing and the hydrostatic

pressure applied to the producing formation or weak

formations. Other additives, such as gypsum, which are highly

acid-soluble, are also expected to deteriorate rapidly in the

presence of CO2 or acid gas.

Inert additives such as fly ash, silicate (sand) and nitrogen

(foamed cement) do not increase the free water ratio and are

assumed for this study to have a lesser effect on the

deterioration of cement in the presence of CO2 (Nelson and

Guillot, 2006a).

The data, provided by the ERCB, include information

regarding the cement types used in the cementing of the

production casing. Table 5 itemizes the cement types found in

the ERCB electronic database and the values assigned for the

purpose of assessing a wells potential to be adversely affected

by CO2 or acid gas and potentially cause leakage. Often, several

different types of cement may be used to cement the wellbore.

Generally, better quality cement, designed for the well purpose,

depth, temperature and reservoir conditions, is run across the

zone or completion interval. Filler type cements are often run in

the shallower areas of the wellbore. The ERCB data indicate

these different cement types in a wellbore, as well as where

they are placed by providing the sequence that the cement was

Figure 3: SEM-BSE image of Class H neat cement cured

for 28 days. The CaCO3(s) is forming a barrier to further

CO2 infiltration (Kutchko et al., 2007a). (Photo courtesy of

B. Kutchko, U.S. Department of Energy).

Table 5: Cement types and values.

Cement Type

1:1 POZ MIX

Assigned

Value

1

Description

Cement, fly ash and various

quantities of bentonite

Unknown

1:1:# POZ

BLACKGOLD

1

1

CAP (NEAT)

CLASS X NEAT

1

1

FILL ECP

1

FOAMED

1

G + # PC SALT

1

G + # PC SAND

GPSL/GPCEM/THX

3

3

Cement and fly ash

Cap pumped on top of foam

cement, not applicable.

Various neat cements

Cement to fill annular packer,

not applicable

Cement foamed with

nitrogen

Cement with various percent

salt additive

Cement with various percent

silica sand additive

Gypsum and gel additives

SLOTTED LINER

Assumed gel additive to

reduce density

No cement, hole allowed to

slough in on casing

Blast furnace slag, reduces

cement porosity

No cement

SLURRY 6D

Unknown

TAPERED CASING

TH CEM/CEM

FNDU

UNCEM

CSG/LINER

No cement

Thermal cement, usually

sand or silica additive

No cement

LIGHT WEIGHT

3

SELF STRESS

1

SLAG

SPE 112924

pumped into the well. Cement data for wells spud prior to 1986 are sparse, however most wells spud after 1986 have detailed

information regarding cement type and placement. From this information it is possible to determine which cement type is in

the deepest portions of the wellbore. The cement type recorded as being at the bottom of the well is the cement type that this

evaluation is based on.

Stimulation and Perforations

The ERCB records information regarding most stimulation treatments to perforations or producing intervals in wellbores,

as well as the number of completed intervals in the wellbore. Two types of treatments and perforating are anticipated to have

potential effects on long term wellbore integrity due to excessive pressures (Watson et al., 2002), as shown in Figure 4, or

chemical reactions. In this study hydraulic fracturing and acidizing with pressure were classified as stimulation methods that

could have a negative impact on wellbore integrity. Carbon dioxide or acid gas

Figure 4: Cement sheath failure and

may migrate through cracks in the cement created by stimulation or

resulting cracks developed from pressure

perforating. These acidic fluids may increase and hasten the leakage by further

cycling the internal casing (Watson et al.,

2002). (Photo courtesy of Halliburton

deteriorating the cement sheath or corroding the steel casing.

Energy Services).

Hydraulic fracturing breaks the reservoir rock using a viscous fluid, high

pump rates and high pressures. The reservoir rock is fractured and the

fractures filled with a propping agent, usually sand, that creates a highly

porous and permeable flow path to the wellbore. Acidizing dissolves wellbore

scales, removes near wellbore damage and dissolves reservoir rock. These

stimulations can remove near-wellbore damage caused by drilling activity and

increase the flow potential near the wellbore.

In the situation where CO2, acid gas and/or water is used for reservoir

EOR, it is anticipated that CO2 or the acid gas may break through to these

reservoir fractures preferentially, bypassing unaltered reservoir rock due to the

higher permeability of the fracture (Marsters, 2007). As well, where wells

have been abandoned due to depletion or produced for long periods of time,

the localized reservoir pressure around these wells may facilitate the flow of

flood fluids to migrate towards these low pressure areas. Multiple completions

or perforated intervals provide a higher potential for cross flow between

discrete geologic zones within the wellbore itself.

The data were analysed to determine if a particular well was stimulated by

fracturing, acidizing or if it had multiple completions. Fracturing has been given a higher risk score due to higher treatment

pressures and deeper penetration into the reservoir, typically achieved by fracturing. In comparison, acidizing and perforating

are usually near-wellbore treatments. Both fracturing and acid treatments were counted for the individual wellbores. This

count information is used based on the assumption that the more times a well is stimulated, the higher the chance that casing,

cement and/or cap rock systems may be damaged. The number of completions is also counted and any well that has multiple

completed intervals was assigned a higher value due to the increased potential of crossflow.

Zonal Abandonment Method

In Alberta the ERCB allows three options for zonal abandonment of cased wells. The methods, as depicted in Figure 5

are: a cement plug that extends a minimum of 15 meters above and below the perforated interval, a cement squeeze through

the perforations with or without a retainer, or, the most commonly used method, a mechanical bridge plug capped with 8

meters of cement (ERCB 2007).

Figure 5: Regulatory approved zonal abandonment methods in Alberta, Canada.

Cement plug set across

perforations.

Cement squeeze with

retainer to perforations.

Bridge plug capped with 8

meters of cement.

SPE 112924

This factor identifies the abandonment method for a particular well and assigns a value based on these criteria. It is

anticipated that the bridge plug abandonment method will have a shorter life than other methods due to mechanical failure,

change of reservoir pressure due to the injection of CO2, acid gas and/or water, or a change in the gas/fluid chemistry below

the bridge plug (Schremp and Roberson, 1975). Bridge plugs are typically made of cast iron and an elastomer sealing unit as

shown in Figure 6. Both iron and the typical nitrile elastomers used are subject to CO2 or acid gas attack that can lead to seal

failure (Schremp and Roberson, 1975).

Cement caps placed above bridge plugs are typically dumpFigure 6: Bridge plug capped with 8 meters of cement

bailed into place. Cement caps evaluated in an earlier client study

with infiltrating CO2.

were found intact in only 50% of the wells investigated. This

corresponds to laboratory findings that indicate dump-bailing of

cement may be ineffective in providing adequate seals (White et al.,

1992). Based on these findings, the ability of dump-bailed cement

plugs to maintain an effective seal above the bridge plug is

considered negligible for this study.

Zonal abandonment type had originally been included in the

potential for shallow wellbore leakage. For this study the zonal

abandonment method has been evaluated as deep potential for

leakage, because it has a direct effect on the potential for wells to

leak from the CO2 sequestration or acid gas disposal formation up

the inside of the production casing where it may impact all horizons

in the wellbore.

Wells that have not been cased are called drilled and abandoned.

These wells have been left out of the analysis since records in

Alberta indicate that the leakage occurrence rate is 0.5% of drilled and abandoned wells compared to 13% of cased

abandoned wells (Bachu and Watson, 2006). Additionally, no data exist to determine the cement type in the cement plugs

used to abandon uncased wells. It is assumed, based on field knowledge, that cement plugs typically consist of neat type

cements, and these wells will therefore have a lower DLP.

Case Studies

The Pembina and Zama oil fields in Alberta (Figure 7) were evaluated using the previously described method. These fields

are being considered for CO2 or acid-gas EOR, and pilots are currently being run in both. The results of the evaluation can be

used to determine the overall leakage potential for existing wells in oil fields where CO2 or acid gas injection may be used for

EOR and/or future sequestration. The information provided by this

analysis can be used to target particular wells for further evaluation based

Figure 7: Map of Alberta, Canada, showing the

location of the Pembina and Zama Fields in red.

on their individual DLP and SLP scores. Table 4 provides general

information for comparison between the two oil fields and the potential

for well leakage based on the predetermined factors.

3

u4

3

u4

1

1

43

u

3

1

4

u

u

34

43

b

1

u

3

34

5

3

"54

4

"5

5

1

"uu4

3

u

3

u

u

"u

1

4

4

b

"5

"3

u

5

*4

43

u

"

M

"4

4

45

1

31

b4

5

1

3

13

*3

1

uu

G

35

4

1

G

G

4

1

IG

5

1

u

5

4

u

3

E

b

4

3

u

u4

*3

*b

E

"b

13

u

1

5

G

1

*3

E

"*3

3

5

u

3

b

3"5

*E

4

3

3

G

4

b

1

4

4

u1

5

u34u

I**5

u4

O

u

1

3

*3

G

1

4

5

1

*4

G

3

5

*G

4

*5

4

5

1

G

K

4

G

5

"1

b

5

4

b

3

b

u

4

b

u

"G

3

u

E

b

3

5

3

u

u

5

34

1"E

*5

4

5

1

*1

O

G

5

"*3

4

1*5

"b

4

*4

3

5

4

5

G

I

E

4

*1

b

"u

4

u

3

4

5

1

1

u

5

3

G

b

"u3

1

3G

4b

5

*bu

u

*G

Zama Field

Table 4: Field data and results summary.

ALBERTA

Edmonton

3*3

5

*u

4"G

3

4

u

D

G

5

1

1u4

1

"3IG

G

3

1

4

31

*5

u5

"3

43

4

"3

"*3

N

O

3

I5

5

1

34

4

3

5

3

u3

u

"5I4

3I5

14

3

5

1

4

"*"4

u

1

"u

4

3

G

"3

1

b

35

3

u5

5

4

"4

1

3

5

"4

u

G

3

"3

4

""E

4

3

33

u

5

u

1

5

u

4

3

4

b

G

*"5

3

D

5

*O

*E

*3

"5

35

45

"u

*

G

"*1

I4

IG

1

G

4

u

3

5

u

I33

b"E

G

1

u

G

5

5

5

4

u

G

u

3

b

*u

5

"I3

5

4

4

4

*5u

u

O

N

4

b

u

4

u

*4

u

"b

D

"G

D

G

*u

*"u

G

3

G

4

D

4

3

3

"u

4

O

"4

G

D

I3

**4u

G

*L*"G

u

3

O

G

"O

"O

3

5

u

1

3

5

3

4

1

D

I

5

3

5

1

3

1

u

b

*5

*u

5

3

3

5

4

45

3

D

G

1

O

G

D

"4

N

1

1

5

1

K

25

*

4

G

3

"G

D

"G

5

IN

N

5

5

I1

"G

4

41

5u

3

1

3

4

E

O

*1

5

4

D

*G

2

4

D

u

3

G

b

2

"*I4

G

5

O

4

u

"

L

N

*5

1

4

E

4

*5

u

u

G

O

1

4

G

u

"

5

G

*"3

u

5

3

2

1

4

**5

G

u

5

1u

3

1

5

*1

u

G

15

E

D

2

ID

3

*5

"u

3

3

I5

O

G

I3

I**O

4

"3

3

3

u

5

u

3

4u

15

IO

3

*"b

4

*"5

u*b

4

G

D

I3

5

3

u

5

b

3

O

5

3

"E

L

5

*N

G

"u

D

O

*G

3

"5

"u

G

*u

""4

b

3*O

4

5

3

G

*"L

u

4

3

5

*G

3G

4

"5

u

5

u4

"u

*3

""Iu

44

3

G

1

G

5

*G

4

4

3

u

"3

3

5

u

*G

I4

b

G

u

*5

1

4

1

5

"N

u

1

4

u

O

5

IO

O

I5

L

"

1

N

D

u

4

3N

4

4

3

L

I5

D

*D

13

5

G

1

5

"G

4

5

3

1"u

I3

O

u

4

3

u

K

3

5

O

N

O

1

3

I"1

u

4

3

3

1

4

3

4

1

4

3

b

"*N

D

5

u"3

*"*5

u5

4

u

3

"I5

*IG

u

N

3

5

""G

*

u

5

**u

G

G

5

N

44

5

5

"O

5

1

M

G

"N

1

3

E

O

3

1

G

*45

4

"L

O

*L

1

O

1

5

u

E

1

5

u

3

u

*3

4

3

4

*4L

5

u

*54

E

5

"G

I1

N

K

E

O

3

u1

*G

3

5

4

G

4

"5

G

D

3

5

O

5

"G

u

3

G

4

5

3

"G

b1

IG

G

4

*1

3

5

3

"G

G

*5

u

5

"u

G

O

*"3

I1

IN

b

*5

""u

5

3

4

4

u

I3

L

"G

*"N

u

I4

E

*

5

O

N

L5

3

"1

G

*Ib

*13

*I5

ID

5

u

I

*

5

G

u

*4

3

4

u

*4

3

1

5

3

Iu

*Iu

5

"O

2

u

O

N

*3

G

N

2

*u

O

u

I5

O

5I

D

G

E

14

b5

4

4

*5

4

"5

"5

4

4

3

4

31

u

13

u

44

u5

G

D

N

O

M

3

O

D

E

3

*5

5

N

53

1

D

O

u

G

**D

1

*

2

4

1

u

5

4

G

4

3

O

4

1G

O

IL

"

4

D

u

*4G

O

N

3

3

5

5

3

4

*Ib

G

3

41

5

I3

L

3

G

*5

3

u

N

4

4

1

"N

I*u

*3

u

"O

4

u

G

"I3

*E

4

5

3

"G

O

I*4

1D

I

5

*3

G

L

D

4

II"O

u

*3

G

"G

u

I3

u

5

5

5

1

D

5

*G

G

I

4

1

3

*D

N

1

3

4

O

D

"

3

3

N

5

u

u

1

D

G

u

"4

*5

3

"1u

u

4

O

1

3

"5

3

u

u

"*5

u

5

N

G

I*O

G

*E

u

G

3

5

1

1

*D

O

4

"4

G

L

4

IG

5

4

N

1

b

IG

*1

5

LG

*O

4

3

1"3

*u

""*5

E

O

ID

5

5

*

u

L

4

G

3

L

4

*I"

1

G

4

4

G

*4

D

3

"1

D

*L

3

1

3

5

4

3

"5

IG

3

u

O

I"1

5

I"uG

4

O

5

5

5

"4

3

5

u

*I

u

3

u

1

u

5

4

3

G

u

5

3

4

*"3

D

u

u

D

O

G

54

O

u

"u

3

1

b

"K

1

I5

b

3

u

5

3

4

1

5

L

I35

14

u

L*G

N

O

I

4

I3

*5

u

L"u

1

"1

5

u

41

5

5

G

4

*5

G

4

5

b

O

1

3

4

4

"*O

4

I3

3

b

5

"5

O

*G

u

5

u

*G

3

u

**

1

5

3

u

4

1

5

*3

u

I"4

u1

*3

3"*5

1

3

G

4

3

4

1

41

I4

*u"5

u3

1

G

u5

35

3

4

u

3u

G

3

3"*G

3

1

"D

u

5

5

b1

u

4

u

1

bG

N

4

1

"5

O

3E

D

1

3

u

4

"5

4

u

IG

5

1

D

G

13

"u

4

4

1

u

4

3

u

14

4

3

"u

5

3

u

4

4

u

*"5

4

u

b

*3

3

u5

4

3

5

u

4

*

*

5

*

u

3

4

3

5

G

1

1

4

3

1

u

1

5

*

"

5

u

5

1

5

u

1

4

"

3

b

3

u

4

4

*

"

3

4

4

u

4

u

5

4

5

u

5

3

3

b

1

4

u

1

3

4

3

D

1

*

G

u

1

5

u

*

3

1

u

I

4

5

4

4

1uu 33

4

u

*3" 543 33

3

Pembina Field

Calgary

Pembina

Zama

Number of cased wells

9860

607

Number of wells drilled and abandoned

1050

106

% of wells with cement data

40%

64%

% of wells with high DLP cement score

28%

20%

% of wells fractured

75%

2%

% of wells acidized

47%

80%

% of wells abandoned

12%

13%

% of wells with multiple completions

11%

55%

% of wells with extreme DLP

14%

28%

% of wells with extreme SLP

7%

18%

% of wells with extreme SLP and DLP

1.6%

4.3%

SPE 112924

Pembina Field Wellbore Leakage Potential

The Pembina Field, the largest oil field in Canada, was discovered in the early 1950s with drilling continuing on until

today. Wells in the field typically are drilled to a depth of approximately 1600-1800 m. The wells are generally completed

and produced from the Cardium Formation which is a sandstone with an overlaying conglomerate and a thick shale caprock.

In recent years some uphole potential has been realized. The wells are generally vertical with single completions. Wells that

have been cased and completed are typically abandoned with a bridge plug set within 15 m of the perforated interval with 8

m of cement dump-bailed on top. Generally, wells in the Pembina Field were stimulated by hydraulic fracturing and to a

lesser extent by acidizing the completed interval.

Historically, the primary cementing requirements have been 100 m above the Cardium Formation at 1400 m or the

overlying Belly River Formation at an average depth of about 800 m (ERCB, 1990). Surface casing setting depth is at

approximately 180 m. The base of groundwater protection varies between 200 and 600 m, with typical Base of Ground Water

Protection (BGWP) at 470 m (Alberta Environment, 1995). Although there are wells with potentially 1200 m of uncemented

casing in the Pembina Field, there are very few gas or oil bearing zones within the overlying horizons to leak to surface.

External casing corrosion does not seem to be problematic in the area, with 1.3% of Pembina wells reporting casing failure

compared to 1.1% province wide.

The distribution of wells, by either DLP or SLP scores, for the Pembina Field is presented in Figures 8 and 9,

respectively. This analysis gives an overall picture of the potential for well leakage and which area of the wellbores is most

prone to leakage. Figures 10 and 11 indicate the geographic location of wells with extreme deep and shallow leakage

potential in the Pembina Field, respectively. This information would be useful when determining the areas of an oil field that

would be most desirable for CO2 EOR or sequestration, and gives some indication of the potential economic impact of

wellbore remediation prior to injection of CO2 at the scoping stage. The well locations of a particular DLP or SLP score or

range of score may be used to determine potential consequences by overlaying population density, ground water, surface

water or other potential leak receptors. Individual factors, such as which wells are abandoned or have at risk cement types can

also be analysed based on the nature of the proposed project.

Figure 9: Pembina Field SLP Score distribution.

1000

20

Figure 10: Location of Pembina wells with extreme

DLP shown in red against all field wells in black.

The green grid indicates 6x6 miles/square.

25

30+

00

+

15

DLP Score

10

10

90

80

0

0

2000

70

200

3000

400

4000

600

Extreme

60

800

High

50

1000

Low

Medium

1200

5000

40

1400

6000

Extreme

30

High

Low Medium

20

1600

10

Number of Wells with DLP

Score

1800

Number of Wells with SLP

Score

Figure 8: Pembina Field DLP Score distribution.

SLP Score

Figure 11: Location of Pembina wells with extreme SLP shown in

red against all field wells in black.

The green grid indicates 6x6 miles/square.

SPE 112924

The analysis of shallow leakage potential in the Pembina Field indicates leakage potential similar to the reported

provincial average of 6.1% (Bachu and Watson 2006), with only 7% of wells falling in the extreme categories. The analysis

of the deep leakage potential indicates that wells are predominantly cemented with neat cements that pose the lowest risk for

deterioration when in contact with CO2 compared to other common wellbore cements. The deep leakage analysis also

indicates that fracture stimulation may create leakage pathways in the deep regions of the wellbore and that fracture

stimulation is the main factor in DLP for the Pembina Field. Figures 10 and 11 also indicate that the potential for shallow

well leakage (SLP) in the field may be of lesser concern and is not as widely distributed as the potential for deep well leakage

(DLP).

The low potential for leakage scores, however, may be underestimated if wellbore abandonment procedures do not

change in the future. With only 12% of cased wells currently abandoned in the Pembina Field, the leakage scores may not

reflect future leakage potential due to abandonment method.

Cement type data are electronically available only for 40% of the wells. It was assumed that the unknown well cement

types would be type neat and would, therefore, have a lower potential for deterioration due to CO2 attack. This assumption

may underestimate the potential for deep well leakage.

Based on the available information it appears as though wells in the Pembina Field could withstand project

implementation of CO2 EOR or CO2 sequestration if wells abandoned in the future use a more robust downhole abandonment

method than bridge plug capped with cement. Investigation to determine zonal isolation after stimulation in wells indicated as

having extreme DLP would be beneficial in determining the actual effect of the stimulation on zonal isolation. More study is

required to determine the durability of neat cement and bridge plugs to improve the confidence of these findings.

Zama Field Wellbore Leakage Potential

The Zama Field was discovered in the mid 1960s. The productive zone is the carbonate reef Keg River Formation at an

average depth of 1600 m. The wells are generally vertical with multiple completions. On average, each well has two

completions, or perforated intervals, with several wells having five or more completions. Wells that have been cased and

completed are typically abandoned with a bridge plug set within 15 m of the perforated interval and with 8 m of cement

dump-bailed on top. Wells in the Zama Field were stimulated by acidizing the completed interval. Very few wells are

hydraulically fractured.

Historically, the cementing requirements have been 100 m above the Slave Point Formation, which overlays the Keg

River formation, at an average depth of about 1200 m (ERCB, 1990). Surface casing setting depth is at approximately 275 m,

however older wells have setting depths less than 200 m. The Base of Ground Water Protection varies between 75 and 400

m, with the average BGWP at 250 m (Alberta Environment, 1995). Within the uncemented depths of the wellbores several

productive intervals have been discovered since many of the wells were drilled. Overlying gas-bearing formations such as the

Jean Marie and the Beaverhill Lake, may contribute to gas leaking to surface. The reported casing failures for the Zama Field

are 6% of all wells compared to failures of 1.1% of wells in Alberta. These high numbers of casing failures may be explained

by the exposure of casing to the Wabamum Group and Banff Formation which are limestones within the exposed casing

depths. The presence of CaCO3 has an adverse effect on external casing corrosion and ultimately casing failure (Caswell,

1988).

The distribution of wells, by either DLP or SLP scores, for the Zama Field is presented in Figures 12 and 13, respectively.

These score distributions indicate that deep leakage potential is quite prevalent within the Zama Field. Figure 14 and 15

indicate the geographical location of wells with extreme leakage potential in the field. Because the Zama Field is made up of

several hundred reefs, this information would be useful when determining which pool would be most desirable for CO2 EOR

or sequestration and gives some indication of the potential economic impact of wellbore remediation prior to injection of CO2

or acid gas at the scoping stage. Both deep and shallow leakage potentials are broadly distributed throughout the field. The

deep leakage potential appears to have a denser distribution across the field. Although Figures 14 and 15 focus on extreme

DLP and SLP scores, the distribution charts indicate that there are large numbers of wells in the high categories for both DLP

and SLP. The well locations of a particular DLP or SLP score or range of score may be used to determine potential

consequences by overlaying population density, ground water, surface water or other potential leak receptors.

SPE 112924

150

100

50

SLP Score

DLP Score

Figure 14: Location of Zama wells with extreme DLP

shown in red against all field wells in black.

The bold green grid indicates 6x6 miles/square.

41

3 u 3 4u u

4

u

3

3 1

4

u

3

1

3

4

3u

u 3

1

4

4

4

u

"

u

34 "

u

4

3 3

"

1 u

4

"4

3

5"5" " ""

1

5

4 5 3

5

4

3

5b

4

" 43

5

5"

u 4

3 u

31

55 3

4

3

3 4

5

4

4

5

5

4

b

3

3

3

5

3 33b

54

5*

5""5

4

uu

u4 3

5

"

1

3

5

4

3 *

4

u

451"

5

3

4

4" 3

55

4

33

u5 5

" 4 " 3

5

4

*3" 553

"15

u

3 5

4

3

u3 4 3

1

5

4

u

5

4

u

5

M

3

*

1

5

5

4

3

4

3

1

3

1 43 u 41*4 3

5

4 3

3

G 5 55

4

5

5

5b

4

b

1 b

4

43

15

4 41 5

"3

5 3 341

4 u 3

5

4

41

*35

1 3

b

33

u3

" u

4

1

1

5

4

54

5" 4

1

4

1

*4

55

4

I*

4

E

*5

G

54

5

4

3

4

5

E

5

4

4

u

5

u

5

4

u

G

5

1

4

5

4

b3

5

4 5G

1

34 4

1u

5

4

431

1

3

"

3

5

G

4

b

1

4

u

"

5

4

4

*

5

4

5

5

G

*

5

G

4

b

4

4

u

5

34

54

u

*5

E

u 4

415

1

5 514

G

4

u

4b

55

54

5

G

u33 3

153 3

5 "5

4

55"3

5

3

4

*53

G

534

333

55

4

51 u

334

5

E5

4

5G

5 5

1

"

*43

4

4

1

"4

u

4 35

54

1

5

4

54

54

**u

3 u

u 4

4

G4

4

u

5

5G*1

4

5

555 *

4

3u

555

5

4 331

54

55u

54G

E

5

u

3 3u

4

E

4

"

5

4

3

4

5

b 4

5

4

5

5

4

3

"

5

5

*

5

u

3

34

5 4" 4

u

1 15

3

5

4

E5"5

43

5

4

5

4

5

4

G

33

33

"

1

5

3 415

3

4

55

G

4

5

4

G

5

3

4

5

5

4

b

5

34

5

4

54

4

3u

5

3 34

5

4

3

4

1

555

4

31

1

*1G

5

55O

4

54

1u

*15

3 34

455 u

3

5

3 135

G

GI5 4

4

II

4

u

G 5

4

45

4 5

4

4

u3

4

5

G *54 4

4

5

3 4

*

1

*

u

5

5

*

4

5

4

5

G

G

5

*5

4 33 u13 334

5G

1 "4

5

4

*1

5 5

4

3

1 *4

4

5 34

1

53

K

5

4

1

*

4

5 "5

" *4

b" b

5 3

4

G3

4

u

u5

4

G

51

4

43

5

*

4

*45

4

5

G

b

1

4

5

3

5

4

b

"

4*u

G

5

4

u

53u5 4

u

5

3

b

1

u

4

5

3

5

u

4

G

5

5

4

"

5

3

E

5

4

b

5

* E

1

3 54

55

5

3

4

u

5

G

3

54 5

3

45

4

5

G

GE

G

43

3

u

5

*

35

"3 " *u

4

5

4

G

5

3 1

4

G5

3 5"4

35

* 5

5 5"5 5 5

4

u

53

E

4

"

1u

5 54

5 b

5 5

3

4

*53

4

1

u

5

G

4

*u 3 54

5

3

G

3

4

5

5

4

5

"

G

5

4

b 4

3

1 4

G

*O

14

3

5b

3

545u

3

"

5 5

G

u3

5

5 G

5

5

555 4

4

5

4

43

5 3 u

51

*b

5u

4

5 G4

4

5 G

4

5

*

4 5IE4

3b

53

4

G

ub

4

54

4

*1515

"4 u

5

4

5

1

5u

55

54

4

3 34 4

5

5

451 5

4 5

5

1 4

4

b5"E

15

3 54

4

u

5

1

5 5

55

5

4

u

5

511

55 * "

4

u

4

O

"u

4

bG 15

4

5

35

*1 u

4

30+

00

+

25

90

20

10

15

80

10

70

60

0

0

200

20

Extreme

50

40

High

60

Low

Medium

40

80

250

100

300

30

Extreme

High

20

120

Low Medium

10

N u m b e r o f W e lls w ith D L P

Sc o re

140

Figure 13: Zama Field SLP Score distribution.

N u m b e r o f W e lls w ith SL P

Sc o re

Figure 12: Zama Field DLP Score distribution.

3

4

b

4 u

3

u

4

u

4

4 3

3

4

4

u

4

u

4 3

1

u

4

u3 13

Figure 15: Location of Zama wells with extreme SLP

shown in red against all field wells in black.

The bold green grid indicates 6x6 miles/square.

3u

4

u1

u 4

4

u

3

3

u

1

3

4

u 3

b

4

"

4 u

u

34 "

u

4

3

3

"

3

1 u

4

"

"4

55 " "

1

3

4

5

4 5 3

4

5

" 433 " " 1

5b

4

u

4

5

5"

4 3

u 4

3

3 u

3

55 5

4

3

3

44

3 4

5

4

5

b5 4

3 5

4

5* 3 53 3 33b

uu

5""

4

u4 3

"5

1

3

"

4

5 5

4

u

555

4

3 *

4

4" 3

u

4

1

4

4

" 3 3

33 u

55 5

u

"

515

4

*3" 5 3

u u

43

3

5

4

u 31 4 3 *44 3

15 " u

51M

55

4

3

4* 5

1

3

3

5 b

4

3

4 3

1

43 u 41 3

5

G

4

4

5b

4

b

5

3

5

3

5

5

1

4

3

4

1

5 4

4

43 4

1

u

"3

5

4 u b

5

4

5 *3

14

1 3

33 3 41

" u

1

5

u3

5

u3 13

4

5 1

5" 4

1

*

4

1

*4

I*

4

5

4

E4

5 4

5G

*

5 5u

E

354

5

54

5

u

u

G

541 b

5" 4

G

54

4

5

4

u

34 44 1

43

"

33

5b

3u

5G

G

4

*4

4

5

4

4 1

5u

54 1

5

4

5b

4

5 *1

4

3 13 3G

5

E

*

5

G

4

u

5

u u

4

5 14

4

55

5

4

1

5

G

54

54

5 "34

4

43

u

4 ""5

b

3153 3 1

5534

G4

*5

3

54 u

5 5

4

5 4

E

*535

5

4

333

5 4

1

"

"5

4

1

5 3

3

u

5

45

1

5

4

553

54

5 1**u

54

54u

3 u

5Gu

5 4

G

4

5

5G

4

*1 335

3u

5

4

4 4

u

E

4

55

4G u

*E3

"*55

4555553

3

3 3 u

53

4 1

5

54

4

" 55

b 4

3

5"5

u

14

4

4

5

4

3

4 "u

E

3

55"31

5G

14

5 "3 3

4

3

5

5 4

4

3

4

4

5

5

G

1

55 534

4 5O

5

45

G

3

445

4

b

5

5

5

4

54

4

3u

5

1

3 34

3

4

55

4

1

554

4

*11G

4

5u

*1u

u

3 331

555

4

5I5 4

G

4

3 135

5

G

G 3

4

I5I

4

4 5

u34 4

*54

5

4

4 *44

5

G

4

34

*

u

5

1

5

*

4

5G

4

5

5

"

"4

G

4

5G

*5

4* 3 3 u13 33 4

1

1

5

4

5

3

5 *4

1

4

5 34

*

55

K

5

4

1

*1

4

" 4

5 "5

b" b

5 3

4

4 3

u

G

G3

u

"4

51

4

43 b 4

*45

4

5

*

4 3

3b

5

51uu

*

4

" 5 G

4 G

5u

4

5

u

4

5

5

bG

1 u

54

4

5 3

5u

4 5u

"

33

4

5

3

E

5

4

*

5

1

5

b

5 E

5

3

E

4

u

5

54

3

54

5

G

3

4

G G

G 44 5

5

55

*

43

3

u

35

"3 " *u

5

4

G

3 5"4

3 1

4

5

5

55

5 55

4

u

3G

53

* 5

E

4

15

"

u 54

35 5

5 "5

3

4 *5

1

*u 3 54

5 5G

G

4

u

5 4

4

b

3

5

G "5

3

4

5

G

1

G

*

4

1

3

O

b

3

5

3

u

5

3

4

51

"

5u

u

4

4

3

5 5

G

b

5

4

5

43

5

5 3

555 4

4

54 u

*b

5u

4

5 G4

4

5 G

4

*

5 4

4

3b

*1

55

G

55

4

" 4

4

ub

4

54

4

5 55

IE

4

3

1

u

5u

54

3 34 4

5

4

51 5

4 5

1 4

4

15

b5u

5

4 3 555

"E

u1 5 4

54

5

15 1

5

5

"

5 54

5

u

5

4

u

G 1"5

4

u 5

4

O

5

3

b

*

*1 5

4

3u

4

1

4

u

4

Within this analysis the wells in the Zama Field show significant potential for leakage, both shallow, which is

independent of fluid type, and deep, which may occur in the event that CO2 or acid gas is introduced to the historical

producing formations.

Previous work identified that approximately 6.1% of all cased wells in the province had shallow leakage in the form of

surface casing vent flow (annular pressure) reported (Bachu and Watson 2006). Based on the analysis of the Zama Field,

18% of the wells have extreme potential of shallow leakage. This result is expected since the reported incidence of surface

casing vent flow, determined from ERCB data, within the Zama Field is 30% of cased wells, well above the provincial

average.

The potential for deep leakage shows that 28% of the wells in the Zama Field have an extreme deep leakage potential.

This assessment for deep leakage potential is based on:

1. Approximately 30% (based on known and extrapolated data) of the wells have cement in the deeper regions of

the wellbore that may be susceptible to CO2 or acid gas attack because of the additives used.

2. Eighty percent of wells are stimulated by acidizing, with 60% of the wells having multiple acid stimulations.

These stimulations may reduce the near wellbore seal, thus affecting isolation, and may reduce the time for CO2

or acid gas breakthrough to the wellbore.

3. Fifty-five percent of the wells have multiple completions, increasing the potential for leakage between zones.

4. Thirteen percent of wells have been abandoned with a bridge plug. The remainder of the wells have not yet been

abandoned. The assigned zonal abandonment value of two for wells that have not yet been abandoned may be

too high. In the future, if zonal abandonment practices change to some other, more robust system the assigned

value for zonal abandonment could be reduced to one.

SPE 112924

Conclusion

The development of a computer-based tool to compile and mine available regulatory data to determine the potential of a well

to leak has created the ability to conduct a first-pass evaluation of large numbers of wellbores to determine their relative

potential for leakage, both shallow and deep. The use of this tool will speed up the wellbore assessment process by zeroing in

on potential problem wells which may require closer scrutiny prior to the implementation of a CO2 EOR, acid gas disposal or

CO2 sequestration scheme. The tool can also be used in risk assessment analysis if potential consequences of leakage are

overlain, such as population density, ground water information or the presence of H2S along the wellbore. The tool need not

be specifically used to determine leakage in the presence of acid gas or CO2, but can also be used to evaluate the potential for

other types of leakage such as annular pressure (surface casing vent flow, aka sustained casing pressure) or gas migration.

Based on the findings of this study, careful well evaluation should be conducted to determine if wells in a particular CO2

EOR or sequestration scheme are at risk for leakage. More study is required to determine the durability of cement and bridge

plugs to improve the confidence of this evaluation.

Acknowledgements

The authors would like to thank Django Dunn (Silent D Software) for the database programming.

References

Alberta Environment 1995. ST-55: Albertas Useable Groundwater Base of Groundwater Protection Information. Alberta Environment,

Edmonton, Canada.

Bachu, S., Watson, T.L., 2006. Possible Indicators for CO2 Leakage along Wells. Paper presented at the 8th International Conference on

Greenhouse Gas Control Technologies, June 19-22, Trondheim, Norway. CD ROM, Elsevier..

Browning, D. 1984. CO2 Corrosion in the Anadarko Basin. Paper SPE 12608, Presented at SPE Deep Drilling and Production Symposium,

Amarillo, USA 1-3 April.

Bruckdorfer, R.A. 1986. Carbon Dioxide Corrosion in Oilwell Cements. Paper SPE 15176, Presented at the Rocky Mountain Regional

Meeting of the Society of Petroleum Engineers, Billings, USA, 19-21 May.

Caswell, D., 1988. External Casing Corrosion Survey. Report prepared for the National Association of Corrosion Engineers. University of

Calgary. Calgary, Canada.

Duguid, A., Radonjic, M., Braunt, R., Mandecki, T., Scherer, G., Celia, M., 2005. The Effect of CO2 Sequestration on Oil Well Cements.

Proceedings of the 7th International Conference on Greenhouse Gas Control Technologies, September 5-9, 2004, Vancouver, Canada.

Wilson, M., Morris, T., Gale, J.J., and Thambimuthu, K., eds., Elsevier, Vol. II Part 2:1997-2001.

ERCB, 1990. Directive 009: Guide to Minimum Requirements for Cementing Intermediate or Production Casing, Multiple Editions.

Energy Resources Conservation Board, Calgary, Canada.

ERCB, 2007. Directive 20: Well Abandonment Guide. Energy Resources Conservation Board, Calgary, Canada.

Krilov, Z., Loncaric, B., Miksa, Z. 2000. Investigation of a Long Term Cement Deterioration Under a High-Temperature, Sour Gas

downhole Environment. Paper SPE 58771, Presented at the International Symposium on Formation Damage Control, Lafayette, USA, 2324 February.

Kutchko, B.G., Strazisar, B.R., Dzombak, D. A., Lowry, G.V., Thaulow, N., 2007a. Degradation of Well Cement by CO2 under Geologic

Sequestration Conditions. Environmental Science Technology, 41(12):4787-4792.

Kutchko, B.G., Strazisar, B.R., Dzombak, D. A., Lowry, G.V., Thaulow, N., 2007b. Degradation of Wellbore Cements: Results of Long

Term Experiments and Effect of Additives. Presented at the 3rd Wellbore Integrity Network Meeting of the IEA Greenhouse Gas R&D

Programme. Available at, www.co2captureandstorage.info/docs/wellbore/3rdWellboreMtg_FinalReportSummary.pdf. Santa Fe, USA, 1213 March, 2007.

Marsters, S. 2007. Enhanced Oil Recovery, Dont Fight Mother Nature, New Technology Magazine, June: 13-16.

Nelson, E. B., Guillot, D. 2006a. Well Cementing, second edition, 244. Schlumberger, Sugar Land, USA.

Nelson, E. B., Guillot, D. 2006b. Well Cementing, second edition, 58. Schlumberger, Sugar Land, USA.

Onan, D. 1984. Effects of Supercritical Carbon Dioxide on Well Cements. Paper SPE 12593, Presented at the Permian Basin Oil and Gas

Recovery Conference, Midland, USA, 8-9 March.

Schremp, F., Roberson, G., 1975. Effect of Supercritical Coarbon Dioxide (CO2) on Construction Materials. Paper SPE 4667, Presented at

the SPE-AIME 48th Annual Fall Meeting, Las Vegas, USA, 30 September- 3 October.

10

SPE 112924

Watson, T.L., Getzlaf, D., Griffith, J.E., 2002. Specialized Cement Design and Placement Procedures Prove Sucessful for Mitigating

Casing Vent Flows-Case Histories. Paper SPE 76333, Presented at the SPE Gas Technology Symposium, Calgary, Canada, 30 April-2

May.

Watson, T.L., Bachu, S. 2007. Evaluation of the Potential for Gas and CO2 Leakage Along Wellbores; Paper SPE 106817, Presented at the

SPE E&P Environmental and Safety Conference, Galveston, USA, 57 March.

White, W.S., Calvert, D.G., Barker, J.M., 1992. A Laboratory Study of Cement and Resin Plugs Placed With Thru-Tubing Dump Bailers.

Paper SPE 24574 presented at the SPE Annual Technical Conference and Exhibition, Washington, USA, 4-7 October.

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Selective Extraction of Neutral Nitrogen Compounds Found in Diesel Feed byDocument8 pagesSelective Extraction of Neutral Nitrogen Compounds Found in Diesel Feed byJohnSmithNo ratings yet

- Zn-Containing Ionic Liquids For The Extractive Denitrogenation of A Model Oil - A Mechanistic ConsiderationDocument7 pagesZn-Containing Ionic Liquids For The Extractive Denitrogenation of A Model Oil - A Mechanistic ConsiderationJohnSmithNo ratings yet

- Selective Adsorption For Removal of Nitrogen Compounds From Liquid HC Streams Over Carbon - and Alumina - Based AdsorbentsDocument10 pagesSelective Adsorption For Removal of Nitrogen Compounds From Liquid HC Streams Over Carbon - and Alumina - Based AdsorbentsJohnSmithNo ratings yet

- Inhibition Effects of Nitrogen Compounds On The HDS of Dibenzothiophene Part 2aDocument8 pagesInhibition Effects of Nitrogen Compounds On The HDS of Dibenzothiophene Part 2aJohnSmithNo ratings yet

- Science:, 792 (2003) Robin D. Rogers and Kenneth R. SeddonDocument3 pagesScience:, 792 (2003) Robin D. Rogers and Kenneth R. SeddonJohnSmithNo ratings yet

- Are Deep EutecticDocument3 pagesAre Deep EutecticJohnSmithNo ratings yet

- Electrodeposition of Co, SM and SmCo From A Deep Eutectic SolventDocument7 pagesElectrodeposition of Co, SM and SmCo From A Deep Eutectic SolventJohnSmithNo ratings yet

- Post-Etch Residue Removal Using Choline Chloride-Malonic Acid Deep Eutectic Solvent (DES)Document6 pagesPost-Etch Residue Removal Using Choline Chloride-Malonic Acid Deep Eutectic Solvent (DES)JohnSmithNo ratings yet

- Molar Heat Capacities of Choline Chloride-Based Deep Eutectic Solvents and Their Binary Mixtures With WaterDocument25 pagesMolar Heat Capacities of Choline Chloride-Based Deep Eutectic Solvents and Their Binary Mixtures With WaterJohnSmithNo ratings yet

- Electrodeposition of Zinc-Tin Alloys From Deep Eutectic Solvents Based On Choline ChlorideDocument7 pagesElectrodeposition of Zinc-Tin Alloys From Deep Eutectic Solvents Based On Choline ChlorideJohnSmithNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Finley ReportDocument46 pagesThe Finley ReportToronto StarNo ratings yet

- EE1000 DC Networks Problem SetDocument7 pagesEE1000 DC Networks Problem SetAmit DipankarNo ratings yet

- Understanding Consumer and Business Buyer BehaviorDocument47 pagesUnderstanding Consumer and Business Buyer BehaviorJia LeNo ratings yet

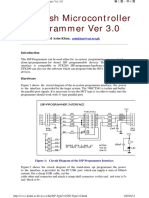

- ISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanDocument4 pagesISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanSrđan PavićNo ratings yet

- Minor Ailments Services: A Starting Point For PharmacistsDocument49 pagesMinor Ailments Services: A Starting Point For PharmacistsacvavNo ratings yet

- Oxygen BarrierDocument20 pagesOxygen BarrierKarina ArdizziNo ratings yet

- Caso Kola RealDocument17 pagesCaso Kola RealEvelyn Dayhanna Escobar PalomequeNo ratings yet

- Staircase and Lintel As-03Document1 pageStaircase and Lintel As-03Divith B SannakkiNo ratings yet

- Gravity Based Foundations For Offshore Wind FarmsDocument121 pagesGravity Based Foundations For Offshore Wind FarmsBent1988No ratings yet

- Heat Exchanger Designing Using Aspen PlusDocument6 pagesHeat Exchanger Designing Using Aspen PlusMeethiPotterNo ratings yet

- Types of MemoryDocument3 pagesTypes of MemoryVenkatareddy Mula0% (1)

- Pega AcademyDocument10 pagesPega AcademySasidharNo ratings yet

- Methods of Teaching Syllabus - FinalDocument6 pagesMethods of Teaching Syllabus - FinalVanessa L. VinluanNo ratings yet

- Chapter 3 Searching and PlanningDocument104 pagesChapter 3 Searching and PlanningTemesgenNo ratings yet

- 87 - Case Study On Multicomponent Distillation and Distillation Column SequencingDocument15 pages87 - Case Study On Multicomponent Distillation and Distillation Column SequencingFranklin Santiago Suclla Podesta50% (2)

- Bug Head - Fromjapanese To EnglishDocument20 pagesBug Head - Fromjapanese To EnglishAnonymous lkkKgdNo ratings yet

- Service Manual: Model: R410, RB410, RV410, RD410 SeriesDocument116 pagesService Manual: Model: R410, RB410, RV410, RD410 SeriesJorge Eustaquio da SilvaNo ratings yet

- Power For All - Myth or RealityDocument11 pagesPower For All - Myth or RealityAshutosh BhaktaNo ratings yet

- Data Mining - Exercise 2Document30 pagesData Mining - Exercise 2Kiều Trần Nguyễn DiễmNo ratings yet

- Terms and Conditions 27 06 PDFDocument4 pagesTerms and Conditions 27 06 PDFShreyash NaikwadiNo ratings yet

- Question Bank For Vlsi LabDocument4 pagesQuestion Bank For Vlsi LabSav ThaNo ratings yet

- Sun Nuclear 3D SCANNERDocument7 pagesSun Nuclear 3D SCANNERFranco OrlandoNo ratings yet

- Load Sharing Strategies in Multiple Compressor Refrigeration SystemsDocument8 pagesLoad Sharing Strategies in Multiple Compressor Refrigeration SystemsLiu YangtzeNo ratings yet

- YeetDocument8 pagesYeetBeLoopersNo ratings yet

- Indictment - 17-Cr-00601-EnV Doc 1 Indictment 11-1-17Document6 pagesIndictment - 17-Cr-00601-EnV Doc 1 Indictment 11-1-17C BealeNo ratings yet

- VP Construction Real Estate Development in NY NJ Resume Edward CondolonDocument4 pagesVP Construction Real Estate Development in NY NJ Resume Edward CondolonEdwardCondolonNo ratings yet

- 6 AsianregionalismDocument32 pages6 AsianregionalismChandria Ford100% (1)

- Review of Accounting Process 1Document2 pagesReview of Accounting Process 1Stacy SmithNo ratings yet

- Introduction To AirtelDocument6 pagesIntroduction To AirtelPriya Gupta100% (1)

- 88 - 02 Exhaust Manifold Gasket Service BulletinDocument3 pages88 - 02 Exhaust Manifold Gasket Service BulletinGerrit DekkerNo ratings yet