Professional Documents

Culture Documents

Rebound Hammer Test

Uploaded by

Ezza MieOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rebound Hammer Test

Uploaded by

Ezza MieCopyright:

Available Formats

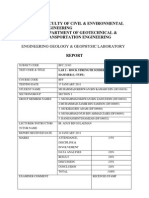

Faculty

: Construction

Management and Entrepreneur

Page

1/6

Department : Structure and Materials

Engineering

Title : REBOUND HAMMER TEST

Edition

Checking No

Effective Date

1

17/6/04

Amendment Date

1.0

OBJECTIVE

1.1

1.2

1.3

2.0

EXPERIMENT OUTCOME

2.1

3.0

4.0

To check the uniformity of concrete

To determine the properties of the surface of the concrete

To estimate strength of concrete in structures

Able to carry out surface hardness testing by rebound hammer according to

BS 1881: Part 202: 1986

EQUIPMENT & MATERIAL

3.1

Equipment

(i)

Rebound hammer type N

3.2

Material

(i)

Close textured concrete

PROCEDURE

(A)

Method of Testing

1.

Select a rebound hammer appropriate to the type of concrete tested, check that it

is working correctly and check its reading on the steel reference anvil.

2.

Choose suitable test locations. Only smooth surfaces should be tested.

3.

Confine the readings of a test to an area not exceeding 300 mm x 300 mm

4.

Draw a regular grid of lines 30 mm apart and to take the intersections of the

lines as test points

5.

Twelve readings are needed at a location.

Faculty : Construction Management and Page

Entrepreneur

2/6

Department : Structure and Materials

Engineering

Edition

Checking No

Effective Date

Title :REBOUND HAMMER TEST

Amendment Date

(B) Procedure of Using Rebound Hammer

1. The hammer is pressed against concrete. Plunger retracts against spring and the

hammer is ready to be used.

2. Press the hammer to the test location until the mass hammer impact against the

surface through the plunger.

3. Hammer should be operated perpendicular to the surface horizontally.

4. Press the button at the side of hammer and read the amount of rebound of the

mass, R from the indicator.

5. Refer to the calibration curve on the standard steel anvil to read the compressive

strength.

6. Estimate the compressive strength with refer to the table given in Appendix I.

Page

Faculty : Construction Management

and Entrepreneur

(5)

3/6

Department : Structure and Materials

Engineering

Title :

Edition

Checking No

Effective Date

REBOUND HAMMER TEST

Amendment Date

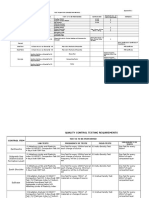

CALCULATION SHEET

Test

Ref.

Test

Location

Under

Staircas

e

Internal

Column

Paveme

nt

Walkway

Column

at

staircase

Beam at

staircase

Recorded

R Value

34

32

32

32

32

30

33

33

30

28

29

28

36

37

41

37

29

30

25

28

27

35

37

34

32

32

32

32

28

31

29

26

29

27

30

28

39

38

39

38

32

32

28

32

35

31

31

35

32

32

28

32

30

26

30

30

31

32

30

30

42

36

36

39

28

28

26

31

39

36

35

32

Mean

R

Inclination

Angle ()

Correcte

d

R

Compressiv

e Strength

(Nmm)

32

90

23.7

30

90

20.6

29

90

19.1

38

90

33.6

29

90

19.1

34

90

26.8

Faculty

Appendix I:

: FPTP

Page

4/6

Department : Structure and Materials

Engineering

Title :

Edition

Checking No

Effective Date

REBOUND HAMMER TEST

Amendment Date

Faculty

: FPTP

Page

6/6

Department : Structure and Materials

Engineering

Title :

Edition

Checking No

Effective Date

REBOUND HAMMER TEST

Amendment Date

Discussion :

During the experiment , the systematic error occur because of rebound hammer. This is

due to the rebound hammer not function well while we knock it to the wall. And also

need to take the reading to get the result. From the table, the result show 12 time

recorded of knock with the different value and at different location. The all 12 value will

be calculated to get the mean at every location and also to get the estimation compressive

strength of concrete in structure.

Conclusion :

From this test, we can conclude that in every location have a different compressive

strength. Besides that, the surface of the concrete as can see on the result, there are not

uniformity.

Faculty

: FPTP

Page

5/6

Department : Structure and Materials

Engineering

Title :

Edition

Checking No

Effective Date

REBOUND HAMMER TEST

Amendment Date

Appendix II :

Figure 1 : Draw a 12 point uniformly before

do the knock on the structure

Figure 3 : The surface before knock by

the rebound hammer

Figure 2 : Do the knock on the beam

with rebound hammer

Figure 4 : The surface after been knock by

the rebound hammer

You might also like

- VICAT TEST LAB REPORTDocument9 pagesVICAT TEST LAB REPORTNurHaziqahNo ratings yet

- Rebound HammerDocument6 pagesRebound Hammerahmadfarriz100% (1)

- Rebound Hammer TestDocument4 pagesRebound Hammer TestFara Atika Bha Ney100% (2)

- Rebound HammerDocument4 pagesRebound HammerNur Faaiqah0% (1)

- Rebound Hammer ReportDocument17 pagesRebound Hammer ReportSYaz WAni0% (2)

- Test 1 - Ultrasonic Pulse Velocity TestDocument6 pagesTest 1 - Ultrasonic Pulse Velocity TestzeanNo ratings yet

- Laboratory Worksheet: Center For Diploma StudiesDocument6 pagesLaboratory Worksheet: Center For Diploma StudiesSyihabuddin Yusoff0% (1)

- Rebound Hammer-RH (Schmidt) TestDocument2 pagesRebound Hammer-RH (Schmidt) TestmandregomesNo ratings yet

- ROCK STRENGTH TESTINGDocument6 pagesROCK STRENGTH TESTINGumarabaziz17100% (1)

- Rebound Hammer TestDocument14 pagesRebound Hammer TestChalakAhmed100% (6)

- Concrete Quality Non-Destructive TestsDocument5 pagesConcrete Quality Non-Destructive TestsNadhirah LnfNo ratings yet

- Plate Bearing Test Data AnalysisDocument21 pagesPlate Bearing Test Data Analysisjkedar_78100% (3)

- ROCK STRENGTH TESTING REPORTDocument12 pagesROCK STRENGTH TESTING REPORTFahmiibrahimNo ratings yet

- How To Do Standard Penetration Test (SPT) of Soil On SiteDocument6 pagesHow To Do Standard Penetration Test (SPT) of Soil On SiteGherzi EasternNo ratings yet

- Standard Penetration TestDocument6 pagesStandard Penetration TestNaveed Naz100% (1)

- Maintain Load Test Jack Machine MethodDocument11 pagesMaintain Load Test Jack Machine MethodNorazizy NordinNo ratings yet

- Sub BaseDocument4 pagesSub BaseAnonymous Dk3ItoC8MFNo ratings yet

- Compressive Strength Test ProcedureDocument9 pagesCompressive Strength Test ProcedureAnique Ur RehmanNo ratings yet

- Interpretation of Pile Integrity Test (PIT) Results by H.S. Thilakasiri 2006Document7 pagesInterpretation of Pile Integrity Test (PIT) Results by H.S. Thilakasiri 2006Ashokan Keloth100% (1)

- Arahan Makmal Sem 11718-NewDocument18 pagesArahan Makmal Sem 11718-NewAidaFarzanaNanaNo ratings yet

- Determination of Field Density of Soils by The Core Cutter Method PDFDocument4 pagesDetermination of Field Density of Soils by The Core Cutter Method PDFShafiq Kadir100% (3)

- Concrete Coring (Eng)Document2 pagesConcrete Coring (Eng)crescentmooon100% (1)

- Rock Strength Schmidt's (Rebound) Hammer (L-Type)Document12 pagesRock Strength Schmidt's (Rebound) Hammer (L-Type)Ikhwan Z.86% (7)

- Concrete CubesDocument7 pagesConcrete CubesMohammed AbbasNo ratings yet

- Roadwork ChecklistDocument10 pagesRoadwork Checklistchinhon100% (1)

- Penetration Test & Softening PointDocument7 pagesPenetration Test & Softening PointAli M. Chehadeh100% (4)

- Geo-Technical Investigation Report for Proposed School ConstructionDocument36 pagesGeo-Technical Investigation Report for Proposed School ConstructionMalayKumarDeb100% (2)

- HVEEMDocument2 pagesHVEEMNigilNo ratings yet

- Concrete Slump TestDocument3 pagesConcrete Slump TestShaan LalwaniNo ratings yet

- Oedometer Test: Soil Mechanics 2 CE PC 504Document26 pagesOedometer Test: Soil Mechanics 2 CE PC 504SumanHaldarNo ratings yet

- WorkabilityDocument3 pagesWorkabilityyay94rebuildNo ratings yet

- REBOUND HAMMER TESTING FOR CONCRETE SURFACE HARDNESSDocument6 pagesREBOUND HAMMER TESTING FOR CONCRETE SURFACE HARDNESSFaizah Sophi100% (1)

- Concrete Grade 30 Design MixDocument1 pageConcrete Grade 30 Design MixLallama100% (2)

- Geotechnical PresentationDocument52 pagesGeotechnical PresentationVinod VadithyaNo ratings yet

- Rebound Hammer Test Procedure For Concrete HardnessDocument4 pagesRebound Hammer Test Procedure For Concrete HardnessSite Engineer.2p2No ratings yet

- Borang Mackintosh ProbeDocument2 pagesBorang Mackintosh ProbezamzuraneeNo ratings yet

- Lab # 8 Objective:: Mirza Muhammmad Zaid 2009-Min-21Document4 pagesLab # 8 Objective:: Mirza Muhammmad Zaid 2009-Min-21loverbacha100% (2)

- Concrete TestingDocument32 pagesConcrete TestingAveesh singh100% (1)

- Aggregate Impact Value TestDocument5 pagesAggregate Impact Value TestMind Rip100% (1)

- Field Density Lab ReportDocument21 pagesField Density Lab ReportAnonymous DR3NznNo ratings yet

- Report Foundation PDFDocument49 pagesReport Foundation PDFAfif AzharNo ratings yet

- Skid-Sand-Outflow ReportDocument11 pagesSkid-Sand-Outflow ReportAthirah Dinata100% (1)

- Silt Test - Fine AggregateDocument2 pagesSilt Test - Fine Aggregatestephenhcc1No ratings yet

- Determination of Aggregate Crushing ValueDocument10 pagesDetermination of Aggregate Crushing ValueArivalagan Revichandran100% (1)

- Specification For Jack in PileDocument4 pagesSpecification For Jack in Pilekhuanoz100% (1)

- Proctor-Crusher Run FT004Document1 pageProctor-Crusher Run FT004maintanahNo ratings yet

- Method Statement For Grout ColumnDocument1 pageMethod Statement For Grout ColumnAlsonChin100% (1)

- Pile TestingDocument32 pagesPile TestingFoyjur Razzak Joney100% (1)

- Windsor Probe and Quantab TestDocument28 pagesWindsor Probe and Quantab Testsabareesan09No ratings yet

- Example Mackintosh Probe TestDocument8 pagesExample Mackintosh Probe Testzamzuranee100% (1)

- Mackintosh Probe TestDocument22 pagesMackintosh Probe Testmoin100% (1)

- CBR TEST CompleteDocument9 pagesCBR TEST CompleteRazman Fozi0% (1)

- Construction Joint PDFDocument4 pagesConstruction Joint PDFravinchandNo ratings yet

- Rebound Hammer TestDocument6 pagesRebound Hammer TestPink MerahJambuNo ratings yet

- Rebound Hammer Lab SheetDocument4 pagesRebound Hammer Lab SheetHalimi HonanNo ratings yet

- A Report ON: Schmidt's Rebound Hammer Test of Paschimanchal Campus HostelDocument12 pagesA Report ON: Schmidt's Rebound Hammer Test of Paschimanchal Campus HostelsushilNo ratings yet

- Module 7: Testing The Tensile Strength of Steel BarsDocument5 pagesModule 7: Testing The Tensile Strength of Steel BarsPrincess Tamani ManzanoNo ratings yet

- NDT report for residential columnsDocument15 pagesNDT report for residential columnsBukayoNo ratings yet

- Concrete Mix DesignDocument13 pagesConcrete Mix Designjesus_vitangcolNo ratings yet

- EXP8Document8 pagesEXP8alolqigoNo ratings yet

- Provision of Law To The Buildings Fascility in Sharp BuildingDocument4 pagesProvision of Law To The Buildings Fascility in Sharp BuildingEzza MieNo ratings yet

- Force Moment SupportDocument3 pagesForce Moment SupportEzza MieNo ratings yet

- Articles Final AccountDocument12 pagesArticles Final AccountEzza MieNo ratings yet

- Contoh Proposal Bisnis PlanDocument31 pagesContoh Proposal Bisnis PlanHadianto Nugroho100% (4)

- Beam Analyis Formulas2Document3 pagesBeam Analyis Formulas2Ezza MieNo ratings yet

- IT2006 Industry ReportDocument13 pagesIT2006 Industry Reportapi-3819238No ratings yet

- I Need Free Serial Key of Acrobat Xi Pro Fixya PDFDocument3 pagesI Need Free Serial Key of Acrobat Xi Pro Fixya PDFsayedNo ratings yet

- Wireless SlidesDocument6 pagesWireless SlidesVinayNo ratings yet

- Tamansari Yogyakarta: A Guide to Visiting the Historic Water CastleDocument3 pagesTamansari Yogyakarta: A Guide to Visiting the Historic Water CastleArdee RahardianNo ratings yet

- Criteria For Design of Lined Canals and Guidance For Selection of Type of LiningDocument14 pagesCriteria For Design of Lined Canals and Guidance For Selection of Type of LiningShrikant PhatakNo ratings yet

- Set 4-digit clock with alarmsDocument4 pagesSet 4-digit clock with alarmsSasa GloginjicNo ratings yet

- New Arrivals: Latest Books AddedDocument22 pagesNew Arrivals: Latest Books Addedmeraj121No ratings yet

- How Adobe Construction Works | HowStuffWorksDocument6 pagesHow Adobe Construction Works | HowStuffWorksshainojkNo ratings yet

- Revetment Wall Design Along Bacao BridgeDocument19 pagesRevetment Wall Design Along Bacao BridgeAngelo MoralNo ratings yet

- Turbine BladeDocument27 pagesTurbine BladesrtanandNo ratings yet

- TextMate Ruby/Rails Cheat SheetDocument3 pagesTextMate Ruby/Rails Cheat SheetFlo100% (2)

- Power Systems For AIX III - Advanced Administration and Problem DeterminationDocument946 pagesPower Systems For AIX III - Advanced Administration and Problem DeterminationgsgheneaNo ratings yet

- Score A Deal in Playa VistaDocument3 pagesScore A Deal in Playa Vistachernissgroup100% (1)

- Design of Pile FoundationDocument16 pagesDesign of Pile FoundationD SRINIVASNo ratings yet

- Shop drawing plumbing legends and detailsDocument9 pagesShop drawing plumbing legends and detailsprinceNo ratings yet

- Redhat OpenStack ResumeDocument3 pagesRedhat OpenStack ResumeHarshal TapadiyaNo ratings yet

- Egyptian Houses: Hanady El MakdissyDocument32 pagesEgyptian Houses: Hanady El MakdissyNani ChowdaryNo ratings yet

- A1 Side A2 Side: Longitudinal Sectional Elevational On 'Xyz'Document1 pageA1 Side A2 Side: Longitudinal Sectional Elevational On 'Xyz'sheikNo ratings yet

- Explore LinuxDocument30 pagesExplore LinuxFranciz CastilloNo ratings yet

- Splunk 8.0.1 Indexer HowindexingworksDocument5 pagesSplunk 8.0.1 Indexer HowindexingworksKarlNo ratings yet

- Design of PropsDocument6 pagesDesign of PropsMohamed AdelNo ratings yet

- Basic Internet Tutorial 1: How Does The Internet Work?Document19 pagesBasic Internet Tutorial 1: How Does The Internet Work?kabadadNo ratings yet

- Arch 232-LP 1-PrintDocument23 pagesArch 232-LP 1-PrintViron LucerianoNo ratings yet

- Function Mapping Reference: Appendix BDocument6 pagesFunction Mapping Reference: Appendix BVeljko JelicNo ratings yet

- RFC in SAP SystemsDocument3 pagesRFC in SAP SystemsAnjan Kumar100% (1)

- Bharath Kumar - Curriculum VitaeDocument4 pagesBharath Kumar - Curriculum VitaeBharathNo ratings yet

- WMAN TMBMSDIW Aug14Document15 pagesWMAN TMBMSDIW Aug14Inventor SolidworksNo ratings yet

- 4MS Exam 2Document2 pages4MS Exam 2aekNo ratings yet

- 64-Bit Linux OS NVSS ApplicationDocument24 pages64-Bit Linux OS NVSS ApplicationmpatricioNo ratings yet

- Cross: Ejot FassadensystemDocument24 pagesCross: Ejot FassadensystemJelena GraovčevićNo ratings yet