Professional Documents

Culture Documents

Op 54

Uploaded by

Rezicky ImamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Op 54

Uploaded by

Rezicky ImamCopyright:

Available Formats

REASON FOR REVISION:

1) O-320/360 Exhaust System installation instructions revised to include greater clarity,

as well as information covering filtered air box options and scat tube routing.

OP54-1 REV 1: Steps rewritten for clarity.

Figure 3 moved to page OP54-3.

OP54-2 REV 1: Steps rewritten for clarity.

In Figure 1, 2 & 3, callouts revised to more accurately reflect installation.

OP54-3 REV 0: New page

OP54-4 REV 0: New page

VAN'S AIRCRAFT, INC.

OP-54: O-320/360 EXHAUST

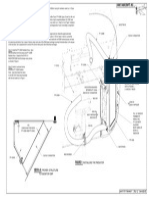

NOTE: Details of the engine installation that do not pertain to the exhaust system are shown for

reference only as some features may have been omitted or are obsolete.

EX-00001

Step 1: Fabricate the EX-00001F Heat Muff Clamp from the HW-00001 Hose Clamp by clamping it over

the Heat Muff Assembly. Mark the bend locations on the

clamp, then remove the hose clamp and bend as

required to ensure a close fit around the Heat Muff

Assembly.

2X EX-00001F

AIR INTAKE TUBE

WARNING: The Heat Muff Assembly must not be

installed over the Exhaust Crossover Slip Joints.

Doing so could cause exhaust gasses to enter the

Heat Muff Assembly & associated ducting.

Step 2: For installations using O-320 engines, trim the

exhaust tube ends to be inserted into the Exhaust

Crossover Slip Joints by 1 (25.4 mm) and install as

shown in Figure 1 and Figure 2.

Only install lock washers upon final installation.

Step 3: For installations using O-360

engines, install as shown in Figure 1

and Figure 2.

Only install lock washers upon

final installation.

CABIN HEAT

TUBE

EX-00004A

EX-00002

EX-00005

EX-00008

CARB HEAT

TUBE

EX-00003

EX-00003B,

8 PL

FIGURE 2:

HEAT MUFF ASSEMBLY

EA GASKET 77611

HEAT MUFF ASSEMBLY

NAS1149F0563P

MS35333-41 (LOCK WASHER)

EXHAUST

CROSSOVER

SLIP JOINT, 2 PL

NUT-00003

FIGURE 1: EXHAUST ASSEMBLY OVERVIEW

DATE: 09/11/14

REVISION:

1 RV 3,4,6,7,8,9

PAGE

OP 54-1

VAN'S AIRCRAFT, INC.

2X EX-00004E

OIL SUMP

6X EX-00004B

2XEX-00004E

6X AN737TW-4

3X EX-00004C

3X EX-00004C

2X EX-00004A

6X EX-00004B

6X

AN3-4A

NAS1149F0363P

MS21042-3

2X EX-00004A

FWD

LEFT

UP

RIGHT

FWD

FIGURE 3:

EXHAUST HANGER ASSEMBLY

FIGURE 1:

EXHAUST HANGER

ASSEMBLY

Step 1: Position the exhaust tubes as desired for cowl and engine mount clearance. Use safety wire to temporarily hold them in place if necessary.

Step 2: Temporarily install the EX-00004A Exhaust Hanger Brackets onto the exhaust tubes.

NOTE: The EX-00004E Exhaust Hanger Support Tab locations shown may vary between aircraft firewall forward installations, use the most convenient bolt locations on the Oil

Sump.

Step 3: Install the EX-00004E Exhaust Hanger Support Tabs in positions somewhat forward and above the EX-00004A Exhaust Hanger Brackets. See Figure 1.

Step 4: Trim all the EX-00004B Exhaust Support Tubes so that the ends reside in the center of their respective spans. Gaps between exhaust support tube ends should be between

1/4 [6.35 mm] and 1/2 [12.7 mm] to allow for motion due to engine vibration. Straight lines between the EX-00004A Exhaust Hanger Brackets and EX-00004E Exhaust Hanger Support Tabs are

prefferable, but may not be possible depending on engine configuration. Slight angles in the connecting geometry formed by the exhaust support tubes are acceptable.

1/4 [6.4 mm]

Step 5: Once the optimum orientation and lengths for the EX-00004B Exhaust Support Tubes have been found, bend the flat ends as necessary to ensure a flat fit against the faces of the

mounting hardware EX-00004A Exhaust Hanger Brackets & EX-00004E Exhaust Hanger Support Tabs. This will help reduce wear and tear on the exhaust support tubes. Ensure each exhaust

support tube is still aligned in an approximately straight line with its counterpart.

ROUND CORNERS

Step 6: Slightly crimp the open ends of all the EX-00004B Exhaust Support Tubes, creating a tube flare that will help to retain the EX-00004C Support Tubing. Round down the sharp corners

created by crimping as shown in Figure 2.

FIGURE 2: TUBING DETAIL

Step 7: Trim the EX-00004C Support Tubing approximately as shown in Figure 2.

(TYPICAL)

DATE: 09/11/14

REVISION:

RV 3,4,6,7,8,9

Step 8: Install all Exhaust Hanger Assembly hardware as shown in Figure 1.

PAGE

OP 54-2

VAN'S AIRCRAFT, INC.

Step 1: If carb heat is not required, bend the EX-00008G

Carb Heat Cover as shown in Figure 1 and match drill the

three #30 holes into the EX-00008 Carb Heat Tube.

Step 12: Match-Drill #40 the FF-01407 FAB Carb Heat Inlet to the VA-130B or VA-131B Air Box Top Plate as

shown in Figure 3.

Step 2: Rivet the EX-00008G Carb Heat Cover to

the EX-00008 Carb Heat Tube as shown in Figure 1.

Step 13: Coordinate the final installation of the FF-01407 FAB Carb Heat Inlet with the final assembly of the filtered air box,

particularly with respect to the carb heat door.

3X LP4-3

FIGURE 1:

CARB HEAT COVER

(OPTIONAL)

CARB HEAT TUBE

HT

IG

RA

ST

EX-00008G

LIN

E

CARBURETOR

NOTE: Perform Steps 3 thru 13 as part of the VA-130 or VA-131 Filtered Air Box fabrication and assembly

instructions. Steps provided here are only a guide, Individual aircraft firewall forward installations may vary.

The position of the carb heat tube from the EX-00001 Heat Muff will affect placement of the filtered air box

door and cutout. See Step 4.

Step 3: Begin assembly and installation of the VA-130 or VA-131 Filtered Air Box as described in the filtered air box

instructions. Perform enough assembly work to determine the physical alignment of the filtered air box to the induction

air inlet on the cowling, then proceed with the steps below.

MATCH-DRILL #40

AN470AD3-4

VA-130B OR VA-131B

6X

CARB HEAT INLET ASSEMBLY

VA-130A OR VA-131A

FIGURE 3:

CARB HEAT INLET INSTALLATION

Step 4: Temporarily install the VA-130B or VA-131B Air Box Top Plate onto the carburetor as described in the Filtered

Air Box instructions.

(O-320 INSTALLATION SHOWN FOR TIGHTEST CLEARANCE)

Step 5: Use a grinder to remove the "lip" inside the tube of the FF-01407 FAB Carb Heat Inlet.

Step 6: Position the FF-01407 FAB Carb Heat Inlet on as straight a line as possible with the carb heat tube from the

EX-00001 Heat Muff on top of the VA-130B or VA-131B Air Box Top Plate. This is especially critical for O-320

installations where there is a very short distance between the filtered air box and the heat muff carb heat tube due to

the shorter height of the O-320 carburetor.

TRIM AS NECESSARY

TO FIT INSIDE VA-130B OR VA-131B

FF-01407

Step 7: Mark and trim the FF-01407 FAB Carb Heat Inlet to fit inside the VA-130B or VA-131B Air Box Top Plate

in the position found in Step 6. Be aware of the location and travel of the VA-122 Arm per the Filtered

Air Box instructions and make allowances in the trim of the FAB carb heat inlet accordingly.

FINAL-DRILL #40

AN470AD3-4

Step 8: Clamp the FF-01407 FAB Carb Heat Inlet Mounting Brackets to the FF-01407

FAB Carb Heat Inlet as shown in Figure 2.

6X

Step 9: Final-Drill #40 six rivet holes into the FF-01407 FAB Carb Heat Inlet

and FF-01407C FAB Carb Heat Inlet Mounting Brackets approximately as shown

in Figure 2.

Step 10: Mark and trim the FF-01407C FAB Carb Heat Inlet Mounting Brackets

as shown in Figure 2.

FF-01407

2X FF-01407C,

TRIM AS NECESSARY TO FIT

INSIDE VA-130B OR VA-131B

Step 11: Cleco and rivet the FF-01407C FAB Carb Heat Inlet Mounting

Brackets to the FF-01407 FAB Carb Heat Inlet as shown in Figure 2.

FIGURE 2: CARB HEAT INLET ASSEMBLY

(EXACT SHAPE MAY VARY BY AIRCRAFT)

DATE: 09/11/14

REVISION:

0 RV 3,4,6,7,8,9

PAGE

OP 54-3

VAN'S AIRCRAFT, INC.

POSITION AIR

INTAKE HOLE

AFT OF THIS BEND

LINE

2 [50.8 mm]

FINAL-DRILL #30

AN470AD3-4

NOTE: The CB-907A or CB-1007A Right Aft Case Baffle may already have an air intake hole pre-punched. If present, seal this hole with a block-off.

4X

VENT DL-03

Step 1: Create the air intake hole in the CB-902A or CB-1002A Forward Left Air Ramp as shown in Figure 1. Position the hole aft of the bend line in the CB-907A or

CB-1007A Right Aft Case Baffle as shown in Figure 1.

Position the hole left and right so that the scat tube will naturally route from the Heat Muff Air Intake to the VENT DL-03 Scat Tube Flange while avoiding interference

from the starter or any other components.

Experiment with the scat tube routing prior to creation of the air intake hole. If necessary, the flange of the VENT DL-03 Scat Tube Flange may be bent to facilitate

positioning. Clamp the VENT DL-03 Scat Tube Flange into position.

CB-902A

OR CB-1002A

Step 2: Clamp, then final-drill #30 the holes in the VENT DL-03 Scat Tube Flange to the CB-902A or CB-1002A Forward Left Air Ramp as shown in Figure 1.

WARNING: Install a vent screen in this location if the vent hole is ONLY to provide cabin heat. A vent screen installed upstream of a carburetor heat

system may obstruct airflow and drastically reduce engine performance.

FIGURE 1: AIR INTAKE HOLE LOCATION

Step 3: Rivet the VENT DL-03 Scat Tube Flange and VENT SCREEN 3X3 (optional) to the CB-902A or CB-1002A

Forward Left Air Ramp as shown in Figure 1.

WARNING: For proper carb heat performance, a vent screen must be installed over the cabin heat tube at the location

shown in Figure 3.

STARTER

INT

AK

E

Step 4: (If using carb heat) Form the VENT SCREEN 3X3 over the end of the cabin heat tube coming from the Heat Muff Assembly.

See Figure 3 for location.

AIR

Step 5: Cut lengths of scat tubing to connect the VENT DL-03 Scat Tube Flange to the heat muff air intake tube; the FF-01407

FAB Carb Heat Inlet to the heat muff carb heat tube; and the heat muff cabin heat tube to the VENT TG-10 Assembly installed on the

firewall in OP-29 or OP-33. See Figure 2 and Figure 3.

VENT DL-03

AN737TW, 2 PL

Step 6: Secure the Scat Tubes as shown in Figure 2 and Figure 3. Use additional tie-wraps and clamps as necessary to ensure

the scat tubes do not interfere with the oil sump drain, exhaust tube, engine mount or any other components.

HEAT MUFF

HEAT MUFF

AIR INTAKE TUBE

3X3 VENT SCREEN

CARB HEAT TUBE

AN737TW, 2 PL

CARB

HEAT

MS21919-DG12

AB

IN

RB

CA AT

HE

HE

AT

H EAT

CA

BIN

AN737TW, 2 PL

FF-01407

AN3-4

AN310-3

MS21919-WDG34

FF-01407

SAFETY WIRE

WRAPPED AROUND

CLAMP

DATE: 09/11/14

REVISION:

RV 3,4,6,7,8,9

PAGE

OP 54-4

FIGURE 2: SCAT TUBE ROUTING

FIGURE 3: SCAT TUBE ROUTING

(O-360 INSTALLATION SHOWN)

(O-360 INSTALLATION SHOWN)

You might also like

- Van'S Aircraft, Inc.: Figure 1: Installing The Radiator View A-A: Proper StructureDocument1 pageVan'S Aircraft, Inc.: Figure 1: Installing The Radiator View A-A: Proper StructureMark Evan SalutinNo ratings yet

- Van'S Aircraft, Inc.: Figure 1: InstallingDocument1 pageVan'S Aircraft, Inc.: Figure 1: InstallingMark Evan SalutinNo ratings yet

- Van'S Aircraft, Inc.: FF-1208A OR FF-1208BDocument1 pageVan'S Aircraft, Inc.: FF-1208A OR FF-1208BMark Evan SalutinNo ratings yet

- Installation and Rigging Procedures: Advanced Technology Performance and Environmental Improvement Systems For YourDocument33 pagesInstallation and Rigging Procedures: Advanced Technology Performance and Environmental Improvement Systems For YourRene QueirozNo ratings yet

- SEars Riello f10 Oil Burner ManualDocument20 pagesSEars Riello f10 Oil Burner ManualLeslie FlemingNo ratings yet

- Van'S Aircraft, Inc.: Figure 4: Adding The Terminal BlockDocument1 pageVan'S Aircraft, Inc.: Figure 4: Adding The Terminal BlockMark Evan SalutinNo ratings yet

- Van'S Aircraft, Inc.: Lighting Bracket Cockpit Light Wires Connections 40-11 RV-12Document1 pageVan'S Aircraft, Inc.: Lighting Bracket Cockpit Light Wires Connections 40-11 RV-12Mark Evan SalutinNo ratings yet

- Split System Indoor Coils Installation InstructionsDocument8 pagesSplit System Indoor Coils Installation Instructionskhopdi_number1No ratings yet

- B U L L E T I N: Application EngineeringDocument6 pagesB U L L E T I N: Application EngineeringMaria DazaNo ratings yet

- Air Intake Duct Number Designation Engine 457.925/ 929Document2 pagesAir Intake Duct Number Designation Engine 457.925/ 929Łukasz HadrzynskiNo ratings yet

- Van'S Aircraft, Inc.: Revision: DateDocument1 pageVan'S Aircraft, Inc.: Revision: DateMark Evan SalutinNo ratings yet

- Figure 1: Making The Battery Spacer: Van'S Aircraft, IncDocument1 pageFigure 1: Making The Battery Spacer: Van'S Aircraft, IncMark Evan SalutinNo ratings yet

- 01 sb264003Document2 pages01 sb264003Christian FloresNo ratings yet

- Manual Sbs OriginalDocument43 pagesManual Sbs OriginalNéstor José Pedrique Silva100% (1)

- MEGA Operating InstructionsDocument14 pagesMEGA Operating InstructionsSumit SinghaNo ratings yet

- Figure 1: Separating The: Rudder Pedal Support ChannelsDocument1 pageFigure 1: Separating The: Rudder Pedal Support ChannelsMark Evan SalutinNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Air Compressor Flange Removal and Installation Has Been Added To The Workshop ManualDocument4 pagesAir Compressor Flange Removal and Installation Has Been Added To The Workshop ManualChandra SutawijayaNo ratings yet

- Dimensions - Inches Product Data: Split-System Evaporator Blowers 15 & 20 TONDocument4 pagesDimensions - Inches Product Data: Split-System Evaporator Blowers 15 & 20 TONRafyss RodriguezNo ratings yet

- 454 GD & HS Fuel Pump Timing & CalibrationsDocument15 pages454 GD & HS Fuel Pump Timing & Calibrationsslipsittin75% (4)

- Carburetor Stromberg BDocument38 pagesCarburetor Stromberg Bddlevy100% (1)

- CEB1051Document6 pagesCEB1051oscar horacio floresNo ratings yet

- Piper SB 952 One Piece Exhaust Pipe InstallationDocument6 pagesPiper SB 952 One Piece Exhaust Pipe InstallationGeorgios AsimakopoulosNo ratings yet

- Si 1185Document6 pagesSi 1185user10002No ratings yet

- 93 15Document4 pages93 15sharawy12No ratings yet

- 2013-01-28 - 022047 - Update - PDF Compresor Kia OptimaDocument9 pages2013-01-28 - 022047 - Update - PDF Compresor Kia OptimaRichard LindarteNo ratings yet

- Alignment and Installation Procedure For UW EqptsDocument79 pagesAlignment and Installation Procedure For UW EqptsSanthosh Kumar100% (1)

- 3042 G Tag Axle R12 Brake Valve RetrofitDocument6 pages3042 G Tag Axle R12 Brake Valve RetrofitHamiltonNo ratings yet

- Delay in Opening of LP Bypass ValveDocument94 pagesDelay in Opening of LP Bypass ValveCharu ChhabraNo ratings yet

- Isc 300Document37 pagesIsc 300AwanNo ratings yet

- 2GR FE CoolingDocument36 pages2GR FE CoolingLuks FernandezNo ratings yet

- Van'S Aircraft, Inc.: Figure 3: Drilling The Terminal BlockDocument1 pageVan'S Aircraft, Inc.: Figure 3: Drilling The Terminal BlockMark Evan SalutinNo ratings yet

- Series FV-4M1 Specification SheetDocument2 pagesSeries FV-4M1 Specification SheetWattsNo ratings yet

- Operator E-Jets News Rel 07Document12 pagesOperator E-Jets News Rel 07PDDELUCA100% (1)

- Man B&W Me EngineDocument20 pagesMan B&W Me EngineSoumyadeep Bhattacharyya100% (7)

- EMBRAER 170/175/190/195 CTA Master Minimum Equipment List: Empresa Brasileira de Aeronáutica S.ADocument185 pagesEMBRAER 170/175/190/195 CTA Master Minimum Equipment List: Empresa Brasileira de Aeronáutica S.AperrymekNo ratings yet

- Air SuspentionDocument42 pagesAir Suspentionbhaskar098100% (1)

- SM64348 PDFDocument24 pagesSM64348 PDFHENKO7659No ratings yet

- Asb - 212 10 140Document12 pagesAsb - 212 10 140smartasss100% (1)

- MC 8 Mod 08 AD 91-15-04Document4 pagesMC 8 Mod 08 AD 91-15-04bhanu pratap lodhiNo ratings yet

- 600 MOM ASME Discussion - Reply by DerekDocument3 pages600 MOM ASME Discussion - Reply by DerekarissaNo ratings yet

- Aw60 40le Zip inDocument10 pagesAw60 40le Zip inMarko PavlovicNo ratings yet

- 2RZ 3RZ SCDocument21 pages2RZ 3RZ SCDiego Pillco0% (1)

- 2.4L Install InstructionsDocument13 pages2.4L Install InstructionskpepasNo ratings yet

- 1644 - 1 - sb-04-0314v2 - Db9 Sportspack Damper LeakDocument3 pages1644 - 1 - sb-04-0314v2 - Db9 Sportspack Damper Leakmink4uNo ratings yet

- Technical Bulletin: CopierDocument22 pagesTechnical Bulletin: CopiernickypanzeNo ratings yet

- Position: Figure 2: Throttle HandleDocument1 pagePosition: Figure 2: Throttle HandleMark Evan SalutinNo ratings yet

- Toyota Hiace MantenimientoDocument20 pagesToyota Hiace Mantenimientofranktrevi75% (4)

- Pump Repair ManualDocument17 pagesPump Repair ManualSergiSerrano100% (1)

- Class 10000 Fans Owner'S ManualDocument19 pagesClass 10000 Fans Owner'S ManualhaosfNo ratings yet

- Service Bulletin PDFDocument8 pagesService Bulletin PDFamrjheyNo ratings yet

- Holden VT 2000 Service TechlinesDocument177 pagesHolden VT 2000 Service Techlinescosky071% (7)

- TB 430-04-37Document63 pagesTB 430-04-37Amparo AlvarezNo ratings yet

- Installation and Rigging ProceduresDocument15 pagesInstallation and Rigging ProceduresRene QueirozNo ratings yet

- Presostat Gaze HoneywellDocument16 pagesPresostat Gaze HoneywellMia ZahariaNo ratings yet

- HKMN Gas Turbine Division: Rolls-Royce Proprietary Data - Uncontrolled PrintedDocument10 pagesHKMN Gas Turbine Division: Rolls-Royce Proprietary Data - Uncontrolled Printedoscar horacio floresNo ratings yet

- Airworthiness Bulletin: AWB Issue: DateDocument2 pagesAirworthiness Bulletin: AWB Issue: DateFran GaritaNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- B NG-Hydraulics PDFDocument15 pagesB NG-Hydraulics PDFanasNo ratings yet

- Lampiran 1 A. Data Pesawat Terbang RV-4Document16 pagesLampiran 1 A. Data Pesawat Terbang RV-4Rezicky ImamNo ratings yet

- Dec. 1, 1953 J. H. Allen: Filed Oct. 11, 1951Document8 pagesDec. 1, 1953 J. H. Allen: Filed Oct. 11, 1951Rezicky ImamNo ratings yet

- A1 2015Document21 pagesA1 2015Rezicky ImamNo ratings yet

- Capability List 16Document106 pagesCapability List 16Rezicky ImamNo ratings yet

- Manual Extra300Document232 pagesManual Extra300Cornel VoicuNo ratings yet

- LicenseDocument1 pageLicenseProdromos MpasmatzisNo ratings yet

- 145 C 05 KwrgwqierDocument30 pages145 C 05 KwrgwqierRezicky ImamNo ratings yet

- Laa Type Acceptance Data Sheet TADS 323 Vans Rv-7 & 7ADocument8 pagesLaa Type Acceptance Data Sheet TADS 323 Vans Rv-7 & 7ARezicky ImamNo ratings yet

- Laa Type Acceptance Data Sheet TADS 323 Vans Rv-7 & 7ADocument8 pagesLaa Type Acceptance Data Sheet TADS 323 Vans Rv-7 & 7ARezicky ImamNo ratings yet

- Laa Type Acceptance Data Sheet TADS 323 Vans Rv-7 & 7ADocument8 pagesLaa Type Acceptance Data Sheet TADS 323 Vans Rv-7 & 7ARezicky ImamNo ratings yet

- S P P M: Eries EAK Ower EtersDocument5 pagesS P P M: Eries EAK Ower EtersRezicky ImamNo ratings yet

- Cinta Terbaik Oleh CassandraDocument2 pagesCinta Terbaik Oleh CassandraRezicky ImamNo ratings yet

- Oil Cooler Thermostat by Pass Valve Check Valve: Sistem EngineDocument1 pageOil Cooler Thermostat by Pass Valve Check Valve: Sistem EngineRezicky ImamNo ratings yet

- TNVS Reqs and Eligible CarsDocument2 pagesTNVS Reqs and Eligible CarsAvarel DPNo ratings yet

- Quality Failures That Shook The World - FordDocument2 pagesQuality Failures That Shook The World - FordSyahril Aizal AhmadNo ratings yet

- Kubota RTV-X900 - RTV-X1120D Utility Vehicle Operators ManualDocument114 pagesKubota RTV-X900 - RTV-X1120D Utility Vehicle Operators ManualСвятославNo ratings yet

- TWD1643 Service PartsDocument104 pagesTWD1643 Service PartsDaniel Muratalla100% (1)

- THULE - Catalog Bare TransversaleDocument55 pagesTHULE - Catalog Bare Transversaledanber815100% (1)

- Quaife ATB DiffDocument5 pagesQuaife ATB DiffMaxim MackenzyNo ratings yet

- Carnation MainDocument11 pagesCarnation MainDipak Ranjan SwainNo ratings yet

- Audi 6 3l w12 Fsi EngineDocument4 pagesAudi 6 3l w12 Fsi EngineMarlon100% (54)

- E60-CAS3 Module FunctionsDocument13 pagesE60-CAS3 Module FunctionsMariusBichiNo ratings yet

- Manual de Partes Crown TSP6000Document364 pagesManual de Partes Crown TSP6000Andrey Fernando Luque SeguraNo ratings yet

- 2014 Jamboree Searcher ManualDocument99 pages2014 Jamboree Searcher ManualdrandaNo ratings yet

- Manual Chylers Dodge 1985Document1,547 pagesManual Chylers Dodge 1985magozriver100% (1)

- Gear SelectionDocument34 pagesGear SelectionManny AnacletoNo ratings yet

- RT 600Document258 pagesRT 600RuddyNo ratings yet

- Prius P Hev ManualDocument16 pagesPrius P Hev Manualrey1004No ratings yet

- Tronair CatalogDocument121 pagesTronair CatalogEdgar Schneider50% (2)

- DFG 545 DFG 550 TFG 540 TFG 545 TFG 550 DFG 540Document169 pagesDFG 545 DFG 550 TFG 540 TFG 545 TFG 550 DFG 540Gaatje EchtniksaanNo ratings yet

- Anti Lock Brake System Tata Motors Information PDFDocument16 pagesAnti Lock Brake System Tata Motors Information PDFValBMSNo ratings yet

- EP0503 - 1. What Is The Airline Industry AboutDocument59 pagesEP0503 - 1. What Is The Airline Industry AboutJackLiewNo ratings yet

- MCM Oil Tools: Chokes and Control PanelsDocument4 pagesMCM Oil Tools: Chokes and Control PanelsCARLOS SANCHEZNo ratings yet

- Bentley Continental GT 2007 Misc Documents-BrochureDocument19 pagesBentley Continental GT 2007 Misc Documents-BrochureMusaHamzic100% (1)

- Handling Precautions On Related Components: 1. Brake SystemDocument1 pageHandling Precautions On Related Components: 1. Brake SystemGrzegorz OlewińskiNo ratings yet

- SPC 450DX Oct 2013 PDFDocument155 pagesSPC 450DX Oct 2013 PDFPIJUSH NANDINo ratings yet

- Liv Cycling Bike 690Document1 pageLiv Cycling Bike 690Giancarlo AcostaNo ratings yet

- 10 Comm Tractor SafetyDocument30 pages10 Comm Tractor Safetymohammad_shahzad_iiuiNo ratings yet

- Torque Converter Catalog - 2012 LoResDocument342 pagesTorque Converter Catalog - 2012 LoResRoberto Perez100% (1)

- C208B QRH Complete 06-Nov-2014Document38 pagesC208B QRH Complete 06-Nov-2014Vivek PatelNo ratings yet

- Maruti ProjectDocument88 pagesMaruti ProjectSahil DangNo ratings yet

- Torques Subaru Impreza 2.5 EJ257Document4 pagesTorques Subaru Impreza 2.5 EJ257ChristianHuiscañancoPerezNo ratings yet

- PC120-6 PC120LC-6: With Tier 2 SAA4D102E-2 EngineDocument12 pagesPC120-6 PC120LC-6: With Tier 2 SAA4D102E-2 EngineJohn MkCito KINo ratings yet