Professional Documents

Culture Documents

52 Filtrex Brochure

Uploaded by

CvitaCvitićCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

52 Filtrex Brochure

Uploaded by

CvitaCvitićCopyright:

Available Formats

best performing filter

FILTREX ACB The

according to IMO requirements

NO COMPETITION No other filter on the market is able to match or even come close to the performance of the ACB

filter for operation with high TSS, reliability, filtration and backwashing efficiency, durability, easy

operation and maintenance. Since 1982 FILTREX has installed worldwide thousands of filters with

the same operating principle.

NO WEAKNESSES

MANY ADVANTAGES

The filter operates continuously, with a precise filtration degree (down to 6 m). The armored filter element is made of stainless steel and is able to withstand high differential pressures without

problems. The filter body and internal parts are built entirely of bronze-aluminum alloy ASTM B148

C95800 with a strict quality control system, approved by all major classification organizations.

Ability to operate with high TSS

Compact dimensions in both height and footprint, even in the presence of the backwashing

pump, that is directly connected to the filter.

The bronze aluminum construction guarantees a high durability, even with improper maintenance.

No need for painting, which may get easily damaged.

Simple: made of a few elements for easy, fast and accurate maintenance.

Reduced flow of backwash.

High regeneration capacity of the filter element, in just a few seconds.

Long service life of the filter element.

Great filtration efficiency (down to 6 m).

Completely manufactured by Filtrex in the Milano (Italy) factory.

Large stock available.

New application of an established technology with proven experience.

IMO approved manual.

FILTREX ACB The protector of Disinfection Systems

The comparative analysis carried out by approved certifying bodies, on samples collected during the IMO certification in diverse oceans, with varying degrees of filtration (in addition to the traditional 40 m) demonstrated the high capacity of the

ACB filter to remove zooplankton, with an efficiency increase of 85%, from 40 m (Average Zooplankton. inds./m3 582) to

20 m (Average Zooplankton. inds./m3 87).

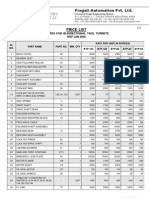

FILTREX ACB Sizing

Footprint dimensions

(without backwashing pump)

Installed

Power (kW)

Size

ND

m3/h (5%)

@ p 0.1 bar

40 m

Backwash

flow

(lt/sec)

filter

pump

902

50

25

1,70

0,36

0,36

0,13

0,12

1,10

61

903

65

35

2,15

0,36

0,36

0,13

0,12

1,10

62

904

80

55

2,66

0,36

0,36

0,13

10

0,12

1,10

73

906

100

87

4,09

0,36

0,36

0,13

12

0,12

1,10

104

910

150

135

6,82

0,45

0,45

0,20

27

0,12

1,50

164

915

150

190

9,55

0,50

0,50

0,25

37

0,12

2,20

198

935

200

255

9,55

0,55

0,55

0,30

46

0,18

2,20

232

945

200

340

12,82

0,55

0,55

0,30

75

0,18

3,00

330

955

250

515

12,82

0,70

0,70

0,49

140

0,25

3,00

440

985

300

770

19,22

0,80

0,80

0,64

210

0,37

4,00

653

999

350

1040

25,95

0,85

0,85

0,72

320

0,37

5,50

842

9100

400

1385

34,60

0,90

0,90

0,81

500

0,37

9,20

1350

9140

500

2080

25,95

1,40

1,40

1,96

1400

0,75

5,50

2085

9200

600

3000

36,81

1,40

1,40

1,96

1900

0,75

9,20

2800

mxm

m3

Volume

(lt)

FILTREX ACB Choice of the Configuration

Depending on the operational requirements, the ACB filter can also be supplied with the following

accessories:

Electric panel

Backwash pump

Bronze aluminium fittings for filter by-pass

Automatic valves for venting, draining and refilling.

FILTREX ACB Technical Informations

Application

Type of filter

Filtration

Cleaning cycle

Cleaning system

Cleaning fluid

Power supply

Nominal Pressure

Inlet/Outlet connections

Nominal Temperature

Material

Building tolerances

Gaskets

Type of filtering element

Filtering element material

Filtration degree

Ship ballast water treatment units, fresh, brackish and sea water

Automatic backwashing

Continuous

By differential pressure and/or timer

Backwash by reverse flow, sector by sector

Same filtered fluid

Electric and pneumatic

From 2 to 10 bar

From ND 50 to ND 600, NP 10

60 deg C

Bronze-Aluminium alloy ASTM B148 C95800

EN 226768-1 class V

Buna

Armored pleated element

Stainless Steel AISI 316L

Down to 6 m

Weight

(kg)

FILTREX ACB Operation

PHASE 1 - FILTRATION

p < p set

Differential pressure gauge ! in "clean" condition

Electric motor " in off position

Backwashing shaft # not rotating

Backwashing valve $ closed

Backwashing pump (optional) % in off position.

1 - FILTRATION: The fluid enters from !, and flows through the sectors of the filter element & (filtration from inside

to outside). The filtered fluid is conveyed into the chamber

" and exits from #.

During this phase, the filter operates as a static filter, and

the cleaning of the filter element is

not active. As the impurities accumulate in the filter element sectors, the differential pressure p

indicated by the pressure gauge

! increases gradually until it reaches the set value, starting phase

2 (backwash cleaning during filtration).

PHASE 2 - FILTRATION and CLEANING

p p set

Differential pressure gauge ! reaches the set value

Electric motor " in on position

Backwashing shaft # rotating

Backwash valve $ open

Backwashing pump (optional) % in on position.

1 - FILTRATION: The filtration is carried on all sectors of the

filter element (filtration from inside to outside), to the exclusion

of the one in correspondence to the backwashing shaft.

2 - CLEANING THE FILTER DURING FILTRATION: While all

sectors of the filter element ensure normal filtration, the sector

in correspondence to the backwashing shaft is cleaned by reverse flow drawn from the filtered fluid chamber " (washing

from outside to inside). The impurities are transported by the

same backwashing fluid, through the chamber $ and the duct

', before leaving from %. In conditions of low pressure the optional

pump % ensures the flow.

At the end of the backwashing cycle,

the electric motor " stops, the

backwash valve $ closes and the

pump (optional) is turned off, bringing the filter back to the Phase 1

(static filtration).

At Work FILTREX ACB

ACB filters have been tested and certified by the leading certifying organizations. Thanks to its small dimensions the automatic filter ACB may be

installed in tight spaces, on all new

and existing ships

Filter ACB-955 - filtration degree 40 m, flowrate 500 m3/h - tested at DHI, Denmark. Type approved by Bureau Veritas

Filter ACB-935 - flowrate 250 m3/h - tested at NIOZ at

various filtration degrees, 40 to 6 m. Approved by LLRR

Filter ACB-999 on test bench. Flowrates up to 4200 m3/h.

Filtrex R&D Centre, Vignate

Filter ACB-935 - filtration degree 40 m, flowrate 250 m3/h - tested for 2 cycles IMO G8 at NIVA, Norway. Type approved by DNV

FILTREX a worldwide organization

Filtrex s.r.l. with its headquarters and state of the art manufacturing

facilities in Milano, Italy provides filtration solutions and technical

services to many industries such as hydrocarbon, chemical, environment protection, power generation, water treatment, Navy and

marine transport. Filtrex operates from its headquartes in Italy and

through worldwide branches, and has received prestigious certifications

for quality and standards of engineering and manufacturing.

Filtrex provides its customers with a comprehensive scope of

work, services and supply, preparing the engineering design specifications and P&IDs, purchasing equipment and materials, fabricating and assembling the filters into module(s) in its fabrication

shop, furnishing data books and operating manuals, and providing

technical services for inspection, installation, commissioning,

start up and after start up.

Filtrex Corporate Headquartes - Milano (Italy)

Filtrex Manufacturing Unit #4 - Vignate (Italy)

ACB is only one of the comprehensive range of filters manufactured by FILTREX.

Please contact us for details and documentation

FILTREX

s.r.l.

CORPORATE HEADQUARTERS

Via R. Rubattino 94/B - 20134 Milano (ITALY) tel: +39 027 533 841- fax: +39 027 531 383 - www.filtrex.it - info@filtrex.it

NORTH AMERICA

SOUTH AMERICA

INDIA

CHINA

J A PA N

FILTREX USA LLC

Virginia Beach, VA23455

USA

FILTREX de VENEZUELA C.A.

8050 Puerto Ordaz - Estado Bolivar

VENEZUELA

FILTREX systems INDIA Pvt. Ltd.

Mumbai 400 072,

INDIA

FILTREX CHINA LLC.

Shanghai 200135,

P.R. CHINA

FILTREX JAPAN Co. Ltd

Kobe Chuo-ku, Hyogo 651-0083

JAPAN

T10.13.GB

Agents worldwide

For details please contact our headquarters or visit www.filtrex.it

Certified

Quality:

ISO 9001 - ISO 14001

AD-HP0

NATIONAL BOARD

U-STAMP

NATO AQAP-110

U.S. NAVY

You might also like

- Alfa Laval Mab 103 24 Spare Parts Manual SPCDocument58 pagesAlfa Laval Mab 103 24 Spare Parts Manual SPCJonathan LisboaNo ratings yet

- Gunclean Toftejorg T-73 Fixed IM-TE91A450-En3Document39 pagesGunclean Toftejorg T-73 Fixed IM-TE91A450-En3cengiz kutukcuNo ratings yet

- PB-05479 v00 PB300 Compact Flex OPDocument463 pagesPB-05479 v00 PB300 Compact Flex OPMichail AleksandrovNo ratings yet

- BTPX Series BTPX 305 SDocument4 pagesBTPX Series BTPX 305 SmcsabeeraliNo ratings yet

- CS Candy BWTS Manual PB-05889 - v0 PDFDocument658 pagesCS Candy BWTS Manual PB-05889 - v0 PDFNikul PanchalNo ratings yet

- Alpacon ALTREAT 400Document2 pagesAlpacon ALTREAT 400ECO Green and BlueNo ratings yet

- Instruction - Cleaning Dolphin-JWP-DPUDocument5 pagesInstruction - Cleaning Dolphin-JWP-DPUGiovanni ColonnaNo ratings yet

- Price List: Spares For Bi-Directional Tool Turrets WEF JAN 2006Document2 pagesPrice List: Spares For Bi-Directional Tool Turrets WEF JAN 2006Arvinder SinghNo ratings yet

- JWP-26-C100 92&92 DrawingDocument82 pagesJWP-26-C100 92&92 DrawingSANDEEPNo ratings yet

- SJ 08 - BrochureDocument2 pagesSJ 08 - BrochureCentrifugal SeparatorNo ratings yet

- Instruction For RBP250-3 and RBP300-3: Anti-Heeling PumpDocument13 pagesInstruction For RBP250-3 and RBP300-3: Anti-Heeling PumpJan MaarschalkerweerdNo ratings yet

- Afpx 517Document2 pagesAfpx 517banerjeeamlanNo ratings yet

- Fesx 412B-30Document74 pagesFesx 412B-30Anonymous mGZOP8No ratings yet

- W-M-2421 - Otc 2Document2 pagesW-M-2421 - Otc 2Danny AriasNo ratings yet

- Filtrex (Eng)Document49 pagesFiltrex (Eng)hamidouhouNo ratings yet

- Kral PumpDocument12 pagesKral PumpBulbul AhmedNo ratings yet

- AFPX 407 Leaflet PDFDocument2 pagesAFPX 407 Leaflet PDFยุทธนา เทียมเมืองNo ratings yet

- Future-Series - Operation Manual 2 - Fie-2000-01-Om2 - Scan3Document106 pagesFuture-Series - Operation Manual 2 - Fie-2000-01-Om2 - Scan3Centrifugal SeparatorNo ratings yet

- Purifier System, PA 605/615: Cleaning System For Fuel and Lubricating OilsDocument4 pagesPurifier System, PA 605/615: Cleaning System For Fuel and Lubricating OilsJohn Lemuel Arquisola0% (1)

- Automatic Separation Systems: ApplicationDocument4 pagesAutomatic Separation Systems: ApplicationJoao FernándezNo ratings yet

- Alfa Laval PHE For REFDocument4 pagesAlfa Laval PHE For REFNiraj ReginaldNo ratings yet

- Performance To Boost Power Generation - GEA Westfalia Separator EagleclassDocument20 pagesPerformance To Boost Power Generation - GEA Westfalia Separator EagleclassbanerjeeamlanNo ratings yet

- 0820 9001 000 - Moc515 Moc8015Document58 pages0820 9001 000 - Moc515 Moc8015gaby2003100% (1)

- OSD Type Engl Separator WestfaliaDocument8 pagesOSD Type Engl Separator WestfaliaLTE002No ratings yet

- Hiller DECANTERDocument4 pagesHiller DECANTERINDRAJIT SAO100% (1)

- Hoi Tung Zhejiang SY Hull - ZJ2001-2010 Air Compressor Approval Dokumentation SSM 41006266 PDFDocument126 pagesHoi Tung Zhejiang SY Hull - ZJ2001-2010 Air Compressor Approval Dokumentation SSM 41006266 PDFWee WeeNo ratings yet

- Tranter PHE GCD-09 X 43Document4 pagesTranter PHE GCD-09 X 43alokNo ratings yet

- Aqua CubicDocument7 pagesAqua CubicdanieleNo ratings yet

- TD - GSC 15-06-177 - Ecoplus - EN - KL - 4Document2 pagesTD - GSC 15-06-177 - Ecoplus - EN - KL - 4banerjeeamlanNo ratings yet

- MSPXDocument2 pagesMSPXMarc van der LindeNo ratings yet

- Aldec Decanter CentrifugeDocument4 pagesAldec Decanter CentrifugejailtonpierreNo ratings yet

- Separator Spares InternationalDocument8 pagesSeparator Spares InternationalAlexanderNo ratings yet

- Evaporator "Alfa Laval"Document22 pagesEvaporator "Alfa Laval"Jittipong HomchitNo ratings yet

- Product Range Alfa LavalDocument13 pagesProduct Range Alfa LavalSoficu DanielNo ratings yet

- Project Guide G50ME C9 - 6 GIDocument674 pagesProject Guide G50ME C9 - 6 GIΚώστας ΧατζηδάκηςNo ratings yet

- Emerson - 3582 Series Valve Positioners Type 3582i - ENDocument48 pagesEmerson - 3582 Series Valve Positioners Type 3582i - ENjulsaezNo ratings yet

- Eyewash Pb7500Document93 pagesEyewash Pb7500Muhd Khir RazaniNo ratings yet

- GEA Separator enDocument4 pagesGEA Separator enApurba Sen SinghaNo ratings yet

- FlowPak - V725 - ANSI - English Veersion Free For Client PDFDocument12 pagesFlowPak - V725 - ANSI - English Veersion Free For Client PDFMisael Castillo CamachoNo ratings yet

- Feed Pump Long TypeDocument20 pagesFeed Pump Long TypeSyam NairNo ratings yet

- HH 845 Render Pure Parts ManualDocument20 pagesHH 845 Render Pure Parts ManualhelbertortizNo ratings yet

- Compatible Spare Parts FOR Centrifugal Separators: Alfa LavalDocument4 pagesCompatible Spare Parts FOR Centrifugal Separators: Alfa LavalJerom RonquilloNo ratings yet

- Installation System Reference: Separation Unit 831/841Document92 pagesInstallation System Reference: Separation Unit 831/841alex_alexutzuuNo ratings yet

- Seepex Pumps Application Work Sheet: Your DetailsDocument1 pageSeepex Pumps Application Work Sheet: Your DetailseduinNo ratings yet

- FWG Explained (Autosaved)Document21 pagesFWG Explained (Autosaved)Junehenry YalduaNo ratings yet

- Steam Generator NGCDocument78 pagesSteam Generator NGCfadi assi100% (1)

- Toyota Cleaner Degraesing Silicon Remover AIM 003 516 0Document5 pagesToyota Cleaner Degraesing Silicon Remover AIM 003 516 0Antonio MartinezNo ratings yet

- 9.5 Oil Purifier - Maintenance ManualDocument104 pages9.5 Oil Purifier - Maintenance Manualsumitchandwaniseros equiptransNo ratings yet

- Separator Manual High Speed Separator: MMB 305S-11Document164 pagesSeparator Manual High Speed Separator: MMB 305S-11Bima Surya UtamaNo ratings yet

- PX 70 - 80 - (Non EX & EX) - Foundation DrawingDocument1 pagePX 70 - 80 - (Non EX & EX) - Foundation DrawingCentrifugal SeparatorNo ratings yet

- Double Lens Navigation Lights: Series 70MDocument2 pagesDouble Lens Navigation Lights: Series 70MbjornutNo ratings yet

- SenseiViewIB Show2 PDFDocument272 pagesSenseiViewIB Show2 PDFkarlo adolfoNo ratings yet

- Epc 50Document1 pageEpc 50mihalikj2190No ratings yet

- SJ30FDocument2 pagesSJ30FRizky Dwi100% (1)

- Reflex - Pressurisation - Gian No-Dieu ApDocument52 pagesReflex - Pressurisation - Gian No-Dieu ApLe Van Phong100% (1)

- Alfa Laval Manaul 26 C 100 PDFDocument131 pagesAlfa Laval Manaul 26 C 100 PDFMARCO VERAMENDINo ratings yet

- Shanghai Test Results - Filtersafe White PaperDocument21 pagesShanghai Test Results - Filtersafe White PaperBlack PantherNo ratings yet

- Eaton Tubular Backwashing AFC AFR & F-Series FiltersDocument14 pagesEaton Tubular Backwashing AFC AFR & F-Series FiltersJuan CarvajalNo ratings yet

- Water Filters Residential 5600SXT Chemical Free Iron Filters ENGLISH Canadian BrochureDocument4 pagesWater Filters Residential 5600SXT Chemical Free Iron Filters ENGLISH Canadian BrochurePromagEnviro.comNo ratings yet

- Technical Proposal For Olympic Pool PDFDocument10 pagesTechnical Proposal For Olympic Pool PDFAlma DerajNo ratings yet

- Nu-Calgon Product Bulletin: Cal-Brite PlusDocument2 pagesNu-Calgon Product Bulletin: Cal-Brite PlusCvitaCvitićNo ratings yet

- CN Ecommerce Onboarding Declaration Non Dangerous Dry Batteries enDocument1 pageCN Ecommerce Onboarding Declaration Non Dangerous Dry Batteries enCvitaCvitićNo ratings yet

- Nitric Acid, 70% W/W: Safety Data SheetDocument9 pagesNitric Acid, 70% W/W: Safety Data SheetMuhammad AfifNo ratings yet

- CN Ecommerce Onboarding Declaration Non Dangerous Dry Batteries enDocument1 pageCN Ecommerce Onboarding Declaration Non Dangerous Dry Batteries enCvitaCvitićNo ratings yet

- ABS Guide - Inventory of Hazardous Materials PDFDocument75 pagesABS Guide - Inventory of Hazardous Materials PDFOctopusNo ratings yet

- Nu-Calgon Product Bulletin: CalcleanDocument1 pageNu-Calgon Product Bulletin: CalcleanCvitaCvitićNo ratings yet

- Nitric Acid, 70% W/W: Safety Data SheetDocument9 pagesNitric Acid, 70% W/W: Safety Data SheetMuhammad AfifNo ratings yet

- T3A80B-2 1,1KW 230/400V B14: Three-Phase Asynchronous Motor in AluminumDocument1 pageT3A80B-2 1,1KW 230/400V B14: Three-Phase Asynchronous Motor in AluminumCvitaCvitićNo ratings yet

- Wartsila SP A Id Slow Steaming PDFDocument7 pagesWartsila SP A Id Slow Steaming PDFCvitaCvitićNo ratings yet

- Imo Inert Gas SystemDocument95 pagesImo Inert Gas SystemMehmet Tokad93% (14)

- Leitz - Lexicon - Edition - 7 - 01 - Kruzne - Pile - EnglDocument69 pagesLeitz - Lexicon - Edition - 7 - 01 - Kruzne - Pile - EnglJura OkrešaNo ratings yet

- Lombard in IDocument6 pagesLombard in ICvitaCvitić0% (1)

- Energy EfficiencyDocument76 pagesEnergy Efficiencydan_artimof100% (1)

- Microbes Ocean Acidification 2009 PDFDocument23 pagesMicrobes Ocean Acidification 2009 PDFCvitaCvitićNo ratings yet

- CapturaCO2 TecnicalSummary EnglishDocument34 pagesCapturaCO2 TecnicalSummary Englishapi-3852515No ratings yet

- International Shipping The First Industry With A Global Climate StandardDocument5 pagesInternational Shipping The First Industry With A Global Climate StandardCvitaCvitićNo ratings yet

- Chapter 18 - Photosynthesis: LightDocument11 pagesChapter 18 - Photosynthesis: LightCvitaCvitićNo ratings yet

- Measures To Improve Energy Efficiency in ShippingDocument10 pagesMeasures To Improve Energy Efficiency in ShippingCvitaCvitićNo ratings yet

- Ozone NOxDocument13 pagesOzone NOxCvitaCvitićNo ratings yet

- Nitrogen Oxides Emissions: Report On The Environment HTTP://WWW - Epa.gov/roeDocument5 pagesNitrogen Oxides Emissions: Report On The Environment HTTP://WWW - Epa.gov/roeCvitaCvitićNo ratings yet

- Essd 7 349 2015 PDFDocument48 pagesEssd 7 349 2015 PDFCvitaCvitićNo ratings yet

- Climate NewsDocument7 pagesClimate NewsCvitaCvitićNo ratings yet

- Shipping Solutions:: Technological and Operational Methods Available To Reduce CoDocument28 pagesShipping Solutions:: Technological and Operational Methods Available To Reduce CoCvitaCvitić100% (1)

- Rightship GHG Emission RatingDocument27 pagesRightship GHG Emission Ratingscribdtaker12345No ratings yet

- Methane Analysis Fs enDocument4 pagesMethane Analysis Fs enCvitaCvitićNo ratings yet

- Cruise Report 2016 PDFDocument2 pagesCruise Report 2016 PDFCvitaCvitićNo ratings yet

- Print Acidity 2016Document7 pagesPrint Acidity 2016CvitaCvitićNo ratings yet

- NOx Formation PDFDocument56 pagesNOx Formation PDFCvitaCvitić100% (1)

- DP806 WebDocument28 pagesDP806 WebCvitaCvitićNo ratings yet

- Interpretation of The Mandatory Requirements For UMS ShipsDocument7 pagesInterpretation of The Mandatory Requirements For UMS ShipsCvitaCvitićNo ratings yet

- PRACTICAL NO. 2 (Particle Size Distribution)Document3 pagesPRACTICAL NO. 2 (Particle Size Distribution)slawek780303No ratings yet

- SmartCityPlan Patna PDFDocument92 pagesSmartCityPlan Patna PDFAvi AchyutNo ratings yet

- ETYS 2016 Appendix A - 3Document1 pageETYS 2016 Appendix A - 3ChairimanNo ratings yet

- Onboard Maintenance Painting GuideDocument12 pagesOnboard Maintenance Painting Guideislima100% (1)

- CHITOSAN WITH Citrus Bergamia (BERGAMOT) OIL AS A PROTECTIVE COATING IN PRESERVING QUALITY AND PROLONGING SHELF LIFE OF Raphanus Sativus (RADISH)Document39 pagesCHITOSAN WITH Citrus Bergamia (BERGAMOT) OIL AS A PROTECTIVE COATING IN PRESERVING QUALITY AND PROLONGING SHELF LIFE OF Raphanus Sativus (RADISH)Shaina AustriaNo ratings yet

- Fujipress - JDR 7 5 9 - PreviewDocument2 pagesFujipress - JDR 7 5 9 - Previewgivazahara0% (1)

- Act 2 3 11 Calculating Property DrainageDocument8 pagesAct 2 3 11 Calculating Property Drainageapi-247437088No ratings yet

- Cemented SandsDocument9 pagesCemented SandsAnonymous kxOcSmhcNo ratings yet

- R. F. J. Jones and D. G. Bird - Roman Gold-Mining in North-West Spain, II Workings On The Rio DuernaDocument21 pagesR. F. J. Jones and D. G. Bird - Roman Gold-Mining in North-West Spain, II Workings On The Rio DuernaLuciusQuietusNo ratings yet

- Long Term Average Monthly Discharge: SUPER Inkhu Hydropwer Project-Option ADocument2 pagesLong Term Average Monthly Discharge: SUPER Inkhu Hydropwer Project-Option APraveen ChaudharyNo ratings yet

- Hydrology and Water Resources3Document26 pagesHydrology and Water Resources3Hazem AlmasryNo ratings yet

- Economic Geography IndiaDocument86 pagesEconomic Geography Indianilofer shallyNo ratings yet

- DENR Administrative Order 35Document15 pagesDENR Administrative Order 35Gabrielo BarrinuevoNo ratings yet

- IS 8329 - DI Pipe Specifications For Water, Gas & SewageDocument27 pagesIS 8329 - DI Pipe Specifications For Water, Gas & SewageChungath Linesh50% (2)

- Global Warming Speech ContestDocument4 pagesGlobal Warming Speech ContestBahi DarusalamNo ratings yet

- Brisbin Aaron UBC 2010 EOSC Honours ThesisDocument56 pagesBrisbin Aaron UBC 2010 EOSC Honours ThesisbufaloteNo ratings yet

- Depliant EasyPACK enDocument12 pagesDepliant EasyPACK ennomi1873No ratings yet

- The Water Cycle - Docx Info ExplainedDocument2 pagesThe Water Cycle - Docx Info ExplainedWalter Ruiz HRNo ratings yet

- Bleaching: Ullmann's Encyclopedia of Industrial ChemistryDocument11 pagesBleaching: Ullmann's Encyclopedia of Industrial ChemistryjaimeNo ratings yet

- Additel ADT927 BrochureDocument1 pageAdditel ADT927 BrochureAgus Be PeNo ratings yet

- Increase Temperature Deep MineDocument44 pagesIncrease Temperature Deep MineVincent J. CataldiNo ratings yet

- Falling Head MethodDocument4 pagesFalling Head MethodYash PersÌeNo ratings yet

- Newton - Water Hyacinth AshDocument41 pagesNewton - Water Hyacinth AshAdonah Mica ObenzaNo ratings yet

- PDFDocument16 pagesPDFmayankNo ratings yet

- CPTA-CCJV-CON-MST-0004 Method Statement For Concrete WorkDocument23 pagesCPTA-CCJV-CON-MST-0004 Method Statement For Concrete WorkMihirduttaNo ratings yet

- SR-36-01-01 HAZOP TOR Rehman Production FacilityDocument30 pagesSR-36-01-01 HAZOP TOR Rehman Production FacilityMuhammad.SaimNo ratings yet

- Hydrology Presentation 1Document91 pagesHydrology Presentation 1lemi celemenNo ratings yet

- Modular Flaker/Cubelet Ice Machine: Slim-Line SeriesDocument2 pagesModular Flaker/Cubelet Ice Machine: Slim-Line SeriesJay SuguitanNo ratings yet

- Ambuja Annual Review FinalDocument116 pagesAmbuja Annual Review Finalshubhang101100% (1)

- AP PGECET 2015 Question Papers & Answer KeysDocument204 pagesAP PGECET 2015 Question Papers & Answer KeysPHANINo ratings yet

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsFrom EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsRating: 3.5 out of 5 stars3.5/5 (2)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 4.5 out of 5 stars4.5/5 (9)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialFrom EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialRating: 3.5 out of 5 stars3.5/5 (3)

- Teach Yourself Electricity and Electronics, 6th EditionFrom EverandTeach Yourself Electricity and Electronics, 6th EditionRating: 3.5 out of 5 stars3.5/5 (15)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesFrom EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesRating: 5 out of 5 stars5/5 (1)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosFrom EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosRating: 5 out of 5 stars5/5 (1)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tFrom EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tRating: 4.5 out of 5 stars4.5/5 (27)

- Analog Design and Simulation Using OrCAD Capture and PSpiceFrom EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNo ratings yet

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonFrom EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonRating: 5 out of 5 stars5/5 (2)

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)From EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Rating: 4.5 out of 5 stars4.5/5 (2)

- Build Your Own Electronics WorkshopFrom EverandBuild Your Own Electronics WorkshopRating: 3.5 out of 5 stars3.5/5 (3)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesFrom EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesRating: 5 out of 5 stars5/5 (1)

- Current Interruption Transients CalculationFrom EverandCurrent Interruption Transients CalculationRating: 4 out of 5 stars4/5 (1)

- Heat Transfer Engineering: Fundamentals and TechniquesFrom EverandHeat Transfer Engineering: Fundamentals and TechniquesRating: 4 out of 5 stars4/5 (1)

- Wearable Sensors: Fundamentals, Implementation and ApplicationsFrom EverandWearable Sensors: Fundamentals, Implementation and ApplicationsEdward SazonovNo ratings yet

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (543)

- ARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)From EverandARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)No ratings yet