Professional Documents

Culture Documents

Desina e Spec

Uploaded by

marcosimuloCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Desina e Spec

Uploaded by

marcosimuloCopyright:

Available Formats

C o p y r ig h t 1 9 9 9

T h is s p e c ific a tio n is a v a ila b le fo r th o s

d e v e lo p , p r o d u c e a n d s e ll p r o d u c ts a

c o p ie s o r c h a n g e s o f th is d o c u m e n ts

T o r e c e iv e th e la te s t r e v is io n , c o p ie s

Im p r o v e m e n ts o r te c h n ic a l n o te s a r e

th e n e x t r e v is io n .

P u b lis h e r :

V e r e in D e u ts

C o r n e liu s s tr .

T e l.: 0 6 9 / 7 5

P ro d u c e d a n

E d ite d b

D E S IN A

T e l.: 0 6 9

e - m a il: d

c h e r W e r k z e u g m a s c h in e

4

D -6 0

6 0 8 1 0

F a x :

d p r in te d :

V D W

e in te r e s

c c o r d in g

- e le c tr o n

s h o u ld o

w e lc o m e

n fa

3 2 5

0 6 9

- O

te d e n

to th e

ic ly o r

n ly b e

a n d w

te r p r is e s w h ic

D E S IN A -S ta n

p r in te d - a r e p

r e c e iv e d fr o m

ill b e c o n s id e

b r ik e n e .V . ( V D W )

F r a n k fu r t a m M a in

/ 7 5 6 0 8 1 1 1

ffic e

y :

- S te e r in g c o m m itte e a n d D ip l.- In g . D e tle f H a g e m a n n

/ 7 5 6 0 8 1 1 9

.h a g e m a n n @ v d w .d e

h in te n d to

d a rd . A n y

r o h ib ite d .

V D W .

r e d w ith in

SPEC_00

Spezifikation

REV. 2.0

Guide to DESINA component specification

documentation

To ensure that suppliers are working to the same standards, specifications have been drawn up for

DESINA-compliant products which are intended to serve as guidelines for the suppliers. Each set of

specifications comprises a file and has been given a number.

The following table gives an overview of the documents and their availability.

Document

Description

D_spec00.doc

Guide to DESINA component

specification documentation

M12 - Pin assignments for I/O

boxes and sensors/valves

I/O boxes functional scope

Hybrid field bus cables

Hybrid field bus plugs

Hybrid field bus sockets

Hybrid field bus couplings

Inductive proximity switches

(sensors)

Hydraulic valves

Pneumatic valves

Motor starters - functionality

Motor starters with 10E socket

plugged directly on the motor,

pin assignment

Mechanical limit switches

Cable colour code

3-phase motors, connections and

pin assignment

Sensor-actuator lines

M12 - identification plugs for

local coding of I/O boxes

Analog sensors - general

Test adapter for M12 plug

connector

D_spec01.doc

D_spec02.doc

D_spec03.doc

D_spec04.doc

D_spec05.doc

D_spec06.doc

D_spec07.doc

D_spec08.doc

D_spec09.doc

D_spec10.doc

D_spec11.doc

D_spec12.doc

D_spec13.doc

D_spec14.doc

D_spec15.doc

D_spec16.doc

D_spec17.doc

File:

Date:

d_spec00_engl_mo 08.12.2003

d.doc

available

not in produc- Version

availtion

able

2.0

08.12.03

2.0

08.12.03

X

X

X

2.0

2.0

2.0

08.12.03

08.12.03

08.12.03

X

X

2.0

2.0

08.12.03

08.12.03

X

X

X

X

2.0

2.0

2.0

2.0

08.12.03

08.12.03

08.12.03

08.12.03

X

X

X

2.0

2.0

2.0

08.12.03

08.12.03

08.12.03

X

X

2.0

2.0

08.12.03

08.12.03

X

X

2.0

2.0

08.12.03

08.12.03

Updated:

08.12.2003

Date

Page:

2.0

1 of 9

SPEC_00

Spezifikation

These specifications especially aim for the observance of the requirements of the EMC EC directive

no. 89/336/EEC, but they do not cause a relief from the observance of the harmonized standards.

The observance of valid standards and regulations does not affect the observance of the

specification.

The product and project management has to consider only materials and components which

withstand also very unfavourable environments.

File:

Date:

d_spec00_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

2.0

2 of 9

SPEC_00

Spezifikation

Appendix:

Glossary of terms in the specifications listed above:

DESINA term

Description

Example

Actuator

Device in a machine which is activated by

an electrical signal from the programmable

controller

Device which detects a physical quantity

and converts it into an electrical quantity.

This signal can then be fed, in either digital

or analog form, to the programmable

controller

Data transmission link which, under

DESINA, includes the supply and data lines

Cable for data and power, consisting of 4 x

Cu 1.5 mm2 and 2 x POF, optionally HCS)

Device which can be connected to the

DESINA-standard hybrid field bus

Hydraulic and

pneumatic valves,

indicators

Inductive

proximity switch,

liquid level

detector, pressure

switch

Sensor

Hybrid field bus

Hybrid field bus cable

Hybrid field bus

module

Hybrid field bus plug

D_spec03

I/O box, motor

circuit, frequency

converter

HanBrid

Plug on hybrid field bus cable which can

take both optical data lines and power

supply lines to the hybrid field bus modules

Plug-in point on a hybrid field bus module HanBrid

to which the hybrid field bus cable can be

attached

Interchange point of data and module

supply to the hybrid cable in the switchgear

cabinet (transition from IP20 to IP67)

Power bus for 3 phase devices with a

maximum total load of 5 kW

Power supply cable and connection cable

between the individual stations on the

power bus

Plug on power bus cable

HAN Q 8/0

male and female

Plug-in point on hybrid field bus module, to HAN Q 8/0

male and female

which the power bus cable can be

connected

Hybrid field bus

connection

Hybrid field buscoupling

Power bus

Power bus cable

Power bus plug

Power bus socket

File:

Spec

Date:

d_spec00_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

D_spec02

D_spec10

D_spec04

D_spec04

D_spec05

D_spec10

Page:

2.0

3 of 9

SPEC_00

Spezifikation

Motor connection

The motor connection is directly on the

HAN 10 E

motor

Motor connection cable Cable between 3-phase motor and motor

circuit

Motor output

Plug-in point or fixed cable connection in

HAN Q 8/0 female

motor circuit providing switched power

HAN 10E female

Motor circuit

Hybrid field bus module for switching and

monitoring 3-phase motors

Motor control

Power section of motor circuit

I/O box

Hybrid field bus module

Identification plug

Plug for setting the station on a hybrid field

bus module

DESINA colour code

Lines which dont comply with any

structure in this specification may be fitted

with a sheathing colour being in accordance

with this specification and marked with the

DESINA colour code

File:

Date:

d_spec00_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

D_spec13

D_spec10

D_spec09

D_spec09

D_spec02

D_spec15

D_spec12

Page:

2.0

4 of 9

SPEC_00

Spezifikation

Revisions:

Date

Version

Spec 00

26.05.98

26.11.98

01.12.03

08.12.03

Guide to DESINA component specification documentation

0

First version

1.0

Revision 1, basic work

New: appendix with glossary of terms

1.5

Specifications release

1.5.1

Changes to Spec_04 and Spec_16, release of the English

version

1.5.2

Review of the previous requirements in Spec_09,

Spec_10, Spec_13

1.6

Updating, addition of revision history

2.0

Overall revision

Spec 01

26.05.98

25.11.98

12.02.99

16.12.02

08.12.03

M12 - pin assignments for I/O boxes and sensors/valves

0

Initial document

1.0

Revision 1, basic work

1.5

Specifications release

1.6

Analog input signal pin 2

2.0

Overall revision

Spec 02

26.05.98

22.06.98

10.11.98

I/O boxes - functional scope

0

Basic discussion

0.9

1st revision by steering group

1.0

Revision 1, basic work

Start of gradual implementation (see appendix)

1.1

Correction of terms, notes 3 and 4

1.2

Measurement range for analog inputs limited to 0-10 V

1.5

Release of specifications

1.6

Measurement range for analog inputs 4-20mA on pin2;

disjunction of analog, digital and safety modules

2.0

Overall revision

12.02.99

19.05.99

02.09.99

27.11.98

09.12.98

12.02.99

13.12.02

08.12.03

File:

Change

Date:

d_spec00_engl_mo 08.12.2003

d.doc

Author

Updated:

08.12.2003

GUT

BEK/GUT

LK

BEK/GUT

HUX

LK

LK

GUT

LK/GUT

LK

LK

LK

GUT

LK

LK/GUT

BEK/GUT

LK

LK

LK

LK

Page:

2.0

5 of 9

SPEC_00

Spezifikation

Spec 03

26.05.98

25.11.98

12.02.99

02.09.99

22.11.01

08.12.03

Hybrid field bus cables

0

Initial document

1.0

Revision 1, basic work

1.5

Specifications release

1.5.2

Terminological revision

1.6

Electrical data transmission added

2.0

Overall revision

GUT

LK/GUT

LK

HAG

LK

LK

Spec 04

22.06.98

25.11.98

12.02.99

19.05.99

30.01.02

08.12.03

Hybrid field bus plugs and field bus sockets

0

Initial document

1.0

Revision 1, basic work

1.5

Appendix 1 added/specifications released

1.5.1

Correction to the pin assignment

1.6

Electrical data transmission added

2.0

Overall revision

GUT

LK/GUT

GUT/LK

GUT/HAG

LK

LK

Spec 05

26.06.98

25.11.98

09.12.98

12.02.99

30.10.02

08.12.03

Hybrid field bus couplings

0

Initial document

1.0

Revision 1, basic work

1.1

Terminal block cancelled

1.5

Specifications released

1.6

two-wire bus added, examples completed

2.0

Overall revision

GUT

GUT

GUT

LK

LK

LK

Spec 06

06.08.98

25.11.98

12.02.99

22.11.01

08.12.03

Inductive proximity switches (sensors)

0

Initial document

0.9

Discussion basis

1.5

Specifications release

1.6

Update, M18 added

2.0

Overall revision

GUT

GUT

LK

LK

LK

Spec 07

06.08.98

25.11.98

09.12.98

09.02.99

12.02.99

12.02.99

11.09.02

08.12.03

Hydraulic valves

0

Initial document

1.0

Basic work

1.1

Appendix 1 added: Time response

1.2

Additions to specifications and appendix

1.5

Additions and corrections

1.5

Specification release

1.6

Updates and corrections

2.0

Overall revision

GUT

BEK/GUT

GUT

GUT

BEK/GUT

LK

LK

LK

File:

Date:

d_spec00_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

2.0

6 of 9

SPEC_00

Spezifikation

Spec 08

06.08.98

25.11.98

12.02.99

12.02.99

08.12.03

Pneumatic valves

0

Initial document

1.0

Basic work

1.5

Additions and amendments

1.5

Specification release

2.0

Overall revision

GUT

GUT

BEK/GUT

LK

LK

Spec 09

16.11.98

30.01.99

10.02.99

12.02.99

02.09.99

08.12.03

Motor starters - functionality

0.9

Initial document

0.91

1st revision

0.92

2nd revision

1.5

Specifications release

1.5.2

Update of existing requirements

2.0

Overall revision

HUX

HUX

HUX

LK

HUX

LK

Spec 10

18.11.98

30.01.99

10.02.99

12.02.99

02.09.99

22.11.01

08.12.03

Motor starters with 10E socket plugged directly on the motor,

pin assignment

0.9

Initial document

0.91

1st revision

0.92

2nd revision

1.5

Specifications release

1.5.2

Update of existing requirements

1.6

AC for brake added

2.0

Overall revision

HUX

HUX

HUX

LK

HUX

LK

LK

Spec 11

06.08.98

26.11.98

12.02.99

22.11.01

08.12.03

Mechanical limit switches

0

Initial document

0.9

Discussion basis

1.5

Specifications release

1.6

Addition of switch with two switching points

2.0

Overall revision

GUT

GUT

LK

LK

LK

Spec 12

06.08.98

26.11.98

12.02.99

11.09.02

08.12.03

Cable colour code

0

Initial document

1.0

Revision 1, basic work

1.5

Specifications release

1.6

Additional el. data transmission for hybrid field bus line

2.0

Overall revision

GUT

LK/GUT

LK

LK

LK

File:

Date:

d_spec00_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

2.0

7 of 9

SPEC_00

Spezifikation

Spec 13

06.08.98

07.01.99

30.01.99

12.02.99

02.09.99

08.12.03

3-phase motors, connections and pin assignment

0

Initial document

0.9

Provisional basic work

0.91

1st revision

1.5

Specifications release

1.5.2

Update of existing requirements

2.0

Overall revision

GUT

GUT

HUX

LK

HUX

LK

Spec 14

11.01.98

12.02.99

08.12.03

Sensor-actuator lines

0.9

Initial document

1.5

Specifications release

2.0

Overall revision

WAG

LK

LK

Spec 15

13.10.98

26.11.98

12.02.99

08.12.03

M12 - identification plugs for local coding of I/O boxes

0

Initial document

1.0

Revision 1, basic work

1.5

Specifications release

2.0

Overall revision

GUT

GUT

LK

LK

Spec 16

09.12.98

Analog sensors - general

0.1

Initial document

GUT

12.02.99

19.05.99

1.5

1.5.1

LK

BEK

22.11.01

28.06.02

08.01.03

08.12.03

1.6

1.6.1

1.6.2

2.0

Spec 17

18.01.99

12.02.99

27.08.99

25.04.03

08.12.03

Test adapter for M12 plug connector

0.1

Initial document

1.5

Specifications release

1.5.1

Diagramm added

1.5.2

Modified for injected current

2.0

Overall revision

File:

Specifications release

Delete current output, replace analog indication with

LED

Minor corrections

Output signal on pin 2

Results of the survey of 09.09.02 added

Overall revision

Date:

d_spec00_engl_mo 08.12.2003

d.doc

HAG

LK

HAG

LK

LK

Updated:

08.12.2003

LK

LK

LK

LK

Page:

2.0

8 of 9

SPEC_00

Spezifikation

LK

BEK

GUT

HAG

HUX

WAG

File:

Steering group

Beckering

Gutekunst

Hagemann

Huxoll

Wagner

Date:

d_spec00_engl_mo 08.12.2003

d.doc

Beckering, Gutekunst, Hagemann, Huxoll, Wagner

Kapp

Murrelektronik

VDW

Waldrich Coburg

iwb, TU Mnchen

Updated:

08.12.2003

Page:

2.0

9 of 9

SPEC_01

Spezifikation

REV. 2.0

M12 - Pin assignments for I/O boxes and sensors/valves

The following assignments apply for all sensors and actuators (i. e. valves etc.) to be connected to

DESINA-specification I/O boxes:

Pin assignments:

Pin

number

Contact:

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Sensor

Actuator

I/O box

Male

digital

24 V DC

diagnosis/

brake

contact

0V

digital

sensor

signal

not assigned

Male

digital

24 V DC

diagnosis

Female

digital

24 V DC

diagnosis/

brake contact

analog

24 V DC

analog

signal

analog

24 V DC

analog

signal

0V

0V

0V

not assigned

not assigned digital

control

signal

not assigned not assigned not assigned

0V

configurable

digital

input/output

not assigned

analog

24 V DC

analog

signal

0V

not assigned

not assigned

The normal assignment of pin 5 is dispensed with as DESINA is based on PELV (Protective Extra

Low Voltage).

Note: The sensor signal can be either digital or analog.

Design:

Check list

fulfilled

Requirement

M12 x 1 plug

not

fulfilled

Extra protection against mechanical loosening through

vibration

All plug connections should have IP67/68

Resistant to all normal industrial coolants/lubricants

Degree of protection

Durability

References:

D_spec02.doc:

D_spec06.doc:

D_spec07.doc:

File:

Function of I/O box

DESINA inductive proximity switches

Hydraulic valves

Date:

D_spec01_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

1 of 1

SPEC_02

Spezifikation

REV. 2.0

I/O boxes Functional scope

A central component in the DESINA scheme is the configurable I/O box. The specifications focus

on two main areas without proposing any specific implementation. The check list is intended to

help the suppliers guarantee the conformity of the product.

1. General system requirements

2. Requirements of digital sensor/actuator connections

3. Requirements of analog sensor/actuator connections

4. Interface connectors

5. Requirements of safety relevant inputs and outputs (later on)

6. Appendix

1. General system requirements

Check list

fulfilled

Requirement

Field bus connection

Field bus address

Supply voltage

Operating indicators

Degree of protection

Durability

Directive conformity

not

fulfilled

Via hybrid field bus plug as per D_spec04.doc

Contacts 1-4 for power supply male, for discharge

female

Can be plugged from outside with identification plug

Rated voltage: 24 V DC, PELV

Operating voltage range: 18 - 30 V DC

Green:

switched power supply

Green:

continuous power supply

Red:

failure in box (internal failure)

Green:

bus operation OK

IP 67/68

Resistant to relevant industrial coolants/lubricants *)

All relevant European directives adhered to, e.g. low

voltage directive 73/23/EEC and EMC directive

93/68/EEC including annexes.

*) Note: Resistance to relevant industrial coolants and lubricants must also include the

labeling.

File:

Date:

D_spec02_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

1 of 6

SPEC_02

Spezifikation

2. Requirements of digital sensor/actuator connections

Check list

Requirement:

Granularity

Channel numbering

M12 channel

connection

Pin 1

Pin 2

Pin 3

Pin 4

Channel indicators

fulfilled

not

fulfilled

4 and/or 8 channel extension boxes must be available

Numbering starts at 1

(Example: 8 channel box: I/O No.: 1 - 8)

M12 x 1 plug

as per specifications in D_spec01.doc

24 V DC supply voltage

Diagnostic input or digital input for break contact (n.c.)

0V

Configurable pin for following functions:

- digital input

- digital output

Yellow:

switching status of pin 4 OK

Red:

diagnostic input pin 2 signalling failure

Yellow:

break contact (n.c.) input pin 2 OK

(Note: red/yellow indicator is a bicolour LED)

Switched outputs

Diagnostic input

(pin 2)

Digital input

(pin 4)

Analog input (pin 4)

Digital output

(pin 4)

File:

Even-number channels are powered continuously

Odd-number channels power can be switched off for

safety reasons

Technical specifications:

Input characteristic: as per IEC 1131

Input filter:

0.5 ms - 3 ms

Voltage strength:

50 V against negative impulses

Configurable to normally closed function

LED switching yellow/red (see note 4)

Input characteristic: as per IEC 1131

Input filter:

0.5 ms - 3 ms

Voltage strength:

50 V against negative impulses

Effective range:

0 - 10 V DC

Resolution:

at least 8 bit

Voltage strength:

50 V against negative impulses

Rated voltage:

24 V DC

Rated current:

minimum 0.5 A, max. 2 A

Protective circuit:

Short circuit, overload

Restart after short circuit:

no

Voltage strength:

50 V against negative impulses

Date:

D_spec02_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

2 of 6

SPEC_02

Spezifikation

Note on process image and status of LED of pin 2:

Configuration

Diagnosis

State 1

24 V

off

0

U on pin 2

LED

PAE

State 2

0V

red

1

Contact breaker (n.c.)

State 1

State 2

24V

0V

yellow

off

1

0

Note 1: If pin 2 is assigned as a diagnostic input, 0 V indicates failure. In this case the red LED lights up. If

pin 2 is used as a contact breaker the yellow LED shows status "1" (24 V). This function is carried

out by a bicolor LED.

Note 2: The power supply is generally on pin 1. All inputs on pin 4 are not affected by the switch off.

3. Requirements of analog sensor/actuator connections

Check list

fulfilled

Requirement

Granularity

Channel numbering

M12 channel

connection

Pin 1

Pin 2

Pin 3

Pin 4

Channel indicators

not

fulfilled

4 and/or 8 channel extension boxes must be available

Numbering starts at 1(Example: 8 channel box: I/O No.:

1 - 8)

M12 x 1 plug

as per specifications in D_spec01.doc

24 V supply voltage

Analog signal: power interface 4-20 mA

0V

Not assigned

Yellow: switching status of pin 2 OK

Red: diagnosis input signalling error <4mA resp.

>20mA

(note: red/yellow indicator is a bicolor LED)

Yellow: switching status of pin 4

Even-number channels are powered continuously, oddnumber channels - power can be switched for safety

reasons

Technical specification

Measurement range: 4-20 mA

Resolution:

at least 8 bit

Voltage strength:

50 V against negative pulses

Short-circuit-proof

Function of diagnosis: current <4 mA or >20 mA are

indicating cable break or error of transmitter and are

analyzed for diagnostic purposes.

Switched channels

Analog signal (pin 2)

File:

Date:

D_spec02_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

3 of 6

SPEC_02

Spezifikation

4. Interface connectors

Check list

fulfilled

Requirement

Field bus connection

not

fulfilled

Hybrid field bus connection as per specifications in

D_spec04.doc

M12 x 1 plug

as per specification in D_spec01.doc

M12 technique 8 pin construction *)

as per specifications in D_spec15.doc

M12 channel

connection

Identification plug

*) Note: The identification plug carries the field bus address and can be connected to the location of the

box via a chain etc.. This produces local coding. The suppliers themselves must provide the

implementation know-how.

References:

D_spec01.doc:

D_spec04.doc:

D_spec15.doc:

M12 - Pin assignment for I/O boxes

Hybrid field bus plugs

Identification plugs

5. Requirements of safety relevant inputs and outputs

(later on)

File:

Date:

D_spec02_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

4 of 6

SPEC_02

Spezifikation

6. Appendix

Resolution passed on 23.10.1998 at iwb (Garching):

1. Plans to be put into action in 2 stages:

Check list

fulfilled

Requirement

Stage 1

I/O box to above specifications but without analog

inputs and outputs, i.e.

- Diagnosis/contact breaker input on pin 2

- Digital input and output, configurable on pin 4

- Identification plug

- Hybrid field bus connection

Stage 2

After stage 1, I/O with additional analog function for

inputs and outputs, i.e. full configuration to be realised.

not

fulfilled

2. Mounting:

The unit should be capable of being mounted using two standard DIN mounting rails, attached with

a 42.5 mm grid.

Check list

fulfilled

Requirement

Mounting

On standard DIN mounting rails as described above

3. Assembly window

Check list

fulfilled

Requirement

Assembly window

File:

not

fulfilled

not

fulfilled

For max. 32 channels: 300 mm x 500 mm

Date:

D_spec02_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

5 of 6

SPEC_02

Spezifikation

Decision made by the Steering Group on 11.09.2002

The present technical options for implementation allow to abandon the configurability of the

channels in respect of safety engineering. In fact safe in-/output modules are used, as single or

hybrid components. Each channel of these modules are determined then to have an input or output

function. This will not exclude the option of parameterizing as to carry out a safety relevant

evaluation on a single channel. The option also to connect unsafe sensors/actuators will so be

guaranteed.

File:

Date:

D_spec02_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

6 of 6

SPEC_03

Spezifikation

REV. 2.0

Hybrid field bus cables

The hybrid field bus cable is the connection between the programmable controller and the field bus

components. Examples of these are I/O boxes or motor circuits. The DESINA work group has

recognised the advantages of optical data transmission, especially in hostile environments, and

defined the hybrid field bus cable accordingly. Besides that, also a Cu-Cu hybrid field bus cable

complies with the requirements of DESINA.

Requirements:

Check list

fulfilled

Requirement

General construction

Data transmission

Energy transmission

Outer sheath

Geometry

Mechanical resistance

not

fulfilled

Hybrid cable: 2 x POF optical fibres and

4 Cu-wires 1.5 mm2

Optical:

2 x Polymer Optical Fibre (POF)

Attenuation:

< 200 dB/km

Electrical:

Shielded twisted pair

Impedances and other electrical characteristics have to

comply with the requirements of the bus system being

used.

Cu wire, diameter: 1,5 mm2 - 2,5 mm2

Number of strands: 4

Strand identification

Material:

*

Colour:

violet, RAL 4001

Outer diameter:

< 12 mm

Resistant to lubricants and coolants *)

Designed for energy chain application

*) Note: The cable must be resistant to all common coolants used in industry.

References:

D_spec04.doc:

Hybrid field bus plugs

File:

Date:

D_spec03_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

1 of 1

SPEC_04

Spezifikation

REV. 2.0

Hybrid field bus plugs

Hybrid field bus sockets

The pin assignment of the hybrid field bus plug is based on the HAN Brid by Harting. If plugs from

other manufacturers are used, plug compatibility should be checked. Full interchangeability should

always be ensured.

Requirements:

Check list

fulfilled

Requirement

General construction

2 x POF fibre optic connector

or electrical contacts for shielded twisted pair bus

systems

4 Cu-wires 1.5 mm2 - 2,5 mm2

Male contact for "cold" end of cable

Female contact for "hot" end of cable

Resistant to industrial coolants/lubricants

Electromagnetically compatible

IP67

5 A per Cu contact

Electrical contacts

Casing

Degree of protection

Current carrying

capacity

Connecting diameter

Casing type

1.5mm2 - 2,5 mm2

Based on Harting HAN Q 5

Optical elements:

Check list

fulfilled

Requirement

Transmitter

not

fulfilled

HP Versatile Link, integrated in hybrid field bus socket

HFBR-XX2X series (or other solutions 100%

compatible)

HP Versatile Link, integrated in hybrid field bus socket

HFBR-XX2X series (or other solutions 100%

compatible)

HP Versatile Link, integrated in hybrid field bus

HFBR-45xx series for POF (or other solutions

100% compatible)

Optional: for HCS fibre HFBR-4521

Receiver

Optical fibre plug

contact

File:

not

fulfilled

Date:

D_spec04_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

1 of 5

SPEC_04

Spezifikation

References:

D_spec03.doc:

D_spec05.doc:

Hybrid field bus cables

Hybrid field bus couplings

Example with optical data transmission

Fibre Optic Hybrid field bus

Fibre Optic Hybrid field bus

Example:

Female contacts in hybrid

field bus socket

File:

Date:

D_spec04_engl_mo 08.12.2003

d.doc

Example:

Male contacts in hybrid

field bus plug

Updated:

08.12.2003

Page:

Rev. 2.0

2 of 5

SPEC_04

Spezifikation

Example with electrical data transmission

Hybrid field bus socket

Example:

Female contacts in hybrid

field bus plug

Example:

Male contacts in hybrid

field bus socket

File:

Date:

D_spec04_engl_mo 08.12.2003

d.doc

Hybrid field bus plug

Updated:

08.12.2003

Page:

Rev. 2.0

3 of 5

SPEC_04

Spezifikation

Appendix 1:

Pin assignment of Cu contacts (male and female) in hybrid field bus socket (flange socket) with

optical data transmission:

1.1

RD

Flange socket with female contacts:

TD

Output side of field bus unit

Pin 1: + 24 V, not switched off

Pin 2: 0 V, corresponding with pin 1

Pin 3: 0 V, corresponding with pin 4

Pin 4: + 24 V, switched off (safety )

1.2

Flange socket with male contacts:

RD

TD

Input side of a field bus unit

Pin 1: + 24 V, not switched off

Pin 2: 0 V, corresponding with pin 1

Pin 3: 0 V, corresponding with pin 4

Pin 4: + 24 V, switched off (safety)

Note: The contacts are numbered clockwise. Accordingly the numbering in the hybrid field bus

plug is anticlockwise (not shown here).

TD: Transmit Data - input into beam waveguide

RD: Receive Data - reception out of the beam waveguide

File:

Date:

D_spec04_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

4 of 5

SPEC_04

Spezifikation

Appendix 2:

Pin assignment of Cu contacts in two-wire-bus (twisted pair) exemplified for RS 485-based

systems.

2.1

Flange socket with female contacts

A(L)

B(H)

Output side of field bus unit

shield

Pin 1:

Pin 2:

Pin 3:

Pin 4:

2.2

+24 V, not switched off

0 V, corresponding with pin 1

0 V, corresponding with pin 4

+24 V, switched off (safety)

Flange socket with male contacts

A(L)

B(H)

Input side of field bus unit

Pin 1:

Pin 2:

Pin 3:

Pin 4:

File:

+24 V, not switched off

0 V, corresponding with pin 1

0 V, corresponding with pin 4

+24 V, switched off (safety)

Date:

D_spec04_engl_mo 08.12.2003

d.doc

shield

Updated:

08.12.2003

Page:

Rev. 2.0

5 of 5

SPEC_05

Spezifikation

REV. 2.0

Hybrid field bus couplings

The hybrid field bus coupling is responsible for facilitating the transition from inside the switchgear

cabinet to the IP67 field bus environment. For this reason it is designed with a partition plate and

the plug connection in the field bus section is a HAN Brid. In the switchgear cabinet itself there is

no need for a high degree of protection, which is why the work group decided upon the unprotected

versatile link components provided by HP.

The coupling unit does not contain any bus-specific electronics in order to ensure bus and protocolneutral functionality.

Requirements:

Check list

fulfilled

Requirement

Interfaces:

IP67

Field bus connection

HAN Brid (or 100% compatible connection)

as electrical or optical version for the bus system

the termination - if necessary - of the two-wire bus is

carried out directly at the hybrid field bus coupling or at

the last device of a line by a terminating plug.

Number of

plugging points

IP20

Switchgear cabinet

connection,

power supply

1

Versatile Link

HFBR-XX2X series (for POF)

and/or through suitable connections for a two-wire bus,

integrated terminating resistors have to be switchable

By terminals on the IP20 side

Energy feeding input

or output

Number of

plugging points

File:

not

fulfilled

Date:

D_spec05_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

1 of 3

SPEC_05

Spezifikation

Electronics:

Data rate O/E converter min. 12 Mbit/s

Current

10 A per line

Other

No bus-specific electronics

Dimensions etc.

max. dimensions

min. dimensions

Construction

100 mm x 100 mm (for simple connection)

55 mm x 55 mm

Pre-fabricated module

Options:

The following additions are permitted:

- Integration of fuse elements in the hybrid field bus coupling

- Additional terminals for further looping of power

Schematic diagram of data route:

O

E

E

optical data

transmission

electrical data

transmission

IP20

File:

O

optical data

transmission

IP67

Date:

D_spec05_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

2 of 3

SPEC_05

Spezifikation

Schematic diagram of mechanical construction (example):

Connections for 24 V

power supply

Hybrid field bus

built-on socket

Hybrid field bus

plug

24 V

Printed circuit

board

Versatile-Link,

IP20 I/O

converter

Data

Mounting plate

(partition plate)

References:

D_spec03.doc:

D_spec04.doc:

Hybrid field bus cable

Hybrid field bus plug

File:

Date:

D_spec05_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

3 of 3

SPEC_06

Spezifikation

REV. 2.1

Inductive Proximity Switches

(Sensors)

In DESINA, the inductive proximity switch is regarded as a core component why it is defined both

as a plugging point and a technical component. Therefore it is specified at the connection as well as

the functionality.

Check list

Requirements:

fulfilled

Requirements

Construction

Length

Fitting

Degree of protection

M12 x 1

According to DIN EN 60947-5-2 max. 80 mm

flush

IP67/IP68

Switching status

Design

PNP make contact (n. o.)

3 wire

Nominal switching

distance

Switching frequency

SN = 2 mm

not

fulfilled

800 Hz

Supply voltage

Rated voltage: 24 V DC

Operating voltage: 10 V to 30 V DC

Indicators

Design: yellow LEDs around periphery

Sensor attenuated: yellow LED constantly on

Connection

M12 x 1 male contacts

Connection assignment Pin 1: + 24 V DC

Pin 2: diagnosis (0 V = error)

Pin 3: 0 V

Pin 4: make contact signal

File:

Date:

D_spec06_engl_mo 08.12.2003

d

Updated:

16.11.2006

Page:

Rev. 2.1

1 of 2

SPEC_06

Spezifikation

Check list

fulfilled

Diagnostic function

not

fulfilled

Line break

Short circuit/overload current

Frontal damage

Electronics failure

References:

D_spec01.doc:

M12 pin assignments for I/O boxes and sensors/actuators

File:

Date:

D_spec06_engl_mo 08.12.2003

d

Updated:

16.11.2006

Page:

Rev. 2.1

2 of 2

SPEC_07

Spezifikation

REV. 2.0

Hydraulic valves

Requirements:

Checkliste

fulfilled

Requirement

Connection

M12 x 1 plug

Male

One connection for each solenoid (M12 x 1)

Pin assignment

Pin 1:

Pin 2:

Pin 3:

Pin 4:

Pin 5:

Valves without

diagnosis

Internal bridge from pin 1 to pin 2 (see appendix 1)

Valves with diagnosis

Diagnostic signal on pin 2 (error: 0 V)

Diagnostic scope:

Gate valve position monitoring

Line break monitoring

Electronics monitoring

Indicators

Yellow LED for switching status

Separate for each solenoid

No indicator for diagnosis

Rated voltage

Operating voltage

Rated output

24 V DC

Rated voltage +/- 10%

min. 8 W, max. 48 W

Protective circuit

A suitable protective circuit must limit negative

voltages to 50 V (to protect I/O box)

The protective circuit must permit the fastest possible

de-excitation of the solenoid

File:

not

fulfilled

+ 24 V DC

Diagnostic feedback

0V

Switching signal (24 V)

Not assigned, pin superfluous

Date:

D_spec07_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

1 of 4

SPEC_07

Spezifikation

Appendix 1:

Definition of diagnosis with non-monitored valves:

The 24 V of pin 1 is fed back to the diagnostic input (pin 2) of the I/O box through the bridge

between pins 1 and 2 of the connection plug on the valve (M12 x 1). This permits simple diagnosis

in the event of the following failures:

Cable badly connected or not connected

Break in cable

Wire break in wires 1 and 2

File:

Date:

D_spec07_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

2 of 4

SPEC_07

Spezifikation

Appendix 2:

Time relationship of diagnosis signal to switching signal:

The following diagrams prove that with a correctly switching valve, the diagnosistic signal should

always be maintained at level "1" (24 V). At no time should there be a failure of the signal, which is

erroneously identified as a failure by the I/O box. The manufacturer of the valve, who knows the

switching and decay times of his products best, should therefore make suitable provisions in the

monitoring electronics.

Case 1: Valve switching correctly:

Switching signal on pin 4

24 V

0V

Diagnostic signal on pin 2

24 V

0V

t = valve switching time

Case 2: Valve not switching correctly:

Switching signal on pin 4

24 V

0V

Diagnostic signal on pin 2

24 V

0V

t

Expected switching time, to be specified by

manufacturer

File:

Date:

D_spec07_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

3 of 4

SPEC_07

Spezifikation

Case 3: Valve returns to initial status (de-excitation of solenoid):

Switching signal on pin 4

24 V

0V

Diagnostic signal on pin 2

24 V

0V

t

Valve release time

Case 4: Valve does not return to initial status after de-excitation:

Switching signal on pin 4

24 V

0V

Diagnostic signal on pin 2

24 V

0V

t

Valve release time t specified by manufacturer

References:

D_spec01:

D_spec02:

D_spec08:

File:

M12 plug assignment

Functions of I/O box

Pneumatic valves

Date:

D_spec07_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

4 of 4

SPEC_08

Spezifikation

REV. 2.0

Pneumatic valves

The DESINA work group's specifications concern the standard ISO valve. Valve groups or cluster

of valves are not covered by this specification.

Requirements:

Check list

fulfilled

Requirement

Connection

M12 x 1 plug

Male

One connection per solenoid (M12 x 1)

Pin assignment

Pin 1:

Pin 2:

Pin 3:

Pin 4:

Pin 5:

Valves with diagnosis

Diagnostic signal on pin 2 (error: 0 V)

Diagnostic scope:

Gate valve position monitoring

Line break monitoring

Electronics monitoring

Internal bridge from pin 1 to pin 2

Valves without

diagnosis

Indicators

Rated voltage

Operating voltage

Rated output

+ 24 V DC

Diagnosistic feedback

0V

Switching signal (24V)

Not assigned, pin superfluous

Yellow LED for switching status

Separate for each solenoid

No indicator for diagnosis

24V DC

Rated voltage +/- 10%

max. 48 W

Proctective circuit

File:

not

fulfilled

A suitable protective circuit must limit negative

voltages to 50 V (to protect I/O box)

The protective circuit must permit the fastest possible

de-excitation of the solenoid

Date:

D_spec08_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

1 of 2

SPEC_08

Spezifikation

References:

D_spec01:

D_spec02:

D_spec07:

File:

M12 plug assignment

Functions of I/O box

Hydraulic valves

Date:

D_spec08_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

2 of 2

SPEC_09

Spezifikation

REV. 2.0

Motor starters

Functionality

Requirements:

Check list

fulfilled

Requirement

Functions:

not

fulfilled

Motor on (direction of rotation can be set through

bridge setting or remote configuration via hybrid field

bus)

Motor off

Brake open

Brake closed

Star connection is set up with a bridge in the socket of

the motor supply cable or in the motor starter itself

Setting of station address of hybrid field bus module via

identification plug

Motor running

Motor control OK (diagnosis)

Overload detection

Status messages

(transmission via

hybrid field bus to

programmable

controller)

Operation indicators on 1. LED: green:

motor control OK

motor starter

red:

motor control not OK

2. LED: yellow:

switching status

3. LED: green:

bus operation OK

red:

bus operation not OK

Load reference values into motor starter (from

Data transmission via

programmable controller to motor starter)

hybrid field bus (in

Diagnostic information (from motor starter to

upcoming 2nd project

programmable controller)

stage)

Note:

File:

1.

Reference values are set on device or loaded into the motor starter via field bus, e.g.

through the central operating station (not by means of an additional programming unit)

2.

Diagnosis can cover e.g. line break, asymmetries, motor starter electronics

3.

Motors up to 5,5 kW are set up with star connection

Date:

D_spec09_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

1 of 1

SPEC_10

Spezifikation

REV. 2.0

Motor starters with 10E socket

plugged directly on the motor,

pin assignment

Requirements:

Check list

fulfilled

Requirement

Hybrid field bus

connection

Power bus connection:

degree of protection

IP 67/68

not

fulfilled

Hybrid field bus module (for connection see Spec_04),

node address set by means of identification plug

1 x HAN Q 8/0 plug (power bus input)

port identification with a symbol

1 x HAN Q 8/0 socket (power bus output)

port identification with a symbol

Assignment:

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin "earth"

Motor output:

Degree of protection

IP 67/68

Optional reserved for N

L2

Optional reserved for e.g. brake AC resp. 24 V DC

Optional reserved for e.g. brake (0 V)

L3

L1

PE

1 x 10E socket (power output)

port identification with a symbol

Mounted using longitudinal single bracket fastening

Assignment:

See 3-phase motor (Spec_13)

Positioning of the

connector insert

The two notches of the male connector insert are

pointing to the motor casing; PE is on the left hand side

References:

D_spec04.doc:

D_spec13.doc:

Hybrid field bus plug

3-phase motor (connection and plug assignment)

File:

Date:

D_spec10_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

1 of 4

SPEC_10

Spezifikation

Motor starters with HAN Q8 socket

Separate assembly

Motor connection via cable adapter HAN Q8-10E

Pin assignment

Requirements:

Check list

fulfilled

Requirement

Hybrid field bus

connection :

Power bus connection:

degree of protection

IP 67/68

not

fulfilled

Hybrid field bus module (for connection see Spec_04)

field bus address set by means of identification plug

1 x HAN Q 8/0 plug (power bus input)

port identification with a symbol

1 x HAN Q 8/0 socket (power bus output)

port identification with a symbol

Assignment:

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin "earth"

Motor output:

Degree of protection

IP 67/68

Assignment:

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin "earth"

File:

Optional reserved for N

L2

Reserved for e.g. brake AC resp. 24 V DC

Reserved for e.g. brake (0 V)

L3

Grooved pin to prevent exchange with the motor output

L1

PE

1 x HAN Q8/0 plug (power output)

port identification with a symbol

L1

Grooved pin to prevent exchange with the power bus

L3

Brake (0 V)

Thermistor

Brake AC resp. 24 V DC

L2

Thermistor

PE

Date:

D_spec10_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

2 of 4

SPEC_10

Spezifikation

References:

D_spec04.doc:

D_spec13.doc:

Hybrid field bus plug

3-phase motor (connection and plug assignment)

File:

Date:

D_spec10_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

3 of 4

SPEC_10

Spezifikation

Motor starter with cable and 10E socket

Separate assembly

Pin assignment

Requirements:

Check list

fulfilled

Requirement

Hybrid field bus

connection:

Power bus connection:

degree of protection

IP 67/68

not

fulfilled

Hybrid field bus module (for connection see Spec_04)

Station address set by means of identification plug

1 x HAN Q 8/0 plug (power bus input)

port identification with a symbol

1 x HAN Q 8/0 socket (power bus output)

port identification with a symbol

Assignment:

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin "earth"

Motor output:

Degree of protection

IP 67/68

Optional reserved for N

L2

Reserved for e.g. brake AC resp. 24 V DC

Reserved for e.g. brake (0 V)

L3

L1

PE

Motor connection cable via cable gland with metric

thread and 10E socket at the motor end

Line length: 1 m; 3 m; 5 m

Assignment:

See 3-phase motor (Spec_13)

References:

D_spec04.doc:

D_spec13.doc:

File:

Hybrid field bus plug

3-phase motor (connection and plug assignment)

Date:

D_spec10_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

4 of 4

SPEC_11

Spezifikation

REV. 2.0

Mechanical limit switches

The DESINA concept covers all kinds of machine devices. However, the minimum requirement is

that they must satisfy the interfaces within the system thereby helping to reduce the number of

variants.

Requirements:

Checkliste

fulfilled

Requirement

Mechanical

make contact (N.O.)

Connection

Pin assignment

Mechanical

break contact (N.C.)

Connection

Pin assignment

Mechanical

changeover contact

Connection

Pin assignment

not

fulfilled

M12 x 1

Pin 1: + 24 V DC

Pin 2 and pin 1 are bridged

Pin 3: - (0 V)

Pin 4: make contact

M12 x 1

Pin 1: + 24 V DC

Pin 2: break contact

Pin 3: - (0 V)

Pin 4: - (not connected, assigned for make contact only)

M12 x 1

Pin 1: + 24 V DC

Pin 2: break contact

Pin 3: - (0 V)

Pin 4: make contact

References:

D_spec01.doc:

Pin assignment of I/O boxes and sensors/actuators

File:

Date:

D_spec11_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

1 of 1

SPEC_12

Spezifikation

REV. 2.0

Cable colour code

This cable colour code defines the DESINA cable colours enabling

a transparent functional wiring,

the indication of potential danger by the voltage.

Requirements:

Check list

Function

Requirement

Guide value

Shielded power lines, servo-lines, frequency

converters etc.

Transmitter lines:

Linear and rotary transmitters, analog

sensors, etc

Field bus:

Hybrid field bus line

(cf. D_spec03)

Orange

RAL 2003

Green

RAL 6018

Switched peripherals, sensors,

pneumatic/hydraulic valves, proximity

switches, pressure switches, etc

Power lines:

appliance supply, 3-phase motors

Control lines

24V DC supply

fulfilled

not

fulfilled

Violet

RAL 4001

4 x 1.5 mm2 2,5 mm2 Cu

2 x POF or shielded

two-wire bus

Yellow

RAL 1021

2

4 x 0.34 mm

Black

RAL 9005

Grey

RAL 7040

The cable sheath must be resistant to coolants and lubricants used in industry. The lines must be

designed for use on machines located in a hostile environment. This includes energy chain

applications. Where the line sections are not specified they can be chosen freely, however they must

conform to the relevant standards and directives and the specific application requirements.

File:

Date:

D_spec12_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

1 of 1

SPEC_13

Spezifikation

REV. 2.0

3-phase motors,

connections and pin assignment

Requirements:

Check list

fulfilled

Requirement

Motor connection:

Degree of protection

IP 67/68

Assignment:

10E plug with longitudinal single bracket fastening direction for fastening: towards the motor. PE on the

left side facing the cable end of the socket

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Winding termination U1

Winding termination V1

Winding termination W1

Brake (reference potential)

Brake

Winding termination W2

Winding termination U2

Winding termination V2

Temperature sensor (socket a) or

temperature switch (n.c.)

Temperature sensor (socket b) or

temperature switch (n.c.)

Coding of contact inserts not specified

Pin 10

Coding

not

fulfilled

References:

D_spec09:

D_spec10:

File:

Motor starters (Function)

Motor starters (Pin assignment)

Date:

D_spec13_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

1 of 2

SPEC_13

Spezifikation

View of the motor plug 10E and the single bracket fastening mounted on a motor together with the

pin assignment.

File:

Date:

D_spec13_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

2 of 2

SPEC_14

Spezifikation

REV. 2.0

Sensor-actuator lines

Requirements:

Check list

fulfilled

Requirement

Wire section

Design

Sheath colour

Type of cable sheath

Connections

Standard lengths

Indicators

*) Note:

not

fulfilled

4 x 0.34mm2

Suitable for industrial applications. European directives

and relevant standards have to be met.

Yellow, RAL 1021 - guide value

The line coating must be resistant to industrial

lubricants and coolants.

M12x1 plug/socket, 4-pin, moulded:

one end socket, one end plug

cable output : straight or angled

0.3m/0.6m/1.0m/1.6m/2m Special lengths possible

None*)

No LED or other components are built into the connector housings.

LED or other loads would prohibit the concept of cable break monitoring.

References:

D_spec01.doc:

D_spec02.doc:

D_spec06.doc:

D_spec07.doc:

D_spec08.doc:

D_spec11.doc:

D_spec12.doc:

File:

M12-pin assignments I/O box

Functions of I/O box

Sensors

Hydraulic valves

Pneumatic valves

Mechanical limit switches

Cable color code

Date:

D_spec14_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

1 of 1

SPEC_15

Spezifikation

REV. 2.0

M12 - identification plugs

for local coding of I/O boxes

A passive identification plug is needed for DESINA I/O boxes based on the M12 x 1 plug. This plug

is mechanically linked to a part of the machine.

Requirements:

Check list

fulfilled

Requirement

Type

Degree of protection

Number of pins

Design

M12 x 1

IP67

8

Male

Pin assignment

Pin 1:

Pin 2:

Pin 3:

Pin 4:

Pin 5:

Pin 6:

Pin 7:

Pin 8:

not

fulfilled

D0

D1

D2

D3

D4

D5

D6

GND

Mechanical properties: Fixture for a chain etc.

Addresses from 0 to 127 can be set in binary code. The address 0 must not be used. This is to

identify whether an identification plug is inserted or not.

Note: The coding itself is not stipulated.

File:

Date:

D_spec15_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

1 of 2

SPEC_15

Spezifikation

Pin out:

5

6

4

3

7

2

1

Example:

References:

D_spec02.doc:

File:

Functional scope of I/O box

Date:

D_spec15_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

2 of 2

SPEC_16

Spezifikation

REV. 2.0

Analog sensors

- general Here, the basic requirements for analog sensors are described which guarantee the trouble-free

functioning of an analog sensor with the I/O box as defined in Document D_spec02.

Requirements:

Check list

fulfilled

Requirement

Connection

M12 x 1 plug

Male

Pin assignment

Pin 1: + 24 V DC

Pin 2: analog output signal 4-20 mA

The diagnostic feedback is implicitly

effected by:

< 4 mA cable break, complete failure

> 21 mA internal failure

Pin 3: 0 V

Pin 4: not assigned - optionally output

Pin 5: not assigned

Degree of protection

IP 67

Output signal

(Pin 2)

4-20 mA 0 100% measuring range

Electrical construction

Measuring transducer 2- or 3-wire switch

Rated voltage: 24 V DC

Operating voltage: 18 V DC - 30 V DC

Indicator

Suitable indication of the analog signal should be

incorporated *)

Diagnosis

By injected current (see pin assignment)

File:

Date:

D_spec16_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

not

fulfilled

Page:

Rev. 2.0

1 of 2

SPEC_16

Spezifikation

*)

Note 1:

Note 2:

Only valid for the 3-wire type:

Example: A yellow LED shows a measured value which is more than 10% of the

range. The LED should be seen from all sides around the sensor or four LED should

be placed on the periphery with a 90 angle in between. - Also other methods of

representation such as numeric oder bar representation are possible.

The change in pin assignment was necessary for several reasons:

- The functions of the power signal are extended, for the diagnosis functionality

can be easily implemented.

- The damage of the sensors caused by a misconnection to a binary output of the

field bus node will be prevented.

References:

D_spec01:

D_spec02:

D_spec06:

File:

M12-pin assignment

Functional scope of I/O box

Inductive proximity switch

Date:

D_spec16_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

2 of 2

SPEC_17

Spezifikation

REV. 2.0

Test adapter for M12 plug connector

Despite the diagnostic function of the field devices and the indicator possibilities of the I/O box it is

necessary to carry out specific measurements and simulations of the sensors and actuators in the

case of a failure. A test adapter is needed for access to the signal lines with which the individual

signals can be connected to measuring and testing instruments.

Requirements:

Check list

fulfilled

Requirement

I/O ports

3 options of connection - 2 M12 ports, 1 measuring port

Connections

M12 x 1 plug

Male contact

M12 x 1 socket

Female contact

Instrumentation port: 3 test points according to pins 1, 3,

4; 2 test points on pin 2 and 5 each of the 2 M12 ports

Pin assignment

Pin 1:

Pin 2:

Pin 3:

Pin 4:

Pin 5:

Electrical design

The 2 M12 ports are wired one by one, pin 2 and 5 of

each port are linked to the test port

not

fulfilled

+ 24 V DC

diagnosis / power

0V

Output signal

not assigned

References:

D_spec01

D_spec02

File:

M12-pin assignment

Functional scope of I/O box

Date:

D_spec17_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

1 of 2

SPEC_17

Spezifikation

Diagram:

1

1

4

4

5

5

3

3

1 5 2 2 4 5 3

Testport

File:

Date:

D_spec17_engl_mo 08.12.2003

d.doc

Updated:

08.12.2003

Page:

Rev. 2.0

2 of 2

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Cable TerminalsDocument134 pagesCable TerminalsmarcosimuloNo ratings yet

- Trident Neptune CircularDocument16 pagesTrident Neptune CircularmarcosimuloNo ratings yet

- Sitecom WLXDocument30 pagesSitecom WLXmarcosimuloNo ratings yet

- Tropica Katalog 2012 ENG NyDocument68 pagesTropica Katalog 2012 ENG NyAlejandro Jorge DominguezNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chapter 4 SlidesDocument36 pagesChapter 4 Slidesmekonen100% (2)

- Odi 065R16NB17JJJ GDocument1 pageOdi 065R16NB17JJJ GMARCO ROALCABANo ratings yet

- Outdoor Directional Penta-Band Antenna: ODI-065R15MJJJJ-GQDocument4 pagesOutdoor Directional Penta-Band Antenna: ODI-065R15MJJJJ-GQAnonymous OM5uU6100% (1)

- Sh79f166 App - Note v2.1Document21 pagesSh79f166 App - Note v2.1nongNo ratings yet

- Avaya Switch - NN47203-300!02!01 - QuickInstallGuideDocument2 pagesAvaya Switch - NN47203-300!02!01 - QuickInstallGuideJames HavocNo ratings yet

- 2SD2012Document6 pages2SD2012Martin SitholeNo ratings yet

- 11.Zero-Crossing Detector For AcDocument6 pages11.Zero-Crossing Detector For AcSourabh kulkarniNo ratings yet

- Ds Esprimo Mobile v6535Document4 pagesDs Esprimo Mobile v6535kasem_beNo ratings yet

- CAN BusDocument7 pagesCAN BusMihnea DobreNo ratings yet

- 4CH HDMI To ISDB-T Encoder Modulator User's Manual PDFDocument28 pages4CH HDMI To ISDB-T Encoder Modulator User's Manual PDFVladimir PeñarandaNo ratings yet

- MaximumDisplacementSweepMDSweep PDFDocument5 pagesMaximumDisplacementSweepMDSweep PDFMustapha ChettouhNo ratings yet

- MGS1600GY: Precision Magnetic Track Following Sensor With GyrosopeDocument21 pagesMGS1600GY: Precision Magnetic Track Following Sensor With GyrosopeDwi SaputroNo ratings yet

- User Manual For ItronSL7000 Electricity Metering Modem v2 60 En-1Document16 pagesUser Manual For ItronSL7000 Electricity Metering Modem v2 60 En-1Santiago MuñozNo ratings yet

- SJ-20200929135033-015-ZXA10 C680&C600&C650&C620 (V1.2.1) Optical Access Aggregation Equipment Routine Maintenance - 996110Document44 pagesSJ-20200929135033-015-ZXA10 C680&C600&C650&C620 (V1.2.1) Optical Access Aggregation Equipment Routine Maintenance - 996110paulo gadelhaNo ratings yet

- Genius IO Modules PDFDocument284 pagesGenius IO Modules PDFCharanNo ratings yet

- Motorola S10-HD Bluetooth Headphones Manual (EN)Document22 pagesMotorola S10-HD Bluetooth Headphones Manual (EN)Jeff0% (2)

- BELDEN STP Cat6 PDFDocument5 pagesBELDEN STP Cat6 PDFRD LumNo ratings yet

- Eee Exp 6Document6 pagesEee Exp 6nupoor rajNo ratings yet

- OGC-FIC-004-I-Cable Insulation Resistance-Field Installation ChecklistDocument2 pagesOGC-FIC-004-I-Cable Insulation Resistance-Field Installation ChecklistTaylorNo ratings yet

- AT Command Set (MTK)Document170 pagesAT Command Set (MTK)ivankinoman387650% (2)

- Komunikasi Data: TEE 843 - Sistem TelekomunikasiDocument69 pagesKomunikasi Data: TEE 843 - Sistem Telekomunikasi1A R. Moch Rizky Sunandar SaputraNo ratings yet

- Electronics 1 (1st Exam) ADocument24 pagesElectronics 1 (1st Exam) AcyarakkNo ratings yet

- Module5 6 Imp QuestionsDocument8 pagesModule5 6 Imp Questionsnikita SinghNo ratings yet

- Wattio Mobilemanual Gate EsDocument17 pagesWattio Mobilemanual Gate EsalienstrikesNo ratings yet

- Flex6012a R71Document1 pageFlex6012a R71yaserNo ratings yet

- C12-Electromagnetic WavesDocument74 pagesC12-Electromagnetic WavesGerald S. FernandezNo ratings yet

- ZTE Cours 1Document37 pagesZTE Cours 1Mohammad AslamNo ratings yet

- Design Examples Using The ToolboxDocument23 pagesDesign Examples Using The Toolboxrajeevjain09No ratings yet

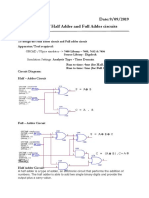

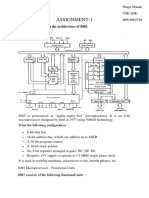

- MPMC Assignment-1Document7 pagesMPMC Assignment-113Panya CSE2No ratings yet

- Hardware Design For Machine LearningDocument22 pagesHardware Design For Machine LearningAdam HansenNo ratings yet