Professional Documents

Culture Documents

PE3 Series Datasheet 10-24-11

Uploaded by

debendra128nitr0 ratings0% found this document useful (0 votes)

18 views2 pagesacacc

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentacacc

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views2 pagesPE3 Series Datasheet 10-24-11

Uploaded by

debendra128nitracacc

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Performance Electronics, Ltd.

www.pe-ltd.com info@pe-ltd.com

Phone: (513) 7775233

Fax: (513) 777-2042

engine control unit is a compact, adjustable system that handles fuel

The

and ignition responsibilities for almost any engine. The long features list, ease of

use and small size make it a great addition to any vehicle, on or off-road.

Not A

Piggyback

General System Features

Completely adjustable via a laptop.

Plug-and-Play versions available for some

applications.

Lightweight and compact with a waterproof

option (4.25x 4.80 x 1.00

and less than 1 lb).

Dedicated CAN bus that

allows communication with

external devices.

Standard 1MB of on-board

data logging for engine

parameters and external

inputs (Approx 5 hrs of

data with 10 channels at

20 Hz).

25,000+ max RPM.

Adjustable rev limits including

Primary, Secondary and

Boost limits.

Password protected access.

Fast and reliable

communication via Ethernet.

Allows for easy wireless

tuning with routers.

Real-time tuning.

Extensive error and diagnostic functions.

Save and load tuning files, or parts of tuning

files, to and from disk.

Primary/Secondary main fuel and ignition

tables.

Fuel Specific Control

25x26 Main fuel table with adjustable indices

and an option to reduce table size to 13x13.

Barometric Pressure, Acceleration,

Deceleration, Battery, Air Temp, Coolant

Temp and Starting compensations.

Individual cylinder trims.

Closed loop control with adaptive learning.

Sequential, batch or semi-sequential injector

firing.

PE reserves the right to change the specifications without notice.

Adjustable injection timing control.

Saturated or peak-and-hold injector drivers.

Adjustable peak current and adjustable hold

current for low impedance injectors.

Staged injection.

Ignition Specific Control

Plastic,

Waterproof

Enclosure

Coil-on-plug, wasted spark or

distributor based ignition.

No external igniters required. Inductive

igniters are built in the ECU.

25x26 Main Ignition table with

adjustable indices and an option to

reduce table size to 13x13.

Starting, Air Temp, Coolant Temp and

Barometric Pressure compensations.

Individual cylinder trims.

Adjustable dwell as a function of

Battery Voltage.

System Inputs

MAP, TPS, Barometric Pressure, Air

Temp, Coolant Temp, Battery Voltage,

Crank, Cam, Thermistors, EGO.

Up to 8 generic analog inputs that can be used to

modify fuel, modify timing, cut fuel, cut timing or

simply be logged.

2 additional thermistor inputs.

Up to 7 user configurable digital inputs that can stop

fuel, stop ignition, measure speeds, initiate secondary

rev limit, start/stop data logging, etc.

Aluminum

Enclosure

System Outputs

Fuel pump driver.

8 peak-and-hold or saturated injector drivers.

4 ignition coil drivers with internal igniters.

Dedicated tachometer driver.

Idle air stepper motor driver.

Up to 10 user configurable digital outputs.

Up to 8 Pulse Width Modulated outputs with

adjustable duty cycles based on 3-D tables.

10/24/11

Advanced Tuning Software

All features are completely adjustable using the

advanced software that communicates to the

ECU via an Ethernet connection.

Huge 25x26 main fuel and ignition tables provide

ample resolution for even the most difficult to

tune engine. User adjustable RPM and Load

indices make the system even more versatile.

In addition to the large fuel and ignition tables,

the PE3 allows you to adjust all fuel and ignition

compensation terms real time.

PE reserves the right to change the specifications without notice.

While tuning, individual compensation terms are

represented in an easy to view bar graph. This

allows instant identification of which factors are

influencing fuel and ignition.

Real-time plotting and internal data logging are

included with every system. 1 MB of data can be

stored in the ECU as the engine runs. Engine

parameters, as well as generic analog and digital

inputs, can be logged.

Advanced diagnostic features, like error logging

and crank/cam trigger scope displays, allow for

easy troubleshooting.

10/24/11

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Mazda 32318 I 16 VBPDocument49 pagesMazda 32318 I 16 VBPJon Luc Pulido Julian0% (2)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- AckermanDocument11 pagesAckermanC.E. Ishmeet Singh50% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Ackerman Erik ZapletalDocument23 pagesAckerman Erik ZapletalMrudula Amar WardeNo ratings yet

- Kubota L4600 Manual PDFDocument100 pagesKubota L4600 Manual PDFamadan64100% (2)

- GQ Patrol Service Manual - Y60Document1,038 pagesGQ Patrol Service Manual - Y60Jan Antonius Djunaedi77% (13)

- Power Cable SizingDocument8 pagesPower Cable SizingPagdi Srini100% (1)

- Actuator PDFDocument62 pagesActuator PDFpdealers100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- TM 1-1520-236-10 (2001 - 0126) Operators Manual, AH-1FDocument360 pagesTM 1-1520-236-10 (2001 - 0126) Operators Manual, AH-1FOlgerd1977100% (1)

- PE3 Series ManualDocument149 pagesPE3 Series Manualdebendra128nitrNo ratings yet

- FSAE Suspension OptimizationDocument32 pagesFSAE Suspension Optimizationisaiahfreerksen100% (1)

- Tt-R50e 2007 1p6-F8197-E0Document211 pagesTt-R50e 2007 1p6-F8197-E0Cristian Cerna50% (4)

- Fluidized Catalytic Cracking Unit (FCCU) Overview (Dta & Sez)Document40 pagesFluidized Catalytic Cracking Unit (FCCU) Overview (Dta & Sez)pavijaya100% (1)

- Earth in Danger: Quiz - How Environmentally Conscious Are You?Document7 pagesEarth in Danger: Quiz - How Environmentally Conscious Are You?Andreea DragomirNo ratings yet

- Audi A2 - Body. Construction and FunctionDocument64 pagesAudi A2 - Body. Construction and Functionspy2o100% (2)

- Pipelines Fundamentals Presentation RevisedDocument44 pagesPipelines Fundamentals Presentation RevisedSharon Freeman100% (1)

- Formulalincolnprogram PDFDocument62 pagesFormulalincolnprogram PDFdebendra128nitrNo ratings yet

- Fsae Suspension Design LawrenceDocument7 pagesFsae Suspension Design LawrenceAbhishek Dixit100% (1)

- Driving A Class 158Document4 pagesDriving A Class 158Frank NelsonNo ratings yet

- Tire ModelsDocument274 pagesTire Modelsdebendra128nitrNo ratings yet

- SOM-ss Rattan PDFDocument502 pagesSOM-ss Rattan PDFsteevecky35% (23)

- Tire ModelsDocument274 pagesTire Modelsdebendra128nitrNo ratings yet

- Rack N PinionDocument16 pagesRack N PinionslummanNo ratings yet

- Wiring Diagram: Function/NotesDocument1 pageWiring Diagram: Function/Notesdebendra128nitrNo ratings yet

- PE3 SP000 - Datasheet - 10 5 13Document1 pagePE3 SP000 - Datasheet - 10 5 13debendra128nitrNo ratings yet

- Compact, Low-Cost Programmable Ignition Controllers: PE3-IG Specifications and FeaturesDocument1 pageCompact, Low-Cost Programmable Ignition Controllers: PE3-IG Specifications and Featuresdebendra128nitrNo ratings yet

- AN400 Rev B Application Note for PE3 Series ECU CAN Bus ProtocolDocument1 pageAN400 Rev B Application Note for PE3 Series ECU CAN Bus Protocoldebendra128nitrNo ratings yet

- Basug BasicTasksDocument640 pagesBasug BasicTasksdebendra128nitr100% (1)

- MECH HovercraftDocument16 pagesMECH HovercraftNagabhushanaNo ratings yet

- Fire Diamond PDFDocument3 pagesFire Diamond PDFbuddy-20087751No ratings yet

- UG Governor: ApplicationsDocument4 pagesUG Governor: ApplicationsralphholingsheadNo ratings yet

- TPC Member ListDocument8 pagesTPC Member ListaliNo ratings yet

- Operation and Startup ProceduresDocument4 pagesOperation and Startup ProceduresAtanasio PerezNo ratings yet

- TR8 Rom SupDocument32 pagesTR8 Rom SupClint CooperNo ratings yet

- Kit Turbo TTEDocument64 pagesKit Turbo TTENokxaNo ratings yet

- Lean Cities: Propane Powered Ford F-150 PresentationDocument4 pagesLean Cities: Propane Powered Ford F-150 PresentationJohny KurubilaNo ratings yet

- Fan Coil Units External System Resistance Calculation (Static Pressure)Document4 pagesFan Coil Units External System Resistance Calculation (Static Pressure)Adnan AttishNo ratings yet

- Alat Uji Emsi Solar CosberDocument2 pagesAlat Uji Emsi Solar CosberJuliansyahNo ratings yet

- Base Oil SN-150 (IRANOL Refinery)Document1 pageBase Oil SN-150 (IRANOL Refinery)Mukesh LoharNo ratings yet

- Renewal and Sustainable Energy ReviewsDocument19 pagesRenewal and Sustainable Energy Reviewsstephenlim7986No ratings yet

- Perforadora HD155Document2 pagesPerforadora HD155anthony jimmy soto hinojosaNo ratings yet

- TN Fire Dept tender for 101m aerial ladder platformsDocument50 pagesTN Fire Dept tender for 101m aerial ladder platformsBalaji RathinavelNo ratings yet

- Hydraulic Drives For Bridges Considering The New DIN Standard 19704Document13 pagesHydraulic Drives For Bridges Considering The New DIN Standard 19704Nguyen Cong Cuong100% (1)

- Map Notes For RalliartDocument4 pagesMap Notes For RalliartJames FlanneryNo ratings yet

- MTU Marine Spec 16V4000M93 PDFDocument2 pagesMTU Marine Spec 16V4000M93 PDFsmithworkNo ratings yet

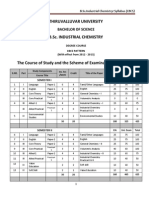

- B.sc. Industrial ChemistryDocument79 pagesB.sc. Industrial ChemistryOmar Abd Elsalam0% (1)