Professional Documents

Culture Documents

EEM 42 Three Phase Asynchr Machines Dahlander Motor

Uploaded by

ZoneoTakan Berpling DrimhuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EEM 42 Three Phase Asynchr Machines Dahlander Motor

Uploaded by

ZoneoTakan Berpling DrimhuCopyright:

Available Formats

Course

"EEM 42 Three-phase asynchronous machines: Dahlander

motors"

Picture source: SEW Eurodrive

SH5002-1H Version 2.1

Author: M.Germeroth

Lucas-Nlle GmbH Siemensstrae 2 D-50170 Kerpen (Sindorf)

Phone: +49 2273 567-0

www.lucas-nuelle.de

Some animations require that a Flash-Player be installed. Should your system not have a Flash-Player installed,

you can download an up to date version any time from Macromedia.

Copyright 2008 LUCAS-NLLE GmbH.

All rights reserved.

LUCAS-NLLE Lehr- und Messgerte GmbH

Siemensstrae 2 D-50170 Kerpen

EEM42 Three-phase asynchronous machines

Training objectives

Equipment - 300W Classic Series

Safety

Asynchronous motor, Dahlander circuit

Connection and starting

Rotation reversal

Load characteristic

Copyright

1

2

3

5

7

15

21

31

EEM42 Three-phase asynchronous machines

EEM42 Three-phase asynchronous machines

Training objectives

Welcome to the three-phase asynchronous machines course. The

LUCAS-NLLE team wishes you lots of fun and success in working

through the course subjects and conducting the experiments. The

following pages provide an overview of the topics and required materials.

This course is intended to impart a practical knowledge of three-phase

asynchronous machines.

Experiments focus on investigating the functionality, response and effect of threephase asynchronous motors with polarity reversal according to Dahlander .

Training objectives

Motor operation

Nominal data, rating plate

Delta connection, double-star connection

Dahlander pole reversal

Measurement of phase-to-phase and line-to-linevariables

Rotation reversal

Power measurement with and without mechanical loads

Prerequisites

Fundamentals of electrical machines

Fundamentals of electrical engineering

Use of measuring equipment

EEM42 Three-phase asynchronous machines

Equipment - 300W Classic Series

SO3636-6V

SE2662-2A

SE2667-2B

SE2672-3K

SO3212-5U

SO3212-2H

SO5127-1Z

SO5148-1F

SO5126-9X

SO5126-9Z

servo drive/servo brake, 300 W

Coupling sleeve, 300 W

Coupling guard, 300 W

Three-phase motor with squirrel cage rotor,

300 W

Power supply for electrical machines

Dahlander pole reverser

Analog/digital multimeter, wattmeter, powerfactor meter

Set of 47 safety connecting leads, 4 mm

Safety connection plug, 19/4 mm

Safety connection plug, 19/4 mm, with tap

1

1

1

1

1

1

1

1

15

5

EEM42 Three-phase asynchronous machines

Safety

Basic safety instructions

In all experiments using mains voltages, high, life-threatening voltages arise. For

that reason use only safety measurement leads and make sure that there are no

short-circuits.

It is imperative that all of the devices, which are provided with an earth or where

earthing is possible, must be earthed. This is particularly the case for the frequency

converter being used.

Always be very careful to check the wiring of the application modules and only

switch on the mains voltage after a check has been completed. Whenever possible

use a robust current monitoring instrument in the circuit..

Always use shaft-end guards and coupling guards as protection against contact with

rotating motor parts.

All locally applicable stipulations and standards governing how electrical equipment

is handled must be complied with.

EEM42 Three-phase asynchronous machines

Safety

General instructions on handling the equipment

Check that the knurled screws at the base of the motor and the coupling

sleeves (power grip) on the motor shaft are all securely fastened.

Use shaft and coupling guards.

Any prolonged running of the machines when operating under high loads can

subject the machines to excessive heating.

The extreme case of the machine being prevented from rotating entirely may

only arise briefly.

All of the machines are equipped with a thermal circuit-breaker, which triggers

when the maximum permissible operating temperature is exceeded. These

switching contacts are accessible on the terminal board and must always be

connected to the corresponding connection sockets of the mains supply and

control unit.

All measurements have been recorded using conventional measuring

instruments (primarily class 1.5) at the standard mains voltage (230/400V +5%

-10% 50Hz) using standard production machines. Experience suggests that

measurements will lie within the tolerance range of +/-15% with respect to the

specified measurement. For more information on this please refer to

VDE0530.

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Asynchronous motor, Dahlander circuit

The following exercises involving an asynchronous motor and Dahlander

circuit are conducted on the next few pages:

Connection and starting

Rotation reversal

Load characteristic

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Training content: "Connection and starting"

Identify the terminal connections of the motor and operate the

motor as a three-phase asynchronous motor on a three-phase

mains network

Utilise the nominal data of the motor based on the rating plate

Measure the phase voltage and phase current

Put the motor into operation with a Dahlander pole reverser

Identify the differences between delta and double star

connections

Understand the function of a pole reverser

Put the motor into operation with the brake

Subject the motor to load

Enter the nominal data for the asynchronous machine

Nominal power (delta)

____W

Nominal power (doublestar) ____W

Nominal voltage

____V

IN delta

____A

IN double star

____A

cos (delta)

____

cos (double star)

____

Rated speed (delta)

____rpm

Rated speed (double star) ____rpm

Frequency

____Hz

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Assembly instructions: "Connection and starting"

Assemble the circuits as specified in the following circuit diagram and

set-up instructions

Switch on the brake. This does not yet subject the motor to any load

Additional More detailed information on the brake can be found in the

corresponding online documentation

Circuit diagram: "Connection & starting"

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Set-up: "Connection & starting"

Starting asynchronous motor with switch in position 1

Required settings:

Brake mode: Torque control

Experiment procedure:

Put the motor into operation and observe its response

Brake the motor down to its nominal speed

At the same time measure the phase variables Uphase and Iphase

Make sure that the ammeter and voltmeters have been connected properly

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Specify the type of connection.

Star connection

Delta connection

Double star connection

What do you measure the torque to be with the switch on setting 1?

M= ____Nm

What do you measure the phase variables Uphase and Iphase to be?

Uphase= ____V

Iphase= ____A

Starting asynchronous motor with switch in position 2

Required settings:

Brake mode: Torque control

Experiment procedure:

Put the motor into operation and observe its response

Brake the motor down to its nominal speed

Measure the phase variables Uphase and Iphase

Make sure that the ammeter and voltmeters have been connected properly

10

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Specify the type ofconnection.

Star connection

Steinmetz connection

Double star connection

What do you measure the torque to be with the switch on setting 2?

M= ____Nm

What do you measure the phase variables Uphase and Iphase to be?

Uphase= ____V

Iphase= ____A

11

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Record a load characteristic for both switch positions

Required settings:

Brake mode: Speed control

Experiment procedure:

Record a load characteristic in each case (switch positions 1 & 2) for delta and

double star connections.

Brake the motor to the speeds stipulated in the table.

Enter the measured values (M, Iphase) in the tables.

Table 1 (Switch position 1)

3.00

2.75

2.50

2.25

2.00

1240

1160

1080

1000

4.0

3.5

1.50

2.5

1.25

2.0

0.50

1320

4.5

3.0

0.75

1400

5.0

1.75

1.00

12

M/Nm

I/A

n/(1/min)

M/Nm

I/A

1.5

1.0

0.25

0.5

0.00

0.0

1000

1050

1100

1150

1200

1250

1300

1350

1400

1450

1500

n/(1/min)

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Table 2 (Switch position 2)

3.00

2.75

2.50

2.25

2.00

1.75

1.50

1.25

1.00

0.75

0.50

0.25

0.00

M/Nm

I/A

n/(1/min)

M/Nm

I/A

2800

2640

2480

2320

2160

2000

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0.0

2000

2100

2200

2300

2400

2500

2600

2700

2800

2900

n/(1/min)

Record load characteristics for both switch positions with the

ActiveDrive/SimuLoad software

Required settings:

Brake:

PC mode

13

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Experiment procedure:

Start the ActiveDrive/ActiveServo software.

Select speed control operating mode.

The motor is to be braked in 20 steps till it stops. ( Note: in

ActiveDrive/ActiveServo, enter the required number of steps under "Presets" > "Default" -> "Ramp".)

The asynchronous motor's load characteristics are to be recorded for delta

and double star connections.

Start with a delta connection.

Both load characteristics are to be recorded on one graph.

Label and scale the graph as indicated by the placeholder.

The following parameters are to be recorded:

Torque M

(n)

Mechanical power P

2(n)

After measurement is complete, export the resultant graph and copy it into the

placeholder below.

Save the settings for the ActiveDrive/ActiveServo software for future

experiments in a file named "eem42_LoadCharacteristic".

Placeholder for load characteristic

(delta and double-star connection)

14

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Training content: Rotation reversal

Identify the difference between clockwise and anti-clockwise

rotation

Start the motor in both rotation directions

Definition of rotation direction

If you look at the drive shaft end of the asynchronous machine from the perspective

of the working machine (in our case the brake), the rotating direction is positive

when it is clockwise. If the motor has two workable shaft ends, then it is the shaft

end opposite the cooling vents, collector or slip-rings that is the shaft end which

defines the rotation direction.

15

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Assembly instructions: Rotation reversal

Assemble the circuits as specified in the circuit diagrams and set-up

instructions below.

Switch on the brake. This does not yet subject the motor to any load.

More detailed information on the brake can be found in the corresponding online

documentation

Circuit diagram: Rotation reversal

16

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Set-up: Rotation reversal

Rotation reversal

Experiment procedure:

Switch on the motor and observe it.

In which direction does the motor turn?

The motor turns clockwise.

The motor turns anti-clockwise.

17

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Switch off the motor and change its wiring as shown in the diagram below.

Start the motor again and observe it.

Circuit diagram: Rotation reversal

18

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

In which direction does the motor turn?

The motor turns clockwise.

The motor turns anti-clockwise.

How can a three-phase asynchronous machine's direction of rotation be

changed?

By exchanging any two phases.

Simply by exchanging L2 & L3

19

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

20

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Training content: Load characteristics

Simulate various loads (load machines) with the

ActiveDrive/ActiveServo software

Set parameters using the software with load-specific values (load

constant and moment)

Record and evaluate characteristics for various operating points

Determine the motor's response to different loads

Assembly instructions: "Load charactacteristics"

Assemble the circuits as specified in the following circuit diagram and

set-up instructions

Switch on the brake. This does not yet subject the motor to any load

Additional More detailed information on the brake can be found in the

corresponding online documentation.

21

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Circuit diagram: Load characteristic

22

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Set-up: Load characteristic

23

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Record the load characteristic with various simulated loads useing

the ActiveDrive/ActiveServo software

Record characteristic in double-star/delta mode with a pump/fan load.

Required settings:

Brake:

PC mode

The settings stipulated below should then be made for the ActiveDrive and

SimuLoad software.

Load machine: Pump/fan

Load constant: refer to the experiment procedure.

Under "View" => "Measured Value Display", select all mechanical and

electrical variables except for slip.

Experiment procedure:

Start the "ActiveDrive / ActiveServo" software and initially open the file

"eem42_load characteristic" (see "connection and starting")

Then carry out the required settings

The following parameters are to be recorded in this measurement:

torque M

(n)

Switch the motor on directly using Stage 1 in the second step (double star

configuration)

Start the measurement and slowly increase the load constant "l" until the line

current I/A shown in the parameter dialog corresponds to the value of INdouble star.

Now store the first operating point

Now switch back to Stage 1 (delta) and wait a brief moment. Now store the

second operating point.

Now after completing the measurement export the diagram into the

appropriate place holder reserved for it below

Now store the settings under the file name "eem42_pump-fan"

More information on the pump/fan load machine and definition of the constant I

can be found in the online documentation for the ActiveDrive/ActiveServo software.

24

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Placeholder for pump/fan load characteristic

(delta and double-star connection)

Enter the measured values for the double star operating point

____Nm

M=

n=

min-1

____W

P2 =

____W

P1 =

____%

=

____VA

S=

____Var

Q=

cos = ____

____V

U=

____A

I=

25

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Enter the measured values of the delta operating point

____Nm

M=

n=

min-1

____W

P2 =

____W

P1 =

____%

=

____VA

S=

____Var

Q=

cos = ____

____V

U=

____A

I=

How would you describe the load characteristic for the pump/fan?

Linear

Quadratic

Cubic

Assume that instead of stage 1, you had set the load constant I to stage 2

corresponding to the motor's power rating. Would the mechanical output then

have been larger, equal or smaller?

Larger

Equal

Smaller

26

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Record characteristic in star/delta starting mode with a lifting drive as the load

machine

Required settings:

Brake:

Industrial series: PC mode

Make the settings stipulated below for the ActiveDrive and ActiveServo

software.

Load machine: Lifting drive

Load moment: refer to the experiment procedure.

Under "View" => "Measured Value Display", select all mechanical and

electrical variables except for slip.

Experiment procedure:

Start the software and begin by opening the file

"eem42_loadcharacteristic" (see "conneciton and starting")

Then carry out the required settings

The following parameter(s) are to be recorded during this measurement:

torque M(n)

Switch the motor on directly through Stage 1 to the second stage (double star

connection)

Start the measurement and slowly increase the load torque "Nm" until line

current I/A shown in the parameter dialog corresponds to the value of INdouble star.

Now store the first operating point

Now switch back to stage 1 (delta) and wait a brief moment. Now store the

second operating point.

After successful measurement export the diagram created and place it in the

appropriate placeholder below

Store teh settings under the file name "eem42_liftingdrive"

More information on the lifting drive load machine and load moment definition can

be found in the (online) documentation for the ActiveDrive/ActiveServo software.

27

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Placeholder for lifting drive load characteristic

(delta and double star connection)

Enter the measured values of the double star operating point

____Nm

M=

n=

min-1

____W

P2 =

____W

P1 =

____%

=

____VA

S=

____Var

Q=

cos = ____

____V

U=

____A

I=

28

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Enter the measured values of the delta operating point

____Nm

M=

n=

min-1

____W

P2 =

____W

P1 =

____%

=

____VA

S=

____Var

Q=

cos = ____

____V

U=

____A

I=

What does a comparison between the values of P2 measured at the two

operating points reveal?

P2 remains constant.

P2 almost doubles.

P2 only depends on the speed.

P2 depends on both speed and load moment.

More than one

answer may

be correct.

Using the formulae below, calculate the ratios (x1 & x2) between the torques

measured at operating points 1 and 2 for the two load machines.

29

EEM42 Three-phase asynchronous machines

Asynchronous motor, Dahlander circuit

Specify the calculated torque ratios "x1" and "x2".

x1= ____

x2= ____

Compare the torque ratios for both load machines. Which statements are

correct?

The ratios are nearly identical.

The torque ratio of the lifting drive load machine is 1,

because the load moment is identical at both

operating points.

The torque ratio of the pump/fan load machine is

based on the relationship M ~ n 2, or M2/M1~(n2/n1)2

The torque ratio of the pump/fan load machine is

based on the relationship M ~ n 3, or M3/M1~(n2/n1)3

30

More than one

answer may

be correct.

EEM42 Three-phase asynchronous machines

Copyright

Congratulations!

This is the last page. You have completed the course "EEM42 Threephase asynchronous machines: Dahlander motors".

Copyright 2004-2008 LUCAS-NLLE GmbH.

This course "EEM 42 Three-phase asynchronous machines: Dahlander

motors" is protected by copyright. All rights pertaining thereto are reserved. Any

reproduction of the document as a file or in written form be it photocopy, microfilm or

any other method or conversion into a machine-compatible language, in particular

for data processing systems, without the expressed written approval of the LUCASNLLE GmbH is strictly forbidden.

The software as described above is made available on the basis of a general

licensing agreement or in the form of a single license. The use or reproduction of the

software is only permitted in strict compliance with the contractual terms stated

therein.

If changes have been performed in a manner which was not strictly authorised by

the LUCAS-NLLE GmbH, any product liability or warranty claims pertaining thereto

are null and void.

31

16

Lucas-Nlle Lehr- und Megerte GmbH

Siemensstrae 2 D-50170 Kerpen-Sindorf

Telefon +49 2273 567-0 Fax +49 2273 567-30

www.lucas-nuelle.de

You might also like

- PhasesDocument74 pagesPhasesRuth Velasquez QuirozNo ratings yet

- Three-Phase Induction Motor Design SoftwareDocument4 pagesThree-Phase Induction Motor Design SoftwareAce TobikumaNo ratings yet

- Conexiones Dahlander PDFDocument1 pageConexiones Dahlander PDFPedroPicapiedraHeyheyNo ratings yet

- Induction Motor Design PDFDocument46 pagesInduction Motor Design PDFdiptiNo ratings yet

- Design of Dual Speed Induction Motor by Using Pole Changing TechnologyDocument15 pagesDesign of Dual Speed Induction Motor by Using Pole Changing TechnologyKrishnaNo ratings yet

- Motor Data Sheet 1A 1#360kW, 4pole, 6600VDocument3 pagesMotor Data Sheet 1A 1#360kW, 4pole, 6600Vasyyas100% (1)

- Determine Phase SequenceDocument5 pagesDetermine Phase SequenceZAIN UL ABIDENNo ratings yet

- 4 - Power Quality Problems - Part IIIIDocument17 pages4 - Power Quality Problems - Part IIIISari M.I100% (1)

- Armature WindingDocument20 pagesArmature Windingk rajendra100% (1)

- AC Armature WindingDocument17 pagesAC Armature WindingusmanNo ratings yet

- Induction Motor Cogging and CrawlingDocument2 pagesInduction Motor Cogging and CrawlingChandaKundaNo ratings yet

- Induction GeneratorDocument12 pagesInduction GeneratorSumaira SaifNo ratings yet

- Synchronous MechineDocument8 pagesSynchronous MechineNaveen BansalNo ratings yet

- Dahlander PoleDocument4 pagesDahlander PoleNur Mirza Kholili SNo ratings yet

- Space Vector Pulse Width Modulation-Libre PDFDocument6 pagesSpace Vector Pulse Width Modulation-Libre PDFlongNo ratings yet

- Introduction To Electrical MachinesDocument47 pagesIntroduction To Electrical MachinesAbel Zermeño MuñozNo ratings yet

- 3-Phase Sequence Checker Protects MotorsDocument7 pages3-Phase Sequence Checker Protects MotorsOmar J. Apaza GuerreroNo ratings yet

- Induction MotorDocument20 pagesInduction MotorC V VIJAY KUMASRNo ratings yet

- Construction of Three Phase Induction MotorDocument18 pagesConstruction of Three Phase Induction MotorRajeev ValunjkarNo ratings yet

- Artificial Loading of Induction MotorsDocument6 pagesArtificial Loading of Induction Motorsamkeew100% (1)

- AC Motor Name Plate - Terms & MeaningsDocument2 pagesAC Motor Name Plate - Terms & Meaningsavandetq15No ratings yet

- Positive, Zero, Negative Sequence of AlternatorDocument3 pagesPositive, Zero, Negative Sequence of AlternatorJeya KannanNo ratings yet

- Assignment 3 (EET302 OCPS)Document2 pagesAssignment 3 (EET302 OCPS)micoNo ratings yet

- EEU104 01 One Phase AC CircuitDocument189 pagesEEU104 01 One Phase AC CircuitReginald AnthonyNo ratings yet

- Inspection ReportDocument4 pagesInspection Reportaryo suryandaruNo ratings yet

- Power Rectifier ASIC ControllerDocument5 pagesPower Rectifier ASIC ControllerQuang TaNo ratings yet

- Synchronous Machines and SCDocument6 pagesSynchronous Machines and SCivancho04mNo ratings yet

- Designing of 3 Phase Induction Motor Blackbook DoneDocument30 pagesDesigning of 3 Phase Induction Motor Blackbook Donetryd0% (1)

- Instructions: Automatic Voltage Regulator AVC63-12 AVC125-10Document4 pagesInstructions: Automatic Voltage Regulator AVC63-12 AVC125-10yao nestorNo ratings yet

- Induction MotorDocument7 pagesInduction MotoruwaifotonyNo ratings yet

- Abb Acs510 - en - Rev DDocument16 pagesAbb Acs510 - en - Rev DJove MultisystemsNo ratings yet

- Simulate Variable Speed Motor ControlDocument4 pagesSimulate Variable Speed Motor ControlsravanNo ratings yet

- Theory of Operation - Autotransformer Starter PDFDocument3 pagesTheory of Operation - Autotransformer Starter PDFDiago100% (1)

- PVM500/DIDRIVE10 Instructions For Conventional and Resonant LoadsDocument9 pagesPVM500/DIDRIVE10 Instructions For Conventional and Resonant Loadsmostafa1alaahobaNo ratings yet

- Open circuit and load characteristics of DC shunt generatorDocument5 pagesOpen circuit and load characteristics of DC shunt generatorramniwas123No ratings yet

- Efficiency Improvements in High Speed Operation Using Slotless Configuration For PMSMDocument7 pagesEfficiency Improvements in High Speed Operation Using Slotless Configuration For PMSMAmit ShuklaNo ratings yet

- Development of Electric Drives in Light Rail Transit (LRT) SystemDocument31 pagesDevelopment of Electric Drives in Light Rail Transit (LRT) SystemArjun Pratap Singh100% (1)

- AC Voltage Measurement Using PIC16F877A MicrocontrollerDocument15 pagesAC Voltage Measurement Using PIC16F877A Microcontrollervallery1No ratings yet

- Generator Protection Relay VAMP 210iDocument3 pagesGenerator Protection Relay VAMP 210iYandri PaulusNo ratings yet

- Assignment 2Document8 pagesAssignment 2phultushiblsNo ratings yet

- SIPROTEC 7SJ85 V7 Profile PDFDocument2 pagesSIPROTEC 7SJ85 V7 Profile PDFpriyanka236No ratings yet

- Vibration of Turbine PDFDocument4 pagesVibration of Turbine PDFsanjeevchhabraNo ratings yet

- 420KW ELECTRICAL MACHINE DESIGNDocument5 pages420KW ELECTRICAL MACHINE DESIGNMiguel LigutanNo ratings yet

- PDF Editor: Computer Aided Electrical Drawing (Caed)Document29 pagesPDF Editor: Computer Aided Electrical Drawing (Caed)tare tamiruNo ratings yet

- Ata 24Document9 pagesAta 24Prince AbbasNo ratings yet

- IEEE Guide For The Interconnection of User-Owned Substations To Electric UtilitiesDocument30 pagesIEEE Guide For The Interconnection of User-Owned Substations To Electric UtilitiesLuisVidelaNo ratings yet

- Cooper TimeCurves R2809134 PDFDocument13 pagesCooper TimeCurves R2809134 PDFMiguel Andres Gatica Diaz0% (1)

- AC Machines Lab Manual PDFDocument91 pagesAC Machines Lab Manual PDFറിജിൽ വി ആർ100% (2)

- Benn Machine Lab ManualDocument14 pagesBenn Machine Lab ManualRahatullah Khan100% (1)

- Parallel Driving of Synchronous GeneratorDocument7 pagesParallel Driving of Synchronous GeneratorMKIBETUNo ratings yet

- #1 Generator Protection ADocument12 pages#1 Generator Protection ARodrigo Mendoza PerezNo ratings yet

- A.C. Series MotorDocument16 pagesA.C. Series MotorM BNo ratings yet

- Tutorial On Load Frequency ControlDocument2 pagesTutorial On Load Frequency ControlNitishPaudel100% (2)

- Chapter3 InductionmachineDocument25 pagesChapter3 InductionmachineAbhijitNo ratings yet

- Analysis of Electric Machinery and Drive Systems Third Edition Paul Krause and Oleg Wasynczuk and Scott Sudhoff and Steven PekarekDocument3 pagesAnalysis of Electric Machinery and Drive Systems Third Edition Paul Krause and Oleg Wasynczuk and Scott Sudhoff and Steven PekarekSuhail KhokharNo ratings yet

- Curso de Maquina AsincronaDocument64 pagesCurso de Maquina AsincronaCcoris JMNo ratings yet

- Course "EEM 42 Three-Phase Asynchronous Machines: Dahlander Motors"Document38 pagesCourse "EEM 42 Three-Phase Asynchronous Machines: Dahlander Motors"Daus VillaNo ratings yet

- EEM 2 DC MachinesDocument106 pagesEEM 2 DC MachinesAbrar Smektwo50% (2)

- Industrial AC MotorsDocument86 pagesIndustrial AC Motorsandry wibowoNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- TinyPPT 3Document1 pageTinyPPT 3ZoneoTakan Berpling DrimhuNo ratings yet

- TinyPPT 2Document1 pageTinyPPT 2ZoneoTakan Berpling DrimhuNo ratings yet

- Presents Infographic: TinypptDocument3 pagesPresents Infographic: TinypptZoneoTakan Berpling DrimhuNo ratings yet

- Tiny PPT253Document1 pageTiny PPT253ZoneoTakan Berpling DrimhuNo ratings yet

- PPT305Document1 pagePPT305Si ZOELNo ratings yet

- PPT305Document1 pagePPT305Si ZOELNo ratings yet

- Tiny PPT253Document1 pageTiny PPT253ZoneoTakan Berpling DrimhuNo ratings yet

- Tiny PPT1Document1 pageTiny PPT1ZoneoTakan Berpling DrimhuNo ratings yet

- TinyPPT 1319Document1 pageTinyPPT 1319ZoneoTakan Berpling DrimhuNo ratings yet

- Tiny PPT234Document1 pageTiny PPT234ZoneoTakan Berpling DrimhuNo ratings yet

- Tiny PPT231Document1 pageTiny PPT231ZoneoTakan Berpling DrimhuNo ratings yet

- Tiny PPT261Document1 pageTiny PPT261DwikyRNo ratings yet

- Tiny PPT231Document1 pageTiny PPT231ZoneoTakan Berpling DrimhuNo ratings yet

- Tiny PPT234Document1 pageTiny PPT234ZoneoTakan Berpling DrimhuNo ratings yet

- Tiny PPT261Document1 pageTiny PPT261DwikyRNo ratings yet

- Tiny PPTDocument1 pageTiny PPTZoneoTakan Berpling DrimhuNo ratings yet

- PowerPoint Infographic Template OptionsDocument8 pagesPowerPoint Infographic Template OptionsKoperasi UmatNo ratings yet

- Tiny PPTDocument1 pageTiny PPTZoneoTakan Berpling DrimhuNo ratings yet

- Tiny PPTDocument1 pageTiny PPTZoneoTakan Berpling DrimhuNo ratings yet

- Tiny PPT52Document1 pageTiny PPT52ZoneoTakan Berpling DrimhuNo ratings yet

- Tiny PPT74Document1 pageTiny PPT74ZoneoTakan Berpling DrimhuNo ratings yet

- Tiny PPTDocument1 pageTiny PPTZoneoTakan Berpling DrimhuNo ratings yet

- Tiny PPT28Document1 pageTiny PPT28ZoneoTakan Berpling DrimhuNo ratings yet

- Tiny PPT60Document1 pageTiny PPT60ZoneoTakan Berpling DrimhuNo ratings yet

- Tiny PPT261Document1 pageTiny PPT261DwikyRNo ratings yet

- PPT305Document1 pagePPT305Si ZOELNo ratings yet

- Tiny PPT94Document1 pageTiny PPT94HerlinaNo ratings yet

- P Werp INT: Designed byDocument2 pagesP Werp INT: Designed byKoperasi UmatNo ratings yet

- Tinyppt: Design Template For Ms PowerpointDocument1 pageTinyppt: Design Template For Ms PowerpointZoneoTakan Berpling DrimhuNo ratings yet

- Tiny PPT253Document1 pageTiny PPT253ZoneoTakan Berpling DrimhuNo ratings yet

- Find energy and charge of capacitors with dielectricsDocument3 pagesFind energy and charge of capacitors with dielectricsNurul Husna MNNo ratings yet

- User Manual TV Power Demoboard TEA8818DB1440: TEA8818 + TEA1995 130W 13V and 90V Power SupplyDocument29 pagesUser Manual TV Power Demoboard TEA8818DB1440: TEA8818 + TEA1995 130W 13V and 90V Power SupplyCube7 Geronimo50% (2)

- BLOWUP SYLLABUS EE ELEMENTS ELECTRICAL ENGINEERINGDocument2 pagesBLOWUP SYLLABUS EE ELEMENTS ELECTRICAL ENGINEERINGLakshmi K100% (1)

- Troubleshooting 1Document15 pagesTroubleshooting 1ANURAG SHARMA100% (1)

- Impedance of Inductance, Resistance and Capacitance CircuitDocument5 pagesImpedance of Inductance, Resistance and Capacitance CircuitJohn Paul BaquiranNo ratings yet

- Lab 2 Report - Resistor Networks 2Document7 pagesLab 2 Report - Resistor Networks 2Moataz AhmedNo ratings yet

- FirePro-Advanced Sequential Activator (FP-SEQACT) DatasheetDocument1 pageFirePro-Advanced Sequential Activator (FP-SEQACT) Datasheetaitkaci.faredj2No ratings yet

- Instruction Bulletin - 01.4Ib.51200C Powlvac-Ar® Arc Resistant SwitchgearDocument106 pagesInstruction Bulletin - 01.4Ib.51200C Powlvac-Ar® Arc Resistant Switchgearqis qusNo ratings yet

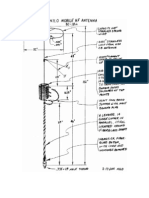

- Antena Movil HFDocument10 pagesAntena Movil HF10sd156100% (1)

- EATON Rp48j01te PDFDocument40 pagesEATON Rp48j01te PDFJavier MaldonadoNo ratings yet

- Power Control System: SectionDocument116 pagesPower Control System: SectionАндрей НадточийNo ratings yet

- Room Air Conditioner Owner's Manual GuideDocument19 pagesRoom Air Conditioner Owner's Manual GuideMunteanu LucianNo ratings yet

- Physics Investigatory Project On Joule ThiefDocument5 pagesPhysics Investigatory Project On Joule ThiefathuNo ratings yet

- Delta T - Charts For Infrared HeatingDocument4 pagesDelta T - Charts For Infrared HeatingArep HammettNo ratings yet

- Dual Slope ADC DesignDocument10 pagesDual Slope ADC DesignMoHaMMeD HaLaByNo ratings yet

- Model Answer Summer 2016Document16 pagesModel Answer Summer 2016GAMING ZONE TECH WORLDNo ratings yet

- Premium Modular PlugsDocument1 pagePremium Modular PlugsBDNo ratings yet

- Parker AC10 Easy Start Guide To 22kWDocument15 pagesParker AC10 Easy Start Guide To 22kWDiana Amaya NatividadNo ratings yet

- PSCAD Cookbook: Induction Machines StudyDocument27 pagesPSCAD Cookbook: Induction Machines Studypower systemNo ratings yet

- Smart Relay - Zelio Logic SR2 - SR3 - SR3XT43BD PDFDocument5 pagesSmart Relay - Zelio Logic SR2 - SR3 - SR3XT43BD PDFasimasim123No ratings yet

- Read device manual before use to avoid injuryDocument3 pagesRead device manual before use to avoid injuryعلي جعبريNo ratings yet

- YEDITEPE UNIVERSITY ENGINEERING FACULTY POWER ELECTRONIC CIRCUITS LABDocument9 pagesYEDITEPE UNIVERSITY ENGINEERING FACULTY POWER ELECTRONIC CIRCUITS LABDhananjay LimayeNo ratings yet

- Antena t2fdDocument3 pagesAntena t2fdlu1agp100% (1)

- Training For LTBDocument20 pagesTraining For LTBrpshvjuNo ratings yet

- Emergency StopDocument2 pagesEmergency StopssNo ratings yet

- X and Y CAPDocument16 pagesX and Y CAPRalph Jason AlvarezNo ratings yet

- O.L.E. C2020 Installation ManualDocument12 pagesO.L.E. C2020 Installation ManualDave PotterNo ratings yet

- NEMA SG11-2013 Guide For Maint of Outdoor HV CBsDocument24 pagesNEMA SG11-2013 Guide For Maint of Outdoor HV CBsChris ParkinsonNo ratings yet

- Targa Instruction ManualDocument18 pagesTarga Instruction ManualPedro Elias SantanaNo ratings yet