Professional Documents

Culture Documents

031-Itp For Piping Fabrication Ag and Ug PDF

Uploaded by

Köksal PatanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

031-Itp For Piping Fabrication Ag and Ug PDF

Uploaded by

Köksal PatanCopyright:

Available Formats

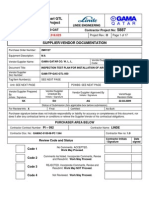

Pearl GTL

Project

Shell Project No: HP-3000-QAT

Project Document Number: T- 4.250.920

Purchase Order Number:

2MH127

Tag/Item Number(s):

N/A

Unit(s):

ASU

PCWBS:

LINDE ENGINEERING

Contractor Project No:

Project Rev.: B

Page 2 of 8

5887

QATAR SHELL GTL PROJECT (PEARL)

C2 AIR SEPARATION UNITS CONSTRUCTION

03.09.08

Ready for Construction

AB

EO

AG

RFC

14.07.08

Issued for Company Comments

AB

EO

AG

ICC

23.12.07

Issued for Company Comments

BR

AU/MC

ZG

ICC

15.12.07

Issued for Review

BR

AU/MC

ZG

IFR

02.12.07

Issued for Internal Review

BR

AU/MC

ZG

IIR

Date

Description

GAMA

Rev.

Project

Rev

No.

No.

Prepared Checked Approved

By

By

By

Status

ORIGINATOR

Document Title:

LINDEGINEERING AG

INSPECTION TEST PLAN FOR PIPING FABRICATION

A/G AND U/G

Document No.

Contractor

LOC470

Gama Qatar Co. W. L. L.

GAM

ITP

QAC

GTL

031

Org.

Doc.

Type

Geogr.

Area

Seq.

Code

Disc.

Code

Rev.

No

Project Document Number: T-4.250.920

No

Vendor Code

Rev No: B

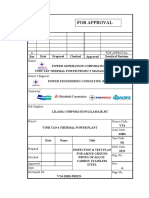

QSGTL PEARL PROJECT

Document No.: GAM-ITP-QAC-GTL-031

C2 ASU Construction Works

ITP FOR PIPING FABRICATION -AG/UG (FSI)

S. GAMA QATAR

X. CONTRACTOR QC

C. COMPANY

DATE: 03.09.08

REV. E

A. THIRD PARTY (TPI)

I: INSPECTION / TEST

R: DOCUMENT ISSUED/REPORT REVIEW

S: SURVEILANCE

H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

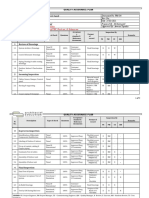

Test

Frequency

Item

Activity

1.0

DOCUMENTATION

1.1

Contractor isometric drawings /

Spool drawings

1.2

Approved W.P.S.

1.3

Approved PQRs

1.4

Welder Performance

Qualifications

100%

1.5

Verify calibration of inspection,

measuring and test equipment

100%

2.0

MATERIALS

2.1

Receiving inspection /

Verification of Material

100%

2.2

Storage & Segregation of

Material

100%

T-4.250.920 Rev. B

100%

Reference Document

Acceptance Criteria

Respons

ible

Party

Verifying Documents

T.4.234.542;T.4.250.935;

T.4.250.936

RFC

QCI

RFC

WI

GAM-QCR-QAC-GTL-106

WI

GAM-QCR-QAC-GTL-105

WI

GAM-QCR-QAC-GTL-100

WSD-QC 2

WSD-QC 3

100%

T.4.251.025; T.4.250.938

100%

T.4.251.025; T.4.250.938

DEP 30.10.60.18;ASME SEC

IX;ASME B31.3;

T.13.377.441;T.13.377.433E;

T.4.250.939

T.4.250.915

DEP 30.10.60.18; T.13.377.433E;

T.13.377.441; T.13.377.437E

QCI

Calibration certificate

T.4.250.927;T.4.250.928;

T.13.376.797E; T.13.377.438E

QCI

LINDE MRCR SYSTEM

T.4.250.927;T.4.250.928;

T.4.250.932

T.13.377.454E; T.13.377.438E

QCI

Page 4 of 8

QSGTL PEARL PROJECT

Document No.: GAM-ITP-QAC-GTL-031

C2 ASU Construction Works

ITP FOR PIPING FABRICATION -AG/UG (FSI)

S. GAMA QATAR

X. CONTRACTOR QC

C. COMPANY

DATE: 03.09.08

REV. E

A. THIRD PARTY (TPI)

I: INSPECTION / TEST

R: DOCUMENT ISSUED/REPORT REVIEW

S: SURVEILANCE

H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item

2.3

Activity

Welding consumable control &

storage procedure

2.4

Cutting /Transfer of heat No.s

2.5

PMI (If applicable)

3.0

WELDING

3.1

Test

Frequency

100%

100%

Reference Document

Acceptance Criteria

Respons

ible

Party

Verifying Documents

WPSs / PQRs; T.4.250.931

ASME SEC II PART C

DEP 30.10.60.18; T.13.377.433E;

T.13.377.437E

T.13.377.441;T.4.096.687

WI

Test certificate 3.1 B

Drawings;T.4.250.928

DEP 30.10.60.18; ASME B 31.3

T.13.377.433E; T.13.376.815E DEP

31.38.01.11; DEP 31.38.01.31;

T.13.376.796E;

QCI

GAM-QCR-QAC-GTL-072

100%

T.4.250.934;T.4.250.938

WI

WSD-QC 4

Welder identification and

performance verification

100%

T.4.250.938;T.4.250.939

WI

WSD-QC 2

3.2

Issue of welding consumable to

welder

100%

WI

GAM-QCR-QAC-GTL-060

3.3

Fit-up and tack welding

100%

3.4

Root pass visual inspection

T-4.250.920 Rev. B

DEP 30.10.60.18; T.13.377.433E ;

T.13.377.441 ASME B 31.3

100%

T.4.250.931: T.4.250.938

T.4.250.938;T.4.250.936

WPSs / PQRs

T.4.250.938;T.4.250.935;

T.4.250.937

DEP 30.10.60.18;ASME B 31.3

T.13.377.433E; DEP 31.38.01.31;

T.13.376.796E; T.13.377.441

DEP 30.10.60.18; ASME B31.3

T.13.377.433E; T.13.377.441

WI

GAM-QCR-QAC-GTL-098

WI

Page 5 of 8

QSGTL PEARL PROJECT

Document No.: GAM-ITP-QAC-GTL-031

C2 ASU Construction Works

ITP FOR PIPING FABRICATION -AG/UG (FSI)

S. GAMA QATAR

X. CONTRACTOR QC

C. COMPANY

DATE: 03.09.08

REV. E

A. THIRD PARTY (TPI)

I: INSPECTION / TEST

R: DOCUMENT ISSUED/REPORT REVIEW

S: SURVEILANCE

H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item

3.5

3.6

Activity

Root pass magnetic check for

Stainless steel materials

Dissimilar joint welding

Test

Frequency

Reference Document

100%

T.4.250.938

Inter pass temp controlling /

cleaning

100%

3.8

Arc strike control and repair

100%

Weld identification and marking

100%

3.10

3.11

Welding, purge log (St-steel),

process parameter monitoring

Visual Inspection of Welds

4.0

POST WELD HEAT TREATMENT

4.1

PWHT

4.2

HARDNESS Test (if required)

T-4.250.920 Rev. B

T.4.250.938

T.4.250.938

Respons

ible

Party

Verifying Documents

WI

GAM-QCR-QAC-GTL-098

WI

GAM-QCR-QAC-GTL-107

DEP 30.10.60.18 T.13.377.433E

100%

3.7

3.9

Acceptance Criteria

DEP 31.38.01.31;ASME B31.3

T.13.376.796E;

DEP 30.10.60.18;ASME B 31.3

T.13.377.433E; T.13.377.441

T.4.250.938;T.4.250.935

WI

WI

GAM-QCR-QAC-GTL-042

GAM-QCR-QAC-GTL-043

WI

GAM-QCR-QAC-GTL-098

100%

T.4.250.938; T.4.250.901

WPSs / PQRs

DEP 30.10.60.18;ASME B31.3

T.13.377.433E; T.13.377.441 DEP

31.38.01.31; T.13.376.796E;

WI

GAM-QCR-QAC-GTL-090

100%

T.4.250.931

DEP 30.10.60.18; ASME B31.3

T.13.377.433E; T.13.377.441

WI

GAM-QCR-QAC-GTL-098

DEP 30.10.60.18;ASME B31.3

T.13.377.433E DEP 31.38.01.31;

T.13.376.796E; T.13.377.441

WI

GAM-QCR-QAC-GTL-083

S/R

S/R

S/R

T.4.250.913;T.4.250.938

WI

WSD-QC 5

100%

100%

Page 6 of 8

QSGTL PEARL PROJECT

Document No.: GAM-ITP-QAC-GTL-031

C2 ASU Construction Works

ITP FOR PIPING FABRICATION -AG/UG (FSI)

S. GAMA QATAR

X. CONTRACTOR QC

C. COMPANY

DATE: 03.09.08

REV. E

A. THIRD PARTY (TPI)

I: INSPECTION / TEST

R: DOCUMENT ISSUED/REPORT REVIEW

S: SURVEILANCE

H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item

Activity

Test

Frequency

Reference Document

5.0

NON DESTRUCTIVE EXAMINATION

5.1

Radiographic Film Interpretation/

ultrasonic examination

100%

Liquid Penetrant

100%

T.4.250.909;T.4.250.938

Magnetic particle

100%

T.4.250.911;T.4.250.938

100%

T.4.250.933; DEP

30.10.60.18; T.13.377.433E

;T.13.377.441

5.2

5.3

5.4

1.1

FERRITE CHECK

6.0

REPAIR CONTROL

6.1

Repair Authorization

Respons

ible

Party

Verifying Documents

WI

WSD-QC 6

WSD-QC 7

W/R

WI

WSD-QC 9

S/R

S/R

WI

WSD-QC 8

S/R

S/R

3-8 FN

WI

WSD-QC 10

DEP 30.10.60.18; T.13.377.433E

WI

ASME B31.3

WI

Acceptance Criteria

T.4.250.914;T.4.250.938

100%

DEP 31.38.01.31; ASME B31.3

T.13.376.796E;

T.4.250.940

6.2

Removal of defects

100%

6.3

Repair welding

100%

T.4.250.940; T.4.250.901

6.4

PWHT control

100%

T.4.250.913

6.5

Hardness test (if required)

100%

T.4.250.912

T-4.250.920 Rev. B

DEP 30.10.60.18;ASME B31.3

T.13.377.433E;T.13.377.441

DEP 30.10.60.18;ASME B31.3

T.13.377.433E; T.13.377.441 DEP

31.38.01.31; T.13.376.796E;

GAM-QCR-QAC-GTL-097

WI

WI

GAM-QCR-QAC-GTL-083

S/R

S/R

S/R

WI

WSD-QC 5

Page 7 of 8

QSGTL PEARL PROJECT

Document No.: GAM-ITP-QAC-GTL-031

C2 ASU Construction Works

ITP FOR PIPING FABRICATION -AG/UG (FSI)

S. GAMA QATAR

X. CONTRACTOR QC

C. COMPANY

DATE: 03.09.08

REV. E

A. THIRD PARTY (TPI)

I: INSPECTION / TEST

R: DOCUMENT ISSUED/REPORT REVIEW

S: SURVEILANCE

H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item

Activity

Test

Frequency

Reference Document

Acceptance Criteria

Respons

ible

Party

Verifying Documents

6.6

NDE of repaired weld

100%

T.4.250.940;T.4.250.938

DEP 31.38.01.31;ASME B 31.3

T.13.376.796E;

WI

SAME AS ACTIVITY 5.0

6.7

NDE (TRACERS)

100%

T.4.250.940;T.4.250.938

ASME B 31.3

WI

WSD-QC 11

7.0

FINAL INSPECTION

7.1

Marking of spool, identification

and Material traceability

100%

T.4.250.928;T.4.250.935

T.13.377.437E;T.13.376.797E

QCI

WSD-QC 12

7.2

Dimensional check

100%

QCI

GAM-QCR-QAC-GTL-086

7.3

Reinforcement pad leak test

QCI

GAM-QCR-QAC-GTL-109

S/R

7.4

Orifice flange internal verification

QCI

GAM-QCR-QAC-GTL-095

7.5

Piping internal cleanliness

QCI

GAM-QCR-QAC-GTL-070

7.6

Closure of all openings and

protection of flanges in each

spool

QCI

GAM-QCR-QAC-GTL-086

7.7

Piping spools release for

painting and updating spool

tracking system

DEP 31.38.01.11; T.13.376.815E;

DEP 31.38.01.31; T.13.376.796E

QCI/WI

GAM-QCR-QAC-GTL-086

7.8

Flawless Start-up Initiative (FSI)

- Cleanliness

No external materials inside the pipe

& Internal Cleaning shall be done

Site Eng

Visual

T-4.250.920 Rev. B

100%

100%

100%

100%

T.4.250.935;

Spool Drawings

T.4.250.908

T.4.250.935

T.4.250.930

T.4.250.935

100%

T.4.250.938; T.4.250.935;

WSD; SPOOL DRAWINGS

Internal

Cleaning

T.13.377.360 Rev E

& T.4.096.688

ASME B 31.3;DEP 31.38.01.31;

T.13.376.796E;DEP 31.38.01.11;

T.13.376.815E

DEP 31.38.01.11;ASME B 31.3

T.13.376.815E;

DEP 31.38.01.11;

T.13.376.815E;T.13.375.791E;DEP

61.38.10.10

T.4.096.688;DEP 61.10.08.11

DEP 31.38.01.11;

T.13.376.815E;ASME B 31.3

Page 8 of 8

You might also like

- 3600-2018 v2Document10 pages3600-2018 v2Abid Ahmad0% (5)

- ITP Installation of Boiler - R1Document14 pagesITP Installation of Boiler - R1crys100% (4)

- ITP For Piping WorksDocument3 pagesITP For Piping WorksOrlando1949100% (3)

- 048-Itp For Installation of Hvac Unit PDFDocument8 pages048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- 030-Itp For Ug GRP Piping PDFDocument22 pages030-Itp For Ug GRP Piping PDFKöksal Patan89% (9)

- KP-00+++-CQ712-G0011 - Rev.0 - ITP For For Cathodic Protection WorksDocument7 pagesKP-00+++-CQ712-G0011 - Rev.0 - ITP For For Cathodic Protection WorksUtku Can KılıçNo ratings yet

- Itp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Document24 pagesItp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Rakhesh Rajeevan100% (3)

- Attachment 6 - Piping Test Package (Manifold 204, 205) (Pages 56 To 121) - A4A0Z7Document66 pagesAttachment 6 - Piping Test Package (Manifold 204, 205) (Pages 56 To 121) - A4A0Z7indusampath100% (2)

- Site Inspection and Test Plan For Tie-In Works: Subcontrac TorDocument24 pagesSite Inspection and Test Plan For Tie-In Works: Subcontrac Torprabu palaniswamyNo ratings yet

- 008 - Field Hydrotest ProcedureDocument17 pages008 - Field Hydrotest Procedurekaruna346100% (2)

- 015-Method Statement For Painting Works (Building) PDFDocument21 pages015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- 015-MS For Night Works PDFDocument16 pages015-MS For Night Works PDFKöksal Patan80% (5)

- 050-Itp For Installation of Air Intake Filter PDFDocument17 pages050-Itp For Installation of Air Intake Filter PDFKöksal PatanNo ratings yet

- 045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFDocument10 pages045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDFKöksal Patan83% (12)

- 043-ITP FOR Water Proofing (Buildings) PDFDocument13 pages043-ITP FOR Water Proofing (Buildings) PDFKöksal Patan100% (3)

- 044-ITP For Installation of Gypsum Board (Buildings) PDFDocument10 pages044-ITP For Installation of Gypsum Board (Buildings) PDFKöksal Patan100% (3)

- Defects Liability PeriodDocument5 pagesDefects Liability PeriodChemical.AliNo ratings yet

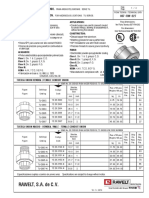

- Union Universal RAWELTDocument4 pagesUnion Universal RAWELTLuisDonairesNo ratings yet

- 033-Itp For Piping Installation Ag and Ug PDFDocument13 pages033-Itp For Piping Installation Ag and Ug PDFKöksal Patan75% (4)

- 046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFDocument18 pages046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFKöksal PatanNo ratings yet

- Field Inspection ChecklistDocument1 pageField Inspection ChecklistHoang Xuan ChauNo ratings yet

- Flow Chart Test PackageDocument1 pageFlow Chart Test PackagejajakaNo ratings yet

- Test Package AttachmentDocument3 pagesTest Package AttachmentFrancis Mayowa Ezekiel100% (1)

- Itp PipingDocument4 pagesItp Pipingerdemlix100% (2)

- Above Ground Piping ProcedureDocument4 pagesAbove Ground Piping Proceduremusthafa_11No ratings yet

- ITP - 003 - Rotating Equipment - IFRDocument3 pagesITP - 003 - Rotating Equipment - IFRMari Belajar100% (1)

- Rai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksDocument4 pagesRai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksVijaya Barani100% (1)

- Field Mechanical Work Inspection & Test Plan: Job No.: Owner: Client: ProjectDocument12 pagesField Mechanical Work Inspection & Test Plan: Job No.: Owner: Client: ProjectbasukiNo ratings yet

- How To Write A Welding Procedure Specification (WPS)Document5 pagesHow To Write A Welding Procedure Specification (WPS)Mohamed Atef100% (1)

- 030-QCP For UG GRP PIPING PDFDocument12 pages030-QCP For UG GRP PIPING PDFKöksal Patan100% (1)

- Test Pack SampleDocument12 pagesTest Pack SampleGomathyselviNo ratings yet

- Tank Erection Procedure: Note: This Is The Sample Document For The Related Job OnlyDocument5 pagesTank Erection Procedure: Note: This Is The Sample Document For The Related Job Onlygeorge israelNo ratings yet

- 12.rotary Erection ProcedureDocument8 pages12.rotary Erection ProcedureDebashish ChatterjeeNo ratings yet

- Field Hydrostatic Testing of Piping Systems-EGDocument9 pagesField Hydrostatic Testing of Piping Systems-EGYusufNo ratings yet

- Itp VesselDocument4 pagesItp VesselHakim BaihaqiNo ratings yet

- WP 11 Corrosion Protection Tape CoatingDocument3 pagesWP 11 Corrosion Protection Tape CoatingKarthikNo ratings yet

- 005-WPS For Carbon Steel (1.6-4.6MM) PDFDocument7 pages005-WPS For Carbon Steel (1.6-4.6MM) PDFKöksal Patan0% (1)

- Field Itp For Piping Work Samur Project Rev-5 (23 April 2013)Document28 pagesField Itp For Piping Work Samur Project Rev-5 (23 April 2013)Echik KiciNo ratings yet

- Inspection Test Plan For Pipeline JobsDocument6 pagesInspection Test Plan For Pipeline Jobsمحمد أزها نو الدينNo ratings yet

- Punch Points For Piping EngineersDocument8 pagesPunch Points For Piping Engineerspratikmande100% (1)

- 006-MS For Purging of Stainless Steel PDFDocument18 pages006-MS For Purging of Stainless Steel PDFKöksal PatanNo ratings yet

- Procedure For Fab, Erec & Testing of Undergroud PipingDocument12 pagesProcedure For Fab, Erec & Testing of Undergroud Pipingvpsimbu86No ratings yet

- Welding Quality Control and Inspection FormDocument1 pageWelding Quality Control and Inspection FormSamer BayatiNo ratings yet

- Inspection and Test Plan Piping Works Main Deck, Service Platform, Module, EtcDocument3 pagesInspection and Test Plan Piping Works Main Deck, Service Platform, Module, Etcaditya kokoNo ratings yet

- GRE Hydrotest Procedure PDFDocument9 pagesGRE Hydrotest Procedure PDFMohammad Saif AliNo ratings yet

- Hydrotest Check ListDocument1 pageHydrotest Check ListSaut Maruli Tua SamosirNo ratings yet

- Piping-Progress-Measurement - (In Dia and in Meter)Document7 pagesPiping-Progress-Measurement - (In Dia and in Meter)RohimNo ratings yet

- 5 Form Test Piping Package Data Sheet CombineDocument1 page5 Form Test Piping Package Data Sheet Combinemashudi_fikriNo ratings yet

- Fabrication Erection Installation Procedure For Piping PDFDocument35 pagesFabrication Erection Installation Procedure For Piping PDFTaofiq100% (1)

- Fabrication Erection and Installation Procedure For PipingDocument60 pagesFabrication Erection and Installation Procedure For Pipinghasan_676489616No ratings yet

- Inspection Checklist For: Control ValvesDocument2 pagesInspection Checklist For: Control Valvesabdelkader benabdallahNo ratings yet

- Scaffold ChecklistDocument5 pagesScaffold ChecklistMohamed GhariebNo ratings yet

- Quality Plan and Checklist (HVAC) - Sandvik G BlockDocument3 pagesQuality Plan and Checklist (HVAC) - Sandvik G BlockParasNo ratings yet

- ITP For Piping SystemsDocument6 pagesITP For Piping SystemssojeckNo ratings yet

- 3p081-Itp ADocument17 pages3p081-Itp AMariah PearsonNo ratings yet

- PPR Pipe Method Statement For Pipe and Fitting Installation and Testing Commissioning PDFDocument14 pagesPPR Pipe Method Statement For Pipe and Fitting Installation and Testing Commissioning PDFBuraq Aircondition Cont & Gen Maint LLC BuraqNo ratings yet

- Test Pack Table of ContentsDocument1 pageTest Pack Table of ContentsRavindra S. JivaniNo ratings yet

- Bolt Tightening ReportDocument2 pagesBolt Tightening Reportmujahed_muhammedNo ratings yet

- ITP For Pipe Materials (Stock)Document7 pagesITP For Pipe Materials (Stock)Hamid Taghipour ArmakiNo ratings yet

- 02 MechanicalDocument44 pages02 Mechanicalmusaismail8863No ratings yet

- Painting & Inspection FormatDocument1 pagePainting & Inspection FormatABEC Trombay siteNo ratings yet

- Inspection, Flushing & Testing of Piping-21Document6 pagesInspection, Flushing & Testing of Piping-21Saurabh Kumar VermaNo ratings yet

- Method Statement For Erection of PipingDocument11 pagesMethod Statement For Erection of PipingMalik Riaz50% (2)

- ITP-P-001 ITP For Above Ground Piping Rev. ADocument9 pagesITP-P-001 ITP For Above Ground Piping Rev. APhong Đỗ100% (1)

- Insp Checklist - Piping AlignmentDocument1 pageInsp Checklist - Piping AlignmentRickesh NunkooNo ratings yet

- 047-Itp For Oxygen Lines Fabrication and Installation PDFDocument28 pages047-Itp For Oxygen Lines Fabrication and Installation PDFKöksal PatanNo ratings yet

- 038-Itp For Coldboxes PDFDocument25 pages038-Itp For Coldboxes PDFKöksal PatanNo ratings yet

- 035-Itp For Pumps PDFDocument30 pages035-Itp For Pumps PDFKöksal Patan100% (3)

- 036-ITP For Compressor PDFDocument29 pages036-ITP For Compressor PDFKöksal PatanNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- 016-CIVIL - MS Anchor Bolt Installation PDFDocument14 pages016-CIVIL - MS Anchor Bolt Installation PDFKöksal Patan71% (7)

- 013-MS Utilization of Hilti DX 76 PDFDocument51 pages013-MS Utilization of Hilti DX 76 PDFKöksal PatanNo ratings yet

- 014-MS For General Scaffolding PDFDocument33 pages014-MS For General Scaffolding PDFKöksal Patan100% (2)

- 014-MS For Bolt Tightening (Piping& Equipments) PDFDocument23 pages014-MS For Bolt Tightening (Piping& Equipments) PDFKöksal PatanNo ratings yet

- 017-CIVIL-MS For Installation of Fence & Gate PDFDocument18 pages017-CIVIL-MS For Installation of Fence & Gate PDFKöksal Patan100% (6)

- 013-MS For Mass Concrete Works PDFDocument26 pages013-MS For Mass Concrete Works PDFKöksal Patan100% (1)

- 012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFDocument18 pages012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFKöksal PatanNo ratings yet

- 049-Itp For Lighting and Small Power (Building) PDFDocument15 pages049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- 012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFDocument16 pages012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFKöksal Patan91% (11)

- 047-Itp For Oxygen Lines Fabrication and Installation PDFDocument28 pages047-Itp For Oxygen Lines Fabrication and Installation PDFKöksal PatanNo ratings yet

- 009-Method Statement - Main Erection Sequence For Acc PDFDocument68 pages009-Method Statement - Main Erection Sequence For Acc PDFKöksal Patan100% (6)

- 011-Method Statement For Repair of Concrete Works PDFDocument25 pages011-Method Statement For Repair of Concrete Works PDFKöksal Patan91% (33)

- 010-MS For Grouting PDFDocument33 pages010-MS For Grouting PDFKöksal PatanNo ratings yet

- 009-Civil-Ms Concrete Works PDFDocument27 pages009-Civil-Ms Concrete Works PDFKöksal PatanNo ratings yet

- 010-MS For Welding and Hot Works For General Activities at TSF Area PDFDocument17 pages010-MS For Welding and Hot Works For General Activities at TSF Area PDFKöksal PatanNo ratings yet

- 041 - ITP For Painting (Building) PDFDocument12 pages041 - ITP For Painting (Building) PDFKöksal Patan78% (9)

- 039-Itp For Embedded Plate PDFDocument7 pages039-Itp For Embedded Plate PDFKöksal PatanNo ratings yet

- 038-Itp For Coldboxes PDFDocument25 pages038-Itp For Coldboxes PDFKöksal PatanNo ratings yet

- 008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFDocument23 pages008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFKöksal PatanNo ratings yet

- 040-ITP For Repair of Steam Distribution Manifold PDFDocument11 pages040-ITP For Repair of Steam Distribution Manifold PDFKöksal PatanNo ratings yet

- 008-CIVIL-MS Backfilling Works PDFDocument16 pages008-CIVIL-MS Backfilling Works PDFKöksal Patan100% (1)

- 007-MS For Structural Steel Assembly Warehouse, Workshops PDFDocument25 pages007-MS For Structural Steel Assembly Warehouse, Workshops PDFKöksal PatanNo ratings yet

- Building Bye RulesDocument11 pagesBuilding Bye RulesRahul RahulNo ratings yet

- Heat Pump RTU SCADocument49 pagesHeat Pump RTU SCAJhoNo ratings yet

- Worked Example 1:: SolutionDocument3 pagesWorked Example 1:: SolutionARVIND SINGH RAWATNo ratings yet

- Sheetmetal DFM PDFDocument5 pagesSheetmetal DFM PDFsharan_nNo ratings yet

- Research Companion To Building Information Modeling - 2022Document763 pagesResearch Companion To Building Information Modeling - 2022adamNo ratings yet

- Naamm Stair Manual FinalDocument126 pagesNaamm Stair Manual FinalAhmed BdairNo ratings yet

- Slab Culvert DrawingDocument3 pagesSlab Culvert DrawingcpachoreNo ratings yet

- Building Maintenance Units: AgendaDocument45 pagesBuilding Maintenance Units: AgendaRanjit SinghNo ratings yet

- Construction of Godown at PACS, AmbajipetaDocument11 pagesConstruction of Godown at PACS, AmbajipetaDurga Rama Swamy KalvakolanuNo ratings yet

- 54-K Model Town-Final SUBMISSIONDocument1 page54-K Model Town-Final SUBMISSIONSohail AshrafNo ratings yet

- Smacna Hvac Duct Construction StandardsDocument284 pagesSmacna Hvac Duct Construction StandardsMEP EngineeringNo ratings yet

- SRB Session2 EofsDocument3 pagesSRB Session2 EofsFullo Flores MarviloneNo ratings yet

- GEOLOGY For ENGG - BridgesAssignmentDocument4 pagesGEOLOGY For ENGG - BridgesAssignmentIrish Sophia OlimpoNo ratings yet

- 5.estimation of Shoring N Structing - Edited by HBIDocument5 pages5.estimation of Shoring N Structing - Edited by HBINIK MUHAMMAD FIRDAUS NIK HASSIMNo ratings yet

- Joshua R. Dela Cruz: ObjectiveDocument4 pagesJoshua R. Dela Cruz: ObjectiveBeth AlgarioNo ratings yet

- ITA Working Group N°5: P H S R M U WDocument7 pagesITA Working Group N°5: P H S R M U WrameshkaaNo ratings yet

- Karnataka State Highway Improvement Project - II, Stage 1: SDBC-2 - GraphDocument1 pageKarnataka State Highway Improvement Project - II, Stage 1: SDBC-2 - GraphKarumuri JayaramNo ratings yet

- TCC MVMCC 7481 TR 2aDocument1 pageTCC MVMCC 7481 TR 2adaniel ortizNo ratings yet

- CupTester Type F - Maintenance PackyardDocument2 pagesCupTester Type F - Maintenance Packyardandrei20041No ratings yet

- Wood Shear Wall Design Examples For WindDocument4 pagesWood Shear Wall Design Examples For WindAbdurrahman ÇINARNo ratings yet

- LRFD-Manual de PuenteDocument883 pagesLRFD-Manual de PuenteLaura ChomoNo ratings yet

- Material Specifications and Testing Standards For Retrofitting WorksDocument16 pagesMaterial Specifications and Testing Standards For Retrofitting WorksEmdadul HuqNo ratings yet

- BOQ Lift Steel Structure 02 - Blank PDFDocument3 pagesBOQ Lift Steel Structure 02 - Blank PDFPatrick OppongNo ratings yet

- OM Document For Seawater Booster Pump For FGDDocument109 pagesOM Document For Seawater Booster Pump For FGDAnh CatNo ratings yet

- Literature Review On Concrete AdmixturesDocument5 pagesLiterature Review On Concrete Admixturesaflsodoam100% (1)

- Compact Courtyard HousingDocument21 pagesCompact Courtyard HousingRana MahfoodhNo ratings yet

- CE Module 29 - StaticsDocument13 pagesCE Module 29 - StaticsAngelice Alliah De la CruzNo ratings yet