Professional Documents

Culture Documents

Studied Refrigerants: 7 IIR Gustav Lorentzen Conference On Natural Working Fluids, Trondheim, Norway, May 28-31, 2006

Uploaded by

amogmhetreOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Studied Refrigerants: 7 IIR Gustav Lorentzen Conference On Natural Working Fluids, Trondheim, Norway, May 28-31, 2006

Uploaded by

amogmhetreCopyright:

Available Formats

apparatus equipped with a variable-speed compressor can provide biased results.

Although,

modulation of the compressor speed allows adjustment of the system capacity for each

refrigerant to the same value, the unchanged designs of evaporator, condenser, and connection

tubing will affect fair performance comparison.

A fair comparison of the performance merits of different refrigerants for a given application

requires systems in which all components are optimized for the given refrigerant. Selecting a

suitable expansion device presents no difficulty, while some care is needed to specify

appropriate connection tubes. A more challenging task is to provide heat exchangers and

compressors that are optimized individually for each refrigerant. In particular, providing

optimized compressors may prove to be the most difficult task because the compressors should

be sized properly to assure equal cooling capacity for each system.

A study on the performance of propane (R-290), R-404A and R-410A combined computer

simulations and laboratory measurements (Hwang et al., 2004). The authors optimized

condenser circuitries for each refrigerant using computer simulations. In the final analysis they

modified their laboratory measurements by using the same compressor isentropic efficiency for

all three refrigerants. The researchers used the same evaporator with the assumption that it is

the least sensitive component of a system used in the medium temperature refrigeration

application they studied.

The goal of this analytical study is to evaluate the relative performance of R600a (isobutane),

R290, R134a, R22, R410A, and R32 in a comfort cooling application with the emphasis on

optimization of the heat exchanger circuitries. This study follows the studies of optimized

finned-tube evaporators (Domanski et al., 2005) and condensers (Domanski and Yashar, 2005).

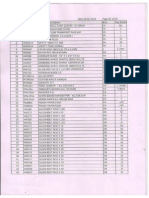

2. STUDIED REFRIGERANTS

Table 1 presents the refrigerants used in this study. They represent a wide range of

thermophysical properties that affect heat exchanger and system performance. Differences in

thermodynamic properties of the studied refrigerants can be visually recognized on a

temperature-entropy diagram, as shown in Figure 1 with the entropy scale normalized for

qualitative comparison. The shown two-phase domes are significantly different, which is

chiefly due to different critical temperatures and molar specific heats.

Regarding evaporator and condenser performance, the critical temperature influences refrigerant

pressure, vapor density, and the change of saturation temperature with respect to pressure drop,

which are important parameters for heat exchanger design. Among transport properties, liquid

thermal conductivity and liquid viscosity are the most important. Figure 2 presents these

properties for the studied refrigerants relative to the corresponding properties of R22.

Table 1. Refrigerant Information(1)

Molar Mass

Molar Vapor

Saturated Vapor

Safety

GWP(5)

(g mol-1)

Specific Heat (2,3)

Pressure(2)

Designation (4)

(100 years

(J mol-1K-1)

(kPa)

horizon)(6)

R600a

199.5

58.122

97.79

A3

20

R134a

374.6

102.03

94.93

A1

1320

R290

584.4

44.096

81.88

A3

20

R22

621.5

86.468

66.63

A1

1780

R410A

995.0

72.585

87.27

A1/A1

2000

R32

1011.5

52.024

69.16

A2

543

(1)

All fluid properties based REFPROP (Lemmon et al., 2002); (2) correspond to 7.0 C dew-point temperature;

(3)

at constant pressure; (4) (ASHRAE. 2001); (5) Global Warming Potential; (6) (Calm and Hourahan, 2001; IPCC, 2001)

Refrigerant

7th IIR Gustav Lorentzen Conference on Natural Working Fluids, Trondheim, Norway, May 28-31, 2006

You might also like

- Madhu Jhariya, Et AlDocument7 pagesMadhu Jhariya, Et Almd junuNo ratings yet

- Optimization andCFD Analysis of A ShellDocument16 pagesOptimization andCFD Analysis of A ShellErmias AbelnehNo ratings yet

- Comparative Numerical Study of Pulse Tube RefrigeratorsDocument10 pagesComparative Numerical Study of Pulse Tube RefrigeratorsKhalil LasferNo ratings yet

- Supervisor:-K. Manjunath Assistant Prof., Department of Mechanical Engineering, Delhi Technological UniversityDocument45 pagesSupervisor:-K. Manjunath Assistant Prof., Department of Mechanical Engineering, Delhi Technological UniversityAnkit GuptaNo ratings yet

- Thermodynamic Analysis On VC Refrigeration CycleDocument50 pagesThermodynamic Analysis On VC Refrigeration Cyclemanshulakesh59No ratings yet

- Optimize Finned Tube Heat Exchanger DesignDocument6 pagesOptimize Finned Tube Heat Exchanger DesignmapalptsNo ratings yet

- Review of Literature and Preliminary Experimental Thermosyphon LoopDocument11 pagesReview of Literature and Preliminary Experimental Thermosyphon LoopspurwonofjpNo ratings yet

- Conjugate Heat Transfer in AirtoRefrigerant Airfoil Heat ExchangersDocument12 pagesConjugate Heat Transfer in AirtoRefrigerant Airfoil Heat ExchangersMohammed AshiqueNo ratings yet

- Validation of A Vapour Compression Refrigeration System Design ModelDocument7 pagesValidation of A Vapour Compression Refrigeration System Design Modelkannanmech87No ratings yet

- EVAPORATORDocument11 pagesEVAPORATOROssama BohamdNo ratings yet

- Thermodynamic Performance Analysis of Two Stage Vapour Compression Refrigeration Systems With Flash-Intercooler Using Eco-Friendly New RefrigerantsDocument6 pagesThermodynamic Performance Analysis of Two Stage Vapour Compression Refrigeration Systems With Flash-Intercooler Using Eco-Friendly New RefrigerantsIjrei JournalNo ratings yet

- Fadhl Equation VOFDocument27 pagesFadhl Equation VOFantoineNo ratings yet

- GSHP Literature ReviewDocument32 pagesGSHP Literature ReviewSu HuangNo ratings yet

- Heat Exchanger Flow Configurations: Parallel vs CounterDocument16 pagesHeat Exchanger Flow Configurations: Parallel vs CounterLight OneNo ratings yet

- Thermal Performance Assessment of Steam Surface CondenserDocument8 pagesThermal Performance Assessment of Steam Surface CondenserJeeEianYannNo ratings yet

- Exergy Analysis of Scroll Compressors Working WithDocument10 pagesExergy Analysis of Scroll Compressors Working WithSaravanan RagupathyNo ratings yet

- Abstract OldDocument2 pagesAbstract OldMuhammad ShujanNo ratings yet

- Optimization of Refrigerator EvaporatorDocument26 pagesOptimization of Refrigerator EvaporatorAnkit GuptaNo ratings yet

- A Simplified Model For The Prediction of The Thermal Performance For Cross Flow Air Cooled Heat Exchangers With A New Air Side Thermal CorrelationDocument32 pagesA Simplified Model For The Prediction of The Thermal Performance For Cross Flow Air Cooled Heat Exchangers With A New Air Side Thermal CorrelationGuillaumeNo ratings yet

- 73 PDFDocument13 pages73 PDFshubhamarvikarNo ratings yet

- Fire - Nist.gov Bfrlpubs Build06 PDF b06043Document1 pageFire - Nist.gov Bfrlpubs Build06 PDF b06043amogmhetreNo ratings yet

- Open WordDocument10 pagesOpen WordAbdla DoskiNo ratings yet

- Intercambiadores de CalorDocument3 pagesIntercambiadores de CalorDIEGO FERNANDO PICON VELASQUEZNo ratings yet

- Mayi Et Al.Document16 pagesMayi Et Al.Lekane nelsonNo ratings yet

- Value Analysis of Advanced Heat Rejection Systems For Geothermal Power PlantsDocument4 pagesValue Analysis of Advanced Heat Rejection Systems For Geothermal Power PlantsYanan CamarazaNo ratings yet

- Thermal Analysis of Multi-Row Cross-Flow Heat ExchangersDocument6 pagesThermal Analysis of Multi-Row Cross-Flow Heat ExchangersnaveenNo ratings yet

- Analysis of Heat Transfer, Friction Factor and Exergy Loss in Plate Heat Exchanger Using FluentDocument8 pagesAnalysis of Heat Transfer, Friction Factor and Exergy Loss in Plate Heat Exchanger Using FluentFadi YasinNo ratings yet

- Experimental Performance Evaluation of Vapour Compression Refrigeration System Without Nano ParticlesDocument7 pagesExperimental Performance Evaluation of Vapour Compression Refrigeration System Without Nano ParticlesIjrei JournalNo ratings yet

- Yang 2021 IOP Conf. Ser. Mater. Sci. Eng. 1180 012051Document10 pagesYang 2021 IOP Conf. Ser. Mater. Sci. Eng. 1180 012051Pooja ChughNo ratings yet

- Performance Analysis of A Hermetic Reciprocating CompressorDocument10 pagesPerformance Analysis of A Hermetic Reciprocating Compressorhermit44535No ratings yet

- Thermodynamic analysis of CO2-NH3 cascade refrigerationDocument6 pagesThermodynamic analysis of CO2-NH3 cascade refrigerationGabriella WidjajaNo ratings yet

- Finned Tube R134a CondenserDocument12 pagesFinned Tube R134a CondensermattiturboNo ratings yet

- 4.ISCA RJEngS 2012 097Document5 pages4.ISCA RJEngS 2012 097andiNo ratings yet

- On Experimental Analysis-Investigate The Effect of Condenser Temperature On The Evaporator and Condenser Section of PHP For Different Temperature RangesDocument7 pagesOn Experimental Analysis-Investigate The Effect of Condenser Temperature On The Evaporator and Condenser Section of PHP For Different Temperature Rangesanon_359379160No ratings yet

- Energy-Analysis and Optimization of ADocument20 pagesEnergy-Analysis and Optimization of AHuma JawaidNo ratings yet

- Simplified Numerical Model For A Flat Continuous Triangle Fins Air Cooled Heat Exchanger Using A Step by Step TechniqueDocument23 pagesSimplified Numerical Model For A Flat Continuous Triangle Fins Air Cooled Heat Exchanger Using A Step by Step TechniquemunkkkkNo ratings yet

- Evaporating Heat Transfer of R22 and R410A in 9.52 MM Smooth andDocument9 pagesEvaporating Heat Transfer of R22 and R410A in 9.52 MM Smooth andMajid RoshaniNo ratings yet

- 25 4jesa Jain EtalDocument14 pages25 4jesa Jain EtalSanjay SharmaNo ratings yet

- Comparison of r22 and r407cDocument7 pagesComparison of r22 and r407cVamsi Priya KatamreddyNo ratings yet

- Optimization of Plate Fin Heat Exchangers Used in Natural Gas Liquefaction - ICFD10-EG-3073Document6 pagesOptimization of Plate Fin Heat Exchangers Used in Natural Gas Liquefaction - ICFD10-EG-3073fujiman35No ratings yet

- CFD Applications in Heat Exchanger DesignDocument4 pagesCFD Applications in Heat Exchanger Designj.nivethanNo ratings yet

- Heat Exchanger System For NH3 ReformngDocument10 pagesHeat Exchanger System For NH3 ReformngSalman ShahzadNo ratings yet

- Experimental Investigation of A Thermosyphon Based Heat Exchanger Used in Energy Efficient Air Handling UnitsDocument8 pagesExperimental Investigation of A Thermosyphon Based Heat Exchanger Used in Energy Efficient Air Handling Unitsmjs9170No ratings yet

- Effectiveness of Rotary Air Preheater in A Thermal Power PlantDocument6 pagesEffectiveness of Rotary Air Preheater in A Thermal Power PlantInnovative Research PublicationsNo ratings yet

- For Summer COolingDocument4 pagesFor Summer COolingBoris Joshua Q. TeodoroNo ratings yet

- Aplicación de Intercambiadores de Calor Coaxiales en La Optimización Del Cop de Sistemas de Refrigeración Automotriz Por Compresión Del Gas R134ADocument16 pagesAplicación de Intercambiadores de Calor Coaxiales en La Optimización Del Cop de Sistemas de Refrigeración Automotriz Por Compresión Del Gas R134ACaballero Gonzalez Erick AdrianNo ratings yet

- Research Article: An Alternative Algorithm For Optimal Design of Plate Heat ExchangersDocument9 pagesResearch Article: An Alternative Algorithm For Optimal Design of Plate Heat ExchangerseNo ratings yet

- Chapter 1 and 2Document25 pagesChapter 1 and 2nwaokorie_thaddeusNo ratings yet

- Energies: Comparison of The Efficiency of Two Types of Heat Exchangers With Parallel Plates Made of Varied MaterialsDocument15 pagesEnergies: Comparison of The Efficiency of Two Types of Heat Exchangers With Parallel Plates Made of Varied MaterialsazertyNo ratings yet

- بحثي المنشور بمؤتمر الاردنDocument13 pagesبحثي المنشور بمؤتمر الاردنShurooq TaibNo ratings yet

- Design and Analysis of Water Cooled Condenser: Sanjana V. Bharambe, Susmit A. Mulay, Suyash JadhavDocument5 pagesDesign and Analysis of Water Cooled Condenser: Sanjana V. Bharambe, Susmit A. Mulay, Suyash JadhavAungThawNyeinChanNo ratings yet

- Vol-1, Issue-5Document5 pagesVol-1, Issue-5Ijrei JournalNo ratings yet

- A Hybrid Simulation Model To Predict The Steady-State Thermal ProDocument11 pagesA Hybrid Simulation Model To Predict The Steady-State Thermal ProMohammed Naim UddinNo ratings yet

- 9544Document16 pages9544Ex LeeNo ratings yet

- PerformanceDocument14 pagesPerformancealmadhagiNo ratings yet

- Heat Exchanger Group 17Document22 pagesHeat Exchanger Group 17ja ma0% (1)

- Fin Pitch To Effect Efficiency of Evaporator and HVACDocument4 pagesFin Pitch To Effect Efficiency of Evaporator and HVACAJER JOURNALNo ratings yet

- 943-947 Ijer - 2016 - 1231 Guttula Anusha CDocument6 pages943-947 Ijer - 2016 - 1231 Guttula Anusha CInnovative Research PublicationsNo ratings yet

- PEM Fuel Cell Cooling with CuO NanofluidDocument13 pagesPEM Fuel Cell Cooling with CuO Nanofluid2K18/PE/007 ANIKET GUPTANo ratings yet

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- Air Conditioning TypesDocument4 pagesAir Conditioning TypesamogmhetreNo ratings yet

- McEnergy air cooled chillersDocument14 pagesMcEnergy air cooled chillersBiljanasteffNo ratings yet

- PC 843 T 5046 Compressor Spare Parts PDF - Google SearchDocument2 pagesPC 843 T 5046 Compressor Spare Parts PDF - Google Searchamogmhetre0% (1)

- Float ValveDocument3 pagesFloat ValveamogmhetreNo ratings yet

- Material Safety Data SheetDocument1 pageMaterial Safety Data SheetamogmhetreNo ratings yet

- Ashrae 62aDocument2 pagesAshrae 62aamogmhetreNo ratings yet

- LoveDocument2 pagesLoveamogmhetreNo ratings yet

- McEnergy air cooled chillersDocument14 pagesMcEnergy air cooled chillersBiljanasteffNo ratings yet

- Carrier 30 GH 220Document2 pagesCarrier 30 GH 220amogmhetreNo ratings yet

- Regulations, Standards and Guidelines - IAQU 108 Iaqa - Google SearchDocument2 pagesRegulations, Standards and Guidelines - IAQU 108 Iaqa - Google SearchamogmhetreNo ratings yet

- BrineDocument2 pagesBrineamogmhetreNo ratings yet

- RefrigerantDocument2 pagesRefrigerantamogmhetreNo ratings yet

- Asharae 55 2013 Site - ScribdDocument2 pagesAsharae 55 2013 Site - ScribdamogmhetreNo ratings yet

- Fire - Nist.gov Bfrlpubs Build06 PDF b06043Document1 pageFire - Nist.gov Bfrlpubs Build06 PDF b06043amogmhetreNo ratings yet

- CompDocument2 pagesCompamogmhetreNo ratings yet

- Emergency Chiller Service - A Troubleshooting Guide - 2Document1 pageEmergency Chiller Service - A Troubleshooting Guide - 2amogmhetreNo ratings yet

- Emergency Chiller Service - A Troubleshooting Guide - 2Document1 pageEmergency Chiller Service - A Troubleshooting Guide - 2amogmhetreNo ratings yet

- Related Articles: Log in RegisterDocument1 pageRelated Articles: Log in RegisteramogmhetreNo ratings yet

- Emergency Chiller Service - A Troubleshooting Guide - Commercial HVAC Content From Contracting BusinessDocument1 pageEmergency Chiller Service - A Troubleshooting Guide - Commercial HVAC Content From Contracting BusinessamogmhetreNo ratings yet

- ROHAN Thite 1Document1 pageROHAN Thite 1amogmhetreNo ratings yet

- Tool Room Requirment 2015Document3 pagesTool Room Requirment 2015amogmhetreNo ratings yet

- Job Description: Application Engineer: 601 Development Drive, Plano, TX 75074 1 of 2Document2 pagesJob Description: Application Engineer: 601 Development Drive, Plano, TX 75074 1 of 2amogmhetreNo ratings yet

- ROHAN Thite 1Document1 pageROHAN Thite 1amogmhetreNo ratings yet

- Thite M.Document1 pageThite M.amogmhetreNo ratings yet

- Name of The Position Applied: Marketing Interns: Login Id:-PasswordDocument2 pagesName of The Position Applied: Marketing Interns: Login Id:-PasswordamogmhetreNo ratings yet

- CMAT Admit CardDocument1 pageCMAT Admit CardamogmhetreNo ratings yet

- RDM 1Document32 pagesRDM 1amogmhetreNo ratings yet

- ME410 Experiment 3 Experiment SheetDocument11 pagesME410 Experiment 3 Experiment SheetCem ÖztürkNo ratings yet

- Tarea #1 PDFDocument2 pagesTarea #1 PDFManuel Hernández MontecilloNo ratings yet

- Afifa Nur Alya - Matrikulasi (1-27) PDFDocument46 pagesAfifa Nur Alya - Matrikulasi (1-27) PDFtsabbita husnaNo ratings yet

- Deliverable 2 ThermodynamicsDocument6 pagesDeliverable 2 ThermodynamicsScribdTranslationsNo ratings yet

- Lecture 6 | Refrigeration & Liquefaction - J. G. Weisend IIDocument36 pagesLecture 6 | Refrigeration & Liquefaction - J. G. Weisend IIVishvesh T SNo ratings yet

- Temperature Log ChecklistDocument3 pagesTemperature Log ChecklistSumit Sharma100% (1)

- Exp 1Document4 pagesExp 1Ihsan SamohNo ratings yet

- ThermodynamicDocument25 pagesThermodynamicSushrut PujahariNo ratings yet

- Thermodynamics NEET PYQ SOLUTIONDocument18 pagesThermodynamics NEET PYQ SOLUTIONsomeone nooneNo ratings yet

- Psychrometric Chart EditedDocument1 pagePsychrometric Chart EditedMelord RoneNo ratings yet

- Hvac Design SeminarDocument29 pagesHvac Design SeminarSherwin SolisNo ratings yet

- Thermal Engineering (MG UNIVERSITY) PART1Document26 pagesThermal Engineering (MG UNIVERSITY) PART1GokulAgNo ratings yet

- Trane Air-to-Air Energy Recovery En29-05 PDFDocument8 pagesTrane Air-to-Air Energy Recovery En29-05 PDFabcNo ratings yet

- GAPL-HVAC People UKDocument20 pagesGAPL-HVAC People UKrandeep ravishNo ratings yet

- r05222103 ThermodynamicsDocument8 pagesr05222103 ThermodynamicsSRINIVASA RAO GANTANo ratings yet

- Thermo Thermodynamic PropertiesDocument59 pagesThermo Thermodynamic PropertiesMayFifth100% (1)

- Cooling Tower Lab Report AnalysisDocument10 pagesCooling Tower Lab Report Analysisseraj ibramemNo ratings yet

- Pure Substance 2015Document19 pagesPure Substance 2015Ranel Simon Rey100% (1)

- Cooling Load Reduction by Using Thermal Mass and Night Ventilation PDFDocument7 pagesCooling Load Reduction by Using Thermal Mass and Night Ventilation PDFSérgio GnipperNo ratings yet

- Air Conditioning Comfort and Cooling Load AnalysisDocument56 pagesAir Conditioning Comfort and Cooling Load AnalysisNazia ZamanNo ratings yet

- Section III 12 TemperatureDocument27 pagesSection III 12 Temperaturedanwilliams85No ratings yet

- Steam Formation: S Solid L Liquid V VapourDocument14 pagesSteam Formation: S Solid L Liquid V VapourDev PatelNo ratings yet

- Efficient Chilled Water Piping Systems ExplainedDocument48 pagesEfficient Chilled Water Piping Systems Explainedryxor-mrbl100% (1)

- Condenser and It's TypesDocument6 pagesCondenser and It's Typeskaacho piece pieceNo ratings yet

- Cooling and Dehumidifying Heat Load Estimate FormDocument4 pagesCooling and Dehumidifying Heat Load Estimate FormKaushikNo ratings yet

- ThermodynamicsDocument33 pagesThermodynamicsJanneNo ratings yet

- Lecture 3. Refrigeration Cycles 2Document37 pagesLecture 3. Refrigeration Cycles 2addisudagneNo ratings yet

- TRANE TRACE™ 700 and TRACE™ 3D Plus Building Energy Modeling Guide For LG Multi V™Document31 pagesTRANE TRACE™ 700 and TRACE™ 3D Plus Building Energy Modeling Guide For LG Multi V™fghabboonNo ratings yet

- Second Law of ThermodynamicsDocument80 pagesSecond Law of ThermodynamicsAnustup MaityNo ratings yet

- Carta Psicrometrica Carrier PDFDocument1 pageCarta Psicrometrica Carrier PDFMarco Mussin VigoNo ratings yet