Professional Documents

Culture Documents

Technical Solutions PC

Uploaded by

Anonymous KdnOsd9Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Solutions PC

Uploaded by

Anonymous KdnOsd9Copyright:

Available Formats

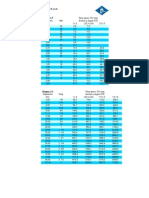

TECHNOLOGIC SOLUTIONS

omnia plastica spa

PC

GENERAL

Density

1,2 g/cm3

ISO 1183

DIN 53479

Water absorption in air 50% r.h.

0,15 %

ISO 62

DIN 53715

Absorption 23-C in water-saturation

0,36 %

ISO 62

DIN 53495

Tensile stress at yield at break

60 N/mm2

ISO 527

DIN53455

Elongation at break

80 %

ISO 527

DIN53455

Tensile Modulus of elasticity

2200 N/mm2

ISO 527

DIN53455

Compression test 1% strain 1000h

ISO 899

DIN53444

Impact strength Charpy 7,5 J

no break

ISO R179

DIN53453

Notched impact strength Charpy

40 KJ/ mm2

ISO179/3C

DIN53453

Ball indentation hardness

110 N/mm2

ISO2039.1

DIN53456

Rockwell hardness (dry)

ISO2039.2

DIN53456

Coefficient of friction to steel [12]

0,55

ISO 8295

DIN 53375

Melting point

ISO 3146

Thermal conductivity

0,2 W/(km)

ISO 22007.2

DIN 52612

Deformation at temperature HDT[15]

135 C

ISO75

DIN 53461

Linear expansion coefficient 23-60C

65 x 10-6 K-1

ISO 11359

DIN 53752

Operating temperature continuously[17]

115 C

Operating temperature short period-no load[18]

145 C

Minimum operating temperature[19]

-60 C

Flammability UL 94

(3-6 mm thickness)

HB

Oxygen index (LOI)

25 %

MECHANICAL PROPERTIES

THERMAL PROPERTIES

UL94

ISO4589

Omnia Plastica Spa Italia 21052 Busto Arsizio, via certosa,7 fax 0331 350076 tel 0331 340153 www.omniaplastica.it

DIN 22117

info@omniaplastica.it

TECHNOLOGIC SOLUTIONS

omnia plastica spa

ELECTRICAL PROPERTIES

Dielectric constant

at 1 MHz.

2,9

ISO 250

DIN 53483

Dielectric strength

30 KV/mm

ISO 243

DIN 53481

Volume resistivity

1015 cm

ISO 93

DIN 53482

Dissipation factor

tan at 1MHz

0,0011

ISO 250

DIN 53483

N.B.

- Figures relate to specimen conditioned at 23C and 50% RH. Figures between brackets relate to dry specimen. Figures for

materials marked with * can change according to their moisture content.

- Figures refer to un-coloured specimen either injection moulded or machined in the easiest way. Tests made on specimen

of different sizes give slightly different results.

- [12] Test on ground steel dry specimen load =0,05 N/mm2 speed=0,6 m/s.

- [15] Deformation at temperature. HDT at 1,8 N/mm2

- [17] Operating temperature continuously 5000h From 23C upwards the materials' features change in an non-uniform and

disproportional way due to the heat. The quoted limits are indicative and based on a tensile stress of 50% of the value at 23

C.

- [18] Operating temperature short period (no load)

- [19] The mechanical features decrease with a reduction in temperature and are influenced also by other factors (moisture,

etc.). The quoted value does not take into consideration impact conditions or heavy loads.

- A Amorphous

- All values and information provided are based on information currently in our possession and/or results archived from tests

conducted in our laboratories. They are given in good faith and are not legally binding. For any particular application, the

technical staff of Omnia Plastica spa is at your disposal to assist with solving your problem.

Omnia Plastica Spa Italia 21052 Busto Arsizio, via certosa,7 fax 0331 350076 tel 0331 340153 www.omniaplastica.it

info@omniaplastica.it

You might also like

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Abs (Basf Terluran Gp22)Document1 pageAbs (Basf Terluran Gp22)hakangokceNo ratings yet

- DI-MC 355: Product DescriptionDocument4 pagesDI-MC 355: Product DescriptionvinodNo ratings yet

- MV Capacitor and Voltage Divider DsDocument4 pagesMV Capacitor and Voltage Divider DsCristiano BruschiniNo ratings yet

- Green PipeDocument62 pagesGreen Pipecrebdt2017No ratings yet

- StandardsDocument4 pagesStandardsflorin_iacob2001No ratings yet

- Datasheet Final de CarreraDocument3 pagesDatasheet Final de CarreraLucas PisitelloNo ratings yet

- Econamid FL 6M20 - Pa6 M2oDocument1 pageEconamid FL 6M20 - Pa6 M2omuthuNo ratings yet

- 20201002114953-DIWETEN 355+M 08 2020 E-AktuellDocument6 pages20201002114953-DIWETEN 355+M 08 2020 E-AktuellHAINo ratings yet

- TermistoresDocument8 pagesTermistoresingcreNo ratings yet

- Sika Plan - 12GDocument3 pagesSika Plan - 12Gthe pilotNo ratings yet

- Osisense XM Xmah12l2135Document2 pagesOsisense XM Xmah12l2135Milan StefanovicNo ratings yet

- Duracon M25-44Document5 pagesDuracon M25-44AVLight AutomotivesNo ratings yet

- X5CrNiCuNb 16-41.4542Document2 pagesX5CrNiCuNb 16-41.4542nuesteNo ratings yet

- Moeller Datasheet MCS4 019711Document5 pagesMoeller Datasheet MCS4 019711mihai37No ratings yet

- PP Raw Material SpecDocument1 pagePP Raw Material SpecAnonymous eq5zSUNo ratings yet

- 2016-03-10 PE-HD 500 - Ficha TécnicaDocument1 page2016-03-10 PE-HD 500 - Ficha TécnicaFrancesco VillaNo ratings yet

- TL 52682 enDocument8 pagesTL 52682 enRenato AlbinoNo ratings yet

- Differential Pressure Gauge Model 732.51, Stainless Steel Version, With Diaphragm Element All Welded ConstructionDocument4 pagesDifferential Pressure Gauge Model 732.51, Stainless Steel Version, With Diaphragm Element All Welded ConstructionClarence AG YueNo ratings yet

- PTC Thermistors For Overcurrent Protection: SMDS, Eia Sizes 3225 and 4032, 63 VDocument11 pagesPTC Thermistors For Overcurrent Protection: SMDS, Eia Sizes 3225 and 4032, 63 VFathe BallaNo ratings yet

- 240 Pin VLP DDR-III Soldertail Sockets: Product Design ObjectiveDocument8 pages240 Pin VLP DDR-III Soldertail Sockets: Product Design Objectivejerome_testNo ratings yet

- D/CRCW E3: VishayDocument8 pagesD/CRCW E3: VishayFilipe BrendlerNo ratings yet

- ASATT07Document3 pagesASATT07José Joaquín Muñoz videsNo ratings yet

- D/CRCW E3: VishayDocument8 pagesD/CRCW E3: VishayelecompinnNo ratings yet

- Pressure Measurement: Engineering Measurement TA ZC 232Document31 pagesPressure Measurement: Engineering Measurement TA ZC 232aj2697No ratings yet

- PTC MotorStarting Disk LPCDocument9 pagesPTC MotorStarting Disk LPCOswaldo CriolloNo ratings yet

- Rhodia - Tds - Technylstar S 218 v30 Black 31 N - enDocument5 pagesRhodia - Tds - Technylstar S 218 v30 Black 31 N - ennimonhNo ratings yet

- TDBL - Polystone P Grey Homopolymer - GBDocument1 pageTDBL - Polystone P Grey Homopolymer - GBreinpolyNo ratings yet

- 2010 Datasheet DMV 825Document4 pages2010 Datasheet DMV 825Roman BorovkovNo ratings yet

- Versatile, Wear-Resistant Universal Material: Iglidur Specialists - General Purpose Iglidur KDocument33 pagesVersatile, Wear-Resistant Universal Material: Iglidur Specialists - General Purpose Iglidur KigusukNo ratings yet

- TDS Antifrogen N EnglishDocument7 pagesTDS Antifrogen N EnglishMartín BaezaNo ratings yet

- DGPT2Document36 pagesDGPT2eliasnasrNo ratings yet

- Low Friction Plastic Provides Long Component LifeDocument1 pageLow Friction Plastic Provides Long Component Lifes_padu3003@yahoo.comNo ratings yet

- Datasheet - M22-DL-G: Part No. Article No. Catalog NoDocument6 pagesDatasheet - M22-DL-G: Part No. Article No. Catalog NoMarcelo HernandezNo ratings yet

- 2n7002k DiodesDocument7 pages2n7002k DiodesRofo2015No ratings yet

- Asatt 16Document3 pagesAsatt 16José Joaquín Muñoz videsNo ratings yet

- Bakelite PF 31Document3 pagesBakelite PF 31dioguitomsolhaNo ratings yet

- Iglidur Bearings-Specialists, For Long Service LifeDocument70 pagesIglidur Bearings-Specialists, For Long Service LifeigusukNo ratings yet

- Engineering Materials Data SheetDocument6 pagesEngineering Materials Data Sheetrajarao1234No ratings yet

- Blind Pressure & Differential Pressure Switches GuideDocument0 pagesBlind Pressure & Differential Pressure Switches GuideMilosglNo ratings yet

- K48-50 Carbon Film ResistorsDocument3 pagesK48-50 Carbon Film ResistorseminuscloudNo ratings yet

- 01 Pressure SwitchesDocument4 pages01 Pressure SwitchesfaviomarchantNo ratings yet

- Approval Sheet: D S C Electronics Co., LTDDocument9 pagesApproval Sheet: D S C Electronics Co., LTDJorge Vásquez CarreñoNo ratings yet

- Surface Finish Tensile TestsDocument6 pagesSurface Finish Tensile TestsPaldexNo ratings yet

- Plates - S420G2 MDocument2 pagesPlates - S420G2 MAdisak AumpiemNo ratings yet

- Llautó M38 CuZn37Document2 pagesLlautó M38 CuZn37Josep TanuNo ratings yet

- High Flow PC/ABS for Automotive InteriorsDocument2 pagesHigh Flow PC/ABS for Automotive InteriorsJosh DineshNo ratings yet

- Sikadur®-42 MP Slow_PDS_GCC_AE_(07-2016)_1_1Document5 pagesSikadur®-42 MP Slow_PDS_GCC_AE_(07-2016)_1_1邢焕震No ratings yet

- TECSUN PV1-F Cable Technical DataDocument5 pagesTECSUN PV1-F Cable Technical Datarommy_boy330No ratings yet

- Ordering Information: Sealed Snap Action SwitchDocument6 pagesOrdering Information: Sealed Snap Action SwitchG Sandeep KumarNo ratings yet

- 23 M-AstDocument4 pages23 M-AstLegi YangNo ratings yet

- Ipr RegDocument34 pagesIpr RegNicolae PopNo ratings yet

- Model DIM20Document2 pagesModel DIM20Alex LascauNo ratings yet

- Gazguard 026: Units Typical Value Initial PropertyDocument2 pagesGazguard 026: Units Typical Value Initial PropertyTeguh SetionoNo ratings yet

- Model Number Structure: Enclosed SwitchDocument10 pagesModel Number Structure: Enclosed SwitchJavierNo ratings yet

- Product Characteristics: Pressure SensorsDocument2 pagesProduct Characteristics: Pressure SensorsnvkjayanthNo ratings yet

- NTC Thermistor SMD Type Specification SheetDocument25 pagesNTC Thermistor SMD Type Specification SheetwoodyyinNo ratings yet

- 4105 DatasheetDocument2 pages4105 DatasheetAsad NaeemNo ratings yet

- Instruction Manual - Unique To Mixproof Tank Outlet Valve - Ese00156enDocument66 pagesInstruction Manual - Unique To Mixproof Tank Outlet Valve - Ese00156enAnonymous KdnOsd9No ratings yet

- ChapasLF LCDocument1 pageChapasLF LCMariano BarrionuevoNo ratings yet

- PTP Supports Catalog 2017 V5 v2 Reduce Size PDFDocument248 pagesPTP Supports Catalog 2017 V5 v2 Reduce Size PDFMONER MANUSNo ratings yet

- Instruction Manual Unique Sanitary Mixproof Valve Including Us Version Ese00923enDocument120 pagesInstruction Manual Unique Sanitary Mixproof Valve Including Us Version Ese00923enAnonymous KdnOsd9No ratings yet

- BELT DRIVE FLAILHEAD ALIGNMENTDocument3 pagesBELT DRIVE FLAILHEAD ALIGNMENTAnonymous KdnOsd9No ratings yet

- Sandisk Extreme Pro® Usb 3.1 Solid State Flash DriveDocument2 pagesSandisk Extreme Pro® Usb 3.1 Solid State Flash DriveAnonymous KdnOsd9No ratings yet

- Alfa Laval Unique SSV Standard Product LeafletDocument6 pagesAlfa Laval Unique SSV Standard Product LeafletAnonymous KdnOsd9No ratings yet

- Alfa Laval Unique Mixproof Tank Outlet Valve Unique To Product LeafletDocument7 pagesAlfa Laval Unique Mixproof Tank Outlet Valve Unique To Product LeafletAnonymous KdnOsd9No ratings yet

- In Good Hands - Everything You Need Close at Hand - BrochureDocument6 pagesIn Good Hands - Everything You Need Close at Hand - BrochureAnonymous KdnOsd9No ratings yet

- Boldrini Company ProfileDocument8 pagesBoldrini Company ProfileAnonymous KdnOsd9No ratings yet

- Alfa Laval Unique SSV Single Seat ValvesDocument1 pageAlfa Laval Unique SSV Single Seat ValvesAnonymous KdnOsd9No ratings yet

- Archmodels Vol 115Document16 pagesArchmodels Vol 115Anonymous KdnOsd9No ratings yet

- Alfa Laval Unique Single Seat Valve - Standard and Reverse Acting - Instruction Manual - Ese00202enDocument54 pagesAlfa Laval Unique Single Seat Valve - Standard and Reverse Acting - Instruction Manual - Ese00202enAnonymous KdnOsd9No ratings yet

- Leaflet Luxembourg A4 - WebDocument1 pageLeaflet Luxembourg A4 - WebAnonymous KdnOsd9No ratings yet

- E&H Instrument Fork Type LS TI00426FEN - 1412 PDFDocument40 pagesE&H Instrument Fork Type LS TI00426FEN - 1412 PDFn.s.patkarNo ratings yet

- Mortenson Construction Customer Story Navisworks en HiresDocument2 pagesMortenson Construction Customer Story Navisworks en HiresAnonymous KdnOsd9No ratings yet

- Optimization 2010 ENG FINAL PDFDocument9 pagesOptimization 2010 ENG FINAL PDFAnonymous KdnOsd9No ratings yet

- 4 4. Nivo: Posamezni Sestavni Deli ISO, Pisava 2: Opis Sap Koda Revizija / IteracijaDocument2 pages4 4. Nivo: Posamezni Sestavni Deli ISO, Pisava 2: Opis Sap Koda Revizija / IteracijaAnonymous KdnOsd9No ratings yet

- SW2014 Datasheet Simulation ENU PDFDocument6 pagesSW2014 Datasheet Simulation ENU PDFAde SNo ratings yet

- SWPrem DesigningBetterProducts by DedicatedComSaDocument14 pagesSWPrem DesigningBetterProducts by DedicatedComSaMX100No ratings yet

- CP-9CP UkDocument2 pagesCP-9CP UkAnonymous KdnOsd9No ratings yet

- Pulley Alignment and Belt AdjustmentDocument3 pagesPulley Alignment and Belt AdjustmentAnonymous KdnOsd9No ratings yet

- Pivoting Connecting Clamps: AluminiumDocument2 pagesPivoting Connecting Clamps: AluminiumAnonymous KdnOsd9No ratings yet

- 3DS 2017 SWK Simulation DatasheetDocument6 pages3DS 2017 SWK Simulation DatasheetThomz AsadinawanNo ratings yet

- Solidworks Simulation 2011 TutorialDocument8 pagesSolidworks Simulation 2011 TutorialCarlos GonzálezNo ratings yet

- Development of A Geometric Model Retrieval System - A Design ExempDocument27 pagesDevelopment of A Geometric Model Retrieval System - A Design ExempAnonymous KdnOsd9No ratings yet

- Acetal Vs DelrinDocument1 pageAcetal Vs DelrinAnonymous KdnOsd9No ratings yet

- Wear Pad Catalog 2010Document10 pagesWear Pad Catalog 2010Anonymous KdnOsd9No ratings yet

- DelrinDocument65 pagesDelrind-fbuser-98630126100% (1)

- Backhoe Loader - 2Cx: A Product of Hard WorkDocument20 pagesBackhoe Loader - 2Cx: A Product of Hard WorkAnonymous KdnOsd9100% (1)

- Kinetics: Effects of Concentration & Temperature on Reaction RatesDocument4 pagesKinetics: Effects of Concentration & Temperature on Reaction Ratescrybaby0% (1)

- SuperOhm 3754 (3748-11) - Technical Data Sheet - ECC - Rev 2 - 2016-09Document2 pagesSuperOhm 3754 (3748-11) - Technical Data Sheet - ECC - Rev 2 - 2016-09igor brocaNo ratings yet

- TSSR 2g Grahafamily3 PKMDocument43 pagesTSSR 2g Grahafamily3 PKMHaryo WNo ratings yet

- Proforma 300 L Dye. Alibaba PDFDocument3 pagesProforma 300 L Dye. Alibaba PDFFer ChicoNo ratings yet

- PPE Question Bank Covers Thermal, Hydro, Nuclear PowerDocument7 pagesPPE Question Bank Covers Thermal, Hydro, Nuclear PowerKanagaraj Chelladurai100% (1)

- General CatalogueDocument26 pagesGeneral CatalogueKasturi LetchumananNo ratings yet

- Pneumatic Maneuvering SystemDocument65 pagesPneumatic Maneuvering Systemminhankyaw100% (3)

- GreenTech EC Technology enDocument44 pagesGreenTech EC Technology enspscribd1No ratings yet

- CT Saturation and Its Influence On Protective Relays: Roberto Cimadevilla, Ainhoa FernándezDocument22 pagesCT Saturation and Its Influence On Protective Relays: Roberto Cimadevilla, Ainhoa FernándezANTONIO SOLISNo ratings yet

- Contractor instrument pressure piping hook-up documentDocument35 pagesContractor instrument pressure piping hook-up documentTahir100% (1)

- Anomaly Events GuideDocument33 pagesAnomaly Events GuideRichard LittlesNo ratings yet

- Accuspin 1 120V 230VDocument60 pagesAccuspin 1 120V 230VAndrew HolmesNo ratings yet

- PPR Techincal Data SheetDocument0 pagesPPR Techincal Data SheetKrish ChennaiNo ratings yet

- Cladding & Hardfacing ProcessesDocument16 pagesCladding & Hardfacing ProcessesMuhammed SulfeekNo ratings yet

- Technical Data Sheet Technical Data Sheet Technical Data Sheet Technical Data Sheet JD 30 M JD 30 M JD 30 M JD 30 MDocument6 pagesTechnical Data Sheet Technical Data Sheet Technical Data Sheet Technical Data Sheet JD 30 M JD 30 M JD 30 M JD 30 MMhammedSimoNo ratings yet

- Renewable RevolutionDocument52 pagesRenewable RevolutionDaisyNo ratings yet

- 2 - Acid and Base TitrationDocument90 pages2 - Acid and Base TitrationEnin SofiyaNo ratings yet

- Submissions - MMC Safety Program, MBFHI & Breastfeeding in The Workplace Orientation - Learning CheckDocument1 pageSubmissions - MMC Safety Program, MBFHI & Breastfeeding in The Workplace Orientation - Learning CheckAbis JohnNo ratings yet

- Climate Change The Facts (Annotated)Document3 pagesClimate Change The Facts (Annotated)api-276929919No ratings yet

- Green ConcreteDocument22 pagesGreen ConcreteQseem Khan100% (1)

- RLA Test FormatDocument11 pagesRLA Test Formatmayur dhandeNo ratings yet

- BIOCNGDocument23 pagesBIOCNGDhruva DNo ratings yet

- Wires The Politics of Climate Change in India Narratives of Equity and Co-Benefits Dubash PDFDocument11 pagesWires The Politics of Climate Change in India Narratives of Equity and Co-Benefits Dubash PDFShubham Kumar JhaNo ratings yet

- Exer 2 - PH and BuffersDocument4 pagesExer 2 - PH and BuffersAsi JenNo ratings yet

- Ce2039 MSW NotesDocument659 pagesCe2039 MSW NotesMuthu Praveen SarwanNo ratings yet

- Clivet Carel PcoDocument80 pagesClivet Carel PcoToni Dlabac100% (2)

- High Speed AerodynamicsDocument62 pagesHigh Speed AerodynamicsDavid Bond100% (2)

- Wuhuan - MR Pi JinlinDocument34 pagesWuhuan - MR Pi JinlinAmanNo ratings yet

- Li FiDocument38 pagesLi FireleeshaaaNo ratings yet

- Mike Busch on Engines What Every Aircraft Owner Needs to Know About the Design Operation Condition Monitoring Maintenance and Troubleshooting of Piston Aircraft Engines 1nbsped 1718608950 9781718608955 CompressDocument509 pagesMike Busch on Engines What Every Aircraft Owner Needs to Know About the Design Operation Condition Monitoring Maintenance and Troubleshooting of Piston Aircraft Engines 1nbsped 1718608950 9781718608955 CompressHugo HernandNo ratings yet