Professional Documents

Culture Documents

CP 601S CP 601S: Elastomeric Firestop Sealant

Uploaded by

richard_qrOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CP 601S CP 601S: Elastomeric Firestop Sealant

Uploaded by

richard_qrCopyright:

Available Formats

Product Information

CP 601S

Product description

Elastomeric Firestop

Sealant

A silicone based firestop sealant that provides maximum

movement in fire-rated joint applications and pipe penetrations

Product features

Halogen and solvent free

Weather and UV-resistant

Asbestos free

Areas of application

Sealing construction/expansion joints

Top-of-wall joints

Metal pipes

Cable bundles

HVAC penetrations*

For use with

System Advantage / Customer Benefits

Examples

Where a gypsum wall assembly meets the underside of a

metal or concrete deck

Sealing expansion joints to impede the passage of fire, smoke

and toxic fumes

Sealing HVAC penetrations through fire-rated assemblies

* For metal ducts with dampers, consult damper manufacturer.

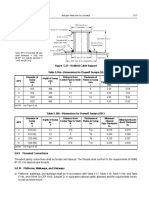

Installation instructions for CP 601S

Opening

1. Clean the opening. Joint sides and surfaces to which CP

601S will be applied must be sound, dry and free from

dust, oil and grease.

Application of firestop

2. Insert fill of mineral wool (or backer as required).

3. Apply firestop over backer.

nearest Hilti center if special requirements for chemical

resistance have to be met.

Notice about approvals

When using Hilti CP 601S Elastomeric Firestop Sealant,

check that the joint or pipe application has been sealed

according to the applicable drawing in the UL/cUL Fire

Resistance Directory or the Hilti Firestop Manual.

4. Smooth firestop sealant with a trowel before the skin forms.

Once cured, CP 601S can only be removed mechanically.

Not for use...

In areas immersed in water

5. For maintenance reasons, a penetration seal can be

permanently marked with an identification plate and

fastened in a visible position next to the seal.

Not to be painted

Chemical resistance

At room temperature the cured silicone sealant is

resistant for a short time to diluted (15%) acids and

lyes/alkalis as well as most commercially available

cleaning agents and disinfectants (except those

containing iodine).

Read the Material Safety Data Sheet

Concentrated acids and lyes/alkalis destroy silicone

rubber over time.

Storage

Store only in the original packaging in a location

protected from moisture at a temperature of 40F to

77F (5C to 25C)

Tested in accordance with

UL 2079

ASTM E 1966

UL 1479

ASTM E 814

ASTM C 920

ASTM E 84

CAN4-S115-95M

ULC-S115-95M

Internationally tested and approved

Safety precautions

Keep out of reach of children

FILL, VOID OR CAVITY MATERIAL

FOR USE IN THROUGH-PENETRATION

FIRESTOP SYSTEMS AND JOINT SYSTEMS

SEE UL FIRE RESISTANCE DIRECTORY

66Y7

Eyes and hands must be suitably protected

Avoid contact with eyes/skin

FM

Only use in well ventilated areas

APPROVED

F

2. Insert backing

material

3. Apply CP 601S

4. Smooth CP 601S

5. Fasten identification plate (if required)

| latest product information :

DUCT

www.ca.hilti.com

ESTIMATING TABLES / TECH DATA

JOINT

Observe expiration date on packaging

Firestop

System

1. Clean opening

SYSTEM DETAILS

Solvents and mineral oils cause cured silicone to swell.

Consequently, proper functioning of the sealant should

be checked after exposure to a solvent or mineral oil.

Please contact your local sales representative or the

At 73F (23C) and 50% relative humidity

Density

Approx. 1.4 g/cm3

Color

Red

Application temperature

40F to 104F (5C to 40C)

Skin-forming time

Approx. 15 min.

Curing rate

Approx. 2 mm / 3 days

Volume shrinkage

Approx. 0 5%

Movement capability

Approx. 25%

Temperature resistance

40F to 320F (40C to 160C)

Surface burning characteristics

(ASTM E84-96)

Flame spread: 0

Smoke development: 30

Sound transmission classification

(ASTM E 90-97): 50

APPLICATIONS / PRODUCTS

Simple use and application

Good adhesion without use of a primer

Smoke, fume and water resistant

Excellent movement capability, meets

500 cycle requirements

(ASTM E 1966 & UL 2079)

Meets UL requirement rating for class

I W rating

Various base materials such as masonry, concrete,

metal, glass, etc.

Wall and floor assemblies rated up to 4 hours

Technical Data

INTRODUCTION

CP 601S

| ordering information see page:

Firestop

System

1. Clean opening

2. Insert backing

material

3. Apply CP 601S

4. Smooth CP 601S

5. Fasten identification

plate (if required)

Saving Lives through innovation & education Hilti Firestop Guide 20052006 1-800-363-4458 www.ca.hilti.com

29

9

Material Safety Data Sheet

APPLICATIONS / PRODUCTS

INTRODUCTION

MSDS No.:

Revision No.:

Revision Date:

Page:

Product identifier:

CP 601S Elastomeric Firestop Sealant

Product use:

Supplier:

Originator:

Emergency number:

Fire resistant silicone based sealant for use in fire rated joint applications

Hilti (Canada) Corporation, 6790 Century Avenue, Suite #300, Mississauga, Ontario L5N 2V8

Hilti, Inc., P. O. Box 21148, Tulsa, Oklahoma, USA 74121

Chem-Trec: 1 800 424 9300

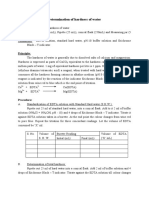

INGREDIENTS INFORMATION

Ingredient

Calcium carbonate

Polydimethylsiloxanes

Siloxanes and silicones, di-Me

Fumed silica

Methyltrimethoxysilane

CAS Number

000471-34-1

068037-58-1

063148-62-9

112945-52-5

001185-55-3

% (wt.)

45 - 55

25 - 35

20 - 40

03 - 09

01 - 05

LC50, (rat)

N/Av

N/Av

N/Av

N/Av

N/Av

LD50 (rat)

N/Av

N/Av

> 24,000 mg/kg

N/Av

N/Av

TLV

N/A

N/E

N/E

N/A

N/E

STEL

N/E

N/E

N/E

N/E

N/E

Hydrogenated castor oil

008001-78-3

<1

N/Av

> 10,000 mg/kg

N/E

N/E

PHYSICAL PROPERTIES

Appearance / Physical state:

Specific gravity (at 20C):

Vapour pressure (at 20C):

Evaporation rate:

Freezing point:

Red paste.

1.3 - 1.4

23 mbar

Not determined.

Not determined.

Odour:

VOC Content:

Vapour density:

Boiling point:

pH:

Negligible odour.

3.0 g/L

Not applicable.

Not determined.

Not determined.

Coefficient of H20 / oil distrib:

Not determined.

Solubility in water:

Negligible.

FIRE AND EXPLOSION DATA

Flash point / Method:

Conditions of flammability:

Means of extinction:

Special fire fighting procedures:

SYSTEM DETAILS

Hazardous combustion products:

Sensitivity to mechanical

impact / static discharge:

ESTIMATING TABLES / TECH DATA

REACTIVITY DATA

Stability:

Incompatible materials:

Hazardous decomposition products:

374

266C

004

08/17/04

1 of 2

TOXICOLOGICAL PROPERTIES

Routes of exposure:

Exposure limits:

Acute effects of exposure:

Chronic effects of exposure:

Synergistic materials:

Nonflammable.

Flammable limits:

Not applicable.

> 300 F / 150 C

Auto-ignition temperature:

Not applicable.

As appropriate for surrounding fire (e.g. Water, CO2, Dry Chemical, Foam).

None known. A NIOSH-approved self-contained breathing apparatus (SCBA) should be worn when fighting

fires involving chemicals.

None known. Thermal decomposition products such as oxides of carbon, carbon fluoride and formaldehyde

may be evolved at temperatures >150C/300F. The chemical nature and quantity of decomposition byproducts

will vary widely depending on the conditions of combustion.

Not susceptible to mechanical impact or to a static discharge.

Stable.

Conditions of reactivity:

None known.

Strong acids, peroxides and amines.

Thermal decomposition can yield oxides of carbon, carbon fluoride and formaldehyde may be evolved at temperatures >150C/300F.

X

X

l

Skin contact

lSkin absorption

lEye

contact

lInhalation

lIngestion

See Ingredients section above.

Eyes: Can cause irritation but injury is unlikely. Skin: No effects expected. Irritation is possible with some

individuals. Inhalation: No effects expected. Ingestion: Not considered a route of exposure. Effects of

ingestion have not been determined. Considered to have a low acute oral toxicity.

None known.

None known.

Saving Lives through innovation & education | Hilti Firestop Guide 20052006 | 1-800-363-4458 | www.ca.hilti.com

Material Safety Data Sheet

MSDS No.:

Revision No.:

Revision Date:

Page:

Other:

Flush with plenty of water. Call a physician if symptoms occur.

Wash with soap and water. Seek medical attention if any effects persist.

No ill effects expected. Should discomfort occur, move to fresh air.

Do not induce vomiting unless large amounts are ingested. If conscious, give plenty of water to drink. Never

give anything by mouth to an unconscious person. Contact a physician immediately.

Referral to a physician is recommended if there is any question about the seriousness of the injury/exposure

CONTROL MEASURES AND PERSONAL PROTECTIVE EQUIPMENT

Engineering controls:

General (natural or mechanically induced fresh air movements).

Eye protection:

As appropriate for the work area or work being done.

Skin protection:

Cloth gloves are suitable.

Respiratory protection:

None normally required.

Other:

No additional measures are normally required.

Special shipping instructions:

Consult with regulatory agencies or your corporate personnel for disposal methods that comply with local,

provincial, and federal safety, health and environmental regulations.

Avoid temperature extremes. Keep from freezing.

REGULATORY INFORMATION

WHMIS classification:

HMIS codes:

D2B

Health 1, Flammability 1, Reactivity 0, PPE A

TDG shipping name:

Not regulated.

Hilti, Inc., Tulsa, OK USA

1 800 424 9300

Hilti (Canada) Corporation, Mississauga, Ontario; 1 800 363 4458

Hilti, Inc., Tulsa, OK USA; 1 800 879 6000, Jerry Metcalf (x6704)

SYSTEM DETAILS

PREPARATION INFORMATION / CONTACTS

Prepared by:

Emergency phone number:

Customer Service:

Health / Safety contacts:

Abbreviations used:

APPLICATIONS / PRODUCTS

PRECAUTIONS FOR SAFE HANDLING AND USE

Handling procedures and equipment:

For industrial use only. Keep out of reach of children. Use with adequate ventilation. Keep container closed

when not in use. Do not get into the eyes. Avoid prolonged or repeated contact with the skin. Practice good

hygiene; i.e., wash after using and before eating or smoking.

Storage requirements:

Store in a cool dry area. Keep from freezing. Store between 5 and 25 C.

Spill, leak or release:

Immediately wipe away spilled material before it hardens. Place in a container for proper disposal.

Waste disposal:

INTRODUCTION

FIRST AID MEASURES

Eyes:

Skin:

Inhalation:

Ingestion:

266C

004

08/17/04

2 of 2

N/E = None Established. N/A = Not Applicable. N/Av = Not Available.

HMIS: Hazardous Materials Identification System

The information and recommendations contained herein are based upon data believed to be correct; however, no guarantee or warranty of any kind expressed

or implied is made with respect to the information provided.

ESTIMATING TABLES / TECH DATA

Saving Lives through innovation & education | Hilti Firestop Guide 20052006 | 1-800-363-4458 | www.ca.hilti.com

375

You might also like

- Adm 870Document54 pagesAdm 870saifulNo ratings yet

- 0.6. UL Design AP DungDocument17 pages0.6. UL Design AP Dunglink4biz1974No ratings yet

- Ball Valve Operation Maintenance ManualDocument7 pagesBall Valve Operation Maintenance Manualj8164322100% (1)

- General Specification For Materials, Fabrication and Installation of StructureDocument74 pagesGeneral Specification For Materials, Fabrication and Installation of StructureOrlando Fang75% (4)

- Charles E. Smith - Feasibility of Thermite Sparking With Impact of Rusted Steel Onto Aluminum Coated SteelDocument66 pagesCharles E. Smith - Feasibility of Thermite Sparking With Impact of Rusted Steel Onto Aluminum Coated SteelAlarmakNo ratings yet

- InternalPainting PDFDocument9 pagesInternalPainting PDFPhilip LonerganNo ratings yet

- Marine Joinery Outfitting PDFDocument43 pagesMarine Joinery Outfitting PDFÇÇağdaş_1No ratings yet

- AdhesionDocument4 pagesAdhesionved100% (1)

- Ross Wood and Timber Condition Assessment Manual CH 4 PDFDocument20 pagesRoss Wood and Timber Condition Assessment Manual CH 4 PDFKen SuNo ratings yet

- Bs Colour Fan Bs 381c & Bs 4800Document5 pagesBs Colour Fan Bs 381c & Bs 4800Lee TuckerNo ratings yet

- CP 606Document1 pageCP 606Jonathan ChavezNo ratings yet

- API 5L Line Pipes Wall Thickness Outside Diameter Tolerance - Stainless SteeDocument2 pagesAPI 5L Line Pipes Wall Thickness Outside Diameter Tolerance - Stainless Steewilxj100% (1)

- Boiler Materials: P.Sundaramoorthy BHEL, TiruchirappalliDocument47 pagesBoiler Materials: P.Sundaramoorthy BHEL, Tiruchirappalliteddy tavaresNo ratings yet

- C 864 - 99 Qzg2naDocument3 pagesC 864 - 99 Qzg2naRufo CascoNo ratings yet

- Boiler Tube Oxide-Scale Thickness Measurement - GEIT Application PDFDocument2 pagesBoiler Tube Oxide-Scale Thickness Measurement - GEIT Application PDFrhinemineNo ratings yet

- Sikafloor 92EGDocument2 pagesSikafloor 92EGthe pilotNo ratings yet

- Astm 999Document12 pagesAstm 999MohammedRafeeqNo ratings yet

- NFPA 31 Fuel Oil Piping, Installation and Testing Chapter 8 Fuel Piping Systems and ComponentsDocument5 pagesNFPA 31 Fuel Oil Piping, Installation and Testing Chapter 8 Fuel Piping Systems and ComponentsprokjongNo ratings yet

- Quiz #5 FireDocument3 pagesQuiz #5 FireJhoms Poja Feria100% (2)

- Spherical ValveDocument4 pagesSpherical ValveHrshiya SharmaNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Aa 60005Document30 pagesAa 60005ashishkesharwaniNo ratings yet

- Section I 2015Document33 pagesSection I 2015ferds2599No ratings yet

- Fab Gate ManualDocument16 pagesFab Gate ManualRahul LavandNo ratings yet

- 1.4313 enDocument2 pages1.4313 envesselNo ratings yet

- Horizontal Lifeline Systems GuidelineDocument4 pagesHorizontal Lifeline Systems GuidelinemohanNo ratings yet

- 025 - Guard Zinc Phosphate Epoxy PrimerDocument3 pages025 - Guard Zinc Phosphate Epoxy PrimerBalgo BalgobinNo ratings yet

- ASM Material Data SheetDocument2 pagesASM Material Data SheetShankar PranavNo ratings yet

- Alodine 6105Document3 pagesAlodine 6105Sivalingam GovindarajanNo ratings yet

- Kae-Kze-Kba-Kbz 050108 RNV o & M ManualDocument26 pagesKae-Kze-Kba-Kbz 050108 RNV o & M ManualKS Pavan NarayanNo ratings yet

- fm5 578Document4 pagesfm5 578kiranNo ratings yet

- Pds Hempel's Urethane 5595u En-UsDocument2 pagesPds Hempel's Urethane 5595u En-UsFreddy Carl FredricksenNo ratings yet

- 1855 1Document2 pages1855 1hogoyoNo ratings yet

- Sfa-5.01 Filler Metal Procurement GuidelinesDocument10 pagesSfa-5.01 Filler Metal Procurement GuidelinesCesar Agustin LimousinNo ratings yet

- Ufgs 13 34 19Document45 pagesUfgs 13 34 19sharandeep1112No ratings yet

- 13 14 Technical Literature and StandardsDocument8 pages13 14 Technical Literature and StandardsMohammad Rashad BarakatNo ratings yet

- TCVN7571-11 - 2019 - Thép CDocument14 pagesTCVN7571-11 - 2019 - Thép CBui Chi TamNo ratings yet

- NF 16101 Explained PDFDocument8 pagesNF 16101 Explained PDFhammouche_soufianeNo ratings yet

- UL1709 ScopeDocument2 pagesUL1709 ScopeSaravanan PanduranganNo ratings yet

- Adsobtion Chiller SpecDocument6 pagesAdsobtion Chiller Specioan1946No ratings yet

- Aluzinc Corrosion Resistance en 2012Document17 pagesAluzinc Corrosion Resistance en 2012electronicmail2ughf6525No ratings yet

- Galvosil 15680 Data SheetDocument2 pagesGalvosil 15680 Data Sheetn00b1810No ratings yet

- 125 128Document4 pages125 128Majdi JerbiNo ratings yet

- Cicol EtslurryDocument4 pagesCicol EtslurryVenkata RaoNo ratings yet

- Infoprd-Geomet 500-gb PDFDocument2 pagesInfoprd-Geomet 500-gb PDFSannohashi MFGNo ratings yet

- Food Grade Epoxy PaintsDocument5 pagesFood Grade Epoxy PaintsEdgar SerafinNo ratings yet

- Carbomastic 15: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarbomastic 15: Selection & Specification Data Substrates & Surface PreparationMarcos MacaiaNo ratings yet

- GPT - Honeywell Pressure SensorDocument10 pagesGPT - Honeywell Pressure SensorKaran Bir SinghNo ratings yet

- Cooling Tower Parts Reference GuideDocument64 pagesCooling Tower Parts Reference GuideLy Ca TieuNo ratings yet

- Thermaline Heat Shield PDSDocument2 pagesThermaline Heat Shield PDSKhemaraj Path100% (1)

- ASTMDocument7 pagesASTMMarko's Brazon'No ratings yet

- Astm F2159Document6 pagesAstm F2159Hernando Andrés Ramírez GilNo ratings yet

- Jotun MSDSDocument2 pagesJotun MSDSMichael AlbuquerqueNo ratings yet

- Galvocoat 16380Document2 pagesGalvocoat 16380MuhammedHafisNo ratings yet

- Esr 1308Document21 pagesEsr 1308dkimNo ratings yet

- Eta-120114 Spax ScrewsDocument84 pagesEta-120114 Spax ScrewsSunnyWongNo ratings yet

- FAQ Processes For Surface Hardening of Stainless Steels Bodycote S3PDocument4 pagesFAQ Processes For Surface Hardening of Stainless Steels Bodycote S3PSinan YıldızNo ratings yet

- General Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessDocument9 pagesGeneral Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessCarlos Ramirez BaltazarNo ratings yet

- Thermalrock S Product Data Sheet inDocument4 pagesThermalrock S Product Data Sheet inIvyrod Umalsa- EnterprisesNo ratings yet

- Posmac: Posco Magnesium Aluminium Alloy Coating ProductDocument48 pagesPosmac: Posco Magnesium Aluminium Alloy Coating ProductCatherine DussnNo ratings yet

- CEVNA KAPA DIN2617-Steel-butt-welding-pipe-fittings-capsDocument2 pagesCEVNA KAPA DIN2617-Steel-butt-welding-pipe-fittings-capsBojan BučarNo ratings yet

- AWWA D100 Tension TableDocument1 pageAWWA D100 Tension Tablejojo_323No ratings yet

- NFPA 31 - FAQsDocument4 pagesNFPA 31 - FAQsReza Andika SetyadiNo ratings yet

- Cement Prodor SK Product Data SheetDocument2 pagesCement Prodor SK Product Data Sheetkhrisna.dipa.utamaNo ratings yet

- Pyroplex Fire Rated Expanding Foam Datasheet enDocument4 pagesPyroplex Fire Rated Expanding Foam Datasheet enrmbalcobiaNo ratings yet

- 16 - ANSI-ISO Standards PDFDocument10 pages16 - ANSI-ISO Standards PDFrichard_qrNo ratings yet

- Condulets Outlet BodiesDocument1 pageCondulets Outlet Bodiesrichard_qrNo ratings yet

- Pressure Transmitter 2600T SeriesDocument8 pagesPressure Transmitter 2600T SeriesQR RichardNo ratings yet

- Dimensions: VAZ-2T1-FK-V1Document1 pageDimensions: VAZ-2T1-FK-V1richard_qrNo ratings yet

- Filter ElementDocument3 pagesFilter Elementmauroman78No ratings yet

- 2-ASME Section IIDocument22 pages2-ASME Section IIazam RazzaqNo ratings yet

- Kaowool Rope and Textiles: North America: +1 (0) 706 796 4200 / Asia: +65 (0) 6595 0000Document1 pageKaowool Rope and Textiles: North America: +1 (0) 706 796 4200 / Asia: +65 (0) 6595 0000ppicNo ratings yet

- Cajas y Tapas TOPAZ F.T.Document28 pagesCajas y Tapas TOPAZ F.T.Brayan CJNo ratings yet

- Determination of Hardness of WaterDocument2 pagesDetermination of Hardness of WaterNitinSrivastavaNo ratings yet

- Technical Review On Alumina InclusionDocument15 pagesTechnical Review On Alumina InclusionMubeenNo ratings yet

- Materials Costing Date23232323Document20 pagesMaterials Costing Date23232323en_emad3322No ratings yet

- Chromium Compounds: Historical. Chrome Iron Ore (Chromite) WasDocument15 pagesChromium Compounds: Historical. Chrome Iron Ore (Chromite) WasYusufNo ratings yet

- Basics On GlueDocument23 pagesBasics On GlueMario Moyon LoaizaNo ratings yet

- Issue/Rev Details of Changes Date: Name Designation Signature Date LevelDocument6 pagesIssue/Rev Details of Changes Date: Name Designation Signature Date LevelAbhey DograNo ratings yet

- H.T BRAUTEK LITHIUM EP SeriesDocument2 pagesH.T BRAUTEK LITHIUM EP SeriesALFREDO CANTOS CORNEJONo ratings yet

- G B Veeresh Kumar, P S Shivakumar Gouda, R Pramod, CspraoDocument6 pagesG B Veeresh Kumar, P S Shivakumar Gouda, R Pramod, CspraoShivu RajNo ratings yet

- SKM-04 MD Inclinaiso N AzimuthDocument6 pagesSKM-04 MD Inclinaiso N AzimuthAwalou MohamadNo ratings yet

- DWR 03-23Document1 pageDWR 03-23Nicon Famarin FameronagNo ratings yet

- Assignment On "Pigment Printing": Dept. of Textile EngineeringDocument20 pagesAssignment On "Pigment Printing": Dept. of Textile EngineeringNakib Ibna BasharNo ratings yet

- Foundry Tools and Equipments: Fig. 11.1 (A)Document9 pagesFoundry Tools and Equipments: Fig. 11.1 (A)M. RazaNo ratings yet

- KMT ws2Document10 pagesKMT ws2Troy MateoNo ratings yet

- Power-Fin 2500-5000 Installation ManualDocument72 pagesPower-Fin 2500-5000 Installation ManualJWNo ratings yet

- Science Class X Periodic Test III Sample Paper 02Document5 pagesScience Class X Periodic Test III Sample Paper 02hweta173No ratings yet

- A'-Sialon Ceramics: Review: J - Chem. Phys. 2668Document11 pagesA'-Sialon Ceramics: Review: J - Chem. Phys. 2668Thanh DinhNo ratings yet

- Laminated Glass: September 2011Document8 pagesLaminated Glass: September 2011batteekhNo ratings yet

- Databook of Hvac Load CalculationDocument46 pagesDatabook of Hvac Load CalculationASHNA K NAVADNo ratings yet

- Multiprep 200: Adhesion PromotionDocument19 pagesMultiprep 200: Adhesion PromotionNgô TrungNo ratings yet

- Plaster of Paris False Ceiling DesignsDocument36 pagesPlaster of Paris False Ceiling DesignsSmriti SNo ratings yet

- Indian Handicrafts IntroductionDocument35 pagesIndian Handicrafts IntroductionPankaj KomreNo ratings yet