Professional Documents

Culture Documents

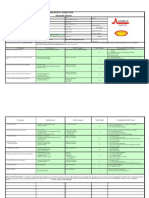

Installation of Propane Gas System Risk Assessment

Uploaded by

Shijad PaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation of Propane Gas System Risk Assessment

Uploaded by

Shijad PaCopyright:

Available Formats

Page 1

Installation of Propane Gas Burj Dubai

System

Development

TASK

Step Description of

No: Task Step

Material

Unloading to

IGS store at

Dubai Mall site

Mr. Shibu P

Approved By:

HSE Officer

Mr. Gafoor A Project Engineer

HAZARD

INITIAL RISK

Who or

what

Hazard Description & Effect

might be

harmed ?

1.1 Fatality or Damage due to

load drop from the Truck

mounted Crane

Risk Level

1/2/3/4/5

Location

Probability

1/2/3

Work activity:

DATE:

ACTIVITY RISK ASSESSMENT DATA SHEET

Assessment

Designation:

Signature:

Date: 02/09/06

Team

Severity

1/2/3

Ref No: 001/RA/06

CONTROLS

RESIDUAL RISK

Risk Control Measures (Preventive Action)

1.1.1. Check to make sure all safety devices

are working correctly

1.1.2 Lifting equipment must be certified;

color- coded, rated to load capacity

and checked before usage

1.1.3 Ensure there no loose objects inside or

outside load

1.2 Over Lad

People

1.2.3 Before attempting to lift the load check the

load capacity of the Crain and load to be lift

1.3 Lifting lines tag lines failure

1.4Unauthorised person during

the operation

Asset

1.2.1 Load indictor must be working efficiently

and calibrated.

1.3.1 The operator should be a competent

personal

1.3.2 Check the tag before the work begins

1.4.1 Control unauthorised person from the

unloading area

1.4.2 Personal working along with the

unloading activity should wear personal

protective equipmnt properly

CORRECTIVE ACTION

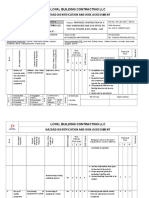

Page 2

TASK

Step Description of

No: Task Step

HAZARD

INITIAL RISK

Who or

what

Hazard Description & Effect

might be

harmed ?

Painting of the 2.1 Injury to eyes while mixing

Pipe in the Store paint and thinner

2.2 Injury to fingers, if caught

by locking device of cap

People

2.3 Fire

Shifting the pipe

from the IGS

3.1 Vehicle collision

store to work

sport by pick up

Asset

Risk Level

1/2/3/4/5

Burj Dubai

Installation of Propane Gas Development

System

DATE:

ACTIVITY RISK ASSESSMENT DATA SHEET

Assessment

Designation:

Signature:

Date: 02/09/06

Team

Mr. Shibu P

HSE Officer

Mr.Gafoor A Project Engineer

CONTROLLS

Approved By:

RESIDUAL RISK

Probability

1/2/3

Location

Severity

1/2/3

Ref No: 001/RA/06

Work activity:

2.2.1 Use personal protective equipment

properly

2.3.1 Paint is a flammable equipment so keep

thepaint and thinner away from the

ignition source

Risk Control Measures (Preventive Action)

2.1.1 Check cap and locking mechanism for

proper working and use suitable tools for

opening .

3.1.1 Park the vehile proper and convenient

place to load

3.1.2 Check the wait of material to be shifted

3.1.3 Obey the speed limits in side the site

3.2 slipping or falling f the pipe

3.2.1 Hook on each side of the pipe

3.3 Injury to the finger, hands or

body part

3.3.1Check the sharp edges on the pipe

3.3.2 Use proper personal protective equipment

3.3.3 keep the shifted pipes in to pipe racks

3.3.4 Use stopper in the rack

CORRECTIVE ACTION

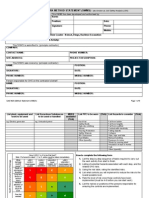

Page 3

Ref No: 001/RA/06

Work activity:

Location

ACTIVITY RISK ASSESSMENT DATA SHEET

Assessment

Designation:

Signature:

Date: 02/09/06

Team

Mr. Shibu P

HSE Officer

DATE:

Approved By:

Mr. Gafoor A Project Engineer

Fixing clevis

hanger on the

roof

Who or

what

Hazard Description & Effect

might be

harmed ?

4.1 Inadequate scaffolding

Risk Level

1/2/3/4/5

INITIAL RISK

Probability 1/2/3

Step Description of

No: Task Step

HAZARD

Severity

1/2/3

TASK

Drilling / Cutting 5.1 Electrical shock, burns if

cable is live

5.2 Tip and fall while working

Asset

when cable are laying down

RESIDUAL RISK

Risk Control Measures (Preventive Action)

4.1.1Check the scaffolding placed in firm and

right place

4.1.2 check the scaffolding visually

4.1.3 Check the scaffolding inspection tag

validity signature

4.1.4 Use safety harness and hook in

4.1.5 Do not push the scafolding by keeping a

man in top

People

CONTROLLS

5.1.1 Make sure that power is switched off prior

to inspection

5.2.1 Make sure that cables insulation are good.

5.2.2 Make sure that cable are located properly

to prevent tripping hazards.

5.1.3 Do not operate with wet hands or standing

on wet surface

5.2.4 Hold the power tools firmly and carefully.

CORRECTIVE ACTION

Page 4

Installation of Propane Gas Burj Dubai

System

Development

TASK

Step Description of

No: Task Step

DATE

Date: 02/09/06

Approved By:

Mr. Gafoor A Project Engineer

HAZARD

INITIAL RISK

Who or

what

Hazard Description & Effect

might be

harmed ?

5.3Injuries to personnel with

moving parts.

Risk Lvel

1/2/3/4/5

Location

Probability

1/2/3

Work activity:

ACTIVITY RISK ASSESSMENT DATA SHEET

Assessment

Designation:

Signature:

Team

Mr. Shibu P

HSE Officer

Severity

1/2/3

Ref No: 001/RA/06

CONTROLS

RESIDUAL RISK

Risk Control Measures (Preventive Action)

5.3.1 Only trained person should operate the

power tools.

5.3.2 Make sure all moving parts are properly

guarded

People

Fixing of the

pipe on the

clives hanger

6.1 Fall off the load structure

fitted on the roof while removing crane

by crane or

manuel

5.3.3 Use PPE (safety glasses / goggles)

6.1.1 Review all safe procedure related to crane

movement

6.1.2 Competent personal should give the

signal to the crane operator.

6.2 Load drops due to striking

Asset

against projections

6.3 Injury to fingers with pinch

points or cut with sharp

edge

6.2.1 Make sure that all material loded in the

crane are properly protected by falling

6.2.2 Remove all obstruction from the lifting

place

2

6.3.1 use all personal protective equipment

while lifting

6.3.2 proper communication shall be provided

CORRECTIVE ACTION

Page 5

TASK

Step Description of

No: Task Step

HAZARD

INITIAL RISK

Who or

what

Hazard Description & Effect

might be

harmed ?

7.1 Damage to body parts

DATE:

Approved By

Date: 02/09/06

Mr. Gafoor A Project Engineer

Risk Level

1/2/3/4/5

Installation of Propane Gas Burj Dubai

Development

System

Probability 1/2/3

Location

ACTIVITY RISK ASSESSMENT DATA SHEET

Assessment

Designation:

Signature:

Team

Mr. Shibu P

HSE Officer

Severity

1/2/3

Ref No: 001/RA/06

Work activity:

Welding &

Grinding

Asset

RESIDUAL RISK

Risk Control Measures (Preventive Action)

7.1.1 Use all personal protective equipment

(welding gloves, face shield and proper

clothing)

7.1.2 Flammable material will be removed

from area where the welding is to be under

taken

People

7.2 Fire

CONTROLS

7.2.1 If the removal of flammable materials is

not practicable . Precautions are to be

taken to reduce the risk of fire

7.2.2 Fire extinguisher is immediately

available in the area of any welding n

operation

7.2.3 Follow WPS procedure and welding to

be carried out Qualified Welder only

CORRECTIVE ACTION

Page 6

7.3 Electrocution

Description of

Task Step

Hazard Description &

Effect

INITIAL RISK

Who or

what

might be

harmed ?

1/2/3

HAZARD

Risk Level

1/2/3/4/5

Step

No:

DATE:

Approved By:

ACTIVITY RISK ASSESSMENT DATA SHEET

Assessment

Designation:

Signature:

Date: 02/09/06

Team

Mr. Shibu P

HSE Officer

Mr. Gafoor A Project Engineer

Severity

TASK

Probability

1/2/3

Ref No: 001/RA/06

Work activity:

Location

Instalation of Propane Gas

Burj Dubai

System

Development

7.3.1 Welding return will be firmly connected

to the welding is taking place. This will

be carry out by means of well

constructed earthing clamps only

CONTROLS

RESIDUAL RISK

Risk Control Measures (Preventive Action)

7.3.2Welding cables and cable joints will be

maintained good condition

7.4.1Grinders should be maintain good

condition and inspected prior to use

People

7.4 Weel burst of grinding

mechine

3

Asset

7.4.2 Guard to be fitted to the grinders

7.4.3 Change of abrasive wheel to be carried

out by trained and authorized personal

using proper disc spanner

7.4.4 Grinding operation will be controlled in order

to prevent the risk of injury to other

personal from spark and metal splinters

CORRECTIVE ACTION

Page 7

7.4.5 House keeping in the areas at grinding

operation to be maintained to a high level

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

You might also like

- RISK ASSE 110 - Fire Fighting System - F03Document8 pagesRISK ASSE 110 - Fire Fighting System - F03Rochdi BahiriNo ratings yet

- Rmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)Document2 pagesRmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)myn maliQueNo ratings yet

- JHA Civil WorksDocument2 pagesJHA Civil Worksethelchudi100% (11)

- Job Safety Analysis for Relay ConfigurationDocument4 pagesJob Safety Analysis for Relay Configurationfrancis_e_tan100% (2)

- Risk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEDocument12 pagesRisk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEnsadnan100% (4)

- Master Hazards Risks RegisterDocument113 pagesMaster Hazards Risks RegisterIvanNo ratings yet

- Risk Assessment of Fire Pipe Flange T ConnectionDocument5 pagesRisk Assessment of Fire Pipe Flange T Connectionimran aliNo ratings yet

- Steel FixingDocument5 pagesSteel Fixingrishanmulky88% (8)

- Diesel RefuelingDocument3 pagesDiesel RefuelingAMINNo ratings yet

- Risk Assesment For Demolition of Factory Buildings at 14 Tuas Ave 1Document4 pagesRisk Assesment For Demolition of Factory Buildings at 14 Tuas Ave 1Yam Balaoing100% (1)

- Casting ConcreteDocument9 pagesCasting ConcreteNontobeko MkhizeNo ratings yet

- Generic Risk AssessmentDocument8 pagesGeneric Risk Assessmentmorgojoyo100% (3)

- JHA Cutting of Asphalt Road For Replacement of Protection SlabsDocument5 pagesJHA Cutting of Asphalt Road For Replacement of Protection SlabsNasrullah JanNo ratings yet

- RA-LBC-007 Risk Assessment Concrete WorksDocument8 pagesRA-LBC-007 Risk Assessment Concrete Worksjones100% (1)

- Project: Site / Office: Contractor: Date: Time:: Topics To Be Discussed During HSE InductionDocument2 pagesProject: Site / Office: Contractor: Date: Time:: Topics To Be Discussed During HSE InductionBashir ArisarNo ratings yet

- Site Specific Health Safety Environment Plan HvacDocument74 pagesSite Specific Health Safety Environment Plan Hvacsyed khaja misbhuddin100% (1)

- Electric Hand Drill Risk AssessmentDocument4 pagesElectric Hand Drill Risk AssessmentTariq AkhtarNo ratings yet

- Concreting and ShutteringDocument3 pagesConcreting and ShutteringAnuj Kjoy0% (1)

- Excavation Risk Assessment KTPS - 8 PAGESDocument7 pagesExcavation Risk Assessment KTPS - 8 PAGESrajalingam100% (1)

- RA, COSHH, MSDS Screed & Waterproofing PDFDocument27 pagesRA, COSHH, MSDS Screed & Waterproofing PDFテレブリコ ジェファーソン60% (5)

- OHS SWMS Form 005 ExcavationDocument8 pagesOHS SWMS Form 005 Excavationazlinaz100% (2)

- Risk Assessment For Sand Blasting PDFDocument8 pagesRisk Assessment For Sand Blasting PDFOvais FarooqNo ratings yet

- 1 MobilizationDocument8 pages1 MobilizationAnthony Macatangay100% (1)

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Document6 pagesJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNo ratings yet

- Old Cables, Conduits and Cable Trays Dismantling - JSEA FormDocument40 pagesOld Cables, Conduits and Cable Trays Dismantling - JSEA FormJayson Escamillan100% (2)

- HAZARD IDENTIFICATION & RISK ASSESSMENT FOR EXCAVATION OF ROAD WITH TLBDocument7 pagesHAZARD IDENTIFICATION & RISK ASSESSMENT FOR EXCAVATION OF ROAD WITH TLBCharles LambNo ratings yet

- RA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & TrenchesDocument11 pagesRA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & Trenchesthomson100% (1)

- Risk Assessment FormDocument8 pagesRisk Assessment FormRochdi BahiriNo ratings yet

- Job Safety Analysis: JSA Reference #: DateDocument3 pagesJob Safety Analysis: JSA Reference #: DateLi QiNo ratings yet

- Construction Risk Assessment ProcedureDocument154 pagesConstruction Risk Assessment ProcedureAsif100% (5)

- Brick Masonry - EHS Risk AssessmentDocument2 pagesBrick Masonry - EHS Risk Assessmentnagarjuna100% (3)

- RC Pipes Installation SafetyDocument15 pagesRC Pipes Installation SafetyTaiwo Oshin100% (1)

- Project HSE Action Plan SummaryDocument101 pagesProject HSE Action Plan SummaryArya RozaanNo ratings yet

- DSM-FRM-0001-27-0, HDPE PE-100 Pipe InstallationDocument4 pagesDSM-FRM-0001-27-0, HDPE PE-100 Pipe Installationkadir tanzaniaNo ratings yet

- All Tyeps Risk Assessment in Construction PDFDocument112 pagesAll Tyeps Risk Assessment in Construction PDFSorin Tec100% (1)

- Assessment No 47 Demolition Basin E40Document4 pagesAssessment No 47 Demolition Basin E40Rochdi Bahiri0% (1)

- Concrete Works Risk AssessmentDocument14 pagesConcrete Works Risk AssessmentUMUT100% (1)

- Risk Assessment - Backfilling Around Foul Sewer and Storm Warter ManholesDocument6 pagesRisk Assessment - Backfilling Around Foul Sewer and Storm Warter Manholesloveson70950% (2)

- 3-REV.1 - Hot Work - Risk Assessment JHADocument16 pages3-REV.1 - Hot Work - Risk Assessment JHAnaiyar100% (1)

- JHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDocument4 pagesJHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDarmawan OnradNo ratings yet

- HSE Statistics PDFDocument5 pagesHSE Statistics PDFRashid100% (1)

- Very Very Good Risk Assessment EnvironmentDocument8 pagesVery Very Good Risk Assessment EnvironmentSalley Bukhari100% (1)

- HIRA (Pipeline Construction Work)Document28 pagesHIRA (Pipeline Construction Work)sheerazali90% (10)

- Hazards of Piling WorksDocument6 pagesHazards of Piling Worksjoaonunes.40544364% (11)

- Risk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CDocument5 pagesRisk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CYash SharmaNo ratings yet

- Risk Assessment & Control Register - Grease Trap CleaningDocument7 pagesRisk Assessment & Control Register - Grease Trap CleaningAbdul RahmanNo ratings yet

- JHA - Handrails and GratingsDocument10 pagesJHA - Handrails and GratingsVidyesh Nair67% (3)

- Risk Assessment Construction SiteDocument9 pagesRisk Assessment Construction SiteJuned Hamid Khan100% (2)

- Welding, Cutting and GrindingDocument6 pagesWelding, Cutting and GrindingMohammed MinhajNo ratings yet

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Document3 pagesRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Environmental, Health and Safety Risk AssessmentDocument2 pagesEnvironmental, Health and Safety Risk AssessmentAdnan100% (2)

- JSA GC-5 Mobile ScaffoldingDocument6 pagesJSA GC-5 Mobile Scaffoldinggrande100% (2)

- RISK ASSES-106-Erection of Steel Structure BuildinDocument4 pagesRISK ASSES-106-Erection of Steel Structure BuildinRochdi Bahiri50% (2)

- Permit To Work FormsDocument8 pagesPermit To Work FormsMarc Vincent SeñorinNo ratings yet

- NEW Form JHA-Road Works (27-03-2018) FinalDocument34 pagesNEW Form JHA-Road Works (27-03-2018) FinalKarthik babu100% (3)

- Construction HSE ProcedureDocument39 pagesConstruction HSE ProcedureAli Hajirassouliha100% (1)

- JHEA Loading and Offloading FENCEDocument13 pagesJHEA Loading and Offloading FENCEStansilous Tatenda NyagomoNo ratings yet

- Demolition Risk AssessmentDocument41 pagesDemolition Risk AssessmentVenkadesh Periathambi100% (3)

- Confined Space Entry Risk AssessmentDocument9 pagesConfined Space Entry Risk Assessmentkoketso0% (1)

- JSA Shut Down and Tie in Work PDFDocument6 pagesJSA Shut Down and Tie in Work PDFpjosesm80% (5)

- Element 1Document73 pagesElement 1Shijad PaNo ratings yet

- Risk Assessment Matrix (Definition and Notes)Document2 pagesRisk Assessment Matrix (Definition and Notes)Shijad PaNo ratings yet

- 18 - Risk Assessment - On-Plot Area - MuftahDocument5 pages18 - Risk Assessment - On-Plot Area - MuftahShijad PaNo ratings yet

- 01 - Risk Assessment - Laydown Area - MuftahDocument6 pages01 - Risk Assessment - Laydown Area - MuftahShijad PaNo ratings yet

- Risk Assessment 1Document1 pageRisk Assessment 1Shijad PaNo ratings yet

- SafetyDocument2 pagesSafetyShijad PaNo ratings yet

- Ref No: 001/RA/06 Activity Risk Assessment Data Sheet Date: Work Activity: Location Designation: Signature: Date: 25/07/06 Assessment TeamDocument6 pagesRef No: 001/RA/06 Activity Risk Assessment Data Sheet Date: Work Activity: Location Designation: Signature: Date: 25/07/06 Assessment TeamShijad PaNo ratings yet

- Slightly Harmful (1) Harmful (2) Extremely Harmful (3) UnlikelyDocument1 pageSlightly Harmful (1) Harmful (2) Extremely Harmful (3) UnlikelyShijad PaNo ratings yet

- 03 - Risk Assessment - Geotechnical Survey - ERIDocument3 pages03 - Risk Assessment - Geotechnical Survey - ERIShijad PaNo ratings yet

- Acergy Interview QuestionnaireDocument5 pagesAcergy Interview QuestionnaireShijad PaNo ratings yet

- Element 1 AnswersDocument2 pagesElement 1 AnswersNabeel Khan100% (1)

- Igc 01 InsDocument25 pagesIgc 01 InsShijad PaNo ratings yet

- Igc 01Document4 pagesIgc 01Shijad PaNo ratings yet

- NEBOSH International General Certificate Paper 1 Management of Health and Safety Element 2 Setting Health & Safety PolicyDocument2 pagesNEBOSH International General Certificate Paper 1 Management of Health and Safety Element 2 Setting Health & Safety PolicyShijad PaNo ratings yet

- Element 2Document52 pagesElement 2Shijad PaNo ratings yet

- Element 1Document73 pagesElement 1Shijad PaNo ratings yet

- EnvDip QAsDocument112 pagesEnvDip QAsShijad PaNo ratings yet

- Element 3Document41 pagesElement 3Shijad PaNo ratings yet

- EnvDiploma All Units 1.1cDocument919 pagesEnvDiploma All Units 1.1cShijad PaNo ratings yet

- Autism AspergerDocument24 pagesAutism AspergerusavelNo ratings yet

- Aiatsoymeo2016t06 SolutionDocument29 pagesAiatsoymeo2016t06 Solutionsanthosh7kumar-24No ratings yet

- Tle-Bpp 8-Q1-M18Document14 pagesTle-Bpp 8-Q1-M18Michelle LlanesNo ratings yet

- The BrigadeDocument517 pagesThe Brigadele_chiffre4860100% (3)

- Materi 2 Academic WritingDocument7 pagesMateri 2 Academic Writingna03friezaNo ratings yet

- Formula Sheet For Astronomy 1 - Paper 1 and Stars & PlanetsDocument2 pagesFormula Sheet For Astronomy 1 - Paper 1 and Stars & PlanetsprashinNo ratings yet

- Personal Weaknesses ListDocument3 pagesPersonal Weaknesses ListKinga SzászNo ratings yet

- Medicalization of Racial Features Asian American Women and Cosmetic SurgeryDocument17 pagesMedicalization of Racial Features Asian American Women and Cosmetic SurgeryMadalina ElenaNo ratings yet

- Science & Technology: Wireless Sensor Network and Internet of Things (Iot) Solution in AgricultureDocument10 pagesScience & Technology: Wireless Sensor Network and Internet of Things (Iot) Solution in AgricultureSivajith SNo ratings yet

- Twin-Field Quantum Key Distribution Without Optical Frequency DisseminationDocument8 pagesTwin-Field Quantum Key Distribution Without Optical Frequency DisseminationHareesh PanakkalNo ratings yet

- 14-15 TDP HandbookDocument28 pages14-15 TDP Handbookapi-266268398No ratings yet

- Origin and Development of Law of Sea PDFDocument135 pagesOrigin and Development of Law of Sea PDFkimmiahujaNo ratings yet

- 1022-Article Text-2961-1-10-20200120Document10 pages1022-Article Text-2961-1-10-20200120Zuber RokhmanNo ratings yet

- AwsDocument8 pagesAwskiranNo ratings yet

- Neoclassicism: Romanticism Realism ImpressionismDocument16 pagesNeoclassicism: Romanticism Realism ImpressionismErika EludoNo ratings yet

- LAWS1150 Principles of Private LawDocument102 pagesLAWS1150 Principles of Private Lawelpatron87100% (2)

- Crypto Portfolio Performance and Market AnalysisDocument12 pagesCrypto Portfolio Performance and Market AnalysisWaseem Ahmed DawoodNo ratings yet

- ViscosityDocument7 pagesViscositykiran2381No ratings yet

- CHEST 6. Chest Trauma 2022 YismawDocument61 pagesCHEST 6. Chest Trauma 2022 YismawrobelNo ratings yet

- The Army Crew Team Case AnalysisDocument3 pagesThe Army Crew Team Case Analysisarshdeep199075% (4)

- Sengoku WakthroughDocument139 pagesSengoku WakthroughferdinanadNo ratings yet

- Merry Almost Christmas - A Year With Frog and Toad (Harmonies)Document6 pagesMerry Almost Christmas - A Year With Frog and Toad (Harmonies)gmit92No ratings yet

- Chapter 10 HandoutDocument18 pagesChapter 10 HandoutChad FerninNo ratings yet

- The Research TeamDocument4 pagesThe Research Teamapi-272078177No ratings yet

- Lived Experiences of Elementary Teachers in A Remote School in Samar, PhilippinesDocument14 pagesLived Experiences of Elementary Teachers in A Remote School in Samar, Philippinesルイス ジャンNo ratings yet

- Perkin Elmer Singapore Distribution CaseDocument3 pagesPerkin Elmer Singapore Distribution CaseJackie Canlas100% (1)

- Modelling of Induction Motor PDFDocument42 pagesModelling of Induction Motor PDFsureshNo ratings yet

- Christian Appraisal of Feminist Ideologies Among Nigerian Women 2020Document78 pagesChristian Appraisal of Feminist Ideologies Among Nigerian Women 2020Nwaozuru JOHNMAJOR ChinecheremNo ratings yet

- Banking & Finance Awareness 2016 (Jan-Nov) by AffairsCloudDocument167 pagesBanking & Finance Awareness 2016 (Jan-Nov) by AffairsCloudkaushikyNo ratings yet

- P7 Summary of ISADocument76 pagesP7 Summary of ISAAlina Tariq100% (1)