Professional Documents

Culture Documents

SUNTEC Pompa AL Fisa-Tehnica

Uploaded by

Stroia Constantin MariusOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SUNTEC Pompa AL Fisa-Tehnica

Uploaded by

Stroia Constantin MariusCopyright:

Available Formats

AL

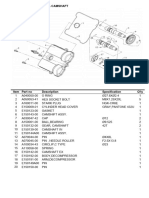

OIL PUMP TYPE AL

GEAR SIZES 35-55-65-75-95

AL - 11 - Ed 14 - February 2014

This is a general specification leaflet; for specific applications not covered

herein, contact Suntec.

The SUNTEC AL oil pump incorporates a blocking solenoid valve with in-line

cut-off function.

APPLICATIONS

PUMP

IDENTIFICATION

(Not all model combinations are available

Consult your Suntec representative)

AL : pressure regulation and blocking

solenoid valve with in-line cut-off function

- Light oil, B10 heating oil/biofuel blend (as defined in DIN V51603-6) and

kerosene.

- One or two-pipe system.

V : B10 applications

Gear set capacity

(see pump capacity curve)

Shaft rotation and

nozzle location

(seen from shaft end)

A : clockwise rotation/

right hand nozzle.

B : clockwise rotation/

left hand nozzle.

C : anti-clockwise rotation

left hand nozzle.

D : anti-clockwise rotation

right hand nozzle.

K : kerosene applications

Pump series

4 : hub 54 mm

5 : hub 32 mm

Model number

PUMP OPERATING PRINCIPLE

The gear set draws oil from the tank through the built-in filter and transfers it to the

nozzle line via the cut-off solenoid valve. A pressure regulating valve is used to dump

all oil which is not required at the nozzle.

In two-pipe operation, the by-pass plug must be fitted in the return port, which

ensures that the oil dumped by the regulating valve is returned to the tank and the

suction line flow is equal to the gear set capacity.

In one-pipe operation, the oil which does not go through the nozzle line is returned

directly to the gear inlet and the suction line flow is equal to the nozzle flow. In that

case, the by-pass plug must be removed from the return port, and the return port

sealed by steel plug and washer.

Bleed

Bleeding in two-pipe operation is automatic : it is assured by a bleed flat on the

piston.

In one-pipe operation, the plug of a pressure gauge port must be loosened until the

air is evacuated from the system.

Cut-off

The solenoid valve of the AL pump is of the "normally closed" type and is situated

in the nozzle line. This design ensures extremely fast response and the switching

can be selected according to the burner operating sequence and is independant of

motor speed.

When the solenoid is non-activated, the valve is closed and all oil pressurised by

the gear set passes through the regulator to the suction or return line, depending

upon pipe arrangement.

As soon as the solenoid is activated, oil passes to the nozzle line at the pressure

set by the pressure regulating valve.

AL V 35 C K 9 5 xx

05 00

Solenoid valve

(NC)

closed

Solenoid valve

(NC)

open

Pressure

gauge port

Pressure

adjustment

Back

to suction

Revision number

Installation

P : by-pass plug inserted in return port

for two-pipe operation

M : without by-pass plug,

return plugged,

for one-pipe operation

Solenoid valve voltage

06 : 110-120 V ; 50/60 Hz

02 : 24 V ; 50/60 Hz

05/07 : 220-240 V ; 50/60 Hz

Connector cable length

00 : no cable

35 : 35 cm cable - 45 :45 cm cable

60 : 60 cm cable - 10 : 1 m cable

To nozzle

Gear set

Shaft seal

Oil under suction

By-pass

plug

removed

Return ONE PIPE

plugged INSTALLATION

Vacuum

gauge port

By-pass

plug

inserted

TWO PIPE

INSTALLATION

Oil under pressure

By-passed oil

returned to tank,

or to suction

Return

Inlet

FLAME

SRL

0744-340566

contact@arzatoare.ro

www.arzatoare.ro

SUNTECDistribuitor:

INDUSTRIES FRANCE

- 1,POWER

rue Lavoisier

- CS021-3121727

60 102 - F-21603;LONGVIC

Cedex - ;Tel.

33 (0)3 80 70 60 70 - Fax 33;(0)3

80 70 61 11- www.suntec.fr

TECHNICAL DATA

Pump capacity

Capacity (L/h)

General

160

Hub mounting according to EN 225.

(Flange mounting available on AL 75/75K/95/95K models)

cylindrical according to ISO 228/1.

G 1/4

(with facilities for conical sealing on revision 6 models)

G 1/8

G 1/8

G 1/8

Pressure regulation.

open area : 6 cm2 (AL 35/35K/55/55K/65/65K)

20 cm2 (AL 75/75K/95/95K).

opening size : 150 m.

8 mm according to EN 225.

inserted in return port for two-pipe system ;

to be removed with a 4 mm Allen key for one pipe system.

1,1- 1,3 kg (depending on the model).

Nozzle outlet

Pressure gauge port

Vacuum gauge port

Valve function

Strainer

Shaft

By-pass plug

Weight

AL95K

120

AL 75

80

AL65K

60

AL 65

AL55K

40

AL 55

AL35K

AL 35

20

0

2

10

Gear size

35/55/65/75

95

35K/55K/65K/75K/95K

* other ranges available on

Operating viscosity

Oil temperature

Inlet pressure

Return pressure

Suction height

Rated speed

Torque (@ 45 rpm)

Nozzle pressure range*

Factory setting

4 - 18 or 8 - 15 bars @ 5 cSt

9 or 12 bars

4 - 18 or 10 - 20 bars @ 5 cSt

9 bars

8 - 15 bars @ 1,8 cSt

12 bars

request, refer to the specified range of the particular fuel unit.

2 - 12 mm/s (cSt) for AL 35/55/65/75/95

1,25 - 12 mm/s (cSt) for AL 35K/55K/65K/75K/95K

0 - 60C in the pump.

2 bars max.

2 bars max.

0,45 bars max. vacuum to prevent air separation from oil

3600 rpm max.

0,10 N.m (AL 35/35K/55/55K) - 0,12 N.m (AL 65/65K)

0,14 N.m (AL 75/75K)

- 0,20 N.m (AL 95/95K)

14

16

20

Power consumption

Power (W)

180

AL95K

160

140

120

AL 95

AL75K

AL 75

AL65K

AL 65

AL55K

AL 55

AL35K

AL 35

100

80

Voltage

220-240 or 110-120 or 24 V; 50/60 Hz

Consumption

9W

Coil Code*

Ambiant temperature

06/02/05

0 - 60 C

07

0 - 80 C

* Refer to "Pump identification - solenoid coil voltage".

Maximum pressure

25 bars

Certified

TV Nr stamped on pump cover.

Protection class

IP 54 according to EN 60529, when used with SUNTEC

connector cable.

PUMP DIMENSIONS

18

Data shown take into account a wear margin.

Do not oversize the pump when selecting the gear capacity.

Solenoid valve characteristics

60

40

20

2

10

Viscosity =

12

14

16

18

20

Pressure (bars)

5 cSt - Rated speed = 2850 rpm

1,8 cSt

Examples show "C" rotation and nozzle outlet.

Pumps revision 4,6

32

77

42

74

Pumps revision 2

46

25

32

21

74

10,5

32

13

7

21

13,5 13,5

47

21

54

35

A-A

63

77

42

13,5 13,5

12

Pressure (bars)

5 cSt - Rated speed = 2850 rpm

1,8 cSt

Viscosity =

Hydraulic Data

46

AL 95

AL75K

100

A-A

13

7

63

92

35

21

51 (AL 75/95)

47 (AL 35/55/65)

118

15

Inlet

and Return

with direct sealing

for revision 6 models

(sealing with washers

can also be used)

Suction

Pressure gauge port

Return and

internal by-pass plug

Vacuum gauge port

Nozzle outlet

Pressure adjustment

G1/4

SRL

021-3121727

WeDistribuitor:

reserve the rightFLAME

to changePOWER

specifications

without

prior notice

Ref: SK144 - 23/01/06; SK317 - 29/01/07

Connection threads

Inlet and return

140

Ref: SK144 - 23/01/06; SK317 - 29/01/07

Mounting

AL - 11 - Ed 14 - Feb. 2014

; 0744-340566 ; contact@arzatoare.ro ; www.arzatoare.ro

You might also like

- ASgbDocument2 pagesASgbathaya013No ratings yet

- AP GBDocument2 pagesAP GBTitu NicuNo ratings yet

- VMCDocument32 pagesVMCJoanaRicardo FigueiredoNo ratings yet

- fp50 fp100 fp200Document10 pagesfp50 fp100 fp200ducmanh83No ratings yet

- Dropsa YoensaDocument73 pagesDropsa YoensaCAGERIGONo ratings yet

- Oil Pump Type E 1001 Gear Sizes 4-6-7Document2 pagesOil Pump Type E 1001 Gear Sizes 4-6-7Titu NicuNo ratings yet

- Bul 36115 Servo Valve OperationDocument12 pagesBul 36115 Servo Valve Operationrikkitech100% (1)

- EC-0404 Yuken-Directional-Control-ValvesDocument50 pagesEC-0404 Yuken-Directional-Control-ValvesphaindikaNo ratings yet

- PVR-108-2 Fueling Model SheetDocument2 pagesPVR-108-2 Fueling Model SheetLetycia RosalesNo ratings yet

- Valves Grese NDocument92 pagesValves Grese NYair Alexis Muñoz Rojas100% (1)

- Valves Grese NDocument92 pagesValves Grese NRandall KirchbergNo ratings yet

- Bom A4VG - REXROTHDocument44 pagesBom A4VG - REXROTHnamduong368100% (4)

- Yukenmodularvalves Yuken CatDocument140 pagesYukenmodularvalves Yuken Catchidambaram kasi100% (1)

- 1995 Ford Escort 1Document11 pages1995 Ford Escort 1Francisco SanchezNo ratings yet

- Fluids Entry HBV Cetop 7 & 8 Series 101109Document12 pagesFluids Entry HBV Cetop 7 & 8 Series 101109Enhtuwshin BarkhasbadiNo ratings yet

- TACO Products 2007 r1Document174 pagesTACO Products 2007 r1yennyoj100% (1)

- HytrolDocument44 pagesHytrolMark Mach AllenNo ratings yet

- Proportional Electro-Hydraulic ControlsDocument31 pagesProportional Electro-Hydraulic ControlshassanHyro43100% (3)

- Comp Carly Scre Refrig 2004Document52 pagesComp Carly Scre Refrig 2004Deco DluxeNo ratings yet

- Series 30: Operating PrincipleDocument8 pagesSeries 30: Operating PrincipleDgek LondonNo ratings yet

- SG Actuator Gas Over OilDocument4 pagesSG Actuator Gas Over Oiltoader56No ratings yet

- SideWinder 40 60 80 CHMCL PMP BrchreDocument4 pagesSideWinder 40 60 80 CHMCL PMP BrchreSH McNo ratings yet

- Asco Ah2d v710Document4 pagesAsco Ah2d v710John Urdaneta0% (1)

- Allenair Catalog 4 Way ValvesDocument5 pagesAllenair Catalog 4 Way ValvesEddie WallsNo ratings yet

- VALVULA DE SOLENOIDE HS7 BulletinDocument4 pagesVALVULA DE SOLENOIDE HS7 BulletinJoséMarcanoNo ratings yet

- Elec Grs Pumps 203seriesDocument5 pagesElec Grs Pumps 203serieschand_yelNo ratings yet

- 2 Continental Hydraulics Directional Control Valves PDFDocument11 pages2 Continental Hydraulics Directional Control Valves PDFDaniel VillarroelNo ratings yet

- Free Fall Valve Pg1-11Document12 pagesFree Fall Valve Pg1-11Roshan ShanmughanNo ratings yet

- Variable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Document8 pagesVariable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Dias EliNo ratings yet

- HVAC+Valves+and+Actuators+Catalogue+07 2011Document64 pagesHVAC+Valves+and+Actuators+Catalogue+07 2011Jafar JalladNo ratings yet

- Slam Shut Serie100+brochureDocument4 pagesSlam Shut Serie100+brochureChelito IxNo ratings yet

- Technical Leaflet Cim 795Document7 pagesTechnical Leaflet Cim 795blindjaxxNo ratings yet

- Manual SSW10Document31 pagesManual SSW10Victor RodriguezNo ratings yet

- Cartridgevalves PDFDocument15 pagesCartridgevalves PDFÂnderson Silva BrasilNo ratings yet

- Dimensions Specifications: 125 Booster Pump ControlDocument6 pagesDimensions Specifications: 125 Booster Pump ControlDheeraj ThakurNo ratings yet

- Valves BarendsenDocument63 pagesValves BarendsenidontlikeebooksNo ratings yet

- Pressure ReliefDocument124 pagesPressure ReliefFrancis5801No ratings yet

- Trokraki On - Off VentilDocument12 pagesTrokraki On - Off VentilAdvokat HadziTonicNo ratings yet

- SL030 PDFDocument2 pagesSL030 PDFchidambaram kasiNo ratings yet

- SATECH - Eagle Control-Matic - WHC System EH36 Series - Product Brochure (Ed011211 1214Hr) PDFDocument20 pagesSATECH - Eagle Control-Matic - WHC System EH36 Series - Product Brochure (Ed011211 1214Hr) PDFuserscribd2011No ratings yet

- Fluid Components Full CatalogDocument464 pagesFluid Components Full Catalognegg 348No ratings yet

- Oil Pump Type D GEAR SIZES 45-47-55-57-67Document2 pagesOil Pump Type D GEAR SIZES 45-47-55-57-67Titu NicuNo ratings yet

- Digital Control ValveDocument8 pagesDigital Control Valvecnrk777100% (1)

- Buchholz Relays PRINCIPLESDocument9 pagesBuchholz Relays PRINCIPLESBui Vanluong100% (1)

- Rexroth 4we10 Data SheetDocument10 pagesRexroth 4we10 Data SheetOrlando Arias100% (1)

- Murphy ShuTDOWNDocument12 pagesMurphy ShuTDOWNReider AmundarayNo ratings yet

- HPB Brochure 0708Document12 pagesHPB Brochure 0708musaluddinNo ratings yet

- Rele A Gas BuchholtsDocument18 pagesRele A Gas BuchholtsMarco GiraldoNo ratings yet

- Chemetron Novec Gamma Specs PDFDocument6 pagesChemetron Novec Gamma Specs PDFambition1340cnNo ratings yet

- Oil Pump Type Ale Gear Sizes 35-55: ALE Oil Pump Incorporates A Blocking Solenoid Valve Fitted With A Built-InDocument2 pagesOil Pump Type Ale Gear Sizes 35-55: ALE Oil Pump Incorporates A Blocking Solenoid Valve Fitted With A Built-Inmochammad RezaNo ratings yet

- SSB 800 05Document2 pagesSSB 800 05Raydoon SadeqNo ratings yet

- All 115 1 Catalogo GPL 2011Document36 pagesAll 115 1 Catalogo GPL 2011prieten20006936No ratings yet

- 574 914 PDFDocument1 page574 914 PDFDee RajaNo ratings yet

- FM 200 Sigma Spec SheetDocument6 pagesFM 200 Sigma Spec SheetPepe ViteriNo ratings yet

- Axial Variable Duoble PumpDocument40 pagesAxial Variable Duoble Pumpveljeg100% (1)

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- P D R HMG 3000: Ortable ATA EcorderDocument76 pagesP D R HMG 3000: Ortable ATA EcorderStroia Constantin MariusNo ratings yet

- PC-Software HMGWIN 3000: User ManualDocument30 pagesPC-Software HMGWIN 3000: User ManualStroia Constantin MariusNo ratings yet

- Transfluid HidrauliccouplingDocument32 pagesTransfluid HidrauliccouplingStroia Constantin Marius100% (1)

- CatalogueDocument55 pagesCatalogueStroia Constantin MariusNo ratings yet

- Turbo SidDocument60 pagesTurbo SidStroia Constantin Marius100% (1)

- CatalogueTroubleshooting HY29 0022 UKDocument62 pagesCatalogueTroubleshooting HY29 0022 UKStroia Constantin MariusNo ratings yet

- B&J Fuel Injection 2014Document24 pagesB&J Fuel Injection 2014island140% (1)

- Volvo EC210BDocument12 pagesVolvo EC210BStroia Constantin Marius78% (27)

- Sensors EuropeDocument107 pagesSensors EuropeStroia Constantin MariusNo ratings yet

- BTNDocument68 pagesBTNStroia Constantin MariusNo ratings yet

- Caterpillar® Engine SpecificationsDocument6 pagesCaterpillar® Engine Specificationsmaman96100% (3)

- Turbocharging Inspection 10-01Document15 pagesTurbocharging Inspection 10-01Stroia Constantin MariusNo ratings yet

- Spec EC460B INT EN 30E4351646Document16 pagesSpec EC460B INT EN 30E4351646Stroia Constantin MariusNo ratings yet

- Selection Guide Eaton1DRDocument20 pagesSelection Guide Eaton1DRStroia Constantin MariusNo ratings yet

- QRF Wa320pz-6 LowresDocument2 pagesQRF Wa320pz-6 LowresStroia Constantin MariusNo ratings yet

- Bell Lubricants European EnglishDocument16 pagesBell Lubricants European EnglishStroia Constantin MariusNo ratings yet

- Volvo L220 Atach Prod ManDocument54 pagesVolvo L220 Atach Prod ManStroia Constantin Marius0% (1)

- Yuchai Yc 8 Models 2010Document6 pagesYuchai Yc 8 Models 2010Stroia Constantin Marius100% (1)

- 2013 - 14 HydraulicsDocument122 pages2013 - 14 HydraulicsStroia Constantin MariusNo ratings yet

- Delphi Electronic Unit Injectors CatalogDocument20 pagesDelphi Electronic Unit Injectors CatalogStroia Constantin Marius100% (4)

- JCB Lubricant Brochure 2009Document13 pagesJCB Lubricant Brochure 2009Henwy Dickinson100% (1)

- VS1131Document2 pagesVS1131Stroia Constantin MariusNo ratings yet

- INA CatalogueDocument110 pagesINA CatalogueStroia Constantin MariusNo ratings yet

- Cat Short BlocksDocument40 pagesCat Short Blockslucianowcap100% (2)

- Formula To Calculate Gear Pump DisplacementDocument1 pageFormula To Calculate Gear Pump DisplacementStroia Constantin MariusNo ratings yet

- 1.6L 4cyl Diesel & Turbo DieselDocument18 pages1.6L 4cyl Diesel & Turbo DieselLeomir BrandaoNo ratings yet

- ManualDocument4 pagesManualmuhammad arif67% (3)

- Motorliste PDFDocument4 pagesMotorliste PDFmostafamarocNo ratings yet

- LMW Turbine Oprn. ManualDocument45 pagesLMW Turbine Oprn. Manualkamal100% (1)

- TM9 2815 210 34 2 2Document972 pagesTM9 2815 210 34 2 2glockpod100% (1)

- SYL Mechanic Motor Vehicle 08 06 14 PDFDocument43 pagesSYL Mechanic Motor Vehicle 08 06 14 PDFபாலவிக்னேஷ்No ratings yet

- PAH - Manual de ServicioDocument14 pagesPAH - Manual de ServiciojairoNo ratings yet

- Dinli 700 Parts BookDocument45 pagesDinli 700 Parts Bookstolerucatalin99No ratings yet

- Instruction Manual WARTSILLADocument458 pagesInstruction Manual WARTSILLAEmilio Portela100% (7)

- H2 & Seal Oil SysDocument33 pagesH2 & Seal Oil Syssanmukha100% (1)

- (MAHINDRA) Manual de Taller Mahindra Scorpio 2006 Ingles PDFDocument510 pages(MAHINDRA) Manual de Taller Mahindra Scorpio 2006 Ingles PDFVictor Montesdeoca100% (1)

- D 8 TDocument2 pagesD 8 TAlberjose Sanchez RuizNo ratings yet

- MEK Marine Equipment Spare PartsDocument6 pagesMEK Marine Equipment Spare PartsMEK MarineNo ratings yet

- Engine: Shop ManualDocument424 pagesEngine: Shop ManualJacob Alberto Quispe QuispeNo ratings yet

- W32 PresentationDocument43 pagesW32 PresentationMiguel Angel PonceNo ratings yet

- Commissioning Procedure For Turbine Lube Oil System - Rev ADocument45 pagesCommissioning Procedure For Turbine Lube Oil System - Rev ALan Rung100% (1)

- Beverly Tourer 250 IeDocument318 pagesBeverly Tourer 250 IeIvan CerovsekNo ratings yet

- Yanmar 3HM35Document104 pagesYanmar 3HM35hastaNo ratings yet

- 1.2 L Renault D4F I4 Engine ManualDocument141 pages1.2 L Renault D4F I4 Engine ManualMahmoud Taher El Khorzaty86% (14)

- Lycoming Special ToolsDocument52 pagesLycoming Special ToolsVarman Aviation Quality DeptNo ratings yet

- Parts Carrier PG Parts Catalog PDFDocument182 pagesParts Carrier PG Parts Catalog PDFJose GuajardoNo ratings yet

- Fallas Transmision 428cDocument20 pagesFallas Transmision 428ccristian chuquicondor torresNo ratings yet

- 854F-Disassembly and AssemblyDocument204 pages854F-Disassembly and AssemblyZIBA KHADIBI100% (2)

- Ingersoll-Rand EDocument86 pagesIngersoll-Rand Erok.feleNo ratings yet

- Form One Report Sheet-1Document2 pagesForm One Report Sheet-1Epul SaepulohNo ratings yet

- Danfos - PMC - Variador e CompressorDocument62 pagesDanfos - PMC - Variador e Compressorvalter almeidaNo ratings yet

- 718 Cayman (982), 2017 - TodayDocument555 pages718 Cayman (982), 2017 - TodayJZM GulfNo ratings yet

- Wartsila 38-F-S-D-BOOKDocument151 pagesWartsila 38-F-S-D-BOOKEgor Xlebnikov88% (8)

- HHP Locomotive Compartments and Parts Location: DTTC/GTLDocument233 pagesHHP Locomotive Compartments and Parts Location: DTTC/GTLarjunsai100% (1)

- Pump Lubrication PlanDocument1 pagePump Lubrication PlanSiraj AhmedNo ratings yet