Professional Documents

Culture Documents

CCJ3 Air Inlet Filters Final

Uploaded by

Domingo PintoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CCJ3 Air Inlet Filters Final

Uploaded by

Domingo PintoCopyright:

Available Formats

GT INLET AIR SYSTEMS

large solid particles (bigger than 10 microns), and

on occasion droplets, impact compressor blades at

high velocities. Over time the damage can be significant enough to change the aerodynamic characteristics of the compressor. In extreme situations,

where very poor intake systems are installed, catastrophic damage can occur.

Corrosion. Even relatively small quantities of

a corrosive substance entering a turbine can cause

substantial damage in a short period of time. For

example, one of the most common contaminants

associated with turbine corrosion is salt. This can

By Steven Howes, Altair Filter Technology Inc

be any metal alkali salt, but sodium chloride and

potassium chloride are the most common. A typical

OEM input limit for the total amount of sodium and

potassium in the air stream is 0.01 ppm (parts per

as-turbine (GT) inlet air systems usually million).

are supplied by the engine OEM (origiFouling. Some contaminants are predisposed to

nal equipment manufacturer) as part of collect on compressor blades. Reasons include: They

a complete turbine package. Competi- are sticky in nature, have a low melting point, or

tive pressures often dictate that

perhaps because another conintake and filtration packages be

taminant, such as oil mist, has

of a standard design, irrespecprecoated the blades. Whattive of where the plant will be

ever the reason, the build up

located. While this approach may

over time of such fouling

Average lifetime efficiency

be cost-effective and viable for

will impair compressor perforMaximum efficiency

some users, for others the specifmance.

Minimum efficiency

ics of their respective site environPlugging, a process similar

ments are such that a standard

to fouling, refers to the blocksolution is not appropriate and

age of blade cooling passages.

Filter life

may lead to operational problems.

Plugged cooling paths eventuCaveat emptor certainly pre- 1. Efficiency of a filter can change

ally force blades to operate at

vails here. To guard against mis- over its lifetime, illustrating the

a higher than desired temperaapplication of design alternatives, importance of carefully comparing

ture. Blade failure is a possibilusers must be aware of the intake alternative offerings when making

ity over time.

solutions available and how they purchasing decisions

The majority of inlet air filperform under various environtration systems will protect a

mental conditions. Bear in mind

turbine sufficiently to prevent

that while inlet air systems may appear similar, catastrophic failure. But the performance of systhe technologies employed and the resulting perfor- tems subjected to harmful contaminants can vary

mance characteristics can be very different.

significantly. Many have poor efficiencies against

Understanding these issues is important to the small and sub-micron particles, particularly when

asset owner purchasing a new inlet air system, and the filters are first installed. This frequently results

even more critical to the engineer responsible for ret- in accelerated fouling of the compressor blades, and

rofitting an existing system or component. Greater operators are left with a choice of accepting a reducknowledge of how various air intake components, tion in turbine output, or doing more maintenance.

such as filtration systems and power augmentation

Filtration efficiency can be difficult to undertechnologies, interact with each other and the local stand given the many different testing methods

environment enable better decisions. Those, in turn, should result

in increased plant output and avail- Avoid these five common errors in the design of GT

ability, and a reduction in intake- inlet air systems

related maintenance issues.

Using low first cost as the basis for design, thereby sacrificing

aerodynamics and inhibiting gas-turbine (GT) performance.

Filtration basics

Forgetting that a poorly designed inlet air cooling system adversely

impacts filter and/or compressor performance.

The main purpose of any filtration Specifying incorrect materials of construction for the inlet housing,

system is to protect the turbine from possibly causing compressor fouling or damage.

harmful airborne contaminants. Selecting an inappropriate type of filter or media for the intended

Typically, contaminants cause dam- service conditions, increasing O&M costs.

age in the following ways:

Installing improper weather protection, or not at all when needed.

Erosion occurs when relatively

Selecting gas-turbine

inlet air systems

for new, retrofit

applications

Filtration efficiency

COMBINED CYCLE JOURNAL, Second Quarter 2004

GT INLET AIR SYSTEMS

Rating filter performance

o understand filters and their application, it

is necessary to rate them for pressure drop,

dust holding capacity, and efficiency. These

factors are often abused in industry when only data

favorable to a particular filter is presented in sales

literature. To fairly evaluate filter effectiveness, several test procedures have been adopted by filter

manufacturers and users. For the kinds of dust

concentrations encountered in most industrial work

areas, including power, the standard most often

used for measuring filter efficiency is ASHRAE

(American Society of Heating, Refrigerating and

Air Conditioning Engineers) Standard 52-76. It

addresses multiple test methods, the most important being:

1. Weight arrestance,

2. Dust spot efficiency, and

3. Hot DOP (Di-octyl Phthalate), also known as

MIL STD 282 (1958).

The weight arrestance test is simple. It

involves feeding a synthetic dust to a filter and

ratioing the weight of dust exiting the filter to the

weight of dust originally fed into the filter. Since

small particles have little mass, this method offers

almost no way of revealing small-particle collection efficiency. The method is used for low- and

medium- efficiency media filters. During testing,

pressure drop is observed until it reaches a final

value (usually 1 in. H2O). The number of grams of

dust, less that logged on a special high efficiency

filter behind the test filter, yields the filters final

dust holding capacity at 1-in.-H2O pressure drop.

Collection efficiency also depends on the weight of

dust collected on the test filter and the final filter.

Since dust weight is not logged until the test filter

becomes loaded, this method yields only an average efficiencyone averaged over the entire test

run. It gives no indication as to how long it took

for the filter to build to the final rated efficiency nor

does it offer any clue about starting efficiency.

Dust spot test. Where small-particle efficiency

is critical (most industrial oil smokes generate particles in the 0.01 to 2 micron size range), the dust

spot test is often used. Here standard ambient air is

passed through the test filter and the air stream has

special test filters in front of and behind the test filter to monitor the presence of airborne particulates.

Over time, both filters become soiled and are measured optically for relative soiling. These results are

then translated into a filter efficiency rating.

available. But it is equally difficult to pick out one

method as being superior to all others. The guidelines offered below may assist in your evaluations

of alternative filter offerings.

First, mass efficiency (also known as weight or

gravimetric arrestance) is of little value to the turbine engineer. Reason: These tests typically use

test dusts with a relatively large average particle

2

Hot DOP test. A common method for measuring the efficiency of high-efficiency filter media

is the hot DOP test. It involves boiling DOP and

injecting the vapor into the air stream in front of the

test filter. As the vapor condenses back to ambient temperature, it forms very uniform droplets of

about 0.3 micron diameter. Use of light scattering

instrumentation allows measurement of upstream

and downstream particle concentrations. HEPA

(high efficiency particulate air) filters, usually rated

for efficiencies in excess of 99.9% on 0.3 micron

size particles, are tested using this method.

To understand how misleading efficiency tests

can be, the table shows how certain filters would

respond to the three tests described above. For

example, assume a standard filter rated 65%

under ASHRAE 52-76 (dust spot). Locate the 6080% range in the center column. Now, look left

and right. Note that this same filter could be rated

95% efficient if measured by the weight arrestance

method or 35-40% efficient if measured by the

hot DOP method. The only types of filters that will

show high efficiency on the sub-micron particles

generated in the hot DOP test are HEPA filters and

electrostatic precipitators.

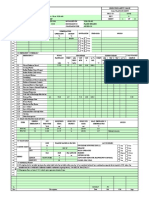

Comparing filter efficiency using different tests

ASHRAE weight

arrestance method, %

70-80

80-90

90-95

95

Not applicable

Not applicable

Not applicable

ASHRAE dust

spot method, %

15-30

20-35

40-60

60-80

80-90

90-98

Not applicable

MIL-STD 282,

hot DOP method, %

0

0

15-25

35-40

50-55

75-90

95-99.999*

*HEPA filters test at -100% efficiency using the arrestance and dust spot methods

Finally, note that every filter configuration can be

tested individually for efficiency and pressure drop.

Standard filters generally have been tested for efficiency by particle size. Most standard filter combinations have been tested for pressure drops at

nominal air flow ratings. When units are specified

as being ducted for source capture, blower speeds

are preset at the factory to match specified field

conditions. Detailed specifications for all standard

unit configurations are listed by their respective

manufacturers.

size (greater than 5 microns, for example). This

makes it difficult to distinguish between a filter

that has good small particle performance, and one

whose performance is poor.

When comparing the efficiencies of filters from

different manufacturers, be sure your comparison is on a like-for-like basis. In particular, pay

attention to the air velocity used as the basis for

COMBINED CYCLE JOURNAL, Second Quarter 2004

the efficiency measurement. Is

it comparable to your operating

conditions? If the actual in-service

air velocity is, say, 50% greater

than the test velocity you should

anticipate significantly reduced

performance.

Additionally, is the efficiency

quoted a maximum, minimum or

an average lifetime value? Many

filters have a relatively low efficiency against small particulates

early in their service lives but

their performance improves as the

element becomes progressively

loaded with contaminants (Fig 1).

ations it is possible for a filter to

quoted maximum efficiency before

it is replaced.

For details on the various tests

used for determining filter efficiency, see the accompanying sidebar and companion table.

Pressure drop. Another major

consideration when selecting a

filtration system is its pressure

drop. Intake pressure lossthat

is, resistance to air flowwill

have a direct impact on turbine

efficiency and power output. A

common mistake is to only consider the clean or startup pressure drop. Of real value to plant

operations personnel is an understanding of how quickly pressure

drop will increase over time. To a

large extent, this depends on the

type of contaminants in the local

environment.

A given filter and filtration system will have inherent characteristics that can be tested to provide

an indication of relative performance. A typical test of a filters

dust holding capacity involves

Filter pressure drop

Pressure drop for filter changeout

Filter A

Filter B

Dust holding capacity (filter life)

2. Steep dust holding curve for

Filter A means a relatively small

amount of dust causes high pressure drop. B holds more dust for a

given pressure drop, lasts longer

Duration of

water spray

Cellulose-based filter

Filter pressure drop

The heat-rate penalty

associated with an

increase in the design

pressure drop of 1 in.

H2O across the inlet

air system for a baseload 150-MW gas

turbine means your

fuel costs will exceed

budget by more than

$70,000 annually.

Leading commercial filter

Test duration (time)

3. Test results of a lab experiment shows a typical cellulose filter

degrades quickly in a high-moisture

environment. Know operating conditions before buying

In certain situnever reach its

GT INLET AIR SYSTEMS

recording the increase in pressure drop as dust-laden air

is passed through the filter.

Using a standard dust test

such as ASHRAE 52-76 (American Society of Heating, Refrigerating and Air Conditioning

Engineers), different filters

can be subjected to the same

test in a comparative manner.

Although not foolproof, this

technique is recognized as giving a good indication of realworld performance.

The best filter will have a

shallow dust retention curve,

which means it has a high

specific dust holding capacity

(Fig 2). If users change filters

at a predetermined pressure

drop, they will maximize the

time between filter changeouts, reducing maintenance

and replacement-filter costs.

Alternatively, if the filters are

changed at a fixed time period, such as during the annual plant shutdown, the lower

average pressure loss over

the life of the filter will allow

greater power production and

higher revenuesprovided, of

course, that the plants maximum capability can be dis-

patched.

Running wet. Another factor to consider when

Relating filter efficiencies and standards

Type

Coarse

dust filter

Eurovent EN 779

class

class Efficiency, % Measured by

Standards

EU1

EU2

EU3

EU4

G1

G2

G3

G4

<65

65 <80

80 <90

>90

Synthetic

ASHRAE

dust weight

52-76,

arrestance Eurovent 4/5

Fine dust

filter

EU5

EU6

EU7

EU8

EU9

F5

F6

F7

F8

F9

40 <60

60 <80

80 <90

90 <95

>95

Atmospheric BS 6540,

dust spot DIN 24 185,

efficiency

EN 779

HEPA

filter

EU10

EU11

EU12

EU13

EU14

H10

H11

H12

H13

H14

85

95

99.5

99.95

99.995

Sodium

chloride

or liquid

aerosol

BS 3928,

Eurovent 4/5,

DIN 24 184

(DIN 24 183)

Ultra-low

EU15

penetration

EU16

air filter (ULPA) EU17

H15

H16

H17

99.9995

99.99995

99.999995

Liquid

aerosol

DIN 24 184

(DIN 24 183)

BS (British Standard) specifications generally have been replaced by ENBS (Euro norm/British Standard) specifications, which are commonly abbreviated EN. DIN are German standards

COMBINED CYCLE JOURNAL, Second Quarter 2004

GT INLET AIR SYSTEMS

User perspective

any plant managers and their key staff will

tell you that they didnt give much thought

to air filters the first time their companies

purchased gas turbines (GT), leaving specification and selection to the turbine manufacturer

and/or the engineer/constructor. Knowledge of

turbine inlet-air systems generally is acquired

on the job when performance issues arise.

Gabe Fleck, an electrical engineer for Associated Electric Cooperative Inc, Springfield, Mo, and

chairman of the 501D5/D5A Users group, says filtration is a learning process. Fleck says AECI has

no filtration problems per se, but that doesnt mean

there isnt room for improvement in the specification/verification process. The company recently

experienced a miscommunication with the vendor selected to supply replacement prefilters that

resulted in receiving high-efficiency filters instead of

low-efficiency filters. The mistake was discovered

after repeated unit trips on high differential pressure

suggested a laboratory review of the product. The

bottom line: The filters supplied were 85% efficient

based on a dust spot test rather than 85% efficient

based on an arrestance test. These and other filter

test procedures that you should become familiar

with are detailed in a companion sidebar.

This was not the only snafu encountered by

AECI regarding filters. In another case a new GT

was to be supplied by the turbine manufacturer

complete with G4 prefilters and F8 final filters.

What the utility received was G3 prefilters and F7

final filters. The message seems clear: To avoid

potential operating problems, sample a prefilter and

final filter from your next order and send them to a

lab to be sure you received what was specified.

Based on his experience, Fleck suggests that

when ordering filters you should specify a dust spot

or arrestance efficiency plus the maximum delta

p across the filter and a minimum dust holding

capacity at the final delta p. One of Flecks current

projects is to determine if the addition of a roughing

filter in front of the prefilters would be beneficial.

If you ask Alan Pearce his opinion on that it

would be an unqualified yes. But then Pearce, an

engineer assigned to the combined-cycle units at

Alabama Power Cos Barry Generating Station, has

experience in a climate that differs from Flecks.

reviewing the pressure-drop characteristics of

alternative offerings is the ability of a filtration

system to operate efficiently when wet. The difference in performance between a system designed

to run wet and one that is not, can be significant

(Fig 3). Running wet is not that unusual, given the

high levels of precipitation in many areas and the

increased use of inlet air cooling systems to boost

GT output.

Testing of various filter types has shown considerable variation in performance going from dry

4

GT inlet air systems are especially sensitive to local

environmental conditions as most industry veterans

have learned.

Pearce says Barrys experience with sheets of

a polyester filtration medium hung by clips in front

of the prefilters has been excellent. The medium

catches bugs and big airborne debris, allowing

prefilters to run a month longer and reduce their

replacement to three times annually from four. The

pre-prefilters for the sites four 7FA gas turbines

(GE Energy, Atlanta) are changed online monthly

and disposed of by incineration.

The Barry units have stainless steel inlet-air

housings supplied by Braden Manufacturing LLC,

Tulsa, Okla, that feature evaporative coolers behind

the filters. One of the changes Barry made to the

inlet air system was to redesign the frame structure supporting the prefilters. The OEMs design

required too many man-hours to change the 340

2-ft-square prefilters for each GT.

The original design required maintenance personnel to unscrew and replace two wingnuts for

each prefilter. Damaged threads, dropped wingnuts, bent studs, and other annoyances were eliminated by a galvanized steel structure that supports

a grid of hinged framesone per prefiltereach

equipped with a simple locking device. The downstream side of the prefilter frames has a gasket to

ensure a tight seal between the prefilters and final

filters. A work crew can replace prefilters on all four

GTs during a normal weekend shutdown. Work is

done off-line to prevent dust re-entrainment and

early fouling of final filters. Used prefilters are incinerated.

A compelling feature of the new prefilter grid

structure is that it permits the use of unframed

coalescing media which is half the cost of framed

prefilters. Pearce figures the modified prefilter

structure paid for itself in about a year, considering

the saving in manpower and material.

Final filters are changed out every two to three

years. The Barry staff uses a visual inspection and

a delta p target for scheduling filter replacement.

Philosophy is to maintain high performance by

changing all filters before they reach their maximum

capacity.

Bob Schwieger

to wet conditions. In some instances, the pressure

drop through a filter subjected to a relatively small

amount of water spray can increase by several hundred percent. This usually happens to filters with

cellulose fibers, which swell when wet. The high

delta p may remain for several hours after the

water spray has been stopped because the cellulose

fibers retain moisture.

Lab results are confirmed by field experience.

Many users report that early morning fog (a common cause of filters running wet) results both in

COMBINED CYCLE JOURNAL, Second Quarter 2004

The importance of proper filter

selection is obvious if you think

of a gas turbine as a huge vacuum cleaner.

GT INLET AIR SYSTEMS

taminants), and high-efficiency filters. There are

many different types of static filters, but prefilters

are normally pleated panels, while high-efficiency

elements tend to be bags or so-called mini-pleat

filters. Unlike a pulse system, a static filter does

not self-clean, and when the filters reach a certain

pressure drop they must be replaced. Prefilters are

changed more frequently than high-efficiency filters, which can last anywhere from 8000 to 24,000

hours depending on the environment (see User

perspective sidebar).

Pulse jet systems have higher capital costs than

static systems, as well as higher lifetime maintenance costs. They were originally developed to

protect turbines operating in the Middle East that

were subjected to frequent sand-storms. And in dry

areas, with high concentrations of airborne particles, they are very effective.

Over the last decade or so pulse filters have

gained acceptance as a more general filtration solution for GT applications, but the system does have

some shortcomings. In addition to the higher lifecycle cost noted above, pulse jets may work poorly

in areas with low or medium levels of airborne

particles. This is because a pulse filter relies on a

buildup of dust (known as a cake) on the surface of

the media to both improve filtration efficiency. In

areas with low or perhaps medium levels of dust,

a cake does not form, and many contaminants,

particularly small and sub-micron particles, penetrate the filter media. It is extremely difficult to

remove particles that have penetrated the media,

and because pulse elements are not designed to

operate as depth filters, the pressure drop can

increase rapidly. This is common in urban environments when the contamination is from automobile

and truck exhaust and oily in nature rather than

dusty.

an increase in pressure drop during the fogs occurrence and also for several hours after the fog has

cleared.

The importance of air velocity through the

filter, noted earlier, deserves greater scrutiny. A

filters operating velocity generally is defined as the

volumetric air flow divided by the filter face area.

Hence, a filter house with an air flow of 500,000

ft3/min and a filter face area of 1250 ft2 would have

a filter velocity of 400 ft/min. Performance data for

a filter normally is given at a nominal velocity,

which is chosen to be representative of the typical

in-service velocity.

The testing of filter characteristics are conducted at the nominal velocity and quoted in sales literature. When the actual in-service velocity is the

same, or close to, the nominal velocity, the filtration

system will perform as expected. But, for a variety

of reasons (typically, poor aerodynamic design of

the filter house and/or intake structure), some systems operate at velocities well above the nominal.

Result is an increase in pressure drop, a reduction

in specific dust holding capacity, and usually a

reduction in filtration efficiency.

To avoid this situation, all intake housings should

be analyzed for proper aerodynamics using computational fluid dynamics. Generic CFD analyses

generally are available for new intakes. But for retrofits to correct design deficiencies or an improper

design for actual conditions, have

a knowledgeable party conduct a

dedicated analysis. Pay particu- Filtration system selection guide

lar attention to the velocity profile Environment

Dust level

Weather protection

through the intake housing, speHot and dry

High

Weather hood

cifically the filtration system. A

Hot

and

dry

Low/medium

Weather

hood

well-designed system will have a

Humid

All

Weather

hood

relatively uniform velocity profile

Coastal

All

Weather

across the entire filter bank. This

hood/separator

velocity should be similar to the

High

rainfall

All

Separator

nominal velocity against which

Ice and snow High

Snow hood

performance data are quoted.

Ice and snow Low/medium Snow hood

How plant location

impacts system design

At the most basic level, the choice of filtration system comes down to either a static (barrier) or a

pulse (self-cleaning) design. Pulse systems usually

consist of some form of weather protection followed

by a deep-pleated cylindrical and/or conical filter.

The filters are periodically cleaned by means of a

reverse pulse of air.

Static systems typically consist of weather protection, prefilters (designed to capture coarse conCOMBINED CYCLE JOURNAL, Second Quarter 2004

Filtration system

Pulse

Static

Static

Static, downstream

separator

Static

Pulse

Static, anti-icing

A pulse filter also is prone to pressure loss and

other problems in high-moisture environments

when the fabric has cellulose fibres woven into its

structure. Also, if the contaminants captured on the

filter media swell in humid conditions, the pressure

drop will increase further and the cake can become

difficult to remove.

For most situations, with the possible exception of

some desert and cold-climate environments, a static

system generally is the filtration solution with the

lowest life-cycle cost (table can help guide your selec5

Water load, gal/hr

GT INLET AIR SYSTEMS

tion). Nevertheless, to ensure optimum perform- cal situation. Reality is that some of the very large

ance, considerable care is required when specifying droplets will take much longer to evaporate, others

a static system for a particular environment.

will fall out of the air stream and still others will

For example, consider a costal location where, impinge on the duct wall. Over time, the mean

on a windy day, the concentration of salt in the water-droplet size increases because of normal fogatmosphere can be in the 0.05 to 0.5 ppm range ging-nozzle wear.

or about five to 50 times the amount GT manufacThe real estate saying location, location, locaturers allow into their enginesfor as far as five tion applies to the positioning of a fogging system

miles inland. Many standard static systems are as well. If it is being retrofitted, the obvious posiunable to cope with airborne salt (which is in the tion is upstream of the filters. However, if there is

form of a fine aerosol) and it will pass directly into not sufficient space between the nozzles and the

the compressor.

filtration system, the prefilters and high-efficiency

This situation can be neutralized with technol- filters will run wet and must be selected to accomogy borrowed from the offshore oil and gas indus- modate moisture.

try, which deals with atmospheric salt all the

Filters may run wet even if adequate space is

time. Perhaps the best solution within 500 yards available because of the high humidity of the air

of shore is to specify an inlet housing with effec- downstream of the fogging system. Suggestion:

tive weather protection, plus a

Avoid filters with cellulose

500

marine separator ahead of filter

fibres, as noted earlier, and

Leading marine separator

elements capable of coalescing

ones with cardboard frames,

400

any salt aerosols that penetrate

which lose their mechanical

300

the weather protection. A downintegrity when wet.

stream separator also should

If the fogging system is

200

be installed to remove any coaplaced downstream of the fillesced droplets that become reters, ensure against small

100

Typical weather hood or louver

entrained in the air stream to

parts coming loose and being

0

prevent their entry into the

ingested by the compressor.

0

250

500

750

1000 1250 Also, provide sufficient draincompressor.

Face velocity, ft/min

Problems with static systems

age from low points in the

usually can be traced to inad- 4. Marine separators are signifiductwork where water can

equate weather protection. The cantly more efficient at removing large

accumulate to prevent both

standard weather hoods supplied amounts of entrained water than a typi- corrosion and turbine ingeswith filtration systems often are cal weather hood or louver

tion. Finally, design the fogsuitable only for light rain. For

ging system to prevent the forlocales subject to heavy rains,

mation of large droplets which

the solution is a marine separator, which is capable could enter the compressor and erode blades.

of removing from 10 to 20 times more water than a

In a chiller system, no water is introduced

standard hood (Fig 4). For heavy snow, the only real directly into the system; the coolant removes heat

solution is to have an extended-area 90-deg hood. from the air via finned-tube heat transfer surface.

However, under some conditions, a chiller system

the potential to cause the formation of free

Marrying filtration and cooling has

water in the air stream. Reason: Even at moderateToday, power augmentation systems are installed ly low relative humidity, it is commonplace for the

on most gas turbines for merchant and utility ser- downstream temperature of air passing through the

vice. Here, the focus is on the three main types of chiller to fall below its dew point. When this occurs,

inlet cooling systems: fogging, chiller coils, and the air is no longer able to support the amount of

evaporative coolers. The engineer challenged with water vapor in it and condensation occurs.

system selection should factor into his or her analyThe amount of condensation can be considerable.

sis the interaction of the inlet cooling system with For example, a chiller coil that cools a 650-lb/sec

other components in the intake housing, including stream of air with a relative humidity of 50% from

filter media. Remember that all three systems can 95F to 50F will produce condensate at the rate of

introduce free water into the intake.

approximately 12 lb/secthats more than 5000

Fogging. With a fogging system, there is no gal/hr.

secret as to how the water gets into the air intake

Clearly, this amount of condensation must be

structure: It purposely injects micron-size droplets controlled, particularly because carryover from

directly into the air stream. These droplets typical- the chiller coil can consist of large droplets that

ly have an average particle size of about 10 microns would erode compressor blades. If a chiller sysand, under ambient conditions, would take around tem is in your future, be sure the drainage system

one second to evaporate.

within the coil is well-designed and of adequate

Thus, at an in-duct air velocity of 600 ft/min, an capacity. You should also plan to use filters that are

average-size water droplet will travel 10 ft before well suited for running wet because this will be a

it evaporates. For this example, the first point to fact of life.

consider is that anything within 10 ft of the fogOrientation of finned tubes is important, too.

ging system will get wet. Second, this is a theoreti- Vertical fins significantly reduce the amount of

6

COMBINED CYCLE JOURNAL, Second Quarter 2004

entrainment coming off the back of a coil module

because water runs down the fins under gravity.

However, from the viewpoint of header connections

it often is more convenient to orient the tubes vertically and the fins horizontally.

Finally, pay close attention to air velocity: The

higher the velocity the more likely that entrainment will occur. A rule of thumb is that, below a face

velocity of about 300 ft/min very little entrainment

occurs, particularly if there is good in-coil drainage. It is not essential that the air flow through the

chiller be at a low velocity, but rather that the operating staff is aware that as the velocity increases,

more elaborate solutions are required to deal with

the carryover.

For example, you can protect the compressor

against ingestion of large water droplets by installing a mist/drift eliminator downstream of the coils.

Careful selection of a mist eliminator is prudent

because the effectiveness of any given design

depends on air velocity.

Location of the chiller coil relative to the filtration system is an important consideration as it

is for fogging systems and evaporative coolers. If

upstream of the filters in an area with a high or

medium level of contamination, the fins will quickly

foul, reducing thermal efficiency. One defense is to

install guard filters upstream of the coils. These

are merely prefilters (normally panels because of

space constraints) that provide a nominal level of

protection for the coils.

Evaporative coolers, like fogging systems,

GT INLET AIR SYSTEMS

introduce water into the intake duct. In theory,

if the system is functioning correctly, water is

retained within the confines of the evaporative

cooling module. However, in practice it is likely

that some carryover will occur. Thats why many

systems are fitted with downstream drift or mist

eliminators. But despite best efforts, carryover

sometimes passes through the mist eliminator for

one or more of these reasons: operating the system

beyond its design air velocity, degradation of cooling media, excessive water flow rate, and poorly

designed mist eliminator.

As with other GT inlet air cooling systems, positioning of the evaporative module is critical. Placing

the unit in front of the filters means they will operate wet and both the coolers cascading water and

media will collect much of the ingested contamination. Depending on the cleanliness of the ambient

air, this may or may not constitute a problem. Of

importance is where contaminants captured by the

wetted media are goingthat is, is it being retained

by the media or flushed away by the cooling water?

Either way, plant operators must ensure that the

buildup of contamination does not adversely impact

the performance of the evaporation module.

If the cooler is placed downstream from the

filtration system, it is essential that the issue of

water carryover be addressed. There have been

various reports of evaporative coolers being held

responsible for compressor blade erosion. Also, all

parts must be secure to prevent foreign-object damage to the compressor. CCJ

The Combined Cycle User Group has been formed in cooperation with the ASME

Power Division Combined Cycles Committee, the ELECTRIC POWER Conference and

other industry groups. It addresses issues concerning the interaction between all major

components of the combined cycle power plant - the gas turbine, HRSG and steam

turbine. These issues are critical at a time when many plants must operate on razor

thin margins and in modes for which they were not designed.

The group's annual meeting addresses topics such as:

Design aspects of the new breed of merchant plants

Construction techniques for new generation

Start up and commissioning issues

Operational considerations to maximize the return on investment while providing reliable power

Staffing ideas to keep your valued and best employees

Maximizing efficiency and output to respond to the day's demand requirements

HAPS - Impact on Design and Operation

Considerations of cycling base load designed CCGT Plants

Start up Emission impacts

Gray market equipment

Topics from the Floor

The Combined Cycle Users Group is developing a data base of power plants, a library of articles and a chat room where

members can exchange experiences. Trial membership is free of charge and is open to power plant owner/operators,

engineering companies, OEMs and other relevant stakeholders.

Join today on the web site www.combinedcycleusers.org or contact:

COMBINED CYCLE JOURNAL, Second Quarter 2004

You might also like

- 074398Document7 pages074398Subhajit Das100% (1)

- Compressor WashingDocument5 pagesCompressor Washingsamil68No ratings yet

- V005t15a001 88 GT 150Document13 pagesV005t15a001 88 GT 150Antonio CilindroNo ratings yet

- 1989 Aker Predicting Gas Turbine Performance Degradation Due To Compressor Fouling Using Computer Simulation TechniquesDocument8 pages1989 Aker Predicting Gas Turbine Performance Degradation Due To Compressor Fouling Using Computer Simulation TechniquesArgenomSaubiNo ratings yet

- V003t07a012 98 GT 590 PDFDocument12 pagesV003t07a012 98 GT 590 PDFvaratharajan g rNo ratings yet

- Advantages of Aeroderivatives IAGT 206 - Final - PaperDocument15 pagesAdvantages of Aeroderivatives IAGT 206 - Final - PapermvanzijpNo ratings yet

- Compressor C65Document1 pageCompressor C65frdnNo ratings yet

- D2880 380331-1 PDFDocument7 pagesD2880 380331-1 PDFVidyasenNo ratings yet

- Fouling Preventive CoatingsDocument3 pagesFouling Preventive CoatingsAnonymous PkeI8e84RsNo ratings yet

- Turbine Off-Frequency Operation: GE Power SystemsDocument4 pagesTurbine Off-Frequency Operation: GE Power Systemskcirrenwod100% (1)

- HP Steam Turbine StageDocument8 pagesHP Steam Turbine StageTarun ChoudharyNo ratings yet

- GEA34130 AeroderivativeGT - Whitepaper - R6Document10 pagesGEA34130 AeroderivativeGT - Whitepaper - R6Cecilia CabreraNo ratings yet

- Operating and maintenance norms for hydraulic cylindersDocument4 pagesOperating and maintenance norms for hydraulic cylinderszsmithNo ratings yet

- Gas Transport-Mallnow-Natural-Gas-Compressor-Station PDFDocument8 pagesGas Transport-Mallnow-Natural-Gas-Compressor-Station PDFJaswindersingh BhatiaNo ratings yet

- Caterpillar Gas Engine Data Update for GERPDocument2 pagesCaterpillar Gas Engine Data Update for GERPvictor.ciprianiNo ratings yet

- Oilon oil, gas, and dual fuel burners technical guideDocument32 pagesOilon oil, gas, and dual fuel burners technical guideHrishikesh RokadeNo ratings yet

- Turbo Tutorial 7Document32 pagesTurbo Tutorial 7Chad HuntNo ratings yet

- The Design and Analysis of Gas Turbine BladeDocument3 pagesThe Design and Analysis of Gas Turbine Bladeaerobrother100% (3)

- Peppers Catalogue PDFDocument64 pagesPeppers Catalogue PDFStone123456789No ratings yet

- Humidity Effects On Gas Turbine PerformanceDocument7 pagesHumidity Effects On Gas Turbine PerformanceTolgahan ŞahinNo ratings yet

- I A G T C: Ndustrial Pplication OF AS Urbines OmmitteeDocument13 pagesI A G T C: Ndustrial Pplication OF AS Urbines Ommittee'Izzad AfifNo ratings yet

- Steam Amonia TurbineDocument21 pagesSteam Amonia TurbineLuis Alexandre MachadoNo ratings yet

- Reciprocating Compressor Condition Monitoring: © 2010 General Electric Company. All Rights ReservedDocument22 pagesReciprocating Compressor Condition Monitoring: © 2010 General Electric Company. All Rights ReservedPablo Alcayaga Penros100% (2)

- Compressor Wash System: MLN Block 405, Algeria Operator TrainingDocument19 pagesCompressor Wash System: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- EPS GT Base PrinciplesDocument32 pagesEPS GT Base PrinciplescdbeardsallNo ratings yet

- SGT-600 GT PowerGen ENDocument4 pagesSGT-600 GT PowerGen ENBehnamayoubzadehNo ratings yet

- 08 09 CT2 ScribdDocument116 pages08 09 CT2 Scribdratninp9368100% (1)

- Microturbines Generate Power from WWTP BiogasDocument2 pagesMicroturbines Generate Power from WWTP BiogasKwang Je LeeNo ratings yet

- Humidified Gas Turbines, by EderDocument66 pagesHumidified Gas Turbines, by EderDomingo PintoNo ratings yet

- Axial Comp On OffDocument4 pagesAxial Comp On OffMohamed OmarNo ratings yet

- APA DOC No. 2014 PDFDocument67 pagesAPA DOC No. 2014 PDFThanapaet RittirutNo ratings yet

- The Effect of Air Inlet System Features On Automotive Turbocharger Compressor PerformanceDocument19 pagesThe Effect of Air Inlet System Features On Automotive Turbocharger Compressor Performancestefan.vince536No ratings yet

- 2.4 MBM Combustor Dilution Air SystemDocument6 pages2.4 MBM Combustor Dilution Air SystemmiladNo ratings yet

- Gas Turbine CombustionDocument9 pagesGas Turbine Combustionvarun kumarNo ratings yet

- Psib 20150212Document10 pagesPsib 20150212Léandre Ettekri NdriNo ratings yet

- FiltrationDocument23 pagesFiltrationJorn DoeNo ratings yet

- 2012 SpiraxialDocument1 page2012 SpiraxialNistha ChakrabortyNo ratings yet

- An-PP-001 Turboexpander Design FeaturesDocument5 pagesAn-PP-001 Turboexpander Design FeaturesSobhy GendykhelaNo ratings yet

- Performance of Industrial GasturbinesDocument28 pagesPerformance of Industrial Gasturbinessomporn duangbuntaoNo ratings yet

- The Inlet Flow...Document7 pagesThe Inlet Flow...MotakikuNo ratings yet

- Asme PTC 17 1991Document40 pagesAsme PTC 17 1991Francisco Brito100% (1)

- Gas Turbine Lm5000 Operations ManualDocument4 pagesGas Turbine Lm5000 Operations ManualMuhammad Ilham RiyadiNo ratings yet

- Fact Sheet Variable Inlet Guide VaneDocument1 pageFact Sheet Variable Inlet Guide VaneDarioNo ratings yet

- Peppers Catalogue GlandsDocument28 pagesPeppers Catalogue GlandsVlad Andronache100% (1)

- Compressor Power PointDocument28 pagesCompressor Power PointDiden Dz100% (1)

- Gas Turbine in Cairo North Power StationDocument38 pagesGas Turbine in Cairo North Power StationAbdul Moeed Kalson0% (1)

- F646 CompleteSampleDocument36 pagesF646 CompleteSampleraj4523No ratings yet

- Vol IV Illustrated Part ListDocument460 pagesVol IV Illustrated Part ListmargaretramosNo ratings yet

- ThermallySprayedAbradableCoatings 2012.10Document9 pagesThermallySprayedAbradableCoatings 2012.10Thanaraj SanmughamNo ratings yet

- F 0077 e 55Document6 pagesF 0077 e 55Bùi Cảnh TrungNo ratings yet

- KT Components E 01Document8 pagesKT Components E 01Mvk RajuNo ratings yet

- Anti-Surge Control - Analysis and Strategies PDFDocument91 pagesAnti-Surge Control - Analysis and Strategies PDFMuhammad ImranNo ratings yet

- Gas Turbine Performance DeteriorationDocument0 pagesGas Turbine Performance DeteriorationGeorge John Amegashie100% (1)

- Kurzke Turbine Map ExtensionpdfDocument14 pagesKurzke Turbine Map ExtensionpdfzzzNo ratings yet

- Understanding NPSH - NPSH Definitions - Page 2 of 2 - PumpsDocument3 pagesUnderstanding NPSH - NPSH Definitions - Page 2 of 2 - PumpsLam TranNo ratings yet

- Liquid Fuel Requirements For Ge Aeroderivative Gas TurbinesDocument5 pagesLiquid Fuel Requirements For Ge Aeroderivative Gas TurbinesMohammed ElarbedNo ratings yet

- Dynamics in One Complex Variable. (AM-160): (AM-160) - Third EditionFrom EverandDynamics in One Complex Variable. (AM-160): (AM-160) - Third EditionNo ratings yet

- International Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectFrom EverandInternational Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectNo ratings yet

- Sampling Natural Gas ISO 10715Document34 pagesSampling Natural Gas ISO 10715Domingo PintoNo ratings yet

- Power CyclesDocument66 pagesPower CyclesDomingo PintoNo ratings yet

- PJM 20150612-June-2015-Capacity-Performance-Parameter-LimitationsDocument3 pagesPJM 20150612-June-2015-Capacity-Performance-Parameter-LimitationsDomingo PintoNo ratings yet

- FERCDocument10 pagesFERCDomingo PintoNo ratings yet

- Main Applications: Case StudyDocument2 pagesMain Applications: Case StudyDomingo PintoNo ratings yet

- Catalytic Combustion SystemDocument29 pagesCatalytic Combustion SystemDomingo PintoNo ratings yet

- Ihabouaida Naturalgas 170523071015Document33 pagesIhabouaida Naturalgas 170523071015Domingo PintoNo ratings yet

- PJM Capacity Performance minimum operating parametersDocument3 pagesPJM Capacity Performance minimum operating parametersDomingo PintoNo ratings yet

- Programa Diario 14jul Chilca Rev0Document6 pagesPrograma Diario 14jul Chilca Rev0Domingo PintoNo ratings yet

- Combined Cycle ConversionDocument61 pagesCombined Cycle ConversionDomingo PintoNo ratings yet

- Steam Survey GuideDocument83 pagesSteam Survey GuideLubrication´s RoomNo ratings yet

- Rio Alto Expobolsa VG PDFDocument43 pagesRio Alto Expobolsa VG PDFDomingo PintoNo ratings yet

- Tema 4 - Lectura 4 Alianzas Sociales Amèrica Lat-BID PDFDocument19 pagesTema 4 - Lectura 4 Alianzas Sociales Amèrica Lat-BID PDFDomingo PintoNo ratings yet

- EPRI - Guide For Maintenance and Remedial Actions On Contaminated InsulationDocument2 pagesEPRI - Guide For Maintenance and Remedial Actions On Contaminated InsulationDomingo PintoNo ratings yet

- Humidified Gas Turbines, by EderDocument66 pagesHumidified Gas Turbines, by EderDomingo PintoNo ratings yet

- Ceramics in Gas TurbinesDocument12 pagesCeramics in Gas TurbinesDomingo Pinto100% (1)

- Energy 04 O&M in The Philippines PDFDocument3 pagesEnergy 04 O&M in The Philippines PDFDomingo PintoNo ratings yet

- Typical Training Plan SampleDocument160 pagesTypical Training Plan SampleDomingo PintoNo ratings yet

- Standards of Performance For New Stationary SourcesDocument5 pagesStandards of Performance For New Stationary SourcesDomingo PintoNo ratings yet

- Unimixer AL66: Combustion Engineering SpecialistsDocument1 pageUnimixer AL66: Combustion Engineering SpecialistsMauricio DonosoNo ratings yet

- PSV Calculation Sheet APIDocument10 pagesPSV Calculation Sheet APIionutlaur86100% (2)

- Zero Escape Virtues Last Reward PDFDocument33 pagesZero Escape Virtues Last Reward PDFfcaicedo7239No ratings yet

- Fdas Technical Specs PDFDocument10 pagesFdas Technical Specs PDFotadoyreychie31No ratings yet

- Zroute Training Lab v1 0Document23 pagesZroute Training Lab v1 0ChetanNo ratings yet

- Trawler SampleDocument80 pagesTrawler SampleChet Stephens100% (2)

- Gigabyte Sandy Bridge Overclocking GuideDocument27 pagesGigabyte Sandy Bridge Overclocking GuideGIGABYTE UK100% (2)

- 410e Repair ExampleDocument6 pages410e Repair ExampleYurii Chinov71% (7)

- Exercises PDFDocument2 pagesExercises PDFNordiana IdrisNo ratings yet

- Tenor Ax Voip Multipath/Gateway Switch: Product GuideDocument131 pagesTenor Ax Voip Multipath/Gateway Switch: Product GuideEdgar A CanizalezNo ratings yet

- Authentication Verification Letter For Portal 1Document2 pagesAuthentication Verification Letter For Portal 1pradeepajadhavNo ratings yet

- Groovy 9 – capturing RawRequest & ResponseDocument4 pagesGroovy 9 – capturing RawRequest & ResponseSirisha ChigurupatiNo ratings yet

- Documents - MX DPV Vertical Multistage Pumps 60 HZ Technical Data DP PumpsDocument80 pagesDocuments - MX DPV Vertical Multistage Pumps 60 HZ Technical Data DP PumpsAnonymous ItzBhUGoi100% (1)

- Online Treasure Hunt TitleDocument3 pagesOnline Treasure Hunt TitleqoufwsjelmkNo ratings yet

- Glory gfs220 Manual (01 90) (31 40)Document10 pagesGlory gfs220 Manual (01 90) (31 40)alexander quintero romeroNo ratings yet

- AW-Automatic Cone WinderDocument2 pagesAW-Automatic Cone WindertexveerNo ratings yet

- Web Based Attendance Management SystemDocument19 pagesWeb Based Attendance Management SystemAnonymous zenL7LNo ratings yet

- Engineering Tilt UpDocument334 pagesEngineering Tilt UpMTCLSNo ratings yet

- Lion - dr.K.S.rangasamy, MJF Founder & PresidentDocument36 pagesLion - dr.K.S.rangasamy, MJF Founder & PresidentpradeepNo ratings yet

- CCR Process GuideDocument55 pagesCCR Process GuideJean Claude EidNo ratings yet

- Manual VISSIM 540 e PDFDocument763 pagesManual VISSIM 540 e PDFEze KA100% (1)

- NPD1 - Small Planetary Catalogue - Apr 2020Document39 pagesNPD1 - Small Planetary Catalogue - Apr 2020Shyam J VyasNo ratings yet

- Wind Load Calculations For PV Arrays: Solar America Board For Codes and StandardsDocument24 pagesWind Load Calculations For PV Arrays: Solar America Board For Codes and StandardsSalman KhanNo ratings yet

- Tollgate-Based Project Management TemplateDocument9 pagesTollgate-Based Project Management TemplateKulanthaivelu RamasamyNo ratings yet

- 1cjcds3j1 316290Document155 pages1cjcds3j1 316290taurusNo ratings yet

- Complete 2010/2011 Catalog - Architecture, Landscape, DesignDocument9 pagesComplete 2010/2011 Catalog - Architecture, Landscape, DesignDoki86No ratings yet

- The Essential Entrelec - Cat - enDocument76 pagesThe Essential Entrelec - Cat - engeekboxcaruaruNo ratings yet

- ADAMS/Solver Subroutines: Overview and ExamplesDocument13 pagesADAMS/Solver Subroutines: Overview and Examplessubit0% (1)

- AlbafixwffDocument7 pagesAlbafixwffjawadbasit0% (1)

- F-Shaped Pattern For Reading Web ContentDocument3 pagesF-Shaped Pattern For Reading Web Contentbortles1No ratings yet