Professional Documents

Culture Documents

Building A Water Wheel

Uploaded by

MANNAJANELAGUNAOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Building A Water Wheel

Uploaded by

MANNAJANELAGUNACopyright:

Available Formats

Building an Undershot Water Wheel

I really miss the old days when we could leisurely peruse the scrap pile within our town

‘recycling facility’ and procure all the material necessary for any home project. These

days however we must rely upon our ability to identify potential sources and secure those

materials prior to them arriving at the collection point. I find doing this to be a bit more

challenging since I must now be on the lookout at all times for the perfect item to fill a

specific need. Perhaps you’ll understand now why it took almost two years to identify

and assemble the materials for this small project.

Required material:

1 large industrial wire spool*

12” – 15” Diameter PVC schedule 80 pipe*

3/8 inch Threaded Rod*

Fiberglass resin*

(2) 1½” Pillow block bearings (Northern Tool Item #1810 @ $13.99 ea)

1½” Cold rolled steel shaft*

14” automotive flex gear (or other gearing mechanism such as chain and sprockets)

Imagination

* (optimal size is site dependent)

In putting together this list, it has occurred to me that there are too many variables and

alternatives available to the rest of the items I used so it would perhaps be best to let your

creative juices flow as you consider what you’ll use to build the sluiceway or power with

this device. I’ll merely relate the adventure as it unfolded…

One particular Spring thaw found me musing over the zillions of gallons of water flowing

over our waterfall and how “… it would be nice to put that to work.” The fall is merely

four feet high so my mind sized out an appropriate overshot water wheel. On the way

home from work that day, I stopped by a local electrical contractors shop to inquire about

that large wire spool I had spied on his lot. To my surprise, he asked me to take as many

as I’d like since he would have to dispose of them otherwise.

Several weeks later I found a source for the

PVC pipe… a nearby town was replacing the

storm drains and had various lengths of broken

and short pieces they were eager to part with. I

had decided to place as many vanes as was

practical on the wheel and that appeared to be

nine, but how would I space them evenly? I

drew upon my high school geometry skills to

sketch out the necessary chord length for the

40” diameter wheel and, after aligning and

clamping the two disks as they would

ultimately be joined (making note of and aligning the previous threaded rod penetrations

and other holes) marked each point on the perimeter of the two wheels using a yard stick

More DIY projects at: www.BuildItSolar.com

and magic marker. My goal was to

ascertain that the center holes and final

rotational balance remained true.

After separating the disks, I drew lines

on the inside surfaces from each of the

points to the center. Measuring the

diameter of the PVC pipe, I fabricated

a piece of metal strap with a small hole

at each end which, when fastened to

the edge of the surface plate on my ø

router and a point on the wooden

disks, would allow me to create a Ø = 360/N Where

N = number of vanes

semicircular slot in the disks which

would accommodate the end of each

vane. I used a 3/8 inch router bit and

made each slot ½” deep starting at the

line marked on the disk perimeter and

rotating around to the inside of the

same line. Please note that before

routing out the slots on the second

disk, you should sketch out and mark

the direction of the proposed slots such that when the disks are assembled, the slots will

correspond to one another.

In order to overcome the challenges involved with cutting 1 foot diameter PVC pipe

lengthwise with straight edges, I clamped a piece of wood strapping to the pipe at both

ends (aligned as to be parallel) and made the initial cut with a skill saw. After

determining and marking the proper cut location on the opposite edge, I once again

clamped the strapping in such a location as to keep the blade on the marked line. That

done, I cut each vane to the appropriate length using my miter saw such that the edges

were square. A little bit of sandpaper and the vanes were ready.

The last thing to do before beginning assembly was to drill holes for the additional

threaded rods that I felt were necessary since the disks would eventually tend to warp.

Laying one disk down, I marked and drilled a 3/8 inch hole directly beneath the cup of

each vane slot at a distance of 4 inches from the perimeter edge of the disk. Placing the

two disks together as they would be mounted (slot to slot), I drilled through each hole

again resulting in a corresponding set of 3/8 inch holes on the other disk.

Undoubtedly the best part is putting all the

pieces together and this is where I always

find I’ve missed something but we’ll get to

that later. I inserted three or four lengths of

threaded rod with retaining nuts into the

inner holes on one disk and, with the disk

flat on the ground, inserted the vanes,

aligned the second disk and secured the rods

but not too tightly. Having examined and

More DIY projects at: www.BuildItSolar.com

assured myself of the proper seating of each vane in its corresponding slot, I inserted and

tightened the remaining threaded rods. I found that I had to “persuade” proper seating

with the judicious use of my sledge hammer, but I suspect that was due to moisture

absorption resulting from the six months between routing the slots and assembling the

wheel. Once the threaded rods where evenly torqued and the wheel appeared to rotate on

a pipe without wobbling, I cut off the protruding rod ends (Notice the countersunk cup

washers) and painted the surfaces flat black to appease my wife who by now had refused

to let this “monstrosity” adorn ‘her’ waterfall and possibly be seen by the neighbors.

While I nursed my wounded ego I decided to coat the “monstrosity” with fiberglass such

that it would be more durable and retain its shape. Through negotiations with my wife, I

was authorized to build another waterfall “somewhere out back” and resorted to more

research. I decided upon an undershot water wheel configuration since I’d located a

natural fall of two feet and wasn’t particularly eager to reroute an entire stream. During

the low flow week or two afforded me in September, I cut into the existing stream path

such that I could place two concrete block pads at a distance of 26” from one another and

using a ½” thick piece of plywood cut 26” wide, formed a 21” radius curved concrete

form into which went rock, rebar and concrete. In fact, knowing how violent this little

stream can become, I ended up placing forty feet of rebar and almost 3,000 pounds of

concrete in such a fashion that the mount should not move from its designated location

(Rebar driven 5’ into the stream bed). I then landscaped the upstream shoreline to more

narrowly confine flow to the wheel. It was my decision to allow water to bypass this

structure if levels exceed the center height of the wheel since no one should

underestimate the destructive forces behind rapidly flowing water. Judicious placement

of a piece of 1” expanded steel assures my wheel will not fall victim to floating debris.

I inserted some “L” – shaped lengths of leftover threaded rod into the concrete before it

set such that I could bolt down two lengths of pressure treated lumber onto which I could

later locate and mount the gearbox and generator. If I was clever and had the pillow block

bearings in hand at the time I would have also inserted threaded rod lengths in the

appropriate locations to mount them, but as it was I ended up drilling holes and placing

5/8 inch threaded anchors later on. The clearance between the wheel and the formed

sluiceway ended up being ¾” so one should be very careful if pre-placing threaded rod

for the pillow blocks.

Getting the wheel mounted however took me until mid November since I still had to

figure out how to secure the axle shaft to the wheel. The epiphany occurred while

performing my annual autumn garage clearing ritual. There among the items scheduled to

return to the future projects parts pool was the satellite dish assembly from which I

More DIY projects at: www.BuildItSolar.com

removed the positioning mechanism for my solar panel tracking mount project. The

assembly consisted of two 14” steel disks bolted together with a 1” hole in the middle. I

merely separated them and increased the hole size to accommodate a 6” length of 1½”

plumbing pipe onto which I threaded a coupling and welded all together securely. The

coupling added extra ‘meat’ to the pipe so I could drill, tap and insert a 3/8 inch set screw

when securing the wheel onto the 1½” axle shaft. I bolted these assemblies onto the water

wheel after locating the center of rotation

as best as I could with a tape measure. It is

truly important that this be done accurately

since any error will result in a multi-axis

wobble and reduced clearance to the

sluice.

Since, as some of you may have known the

true interior diameter of 1½” pipe is 1 5/8

inch, I had to insert sleeves such that the

axle would fit snug and run true… the

chosen sleeve was a length of 1½” type L

copper plumbing pipe which just happens

to have the perfect dimension (1.503” ID

& 1.625” OD).

Since I’d been gathering parts for this project for many months, I had located (and

rescued) a 14” Chevrolet flex gear residing in the junk outside a service station knowing

that I’d need quite a large gear ratio to reach adequate generator speed. The gear has a 12

pitch and mates perfectly with a Boston Gear #ND12B (Grainger #1L964 @ $13.09) spur

gear which has a pitch diameter of 1” and therefore provides me a 14 to 1 gear ratio. I had

a machinist friend turn a hub onto which I welded the flex gear (cost me a coffee) but

when my son, the automotive instructor, saw it he thought it was a bored out vibration

dampener welded to the gear so that may well be an option as could be the use of roller

chain and bicycle gears. As it is, the 14 to 1 ratio is inadequate and must be multiplied

again by 3 to 1 in order to reach an appropriate

speed of 1000 rpm for my particular generator.

For this I’m using roller chain and sprockets

(U.S. TSUBAKI 40B9F-5/8 and 40B28F-5/8)

on a 5/8 inch axle to be installed in the chassis

shown.

These gear ratios and necessary speeds will

vary from one application to another since the

diameter and width of the wheel as well as

water flow determines how fast your wheel

will rotate and the required generator speed

will be dependant upon your generator. I’m

using a surplused permanent magnet computer

tape drive motor which, though not ideal, is

very convenient. This specific motor should

generate about 48 volts at 1260 rpm and

More DIY projects at: www.BuildItSolar.com

provide 12 amperes into a 12-volt battery load. Further information on the use of these

motors is available at

http://www.otherpower.com/otherpower_experiments_tapedrivemotors.html.

The 40” wheel I assembled rotates at about 25.5 rpm at the nominal flow rate with a stall

torque of 35 pounds measured on the perimeter, varying relative to flow. I’ve provided an

Excel spreadsheet, which will be convenient for determining maximum power potential

and construction measurements for those who are geometrically challenged.

My wife now frequently visits the water wheel and seems to be mesmerized by it… the

other day, while working in the pasture, I caught her standing there talking to herself (or

the dog) and I inquired as to whether she was speaking to me or not since I didn’t hear

her clearly. As she walked away she repeated herself… “Elegantly simple!”

More DIY projects at: www.BuildItSolar.com

You might also like

- Duck Breeding - A Collection of Articles on Selection, Crossing, Feeding and Other Aspects of Breeding DucksFrom EverandDuck Breeding - A Collection of Articles on Selection, Crossing, Feeding and Other Aspects of Breeding DucksNo ratings yet

- USDA - Crosscut Saw Tooth-Setting ToolDocument3 pagesUSDA - Crosscut Saw Tooth-Setting ToolSurvivItNo ratings yet

- Flora de Guatemala Vol.24 - Parte 3Document454 pagesFlora de Guatemala Vol.24 - Parte 3Dana NelumboNo ratings yet

- Wood Conserving Cook Stoves A Design Guide 1980 PDFDocument117 pagesWood Conserving Cook Stoves A Design Guide 1980 PDFzizi zizicNo ratings yet

- AMISH CANNING AND PRESERVING COOKBOOK: The Complete Delicious Water Bath Canning and Preserving RecipesFrom EverandAMISH CANNING AND PRESERVING COOKBOOK: The Complete Delicious Water Bath Canning and Preserving RecipesNo ratings yet

- Design Calculations For No-Head, Low-Head Waterwheels... by RuDocument2 pagesDesign Calculations For No-Head, Low-Head Waterwheels... by RuSPYDERSKILL100% (1)

- The Bark Tanning Process - A Collection of Historical Articles on Leather ProductionFrom EverandThe Bark Tanning Process - A Collection of Historical Articles on Leather ProductionNo ratings yet

- Food Plot Plantings: For Hite Tailed Eer in OuisianaDocument8 pagesFood Plot Plantings: For Hite Tailed Eer in Ouisianatom2playNo ratings yet

- Buried Clay PotDocument4 pagesBuried Clay PotJayde Murphy-StewartNo ratings yet

- Care of the Farm Sow - With Information on Farrowing, Parturition, Feeding and Taking Care of Female PigsFrom EverandCare of the Farm Sow - With Information on Farrowing, Parturition, Feeding and Taking Care of Female PigsNo ratings yet

- How To Store Your Home Grown Produce - John and Val HarrisonDocument23 pagesHow To Store Your Home Grown Produce - John and Val HarrisonConstable & Robinson100% (1)

- How To Make Rope: Hickory Withes. Select A Green Branch of Mockernut, Shagbark, or PignutDocument3 pagesHow To Make Rope: Hickory Withes. Select A Green Branch of Mockernut, Shagbark, or PignutnightclownNo ratings yet

- Herbal Tobacco.: HerbaccoDocument92 pagesHerbal Tobacco.: Herbaccopakde jongko100% (1)

- Wicking Bed Gardening For Drought GardeningDocument5 pagesWicking Bed Gardening For Drought GardeningU8x58No ratings yet

- Growing Guide Radishes TurnipsDocument8 pagesGrowing Guide Radishes TurnipsharleyNo ratings yet

- Germination Instructions For Seeds (Prairie Moon Nursery)Document21 pagesGermination Instructions For Seeds (Prairie Moon Nursery)jonowelserNo ratings yet

- Building A Better Beehive: Innovative Beekeeping & Value-Added MarketingDocument7 pagesBuilding A Better Beehive: Innovative Beekeeping & Value-Added MarketingChris SevenNo ratings yet

- Making and Using A Solar Cooker... by Joe RadabaughDocument4 pagesMaking and Using A Solar Cooker... by Joe RadabaughBLINDED185231100% (1)

- Rain GardenDocument27 pagesRain GardenSyarifah NisaNo ratings yet

- Morel CultivationDocument1 pageMorel Cultivationvas2000No ratings yet

- How To Build A Rammed Earth HouseDocument3 pagesHow To Build A Rammed Earth HousetaniastolnicNo ratings yet

- Home-Canning Pressures and Processing Times: MontguideDocument4 pagesHome-Canning Pressures and Processing Times: MontguideChindhu SivasubramanianNo ratings yet

- How To Feed Your Chickens Without Grain - 20 Ways To Cut Your Costs 100% - Abundant PermacultureDocument33 pagesHow To Feed Your Chickens Without Grain - 20 Ways To Cut Your Costs 100% - Abundant PermacultureJhanese Bastes SarigumbaNo ratings yet

- Spinacia Oleracea: SpinachDocument24 pagesSpinacia Oleracea: SpinachWaseem KhanNo ratings yet

- Indian Corn Planting MethodsDocument12 pagesIndian Corn Planting MethodsnerapsnartNo ratings yet

- BeekeepingDocument50 pagesBeekeepingrakeshmenon73No ratings yet

- Homemade Refractories: "2 Bucks" FurnaceDocument6 pagesHomemade Refractories: "2 Bucks" FurnaceFIREREALM66No ratings yet

- Making An Undershoot Water WheelDocument6 pagesMaking An Undershoot Water Wheelkundra007No ratings yet

- Laying A Small Concrete Slab in Your GardenDocument6 pagesLaying A Small Concrete Slab in Your GardenLily ShubinaNo ratings yet

- Gabions Install GuideDocument2 pagesGabions Install GuideTele2 Phone2100% (1)

- How to Cook with a Hay BoxDocument7 pagesHow to Cook with a Hay BoxadnhasNo ratings yet

- The Book Choice FernsDocument788 pagesThe Book Choice FernsSaibal ChakrabortyNo ratings yet

- 2021 - George Felfoldi - Ebook-Herbal - Healing Properties of CranberryDocument53 pages2021 - George Felfoldi - Ebook-Herbal - Healing Properties of CranberryGeorge FelfoldiNo ratings yet

- Improving Hatching and Brooding in Small-Scale Poultry KeepingDocument80 pagesImproving Hatching and Brooding in Small-Scale Poultry KeepingSeyha L. AgriFoodNo ratings yet

- Learn Ancient Basketry SkillsDocument16 pagesLearn Ancient Basketry SkillsLeeNo ratings yet

- North America2Document43 pagesNorth America2harshildoshiNo ratings yet

- Cord Wood MasonryDocument3 pagesCord Wood MasonryJason DiGiulioNo ratings yet

- Pruning Neglected Fruit TreesDocument4 pagesPruning Neglected Fruit TreesSharad BhutoriaNo ratings yet

- How To Build An Oil Barrel StoveDocument26 pagesHow To Build An Oil Barrel StovepcbstepNo ratings yet

- Factsheet - How To Worm FarmDocument2 pagesFactsheet - How To Worm Farmffff100% (1)

- Manual, Craftsman Table Saw, Model 113-298720 and 750Document52 pagesManual, Craftsman Table Saw, Model 113-298720 and 750Eng-JR80% (5)

- Butter For StorageDocument36 pagesButter For StorageDonT_RNNo ratings yet

- Garden Soil ManagementDocument8 pagesGarden Soil ManagementCharlesNo ratings yet

- Household Cyclopedia of General Information 2004Document878 pagesHousehold Cyclopedia of General Information 2004SurvivItNo ratings yet

- Silver recovery from photographic fixer using electrolysisDocument3 pagesSilver recovery from photographic fixer using electrolysisSatyabodha VyasasamudraNo ratings yet

- Some Medicinal WildingsDocument27 pagesSome Medicinal Wildingsapi-3747641No ratings yet

- Dutch Oven Cookbook PDFDocument27 pagesDutch Oven Cookbook PDFMoreMoseySpeedNo ratings yet

- My Beekeeping YearDocument27 pagesMy Beekeeping Yearb8730027No ratings yet

- The Chores: Anatomy of An AcreageDocument13 pagesThe Chores: Anatomy of An AcreagematthewjmillerNo ratings yet

- 0801476941-The Beekeeper's Handbook by Diana SammataroDocument6 pages0801476941-The Beekeeper's Handbook by Diana SammatarohogejaraNo ratings yet

- How To Grow LentilsDocument13 pagesHow To Grow LentilsJosephLaderaFugataNo ratings yet

- McBay, Aric - Tools For Gridcrash in The WakeDocument52 pagesMcBay, Aric - Tools For Gridcrash in The WakeBill R Wilsberg100% (1)

- 02 Beekeeperscalendar Session2Document8 pages02 Beekeeperscalendar Session2ahg196No ratings yet

- Wood Gas Camp Stove: Build a Simple Tin-Can Stove for Cooking with WoodDocument10 pagesWood Gas Camp Stove: Build a Simple Tin-Can Stove for Cooking with WoodWidi Toss Muda PurwodadiNo ratings yet

- The Fall Vegetable GardenDocument2 pagesThe Fall Vegetable GardenMoreMoseySpeedNo ratings yet

- Making: Cheese, Butter & YogurtDocument18 pagesMaking: Cheese, Butter & YogurtjuanNo ratings yet

- Viktor SchaubergerDocument8 pagesViktor SchaubergerMANNAJANELAGUNANo ratings yet

- 250 KV Tesla CoilDocument20 pages250 KV Tesla Coilapi-3715567100% (2)

- T.h.moray Patent 02460707Document8 pagesT.h.moray Patent 02460707MANNAJANELAGUNANo ratings yet

- Rosemary Ainslie. Quantum October 2002Document5 pagesRosemary Ainslie. Quantum October 2002MANNAJANELAGUNANo ratings yet

- Evolution of Forces by Gustav Le BonDocument452 pagesEvolution of Forces by Gustav Le BonMANNAJANELAGUNA100% (2)

- Messias Machine2Document2 pagesMessias Machine2MANNAJANELAGUNANo ratings yet

- MYT Engine Morgando InterviewDocument8 pagesMYT Engine Morgando InterviewMANNAJANELAGUNANo ratings yet

- MWO Info Pack April 2009 - Multiple Wave Oscillator Circuit SchematicDocument50 pagesMWO Info Pack April 2009 - Multiple Wave Oscillator Circuit Schematicburn2time96% (26)

- ++++++us1962565 LakhovskyDocument3 pages++++++us1962565 LakhovskyMANNAJANELAGUNANo ratings yet

- MYT Engine Morgando InterviewDocument8 pagesMYT Engine Morgando InterviewMANNAJANELAGUNANo ratings yet

- ROSEMARY AINSLIE Electric Heater ExperimentDocument18 pagesROSEMARY AINSLIE Electric Heater ExperimentMANNAJANELAGUNANo ratings yet

- ROSEMARY AINSLIE Magnetic Field ModelDocument37 pagesROSEMARY AINSLIE Magnetic Field ModelMANNAJANELAGUNANo ratings yet

- Messias MachineDocument5 pagesMessias MachineMANNAJANELAGUNANo ratings yet

- Moray Declaration Harvey FletcherDocument1 pageMoray Declaration Harvey FletcherMANNAJANELAGUNANo ratings yet

- Gray 4595975Document7 pagesGray 4595975MANNAJANELAGUNANo ratings yet

- How The Gray Tube WorksDocument5 pagesHow The Gray Tube WorksMANNAJANELAGUNANo ratings yet

- Electric RockDocument22 pagesElectric RockMANNAJANELAGUNANo ratings yet

- Mechanical - Engine Johan BeslerDocument12 pagesMechanical - Engine Johan BeslerLaurentia PetcuNo ratings yet

- EGWIN Gray SuppressedDocument2 pagesEGWIN Gray SuppressedMANNAJANELAGUNANo ratings yet

- EDWIN GRAY Various - ArticlesDocument6 pagesEDWIN GRAY Various - ArticlesMANNAJANELAGUNANo ratings yet

- EDWIN GRAY Ems Electronic PowerDocument3 pagesEDWIN GRAY Ems Electronic PowerMANNAJANELAGUNANo ratings yet

- Edwin Gray Patent 4661747Document7 pagesEdwin Gray Patent 4661747MANNAJANELAGUNANo ratings yet

- The N Machine by Bruce DePalmaDocument10 pagesThe N Machine by Bruce DePalmaSebastienKlementNo ratings yet

- Edwin Gray Patent 2030801Document5 pagesEdwin Gray Patent 2030801MANNAJANELAGUNANo ratings yet

- Diode Array Charles Brown Us3890161Document7 pagesDiode Array Charles Brown Us3890161MANNAJANELAGUNANo ratings yet

- BRUCE de PALMA Secret of The Faraday DiscDocument5 pagesBRUCE de PALMA Secret of The Faraday DiscMANNAJANELAGUNANo ratings yet

- EDWIN GRAY Engine Runs ItselfDocument7 pagesEDWIN GRAY Engine Runs ItselfMANNAJANELAGUNANo ratings yet

- Car Ignition 1Document8 pagesCar Ignition 1MANNAJANELAGUNANo ratings yet

- BRUCE de PALMA That Is ScienceDocument2 pagesBRUCE de PALMA That Is ScienceMANNAJANELAGUNANo ratings yet

- Performance of The Sunburst N Machine by Bruce DePalmaDocument5 pagesPerformance of The Sunburst N Machine by Bruce DePalmaSebastienKlementNo ratings yet

- Big Joe Pds30-40Document198 pagesBig Joe Pds30-40mauro garciaNo ratings yet

- Statistical Quality Control, 7th Edition by Douglas C. Montgomery. 1Document76 pagesStatistical Quality Control, 7th Edition by Douglas C. Montgomery. 1omerfaruk200141No ratings yet

- Managerial EconomicsDocument3 pagesManagerial EconomicsGuruKPONo ratings yet

- PowerPointHub Student Planner B2hqY8Document25 pagesPowerPointHub Student Planner B2hqY8jersey10kNo ratings yet

- Three Comparison of Homoeopathic MedicinesDocument22 pagesThree Comparison of Homoeopathic MedicinesSayeed AhmadNo ratings yet

- Copula and Multivariate Dependencies: Eric MarsdenDocument48 pagesCopula and Multivariate Dependencies: Eric MarsdenJeampierr Jiménez CheroNo ratings yet

- Corporate Governance, Corporate Profitability Toward Corporate Social Responsibility Disclosure and Corporate Value (Comparative Study in Indonesia, China and India Stock Exchange in 2013-2016) .Document18 pagesCorporate Governance, Corporate Profitability Toward Corporate Social Responsibility Disclosure and Corporate Value (Comparative Study in Indonesia, China and India Stock Exchange in 2013-2016) .Lia asnamNo ratings yet

- THE DOSE, Issue 1 (Tokyo)Document142 pagesTHE DOSE, Issue 1 (Tokyo)Damage85% (20)

- Returnable Goods Register: STR/4/005 Issue 1 Page1Of1Document1 pageReturnable Goods Register: STR/4/005 Issue 1 Page1Of1Zohaib QasimNo ratings yet

- Advantages of Using Mobile ApplicationsDocument30 pagesAdvantages of Using Mobile ApplicationsGian Carlo LajarcaNo ratings yet

- Duca Industries March 2023 pay slip for Dipankar MondalDocument1 pageDuca Industries March 2023 pay slip for Dipankar MondalPritam GoswamiNo ratings yet

- White Box Testing Techniques: Ratna SanyalDocument23 pagesWhite Box Testing Techniques: Ratna SanyalYogesh MundhraNo ratings yet

- 1st SemDocument3 pages1st SemARUPARNA MAITYNo ratings yet

- JM Guide To ATE Flier (c2020)Document2 pagesJM Guide To ATE Flier (c2020)Maged HegabNo ratings yet

- 4 Influencing Factors of Learners Career Choice Parents Choice Vs Personal DescisionDocument24 pages4 Influencing Factors of Learners Career Choice Parents Choice Vs Personal Descisionmatteo mamaloNo ratings yet

- HVAC Master Validation PlanDocument51 pagesHVAC Master Validation Plannavas197293% (30)

- Assignment Gen PsyDocument3 pagesAssignment Gen PsyHelenNo ratings yet

- Endangered EcosystemDocument11 pagesEndangered EcosystemNur SyahirahNo ratings yet

- Pasadena Nursery Roses Inventory ReportDocument2 pagesPasadena Nursery Roses Inventory ReportHeng SrunNo ratings yet

- Bio310 Summary 1-5Document22 pagesBio310 Summary 1-5Syafiqah ArdillaNo ratings yet

- Master SEODocument8 pagesMaster SEOOkane MochiNo ratings yet

- ERIKS Dynamic SealsDocument28 pagesERIKS Dynamic Sealsdd82ddNo ratings yet

- Kaydon Dry Gas SealDocument12 pagesKaydon Dry Gas Sealxsi666No ratings yet

- Training Customer CareDocument6 pagesTraining Customer Careyahya sabilNo ratings yet

- PEDs and InterferenceDocument28 pagesPEDs and Interferencezakool21No ratings yet

- New Hire WorkbookDocument40 pagesNew Hire WorkbookkNo ratings yet

- Shouldice Hospital Ltd.Document5 pagesShouldice Hospital Ltd.Martín Gómez CortésNo ratings yet

- Cell Organelles ColoringDocument2 pagesCell Organelles ColoringThomas Neace-FranklinNo ratings yet

- Flowmon Ads Enterprise Userguide enDocument82 pagesFlowmon Ads Enterprise Userguide ennagasatoNo ratings yet

- Ball Valves Pentair Valves and ControlsDocument16 pagesBall Valves Pentair Valves and ControlsABDUL KADHARNo ratings yet

- Eat That Frog!: 21 Great Ways to Stop Procrastinating and Get More Done in Less TimeFrom EverandEat That Frog!: 21 Great Ways to Stop Procrastinating and Get More Done in Less TimeRating: 4.5 out of 5 stars4.5/5 (3223)

- The Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterFrom EverandThe Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterRating: 4 out of 5 stars4/5 (467)

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingFrom EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingRating: 4.5 out of 5 stars4.5/5 (843)

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- Lightly: How to Live a Simple, Serene & Stress-free LifeFrom EverandLightly: How to Live a Simple, Serene & Stress-free LifeRating: 4 out of 5 stars4/5 (12)

- How To Win Friends And Influence PeopleFrom EverandHow To Win Friends And Influence PeopleRating: 4.5 out of 5 stars4.5/5 (6510)

- The Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldFrom EverandThe Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldRating: 3.5 out of 5 stars3.5/5 (5)

- Plant Based Sauces and Dips Recipes: Beginner’s Cookbook to Healthy Plant-Based EatingFrom EverandPlant Based Sauces and Dips Recipes: Beginner’s Cookbook to Healthy Plant-Based EatingRating: 4.5 out of 5 stars4.5/5 (20)

- Root to Leaf: A Southern Chef Cooks Through the SeasonsFrom EverandRoot to Leaf: A Southern Chef Cooks Through the SeasonsRating: 4.5 out of 5 stars4.5/5 (3)

- Survival Mom: How to Prepare Your Family for Everyday Disasters and Worst-Case ScenariosFrom EverandSurvival Mom: How to Prepare Your Family for Everyday Disasters and Worst-Case ScenariosRating: 3.5 out of 5 stars3.5/5 (8)

- Aristotle and Dante Discover the Secrets of the UniverseFrom EverandAristotle and Dante Discover the Secrets of the UniverseRating: 4.5 out of 5 stars4.5/5 (2341)

- The Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyFrom EverandThe Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyRating: 4 out of 5 stars4/5 (40)

- Crochet Impkins: Over a million possible combinations! Yes, really!From EverandCrochet Impkins: Over a million possible combinations! Yes, really!Rating: 4.5 out of 5 stars4.5/5 (9)

- A Girl and Her Greens: Hearty Meals from the GardenFrom EverandA Girl and Her Greens: Hearty Meals from the GardenRating: 3.5 out of 5 stars3.5/5 (7)

- The Fitness Mindset: Eat for energy, Train for tension, Manage your mindset, Reap the resultsFrom EverandThe Fitness Mindset: Eat for energy, Train for tension, Manage your mindset, Reap the resultsRating: 4.5 out of 5 stars4.5/5 (30)

- Kintsugi Wellness: The Japanese Art of Nourishing Mind, Body, and SpiritFrom EverandKintsugi Wellness: The Japanese Art of Nourishing Mind, Body, and SpiritRating: 4.5 out of 5 stars4.5/5 (3)

- Soil: The Story of a Black Mother's GardenFrom EverandSoil: The Story of a Black Mother's GardenRating: 4.5 out of 5 stars4.5/5 (16)

- Success at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.From EverandSuccess at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Rating: 4 out of 5 stars4/5 (17)

- The 21 Irrefutable Laws of Leadership 25th Anniversary: Follow Them and People Will Follow YouFrom EverandThe 21 Irrefutable Laws of Leadership 25th Anniversary: Follow Them and People Will Follow YouRating: 4 out of 5 stars4/5 (413)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiFrom Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiRating: 5 out of 5 stars5/5 (2)

- The Hidden Life of Trees: What They Feel, How They CommunicateFrom EverandThe Hidden Life of Trees: What They Feel, How They CommunicateRating: 4 out of 5 stars4/5 (1002)

- Wild Witchcraft: Folk Herbalism, Garden Magic, and Foraging for Spells, Rituals, and RemediesFrom EverandWild Witchcraft: Folk Herbalism, Garden Magic, and Foraging for Spells, Rituals, and RemediesRating: 5 out of 5 stars5/5 (32)

- The Well-Gardened Mind: The Restorative Power of NatureFrom EverandThe Well-Gardened Mind: The Restorative Power of NatureRating: 4 out of 5 stars4/5 (3)

- The Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyFrom EverandThe Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyRating: 4 out of 5 stars4/5 (276)

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastFrom EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastRating: 5 out of 5 stars5/5 (1)

- The Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingFrom EverandThe Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingRating: 4 out of 5 stars4/5 (2993)

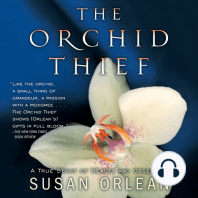

- The Orchid Thief: A True Story of Beauty and ObsessionFrom EverandThe Orchid Thief: A True Story of Beauty and ObsessionRating: 3.5 out of 5 stars3.5/5 (686)