Professional Documents

Culture Documents

Rezultat

Uploaded by

Pop PollyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rezultat

Uploaded by

Pop PollyCopyright:

Available Formats

(v4.

03)

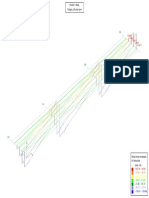

ArcelorMittal Composite Bridge Predesign

Preliminary design software for composite bridges

PRELIMINARY DESIGN NOTE

Company : Universitatea Tehnica Cluj-Napoca

User name : Pop Paul

Project name : Structuri compuse otel-beton

Project reference :

Comment :

Date : 01.02.2015

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v4.03)

Project reference :

Comment :

All the preliminary design notes done by our company and/or by any other subsidiaries of the ARCELORMITTAL group of

our choice are based on the information received from the Customer. These preliminary design notes are given for guidance

only. As such, they do not commit our company and/or any other subsidiary of the ARCELORMITTAL group to the

achievement of a result expected by the Customer and/or any third person. These preliminary design notes cannot replace

all the preliminary design notes which shall be done by an external engineering office chosen by the Customer. Our

company and/or any other subsidiary of the ARCELORMITTAL group cannot be held liable for any loss or damage, directly or

indirectly sustained as a result of the use of the preliminary design notes done by our company and\or by any other

subsidiaries of the ARCELORMITTAL group, whatever the origin of the damage.

User name : Pop Paul

Date : 01.02.2015

Page 1 / 19

F:\...\COMPLET PAUL\VARIANTA 1\PAUL.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v4.03)

Project reference :

Comment :

DATA

ROAD BRIDGE - Conventional beam and slab superstructure

Eurocodes EN

Span length 1 = 24.000 m

3 spans

Span length 2 = 29.000 m

Span length 3 = 24.000 m

Slab dimensions

Width = 10.000 m

Thickness = 30.0 cm

Haunch = 15.0 cm

5 beam lines (Distance to left-hand edge of deck slab)

Line 1 : 1.500 m

Centre distance = 1.750 m

Line 2 : 3.250 m

Centre distance = 1.750 m

Line 3 : 5.000 m

Centre distance = 1.750 m

Line 4 : 6.750 m

Centre distance = 1.750 m

Line 5 : 8.500 m

Shear studs : 19x175

Reinforcement ratio = 3.0 %

Top layer : 70 %

Distance to top of slab = 4.0 cm

Bottom layer : 30 %

Distance between bottom of slab = 4.0 cm

Propping :

No propping of main beams during deck slab concreting.

Overhang :

Overhang formwork suspended from the two outermost beams only.

An equivalent superimposed dead load is taken into account in the calculation of the slab weight

Reinforcing steel

fy = 500.00 N/mm

Structural steel S355 (WITH reduction of yield strength with thickness)

3

Density = 7850 kg/m

Concrete Class C35/45

Density = 2650 kg/m

-6

Shrinkage strain = 200.10

Temperature difference between slab and beams = 10 C

Material properties used in calculations

Yield strength of the steel of girders

Yield strength of the reinforcing steel

fy = 345.0 MPa

fy = 500.0 MPa

User name : Pop Paul

Date : 01.02.2015

Page 2 / 19

F:\...\COMPLET PAUL\VARIANTA 1\PAUL.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v4.03)

Project reference :

Comment :

Modulus of elasticity

Limit compressive strenght of concrete

Ecm = 34077 MPa

fck = 35 MPa

Steel sections

span 1

Left-hand edge beam

HE 1000 M

Intermediate beams

HE 1000 M

Right-hand edge beam

HE 1000 M

Left-hand edge beam

HE 1000 M

span 2

Intermediate beams

HE 1000 M

Right-hand edge beam

HE 1000 M

Left-hand edge beam

HE 1000 M

Intermediate beams

HE 1000 M

Right-hand edge beam

HE 1000 M

span 3

Cracked regions

Support lines

LH side (m)

RH side (m)

C0

P1

3.600 (15 %)

4.350 (15 %)

P2

4.350 (15 %)

3.600 (15 %)

C3

Footways and restraint systems

LH footway width: 1.500 m

RH footway, width: 1.500 m

LH restraint system, distance to LH edge of deck slab 1.500 m

RH restraint system, distance to RH edge of deck slab 1.500 m

Bridge class : 1

Superimposed dead loads of deck surfacing or ballast, footways or maintenance walkways etc - SDL1

3

Footways

Thickness = 20.0 cm

LH footway width = 1.50 m

RH footway width = 1.50 m

Density = 2000.0 kg/m

Waterproofing

Thickness = 3.0 cm

Density = 2400.0 kg/m

Surfacing

Thickness = 8.0 cm

Density = 2400.0 kg/m

Parapets

left-hand side

right-hand side

x = 0.10 m

x = 0.10 m

q = 1.00 kN/m

q = 1.00 kN/m

Restraint system

left-hand side

right-hand side

x = 1.50 m

x = 1.50 m

q = 1.00 kN/m

q = 1.00 kN/m

3

3

User name : Pop Paul

Date : 01.02.2015

Page 3 / 19

F:\...\COMPLET PAUL\VARIANTA 1\PAUL.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v4.03)

Project reference :

Comment :

2

Distributed load = 5.00 kN/m

Live loads on footways

Left-hand footway

Width of loaded area = 1.50 m

Distance to slab edge = 0.00 m

Right-hand footway

Width of loaded area = 1.50 m

Distance to slab edge = 0.00 m

Definition of truck load models

Abnormal load :

None

Fatigue load model :

Load model on both edge lanes

Mean gross weight of truck : 600. kN

Number of trucks : 2.00 millions per year and slow lane

Service life (years) : 100

Support height ajustments and settlements

Height adjustments

Settlements

Support line No. 0

0 mm

0 mm

Support line No. 1

0 mm

0 mm

Support line No. 2

0 mm

0 mm

Support line No. 3

0 mm

0 mm

User name : Pop Paul

Date : 01.02.2015

Page 4 / 19

F:\...\COMPLET PAUL\VARIANTA 1\PAUL.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v4.03)

Project reference :

Comment :

Assumptions for calculation and checks

Calculation coefficients

Diaphragms

Coefficient for inertia = 0.10

Coefficient for mass = 0.10

Slab elements

Coefficient for inertia - longitudinal = 1.00

Coefficient for inertia - transverse = 1.00

Serviceability Limit States

Deflection due to live loads limited to 1/ 500 of span length

Partial safety factor for the structural steel

Partial safety factor for shear resistance of studs

M,ser = 1.00

v = 1.25

Ultimate Limit States

Partial safety factors :

for sections resistance

for buckling resistance

for slab concrete strength

for shear resistance of studs

M0 = 1.00

M1 = 1.10

c = 1.50

M = 1.15

Fatigue Limit States

Ff = 1.00

Partial safety factors for fatigue loading

Top flange :

Partial safety factor for fatigue strength

Detail category

Mf = 1.15

80 MPa

Bottom flange :

Partial safety factor for fatigue strength

Detail category

Mf = 1.15

160 MPa

User name : Pop Paul

Date : 01.02.2015

Page 5 / 19

F:\...\COMPLET PAUL\VARIANTA 1\PAUL.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v4.03)

Project reference :

Comment :

Weighting factors for SDL1 :

Increase

Reduction

Waterproofing

1.20

0.80

Surfacing

1.40

0.80

Footways

1.00

1.00

Adjustment factors applied to load model 1 (UDL + TS) :

Q1

Qi (i>1)

q1

qi(i>1)

qr

Class 1

1.0

1.0

1.0

1.0

1.0

Class 2

1.0

1.0

1.0

1.0

1.0

Class 3

1.0

1.0

1.0

1.0

1.0

The class of the bridge is : Class 1

Partial factors for loads - Combination factors :

Partial factors for loads (ULS) :

G = 1.35

Q = 1.35

Q = 1.50

P = 1.00

G,set = 1.20

S = 1.00

Permanent loads

Traffic loads

Other variable loads

Height adjustments

Settlements

Shrinkage

Combination factors :

0

'1

gr1a TS

0.75

0.75

0.00

0.80

gr1a UDL

0.40

0.40

0.00

0.80

gr5

0.00

0.00

0.00

1.00

TK

0.60

0.60

0.50

User name : Pop Paul

Date : 01.02.2015

Page 6 / 19

F:\...\COMPLET PAUL\VARIANTA 1\PAUL.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v4.03)

Project reference :

Comment :

LIST OF LOAD CASES

No.

Symbol

Name of load case

PP

Self-weight

SS

SDL1

15.54

SS+

Increased SDL1

15.54

SS-

Reduced SDL1

15.54

EQ

SDL2

15.54

TH+

Simpl. temp. load +DTC

15.72

TH-

Simpl. temp. load -DTC

15.72

RE

Concrete shrinkage

15.72

Modular ratio

-

Eigenmode

6.16

10

UDL

Load model 1 UDL

6.16

11

TS

Load model 1 TS

6.16

12

TR

Load on footways

6.16

User name : Pop Paul

Date : 01.02.2015

Page 7 / 19

F:\...\COMPLET PAUL\VARIANTA 1\PAUL.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v4.03)

Project reference :

Comment :

LIST OF ULS COMBINATIONS

ULS combinations

1

10

11

12

PP

SS+

SS-

EQ

TH+

TH-

RE

UDL

TS

TR

1.35

1.35

1.35

1.35

0.81

1.35

1.35

1.35

0.81

0.54

1.01

0.32

0.54

1.01

0.32

0.54

1.01

0.32

1.35

1.35

1.35

1.35

1.35

1.35

1.35

1.35

1.35

1.35

1.35

1.35

1.50

1.35

1.35

1.35

1.35

1.35

1.35

1.35

1.50

1.50

0.54

1.01

0.32

1.35

1.00

1.35

1.35

0.81

1.35

1.00

1.35

1.35

0.81

1.00

0.54

1.01

0.32

1.00

0.54

1.01

0.32

1.00

0.54

1.01

0.32

1.00

0.54

1.01

0.32

1.35

1.35

1.35

10

1.35

1.35

1.35

11

1.35

1.35

1.35

12

1.35

1.35

1.35

1.50

1.50

1.50

1.50

1.50

User name : Pop Paul

Date : 01.02.2015

Page 8 / 19

F:\...\COMPLET PAUL\VARIANTA 1\PAUL.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v4.03)

Project reference :

Comment :

LIST OF SLS COMBINATIONS

Characteristics SLS combinations

1

10

11

12

PP

SS+

SS-

EQ

TH+

TH-

RE

UDL

TS

TR

1.00

1.00

0.60

1.00

1.00

0.60

1.00

0.60

1.00

1.00

0.60

0.60

1.00

1.00

0.60

0.60

1.00

1.00

0.60

0.40

0.75

0.24

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

10

1.00

11

1.00

12

1.00

13

1.00

14

1.00

15

1.00

16

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

0.40

0.75

0.24

1.00

1.00

0.40

0.75

0.24

1.00

1.00

0.40

0.75

0.24

1.00

0.60

1.00

1.00

1.00

0.60

1.00

0.60

1.00

1.00

1.00

0.60

0.60

1.00

1.00

1.00

0.60

0.60

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

0.60

1.00

1.00

1.00

0.40

0.75

0.24

1.00

1.00

1.00

0.40

0.75

0.24

1.00

1.00

1.00

0.40

0.75

0.24

1.00

1.00

1.00

0.40

0.75

0.24

User name : Pop Paul

Date : 01.02.2015

Page 9 / 19

F:\...\COMPLET PAUL\VARIANTA 1\PAUL.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v4.03)

Project reference :

Comment :

Frequent SLS combinations

1

10

11

12

PP

SS+

SS-

EQ

TH+

TH-

RE

UDL

TS

TR

17

1.00

1.00

1.00

0.50

0.40

0.75

0.24

18

1.00

1.00

0.50

19

1.00

20

1.00

21

1.00

22

1.00

23

1.00

24

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

0.40

0.75

0.24

1.00

0.50

0.40

0.75

0.24

1.00

0.50

0.40

0.75

0.24

1.00

0.50

1.00

0.40

0.75

0.24

1.00

0.50

1.00

0.40

0.75

0.24

1.00

0.50

1.00

0.40

0.75

0.24

1.00

0.50

1.00

0.40

0.75

0.24

User name : Pop Paul

Date : 01.02.2015

Page 10 / 19

F:\...\COMPLET PAUL\VARIANTA 1\PAUL.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v4.03)

Project reference :

Comment :

Quasi-permanent SLS combinations

1

10

11

12

PP

SS+

SS-

EQ

TH+

TH-

RE

UDL

TS

TR

25

1.00

1.00

1.00

0.50

26

1.00

1.00

27

1.00

1.00

1.00

28

1.00

1.00

1.00

29

1.00

1.00

1.00

30

1.00

1.00

1.00

31

1.00

1.00

1.00

32

1.00

1.00

1.00

1.00

0.50

0.50

0.50

0.50

1.00

0.50

0.50

1.00

1.00

0.50

1.00

User name : Pop Paul

Date : 01.02.2015

Page 11 / 19

F:\...\COMPLET PAUL\VARIANTA 1\PAUL.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v4.03)

Project reference :

Comment :

Infrequent SLS combinations

1

10

11

12

PP

SS+

SS-

EQ

TH+

TH-

RE

UDL

TS

TR

33

1.00

1.00

1.00

0.60

0.80

0.80

0.48

34

1.00

1.00

0.60

35

1.00

36

1.00

37

1.00

38

1.00

39

1.00

40

1.00

1.00

1.00

1.00

1.00

1.00

1.00

1.00

0.80

0.80

0.48

1.00

0.60

0.80

0.80

0.48

1.00

0.60

0.80

0.80

0.48

1.00

0.60

1.00

0.80

0.80

0.48

1.00

0.60

1.00

0.80

0.80

0.48

1.00

0.60

1.00

0.80

0.80

0.48

1.00

0.60

1.00

0.80

0.80

0.48

User name : Pop Paul

Date : 01.02.2015

Page 12 / 19

F:\...\COMPLET PAUL\VARIANTA 1\PAUL.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v4.03)

Project reference :

Comment :

ESTIMATED QUANTITIES

Structural steel sections :

Steel grade : S355

Lengths (m)

Position

Span

Number

Profile

Nominal

On/Under

Sum

Weight (t)

Pre-camber (cm)

HE 1000 M

24.00

0.20

24.20

42.195

4.3

HE 1000 M

29.00

0.00

29.00

50.562

3.9

HE 1000 M

24.00

0.20

24.20

42.195

4.3

134.951

Shear connectors :

Position

Span

Number

Weight (t)

997

0.428

1233

0.529

1000

0.429

1.386

Slab concrete :

2

Surface of slab : 770.00 m

Volume (m3)

Position

Span

77.4

93.6

77.4

248.4

NB :

- The indicated beam lengths and pre-cambers correspond to span lengths.

Supply specifications may differ, depending on the position of any splices.

Constraints associated with fabrication, finishing, transport, and handling are to be checked on a case-by-case basis.

- The quantities indicated for beams do not include stiffeners, bearing plates, diaphragms, end plates, etc.

These items are to be added in accordance with the features of the structure.

- The number of shear connectors given includes a flat 30% increase over the theoretical quantity

to take account of fabrication practice.

User name : Pop Paul

Date : 01.02.2015

Page 13 / 19

F:\...\COMPLET PAUL\VARIANTA 1\PAUL.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v4.03)

Project reference :

Comment :

Mass on slab :

Waterproofing (t)

Surfacing (t)

Footways (t)

Subtotal (t)

Span 1

12.096

32.256

28.800

73.152

Span 2

14.616

38.976

34.800

88.392

Span 3

12.096

32.256

28.800

73.152

TOTAL

38.808

103.488

92.400

234.696

User name : Pop Paul

Date : 01.02.2015

Page 14 / 19

F:\...\COMPLET PAUL\VARIANTA 1\PAUL.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v4.03)

Project reference :

Comment :

NUMBER OF CONNECTORS

19x175 : d = 19.0 mm - h = 175.0 mm

Row 1

Row 2

Row 3

Row 4

Row 5

254

165

159

165

254

997

0.428

315

204

195

204

315

1233

0.529

254

164

164

164

254

1000

0.429

3230

1.386

span

NB :

Total

Weight (t)

- The number of shear connectors given includes a flat 30% increase over the theoretical quantity

to take account of fabrication practice.

User name : Pop Paul

Date : 01.02.2015

Page 15 / 19

F:\...\COMPLET PAUL\VARIANTA 1\PAUL.APM

Universitatea Tehnica Cluj-Napoca

Project name : Structuri compuse otel-beton

ArcelorMittal Composite Bridge Predesign

(v4.03)

Project reference :

Comment :

SUMMARY OF RESULTS

Summary for bridge

Criterion : LTBuckling (Ultimate Limit State)

Max. ratio = 0.91

< 1.00

SATISFACTORY

Combination No.7

Beam line No.5 - Cross-section No.27 : Position = 24.00 m (intermediate support)

_________________________________

Summary for span No. 1

Criterion : LTBuckling (Ultimate Limit State)

Max. ratio = 0.83

< 1.00

SATISFACTORY

Combination No.7

Beam line No.1 - Cross-section No.27 : Position = 24.00 m (intermediate support)

Summary for span No. 2

Criterion : LTBuckling (Ultimate Limit State)

Max. ratio = 0.91

< 1.00

SATISFACTORY

Combination No.7

Beam line No.5 - Cross-section No.27 : Position = 24.00 m (intermediate support)

Summary for span No. 3

Criterion : LTBuckling (Ultimate Limit State)

Max. ratio = 0.83

< 1.00

SATISFACTORY

Combination No.7

Beam line No.1 - Cross-section No.59 : Position = 53.00 m (intermediate support)

Checking minimum reinforcement criterion

Reference : EN 1994-2:2005 7.4.2

Slab reinforcement ratio : 3.00 %

The criterion is satisfied for all design cross-sections, for 20 mm diameter bars.

User name : Pop Paul

Date : 01.02.2015

Page 16 / 19

F:\...\COMPLET PAUL\VARIANTA 1\PAUL.APM

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Compass Solution User Guide - V1.0.1 - 2016.04.06Document21 pagesCompass Solution User Guide - V1.0.1 - 2016.04.06Pop PollyNo ratings yet

- Handbook of Practical Gear DesignDocument7 pagesHandbook of Practical Gear DesignPooria1989No ratings yet

- 012.0 - Cat-6060 - Central Greasing System - AttachmentDocument50 pages012.0 - Cat-6060 - Central Greasing System - AttachmentJorby Cuadros100% (2)

- ANSYS Stress Analysis of Impeller Blade at Various RPMDocument13 pagesANSYS Stress Analysis of Impeller Blade at Various RPMcena3135No ratings yet

- Mechanical Engineering Design Drawings CollectionDocument41 pagesMechanical Engineering Design Drawings CollectiongundhiufsNo ratings yet

- Tabel MotorinaDocument2 pagesTabel MotorinaPop PollyNo ratings yet

- Tasare Stalp MarginalDocument2 pagesTasare Stalp MarginalPop PollyNo ratings yet

- Tasare Stalp MarginalDocument2 pagesTasare Stalp MarginalPop PollyNo ratings yet

- 7Document8 pages7Pop PollyNo ratings yet

- Sup Med 0 Z Sup Z Med I (M) GZ Sup GZ Med Inf Z Inf GZ InfDocument2 pagesSup Med 0 Z Sup Z Med I (M) GZ Sup GZ Med Inf Z Inf GZ InfPop PollyNo ratings yet

- ArcelorMittal Composite Bridge DesignDocument3 pagesArcelorMittal Composite Bridge DesignPop PollyNo ratings yet

- Macara Turn Coeficient PaulaDocument2 pagesMacara Turn Coeficient PaulaPop PollyNo ratings yet

- RezultatDocument17 pagesRezultatPop PollyNo ratings yet

- Var 1 ConsolidareDocument1 pageVar 1 ConsolidarePop PollyNo ratings yet

- Diagram ADocument1 pageDiagram APop PollyNo ratings yet

- Universitatea Tehnica Cluj-Napoca: Project Name: Structuri Compuse Otel-Beton Project Reference: CommentDocument3 pagesUniversitatea Tehnica Cluj-Napoca: Project Name: Structuri Compuse Otel-Beton Project Reference: CommentPop PollyNo ratings yet

- RezultatDocument17 pagesRezultatPop PollyNo ratings yet

- Diagram ADocument1 pageDiagram APop PollyNo ratings yet

- Diagrama 4Document1 pageDiagrama 4Pop PollyNo ratings yet

- Diagrama 5Document1 pageDiagrama 5Pop PollyNo ratings yet

- Universitatea Tehnica Cluj-Napoca: Project Name: Structuri Compuse Otel-Beton Project Reference: CommentDocument3 pagesUniversitatea Tehnica Cluj-Napoca: Project Name: Structuri Compuse Otel-Beton Project Reference: CommentPop PollyNo ratings yet

- Universitatea Tehnica Cluj-Napoca: Summary of Results Summary For BridgeDocument1 pageUniversitatea Tehnica Cluj-Napoca: Summary of Results Summary For BridgePop PollyNo ratings yet

- DeseneDocument3 pagesDesenePop PollyNo ratings yet

- Var 1 - Diagrama Oboseala DalaDocument1 pageVar 1 - Diagrama Oboseala DalaPop PollyNo ratings yet

- Var 1 ConsolidareDocument1 pageVar 1 ConsolidarePop PollyNo ratings yet

- Auto DeskDocument2 pagesAuto DeskPop PollyNo ratings yet

- Universitatea Tehnica Cluj-Napoca: Summary of Results Summary For BridgeDocument1 pageUniversitatea Tehnica Cluj-Napoca: Summary of Results Summary For BridgePop PollyNo ratings yet

- DateDocument165 pagesDatePop PollyNo ratings yet

- Universitatea Tehnica Cluj-Napoca: Project Name: Structuri Compuse Otel-Beton Project Reference: CommentDocument3 pagesUniversitatea Tehnica Cluj-Napoca: Project Name: Structuri Compuse Otel-Beton Project Reference: CommentPop PollyNo ratings yet

- Universitatea Tehnica Cluj-Napoca: Project Name: Structuri Compuse Otel-Beton Project Reference: CommentDocument3 pagesUniversitatea Tehnica Cluj-Napoca: Project Name: Structuri Compuse Otel-Beton Project Reference: CommentPop PollyNo ratings yet

- Universitatea Tehnica Cluj-Napoca: Project Name: Structuri Compuse Otel-Beton Project Reference: CommentDocument3 pagesUniversitatea Tehnica Cluj-Napoca: Project Name: Structuri Compuse Otel-Beton Project Reference: CommentPop PollyNo ratings yet

- Var 3Document9 pagesVar 3Pop PollyNo ratings yet

- Scan TuneluriDocument19 pagesScan TuneluriPop PollyNo ratings yet

- 11 10K Double Cameron U BOPDocument2 pages11 10K Double Cameron U BOPbalaji baluNo ratings yet

- Sheet Metal OperationsDocument27 pagesSheet Metal OperationsbmvinayNo ratings yet

- Your First Day Lifeguarding: How To Vacuum and Backwash A PoolDocument4 pagesYour First Day Lifeguarding: How To Vacuum and Backwash A PoolMattMonroeNo ratings yet

- Hazard and Operability Analysis (HAZOP) of A Plastic Manufacturing Plant at Karachi, PakistanDocument7 pagesHazard and Operability Analysis (HAZOP) of A Plastic Manufacturing Plant at Karachi, PakistanFaisal AkhterNo ratings yet

- Application of Stone Column For Ground Improvement: A ReviewDocument12 pagesApplication of Stone Column For Ground Improvement: A ReviewRameshNo ratings yet

- Structural Reliability FrameworkDocument65 pagesStructural Reliability FrameworkkhairurNo ratings yet

- Genie Scc755psDocument2 pagesGenie Scc755psWellington Xavier Pazmiño RodríguezNo ratings yet

- Optimization of Geodetic DesignDocument9 pagesOptimization of Geodetic Designdev burmanNo ratings yet

- PART-66 Training - Aircraft Maintenance LicenceDocument11 pagesPART-66 Training - Aircraft Maintenance LicenceFemi AgbanaNo ratings yet

- 4.DB Flats (1-7) & SMDB TypicalDocument9 pages4.DB Flats (1-7) & SMDB TypicalhpzenNo ratings yet

- Vdocuments - MX Emr3 System Description 091107 1Document96 pagesVdocuments - MX Emr3 System Description 091107 1yudiNo ratings yet

- Cee 451 Lecture 8Document23 pagesCee 451 Lecture 8ahmed almhjaniNo ratings yet

- Product Information: Diesel Extra LD 15W40Document2 pagesProduct Information: Diesel Extra LD 15W40movie hunterNo ratings yet

- Pile CapDocument27 pagesPile CapHafeel Ahamed Ashraf AliNo ratings yet

- Curvilinear Motion and ProjectilesDocument15 pagesCurvilinear Motion and ProjectilesAltammar1367% (3)

- Article DetailDocument78 pagesArticle Detailandi_lb9453No ratings yet

- Solidworks Simulation BasicsDocument28 pagesSolidworks Simulation BasicsvinunfNo ratings yet

- Y-Geo New Combined Finite-Discrete Element Numerical Code For Geomechanical ApplicationsDocument14 pagesY-Geo New Combined Finite-Discrete Element Numerical Code For Geomechanical ApplicationsRicardo Huisa BustiosNo ratings yet

- Caterpillar C13 C15 C18 Engine Fault Codes DTCDocument55 pagesCaterpillar C13 C15 C18 Engine Fault Codes DTCMiguel Angel Escobedo Reyes100% (2)

- Drying solids fundamentals and equipment selectionDocument30 pagesDrying solids fundamentals and equipment selectionArfel Marie FuentesNo ratings yet

- CCMC Canadian Code Compliance Evaluation - National Research Council CanadaDocument14 pagesCCMC Canadian Code Compliance Evaluation - National Research Council CanadaMark AdamsNo ratings yet

- Ducato 290 Handbook 05-15 PDFDocument387 pagesDucato 290 Handbook 05-15 PDFDaniNo ratings yet

- Technical Handbook Version 11 5cDocument72 pagesTechnical Handbook Version 11 5cguerrezNo ratings yet

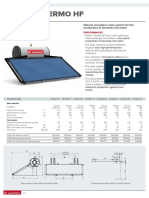

- Kairos Thermo HF Natural Circulation Solar System for Domestic Hot Water ProductionDocument4 pagesKairos Thermo HF Natural Circulation Solar System for Domestic Hot Water ProductionFILID MADNo ratings yet

- Slide Valves - Flachschieber - Klizni Ventili - Valvole A GhigliottinaDocument54 pagesSlide Valves - Flachschieber - Klizni Ventili - Valvole A GhigliottinaTiberiu PalNo ratings yet

- B-3801 IOM - Rev - 2011-09-02 (1) MidlandDocument23 pagesB-3801 IOM - Rev - 2011-09-02 (1) MidlandLucas MonteNo ratings yet