Professional Documents

Culture Documents

Method Statement For In-Situ Pull Off Test On Marble

Uploaded by

Gary LoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement For In-Situ Pull Off Test On Marble

Uploaded by

Gary LoCopyright:

Available Formats

TOP BUILDERS

INTERNATIONAL CO. LTD.

Method Statement

for In-Situ Pull Off Test on Marble

Project: Venetian Macau in Cotai, Macau

Re: Work Package 5115 (Top Builders), Prefabricated Bathroom

Revision: B

Date: 2006/07/13

METHOD STATEMENT FOR IN-SITU PULL OFF TEST ON

MARBLE

In Accordance With In-house Method DLA31

1.

EQUIPMENT

z Pull off test apparatus

z Saw cut machine

z Vacuum Apparatus

z Vernier Caliper

z Engineers square

2. PROCEDURE

2.1

Record all the information and test result on work sheet DLA 31A

2.2

Set up vacuum apparatus at the selected location,

2.3

Mix the epoxy resin adhesive: ARALDITE XH 111 A/B as the manufacturers

2.4

2.5

2.6

2.7

2.8

2.9

2.10

2.11

2.12

2.13

2.14

2.15

2.16

2.17

2.18

instruction.

Fix the aluminum dolly onto the exposed marble surface and the marble size to

be 100100mm.

Carefully position the aluminum dolly ensuring the axis of the dolly is same as

the axis of tile sample and be right angled to its surrounding surface.

Apply the dolly holder to hold the dolly in position

Allow minimum one hour for the adhesive be hardened.

Check the hardness of adhesive before setting up the pull off machine.

Screw the pulling rod of the pull off machine into the dolly as far as possible.

Connect the pulling rod to the pull off machine

Check the pull off machine is perpendicular to the surrounding surface using

the engineers square.

Pre-set loading rate at 0.05 N/mm/second, see Table 1 for the accrual setting

for the specific size of the tile under test.

Zero the pull off machine and apply loading by rotating the handle of the pull

off machine.

The loading speed should follow the pacer bar of the screen of the pull off

machine until failure.

Record the failure load which shown on the pull off machine.

Measure and record the dimension of the test specimen by the vernier caliper,

taking the average of each pair of two measurements as its length and width.

Inspect and record the proportion of failure in concrete, render, tile adhesive,

tile and interface between layers in percentage.

Record the condition of the opening (the broken surface of the actual element

2.19

tested) by taking a photograph, making sure a sticky label with key

information on it which stuck right next to the hole when taking the

photograph.

Take photographs in the laboratory at 90 intervals of its surfaces and one at

the broken end of the tile sample which still adhered on the dolly.

3. CALCULATION AND TOLERENCE

Calculate the pull off strength by dividing the failure load by the measured sectional

area and express the final result to the nearest 0.1 N/mm.

4. REPORT

Report test result on report form DLA 31. Sample as below:

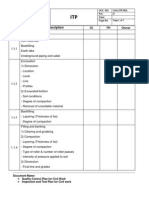

Size Of Tile

(mm)

4545

Calculated Sectional Area

(mm)

Setting

(KN/second)

2025

0.1013

4595

4275

0.2138

100100

10000

0.5

150150

22500

1.125

200200

40000

2.0

300300

90000

4.5

TABLE 1

You might also like

- Inspection and Test Plan For HVAC Cladding Works: 0-WD860-CA250-00312 0Document3 pagesInspection and Test Plan For HVAC Cladding Works: 0-WD860-CA250-00312 0ResearcherNo ratings yet

- Performance Lawn EquipmentDocument6 pagesPerformance Lawn Equipmentrddavis3100% (2)

- Method Statement For Concrete Topping (Ramp Slab)Document2 pagesMethod Statement For Concrete Topping (Ramp Slab)mikollim100% (3)

- Method Statement For Excavating Additional 3m Deep Trial Pits (2013!08!13)Document16 pagesMethod Statement For Excavating Additional 3m Deep Trial Pits (2013!08!13)Gary Lo0% (2)

- Method Statement For Demolition & Modification Works at Existing Retaining Wall RW5Document47 pagesMethod Statement For Demolition & Modification Works at Existing Retaining Wall RW5Gary Lo75% (4)

- Method Statement For Excavating Additional 3m Deep Trial Pits (2013!08!13)Document16 pagesMethod Statement For Excavating Additional 3m Deep Trial Pits (2013!08!13)Gary Lo0% (2)

- MS For Wet TradeDocument11 pagesMS For Wet TradeGary LoNo ratings yet

- QCS 2014 Section 13 Part 04Document5 pagesQCS 2014 Section 13 Part 04Glexer Dazo CorralesNo ratings yet

- Qcs 2010 Part 24.05 TilesDocument6 pagesQcs 2010 Part 24.05 TilesRotsapNayrb100% (1)

- T211 Method Statement - RC SlabDocument11 pagesT211 Method Statement - RC SlabStephen David GozunNo ratings yet

- Method Statement For Rock BlastingDocument2 pagesMethod Statement For Rock BlastingRafael Luis Marasigan100% (1)

- ITP-CI-026a-02 (Building Finishing Works)Document4 pagesITP-CI-026a-02 (Building Finishing Works)Delta akathehuskyNo ratings yet

- Method Statement For Installation of Wooden Flooring PDFDocument18 pagesMethod Statement For Installation of Wooden Flooring PDFChris EnyinnayaNo ratings yet

- Method of Statement For Blinding WorkDocument6 pagesMethod of Statement For Blinding WorkMohd Muksin100% (1)

- BD List of Approved Foundation SystemDocument2 pagesBD List of Approved Foundation SystemGary LoNo ratings yet

- Zaxis 75Document2 pagesZaxis 75Gary Lo100% (1)

- Conmix Utg 2011Document2 pagesConmix Utg 2011Fredj Ben SalemNo ratings yet

- Repairing of Plaster WallsDocument4 pagesRepairing of Plaster WallsSayan GharNo ratings yet

- Concrete Repair Work - MSTDocument14 pagesConcrete Repair Work - MSTwafikmh4No ratings yet

- Procedure For Inspection of Suspended CeilingDocument11 pagesProcedure For Inspection of Suspended Ceilingzaman musa100% (1)

- Tile Works - Terrazzo TilesDocument5 pagesTile Works - Terrazzo TilesglenNo ratings yet

- Installation On: Tiles Dado DryDocument35 pagesInstallation On: Tiles Dado Drylokesh.kukadiyaNo ratings yet

- AAC Block Masonary - Method StatementDocument2 pagesAAC Block Masonary - Method StatementdawoodnagnurNo ratings yet

- Floor Tiling-Method StatementDocument5 pagesFloor Tiling-Method StatementamroNo ratings yet

- A1-80-2 External Wall Tiling - 1 PDFDocument15 pagesA1-80-2 External Wall Tiling - 1 PDFZYWNo ratings yet

- BlockworkDocument5 pagesBlockworkVikram DhabaleNo ratings yet

- MS C 07 PaintingDocument6 pagesMS C 07 PaintingYENDRU LALITHAKUMARINo ratings yet

- Method StatementDocument4 pagesMethod StatementSagar ParabNo ratings yet

- Methodology For Floor Tiling.Document2 pagesMethodology For Floor Tiling.murali100% (2)

- PDS - SikaSeal-402 Fillerboard MYDocument2 pagesPDS - SikaSeal-402 Fillerboard MYSiji OktoberNo ratings yet

- Contractor: Edward and ChristieDocument5 pagesContractor: Edward and ChristieSubasinghe DharmapalaparkNo ratings yet

- Method Statement For Surveying WorkDocument3 pagesMethod Statement For Surveying WorkShenbagaraja PandianNo ratings yet

- Specification PDFDocument54 pagesSpecification PDFsothilingamnNo ratings yet

- Checklist For Painting WorksDocument4 pagesChecklist For Painting WorksBang JoyNo ratings yet

- Volume Ii: Specifications (Stamped Concrete) : Issue: FINAL, 14th FEB 2013Document8 pagesVolume Ii: Specifications (Stamped Concrete) : Issue: FINAL, 14th FEB 2013Ahmad Saadeldin100% (1)

- Anti TermiteDocument19 pagesAnti TermiteAjoy McNo ratings yet

- CONQUAS Ver 2editDocument3 pagesCONQUAS Ver 2editbyleekkNo ratings yet

- Method Statement Concrete Coring (ASTM C 142)Document2 pagesMethod Statement Concrete Coring (ASTM C 142)Twin Bulls100% (1)

- Method Statement& Risk Assesment For Demolition WorksDocument5 pagesMethod Statement& Risk Assesment For Demolition Workschandanprakash30No ratings yet

- Chain Link FenceDocument3 pagesChain Link Fencekarimakki100% (1)

- Brick and Block Sizes, Imperial and Metric, Mortar, Concrete, Brick Quantities and Block Quantities - How Much Do You NeedDocument3 pagesBrick and Block Sizes, Imperial and Metric, Mortar, Concrete, Brick Quantities and Block Quantities - How Much Do You NeedDeji JohnsonNo ratings yet

- QCS Section 16Document59 pagesQCS Section 16MurugananthamParamasivam67% (3)

- Sikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarDocument3 pagesSikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarSulaim Al KautsarNo ratings yet

- Method StatementDocument8 pagesMethod StatementardsilvaNo ratings yet

- QES PEVC-ENG237 - Checklist For PSS Fencing DetailsDocument2 pagesQES PEVC-ENG237 - Checklist For PSS Fencing DetailsRupesh Khandekar100% (1)

- Sto Skim Coat 82216 Guide Specifications B26371Document4 pagesSto Skim Coat 82216 Guide Specifications B26371Anthony Al Lakiss100% (1)

- Piling Work Mock-Up ReportDocument5 pagesPiling Work Mock-Up ReportMohammad Hadoumi SaldanNo ratings yet

- Work Method Statement - GYPSUM FALSE CEILINGDocument3 pagesWork Method Statement - GYPSUM FALSE CEILINGSathish GowdaNo ratings yet

- PQCP-06.03.09 Concrete Crack RepairDocument3 pagesPQCP-06.03.09 Concrete Crack RepairmiaicarbaNo ratings yet

- ItpDocument7 pagesItpJose Sherin100% (1)

- Dampproofing (Revised)Document29 pagesDampproofing (Revised)masahinNo ratings yet

- 13.Ms-Plumbing and Drainage WorkDocument15 pages13.Ms-Plumbing and Drainage WorkShenbagaraja PandianNo ratings yet

- Proposed Marudi Bridge Over Batang Baram, Miri Division, SarawakDocument8 pagesProposed Marudi Bridge Over Batang Baram, Miri Division, SarawakKelvin LauNo ratings yet

- FDT FormDocument3 pagesFDT FormEdison WalitNo ratings yet

- 33 05 13 Manholes and Structures 10Document4 pages33 05 13 Manholes and Structures 10salamNo ratings yet

- Method Statement For Installation of Fan Coil UnitDocument4 pagesMethod Statement For Installation of Fan Coil UnitGary LoNo ratings yet

- ITP of Admin Building NEW AutosavedDocument14 pagesITP of Admin Building NEW Autosavedomda4wady0% (1)

- 05-14 QCS 2014Document7 pages05-14 QCS 2014Raja Ahmed HassanNo ratings yet

- Method Statement For HoneycombDocument2 pagesMethod Statement For HoneycombCHAR JIN CHEENo ratings yet

- ML-KW-MST-001 R1 False Ceiling WorksDocument7 pagesML-KW-MST-001 R1 False Ceiling WorksprithivirajNo ratings yet

- Method Statement For Compression Pile Load TestDocument5 pagesMethod Statement For Compression Pile Load TestNguyễn Văn GiápNo ratings yet

- Method Statement For Curtain Wall & Glazing InstallationDocument7 pagesMethod Statement For Curtain Wall & Glazing InstallationRaja NasirNo ratings yet

- MS For BlindingDocument8 pagesMS For Blindingprasath_subramanianNo ratings yet

- Construction Methodologies Floor FinishesDocument15 pagesConstruction Methodologies Floor FinishesDonita DaquizNo ratings yet

- Terazzo TestingDocument6 pagesTerazzo TestingA Manuel GirmaNo ratings yet

- SECTION 02505 Paving Base and Subbase CourseDocument4 pagesSECTION 02505 Paving Base and Subbase CourseStraus WaseemNo ratings yet

- Astm C603Document2 pagesAstm C603Gary Lo100% (1)

- Typical SectionDocument1 pageTypical SectionGary LoNo ratings yet

- Kobelco Rk250-7 SpecDocument4 pagesKobelco Rk250-7 SpecVictor Abel Prieto Pizarro100% (4)

- Haul RoadDocument8 pagesHaul RoadGary LoNo ratings yet

- Astm F1292-2004Document25 pagesAstm F1292-2004Gary Lo100% (3)

- 1102 W Hik SWL Q08 395aDocument1 page1102 W Hik SWL Q08 395aGary LoNo ratings yet

- Method Statement For Decommiss - 1102 CSF POC CS 000197Document20 pagesMethod Statement For Decommiss - 1102 CSF POC CS 000197Gary LoNo ratings yet

- 1102 W Hik SWL C10 301aDocument1 page1102 W Hik SWL C10 301aGary LoNo ratings yet

- Method Statement For Eredtion - 1102 ERFC CM (SCLC) CS 000126Document3 pagesMethod Statement For Eredtion - 1102 ERFC CM (SCLC) CS 000126Gary LoNo ratings yet

- 1102 W Hik SWL C10 301aDocument1 page1102 W Hik SWL C10 301aGary LoNo ratings yet

- Location Plan: East RailDocument1 pageLocation Plan: East RailGary LoNo ratings yet

- Tree LayoutDocument1 pageTree LayoutGary LoNo ratings yet

- 1102 W Hik SWL Q08 395aDocument1 page1102 W Hik SWL Q08 395aGary LoNo ratings yet

- Appendix - A Details of Temporary OHL Mast, Back-Tie Brackets & Protective FenceDocument6 pagesAppendix - A Details of Temporary OHL Mast, Back-Tie Brackets & Protective FenceGary LoNo ratings yet

- Short Term Program - Pit by Pit (7sw-D-fr65)Document3 pagesShort Term Program - Pit by Pit (7sw-D-fr65)Gary LoNo ratings yet

- APP129Document10 pagesAPP129Gary LoNo ratings yet

- Central Data Bank List For FixingDocument49 pagesCentral Data Bank List For FixingGary LoNo ratings yet

- FR65 (Instrumentation) Initial ReportDocument1 pageFR65 (Instrumentation) Initial ReportGary LoNo ratings yet

- Details of TM3Document1 pageDetails of TM3Gary LoNo ratings yet

- FR65 (Instrumentation) Initial ReportDocument1 pageFR65 (Instrumentation) Initial ReportGary LoNo ratings yet

- RA-003-Risk Assessment For Installation of Temporary OHL Masts & Back-TiesDocument5 pagesRA-003-Risk Assessment For Installation of Temporary OHL Masts & Back-TiesGary LoNo ratings yet

- Short Term Program For Temporary OHL Mast & Back TieDocument1 pageShort Term Program For Temporary OHL Mast & Back TieGary LoNo ratings yet

- Method Statement of Pre Bored - 1102-ERFC-CM (SCLC) - FDN-000291Document3 pagesMethod Statement of Pre Bored - 1102-ERFC-CM (SCLC) - FDN-000291Gary LoNo ratings yet

- FR65 (Instrumentation) Initial ReportDocument1 pageFR65 (Instrumentation) Initial ReportGary LoNo ratings yet

- URS Hong Kong LTD: Shatin To Central LinkDocument1 pageURS Hong Kong LTD: Shatin To Central LinkGary LoNo ratings yet

- 802.11n: Next-Generation Wireless LAN Technology: White PaperDocument13 pages802.11n: Next-Generation Wireless LAN Technology: White PaperALEXANDRE JOSE FIGUEIREDO LOUREIRONo ratings yet

- Soil MechanicsDocument38 pagesSoil MechanicsAnsh Kushwaha50% (2)

- A1603 WTDocument9 pagesA1603 WTnanichowsNo ratings yet

- Bar Coding Tubular ProductsDocument4 pagesBar Coding Tubular ProductsGusti PanjaitanNo ratings yet

- Chapter 3 Physical Resources PDFDocument15 pagesChapter 3 Physical Resources PDFfloNo ratings yet

- Biblioteq Administrator Guide: Release - Notes. HTMLDocument3 pagesBiblioteq Administrator Guide: Release - Notes. HTMLjoserxNo ratings yet

- Muscle Tone PhysiologyDocument5 pagesMuscle Tone PhysiologyfatimaNo ratings yet

- Astro PhotoDocument12 pagesAstro PhotoPavelNo ratings yet

- WHITECROFT Energy Directive BrochureDocument32 pagesWHITECROFT Energy Directive BrochureAriel TambisNo ratings yet

- MBTI StepDocument21 pagesMBTI StepRedgie G. GabaneNo ratings yet

- Orientation, Training and Development, and Career Planning: Chapter ObjectivesDocument17 pagesOrientation, Training and Development, and Career Planning: Chapter ObjectiveslinhNo ratings yet

- Mechanical Design of Machine Elements-CouplingDocument10 pagesMechanical Design of Machine Elements-Couplingmuhammad azmiNo ratings yet

- Mets 6-8 129586 7Document3 pagesMets 6-8 129586 7api-218300695No ratings yet

- TEACHeXCELS Required ReadingsDocument69 pagesTEACHeXCELS Required ReadingsJessica MarieNo ratings yet

- CV - Munvar M ShaikDocument5 pagesCV - Munvar M ShaikMohammad GouseNo ratings yet

- ABC & Balance ScorecardDocument9 pagesABC & Balance Scorecardnanduri1979No ratings yet

- Mini Fellowship Program OutlineDocument4 pagesMini Fellowship Program OutlineVijayraj GohilNo ratings yet

- Science Investigatory Project PDFDocument2 pagesScience Investigatory Project PDFNick john CaminadeNo ratings yet

- Finding Answers Through Data Collection: Data Collection Procedure and Skills Using Varied InstrumentsDocument4 pagesFinding Answers Through Data Collection: Data Collection Procedure and Skills Using Varied InstrumentsJude BautistaNo ratings yet

- Anjali............................. Internship ReportDocument19 pagesAnjali............................. Internship ReportamitanjuNo ratings yet

- Class 8 - CH 12 Exponents Powers - Ws 2Document3 pagesClass 8 - CH 12 Exponents Powers - Ws 2Sparsh BhatnagarNo ratings yet

- Automatic Garbage Collector Machine: S. A. Karande S. W. Thakare S. P. Wankhede A. V. SakharkarDocument3 pagesAutomatic Garbage Collector Machine: S. A. Karande S. W. Thakare S. P. Wankhede A. V. Sakharkarpramo_dassNo ratings yet

- A Voicemail Message: Before ListeningDocument3 pagesA Voicemail Message: Before ListeningLudwina EugeniaNo ratings yet

- Mevlana Jelaluddin RumiDocument3 pagesMevlana Jelaluddin RumiMohammed Abdul Hafeez, B.Com., Hyderabad, IndiaNo ratings yet

- Raj Yoga ReportDocument17 pagesRaj Yoga ReportSweaty Sunny50% (2)

- ERPDocument9 pagesERPWindadahri PuslitkaretNo ratings yet

- Pengaruh Dukungan Suami Dalam Proses Persalinan Dengan Nyeri Persalinan Di Rsia Bunda Arif PurwokertoDocument12 pagesPengaruh Dukungan Suami Dalam Proses Persalinan Dengan Nyeri Persalinan Di Rsia Bunda Arif PurwokertoCerry Putri MaharaniNo ratings yet

- STM32 P407Document32 pagesSTM32 P407iker97wNo ratings yet

- Servomotor PptsDocument26 pagesServomotor Pptsjasdeep_kour236066No ratings yet