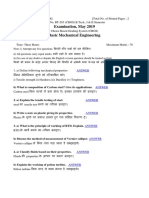

Professional Documents

Culture Documents

Larra Lde 2010

Uploaded by

djcafCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Larra Lde 2010

Uploaded by

djcafCopyright:

Available Formats

24

Feature

WORLD PUMPS

February 2010

Pump selection

Centrifugal pump

selection process

Centrifugal pumps can be used in many applications, but in order

to operate reliably, with optimal energy use and maximum life span,

a pumps design characteristics must suit the intended service.

Correct pump selection is the first step to ensure this, as Eduardo

Larralde and Rafael Ocampo demonstrate in this first of two articles.

perational versatility is an

outstanding feature of centrifugal

pumps that has contributed to

their extended use in a wide range of

applications. But, although a centrifugal

pump can serve many dierent operating

conditions, it will not provide suitable and

satisfactory performance in all of them.

In order for a pump to run correctly,

without wasting energy or sustaining

internal damage, its design characteristics

must be suitable for the intended service.

Therefore, the correct selection of the

pump is the rst step in guaranteeing

ecient and appropriate performance,

reliable operation and a reasonably long

life span.

In spite of the existence of a large volume

of literature concerning the selection of

pumps, there are still essential aspects that

are sometimes overlooked, leading to an

inadequate selection. The main purpose of

this article is to review the most important

technological details to be dened before

seeking a quotation for a new centrifugal

pump, the aspects to be included in the

enquiry and those to be carefully checked

in the oers received before taking the

decision as to which is the best pump to

full the required service.

1. Denition of the technological process

outline and main process parameters such

as ow, pressure and temperature.

2. Determination of the required

pumping services.

3. Complete description of the uid to be

handled in each pumping service (type

of uid, temperature, density, viscosity,

corrosiveness, erosiveness, vapour pressure,

solids in suspension, toxicity, volatility).

4. Plot of general layout of the plant

and determination of available space in

three dimensions.

5. General arrangement and dimensions

of the piping according to the recommended velocities for each uid and type

of pipe.

6. Determination of elevation for suction

and discharge points or vessels relative to

the centre line of the pump.

7. Preliminary calculation of friction losses

and plotting of system characteristic curve.

Consider allowance for future corrosion

of pipes.

Preliminary denitions

8. Denition of the working parameters

of the pump, namely, capacity, head,

suction and discharge pressures, taking

into account any possibility of variations

in pressure or temperature at dierent

pumping conditions.

The initial selection process for any pump

should include the following steps:

9. Determination of any possible exceptional start, stop or running conditions.

www.worldpumps.com

0262 1762/10 2010 Elsevier Ltd. All rights reserved

10. Determination of available NPSH.

11. Preliminary selection of the pump

type, design, position, driver, type of

sealing, and cooling of seal and bearings

if required.

12. Determination of the type of drive

unit (electric motor, steam turbine, etc.)

and its main operating parameters. In

the case of an electric motor, special

attention should be paid to its eciency

(only high-eciency motors should be

specied) and to the advisability of using

a variable speed drive (VSD).

In the authors experience, the buyer

should take the preliminary denitions

highlighted in item 11 and include

them in the technical specications of

the bid request sent to the suppliers.

This action should not eliminate the

possibility and advisability of communication and exchange of criteria between

buyer and seller leading to mutually

agreed changes.

After gathering all the information

outlined in the 12 items listed above,

the buyer will be ready to prepare the

specications for the quotation request.

According to the API 610 standard1,

a good practice is to ll in as much

information as possible in the data sheet

shown in its appendix. Undoubtedly, this

data sheet is a valuable document for

pump owners, which is why its length

has increased from one page in the Fifth

WORLD PUMPS

Feature

February 2010

Edition (March 1971) to ve pages in the

Eighth Edition (August 1995).

the process; using several pumps in parallel;

or using a VSD.

The rst box shows the data that must be

included in the technical specication. The

data shown relate to an actual pump whose

selection will be discussed in the case study to

be presented in the second article in this twopart series. The second box shows the required

scope of supply.

It may happen that the option adopted entails

the pump running in a capacity range wider

than the recommended 80% 110% of the

ow at the best eciency point (BEP), losing

not only eciency but also reliability, as shown

in Figure 12.

Nevertheless, the previously listed information is not enough. Operational requirements are of the upmost importance,

and therefore should be dened with the

maximum accuracy. Frequently, capacity

and head are established only for normal

and maximum values without taking into

account that the pump could run through

a wide range of capacities and that the

process may not allow pressure dierences

beyond certain limits. This is just the case

in the example to be presented in the next

article. This condition will obviously force

an arrangement to be found to full that

basic requirement with the highest possible

eciency. Several options could be considered, such as choosing a pump whose Q-H

(capacityhead) characteristic curve is at

enough to satisfy the conditions imposed by

Additionally, the minimum safe ow recommended by the manufacturer for the pump

should be clearly stated in order to prepare

the system to ensure the safe, continuous

operation of the pump when the process ow

demand is lower than that value.

Bid analysis

At this point the buyer is ready to ask for

preliminary oers in order to carry out

a thorough analysis of the characteristic

curves of the oered pumps and, of course,

a detailed check of all the other information contained in the oers. When checking

the characteristic curves there are three

main aspects to consider.

Firstly, the API 610 standard must be

fullled concerning the supply of all the

required curves, namely, dierential head,

eciency, NPSH(R) and power consumption, all of them plotted against the

capacity of the pump. The scope of these

curves should cover at least up to 125%

of the pump capacity at the BEP. Additionally, headcapacity curves for minimum

and maximum impeller diameters should

be shown. The necessary corrections for

viscosity should be clearly indicated. The

area of ow for the eye of the rst-stage

impeller as well as its identity number

should also be shown. Although the API

610 standard requires the inclusion of these

data for the rst-stage impeller in the characteristic curves, it should be pointed out

that only a few manufacturers do so and

therefore this information will have to be

insisted on by the buyer. The worst case is

when the supplier fails to include the eciency curve or the NPSH(R) curve, which is

completely unacceptable if a correct selection of the pump is to be made.

Secondly, the rotational speed, density and

viscosity to which the curves relate must

be taken into consideration. If they do not

match up with the data in the bid request

it will be necessary to do the pertinent

corrections. Failure to do this detailed

checking can cause misunderstandings,

www.worldpumps.com

25

26

Feature

WORLD PUMPS

February 2010

leading to mistakes. A common problem

for electrically driven pumps occurs when

the pump is to be installed in a country

using a dierent electric voltage and/or

frequency from that used in the country of

the manufacturer.

Lastly, the actual eciency occurring at

the operating point of the pump and

the maximum eciency the pump can

achieve should be compared; unreasonably

large dierences should not be allowed.

This comparison is made by intersecting

the system characteristic curve with the

pumps head curve in order to establish

what the operating point of the pump

will be and compare it with the BEP. As

mentioned before, it is recommended that

the pump run between 80% and 110%

of the capacity at the BEP. Overlooking

this important detail leads to a signicant energy loss. Many pump users do

not realize that the cost of energy can

represent between 30% and 90% of the

life cycle cost (LCC) of the pump36. The

curves shown in Figure 2 and the pie

chart in Figure 3 clearly illustrate this fact.

According to process variations, a pump

service might need to cover several duty

points, of which the largest ow and/or

head will determine the rated duty for the

pump. The engineer in charge of pump

selection must carefully consider the duration of operation at each duty point to

select properly the number of pumps and

the control system to use.

In order to carry out a thorough analysis and

correctly select the pump it is advisable to

obtain complete information from the supplier

about the full range of pump models, rotational speeds and impeller diameters as well as

the characteristic curves for all the proposed

pumps. The suppliers should be consulted

during the bid analysis in order to clarify every

detail and ensure the selection of the best

pump model.

Selection and acquisition

After fullling all the preliminary steps and

obtaining all the aforementioned information,

the buyer can ask for nal oers for the pump

models that best t the requirements. Comparisons between oers will then be made

focusing on aspects such as the purchase

price, the payment conditions and facilities,

the time for delivery, the guarantee for spare

parts supply over a reasonably long period, the

prestige of the manufacturer and its references.

It is good practice to contact previous buyers

of the same or a similar pump type to get

information about its behaviour.

www.worldpumps.com

Figure 1. Adverse eects of operating away from the BEP (reproduced from Ref. 2, courtesy of Allweiler AG).

From both the engineering and economical standpoints, the efficiency of the

pumpmotor set is of the upmost importance. The selection of pump and motor

should ensure high efficiency values,

aiming for the lowest possible energy

consumption per volume of pumped fluid.

It is very convenient (sometimes mandatory) to choose high-efficiency motors,

whose initial cost is higher, but that

reimburse the expense through the saving

in energy consumption in the long run.

Nowadays, some authors consider that

a low-efficiency motor is too expensive

even if it is free7. The decisions taken

concerning efficiency and energy saving

will have an influence not only on the

LCC of the pumpmotor set but also in

reducing carbon dioxide emissions to the

atmosphere.

Pump owners should be aware that selecting

ecient pumps and motors alone is not

enough to achieve cost-eective and reliable operation. The pump characteristics

must properly t the system requirements

throughout the variations occurring in the

process, ensuring operation as close as

possible to the BEP for the majority of the

operating time.

Operating a pump away from its BEP can

cause adverse eects such as cavitation,

shortening of the life of seals, impellers and

bearings, internal uid recirculation and

internal heating. On the other hand, running

a pump at or close to its BEP avoids those

WORLD PUMPS

Feature

February 2010

Minimum specications required

for pump quotation request

Service: hot water circulating pumps

Type of pump: centrifugal.

Preferred position of the shaft: horizontal.

Fluid: treated water, pH: 9.5

Corrosive/erosive agent: no.

Normal pumping temperature: 185C; maximum: 195C.

Density at pumping temperature: 881 kg/m3.

Viscosity at pumping temperature: 1.68 x 10-7 m2/s.

Vapour pressure at pumping temperature: 1.123 MPa.

Normal capacity at pumping temperature: 105 m3/h.

Rated capacity at pumping temperature: 120 m3/h.

Minimum operating ow: 45 m3/h.

Rated dierential head (water at 20C): 111.3 m.

Rated dierential head (corrected for the density): 126.3 m.

Maximum suction pressure: 1.37 MPa (from a pressurized vessel).

Discharge pressure: 2.46 MPa.

Maximum discharge pressure allowed by the process: 2.58 MPa.

NPSH available: 20 m.

Preferred rotational speed: 3500 rpm.

Shaft sealing: packing.

Seal cooling: yes.

Bearing cooling: yes.

Cooling uid available: treated water, 35C.

Construction materials: according to the manufacturing standards

taking into account the pump design and operating conditions

indicated above.

Drive: electric motor with the following features:

Phases: 3

Start: delta-star.

Voltage: 760/440 V; voltage tolerance: 10%

Frequency: 60 Hz; frequency tolerance: 4%

Eciency class: EFF 1

Minimum protection: IP 55 for tropical conditions.

Type of service: continuous, industrial, heavy.

Operating conditions: 24 hours/day, 6 days/week.

Starting: not less than 3 starts per hour. Interval

between starts could be as short as 30 seconds.

Power: suitable for the whole Q-H curve of the pump.

Environmental conditions:

Maximum temperature: 40C.

Minimum temperature: 10C.

Relative humidity: 85%.

Altitude: 100 m above sea level.

Location of installation: under shed, without walls.

www.worldpumps.com

27

28

Feature

WORLD PUMPS

February 2010

Scope of supply

Pump.

Induction electric motor (with VSD if

required).

Steel base plate, common to pump and

motor.

Flexible coupling.

Protection of mobile parts.

Counter anges, neck type UNI/DIN for

welding to ANSI Schedule 40 pipes.

Technical documentation, which

should include: complete data sheets

for pump and driver as stated by API

610; drawings and specifications for

driver, coupling and pump; materials

specications; characteristic curves;

installation, operation and maintenance

instructions; lubrication instructions;

spare parts recommendations; and

so on.

Inspection and testing certicates as per

the scope stated by API 610.

outlined here and explaining the decisionmaking process.

Figure 2. Eciency drop versus capacity.

problems and therefore increases its reliability (Figure 1).

Nowadays, the increase in the costs associated with running a pump, mainly the cost

of energy, has made the initial cost less

important when compared with the LCC

of the pump, making the LCC calculation

an indispensable tool to be used for the

acquisition of any type of pump. After the

full selection process described has been

completed, the nal selection of the pump

can be made.

Other considerations

Besides the selection of the pump itself there

are some points worth considering. Shop

inspection and testing of the pumps must

full the standards regarding the type of test

to be made, the correct application of the

test procedure and the handing over of the

resulting test data. More frequently than is

desirable, some manufacturers submit scant

information on tests results. Depending on

the quantity and importance of the equipment being bought, the buyer should assess

the practicality of his personnel or hired technicians participating in the shop inspection

and testing of the pumps.

The buyer should conrm that the standard

applied for manufacture and testing

is a recognized international standard

and should check it and verify that it

satises requirements.

In the second article a case study will be

discussed, applying all the procedures

References

[1] API 610, Centrifugal Pumps for

Petroleum, Heavy Duty Chemical and

Gas Industry Services, Eighth Edition,

American Petroleum Institute, (1995).

[2] E. Braun and W. Leiber, The right

pump lowers total cost of ownership,

World Pumps, No. 491, pp. 3033, (2007).

[3] B. Went, The systems approach to

reducing carbon emissions, World Pumps,

No. 500, pp. 5255, (2008).

[4] L. Dingley, Will sustainability end

up costing the earth?, World Pumps,

No. 494, pp. 2628, (2007).

[5] P. Noll, Determining the real cost

of powering a pump, World Pumps,

No. 496, pp. 3234, (2008).

[6] M. Cieslak, Life cycle costs of

pumping stations, World Pumps,

No. 505, pp. 3033, (2008).

[7] H-J. Bittermann, Germany makes strides

into energy eciency, World Pumps,

No. 493, pp. 3639, (2007).

Contact

Eduardo Larralde

E-mail: larralde@quimica.minbas.cu

Rafael Ocampo

E-mail: rocampod@gmail.com

Figure 3. Typical breakdown of pump costs.

www.worldpumps.com

You might also like

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Moldavite Ukazka PDFDocument15 pagesMoldavite Ukazka PDFNeven Žižić100% (1)

- Spec For Centrifugal Pumps - APIDocument12 pagesSpec For Centrifugal Pumps - APIjowar100% (1)

- Layout Arrangement For Centrifugal Pump PipingDocument20 pagesLayout Arrangement For Centrifugal Pump PipingKyaw Kyaw Aung50% (2)

- Centrifugal Pump PipingDocument22 pagesCentrifugal Pump PipingBhupender Sharma100% (3)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo ratings yet

- Sewage Pump Lift StationDocument23 pagesSewage Pump Lift StationLuis Gabriel BautistaNo ratings yet

- Designing Efficient Sewage Pumping SystemsDocument10 pagesDesigning Efficient Sewage Pumping SystemsPriyanka Rupasinghe67% (3)

- Pump Inspection HandbookDocument16 pagesPump Inspection Handbookyoonchankim0911100% (2)

- 10 Steps To Pump ReliabilityDocument13 pages10 Steps To Pump ReliabilityfalconesasNo ratings yet

- Working Guide to Pump and Pumping Stations: Calculations and SimulationsFrom EverandWorking Guide to Pump and Pumping Stations: Calculations and SimulationsRating: 5 out of 5 stars5/5 (3)

- HVAC-Indoor Air Quality Reference GuideDocument32 pagesHVAC-Indoor Air Quality Reference Guidedjcaf100% (2)

- Pump MaintenanceDocument5 pagesPump MaintenanceCheyanSathish100% (1)

- API 610 - Why BEP Should Be Between Normal Point and Rated PointDocument7 pagesAPI 610 - Why BEP Should Be Between Normal Point and Rated PointMuhammad ImranNo ratings yet

- Peerless Pump Tech BulletinsDocument176 pagesPeerless Pump Tech BulletinsWilhelm ThorleyNo ratings yet

- Layout Arrangement For Centrifugal Pump PipingDocument30 pagesLayout Arrangement For Centrifugal Pump PipingAlderit BarajasNo ratings yet

- To Study The Bending Behavior of Z-SecDocument10 pagesTo Study The Bending Behavior of Z-SecFaisal SardarNo ratings yet

- Benefits of HI 14-6 FINAL FULL VERSION PDFDocument8 pagesBenefits of HI 14-6 FINAL FULL VERSION PDF1sympatyagaNo ratings yet

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowRating: 2 out of 5 stars2/5 (1)

- Tender For Centrifugal Pumps HPDocument96 pagesTender For Centrifugal Pumps HPAnne Sharon100% (1)

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- 10 Steps To Pump ReliabilityDocument15 pages10 Steps To Pump ReliabilityaqhammamNo ratings yet

- Reading The Pump Curve - Intro To PumpsDocument4 pagesReading The Pump Curve - Intro To PumpsVIVANo ratings yet

- Confined Space EntryDocument15 pagesConfined Space EntryEnginnering Section100% (1)

- Hanbook Airah2Document88 pagesHanbook Airah2niceday9_40% (1)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Process Engineering Manual 005 IIDocument29 pagesProcess Engineering Manual 005 IIzoeNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Applying NPSH To Metering PumpsDocument3 pagesApplying NPSH To Metering PumpsJoce88888100% (1)

- Navigating Pump CurvesDocument7 pagesNavigating Pump Curvescastingforge4875No ratings yet

- Six Considerations For Proper Dust Collection System DesignDocument9 pagesSix Considerations For Proper Dust Collection System DesignJoão CoelhoNo ratings yet

- Aetheric Battery - Copy #1Document6 pagesAetheric Battery - Copy #1Keresztúri FerencNo ratings yet

- Applying-NPSH-to-metering-pumps - WORLD PUMPS PDFDocument3 pagesApplying-NPSH-to-metering-pumps - WORLD PUMPS PDFMuhammad ImranNo ratings yet

- Optimize pump and fan applications with a 4-step assessmentDocument7 pagesOptimize pump and fan applications with a 4-step assessmentallahuakbar2011No ratings yet

- Quiz Oil & Gas EngineeringDocument110 pagesQuiz Oil & Gas EngineeringLisa Malone100% (1)

- Selecting The Best Slurry Pump For Specific Operating ConditionsDocument9 pagesSelecting The Best Slurry Pump For Specific Operating ConditionssmendozaNo ratings yet

- Selecting A Centrifugal Pumps by System Analysis PDFDocument27 pagesSelecting A Centrifugal Pumps by System Analysis PDFmishraenggNo ratings yet

- Pump Basics. A Guide To Installation and SelectionDocument18 pagesPump Basics. A Guide To Installation and SelectionArsalan QadirNo ratings yet

- Energy Saving in PumpDocument2 pagesEnergy Saving in PumpAaron AngNo ratings yet

- Ed43 441Document87 pagesEd43 441djcaf100% (2)

- Design Guidelines For Water and SewerDocument23 pagesDesign Guidelines For Water and SewerZeina FarhatNo ratings yet

- Optimizing Pumping Systems P-IDocument4 pagesOptimizing Pumping Systems P-Imatrix69No ratings yet

- Pump Selection For The LNG IndustryDocument0 pagesPump Selection For The LNG IndustryZaid Tariq AlabiryNo ratings yet

- Clean RoomDocument322 pagesClean RoomCalin Truta100% (11)

- Centrifugal PumpsDocument6 pagesCentrifugal PumpsjoasobralNo ratings yet

- Manufacturing of Light Weight Composite Parts For Automotive ApplicationsDocument84 pagesManufacturing of Light Weight Composite Parts For Automotive ApplicationsvkrishnarajNo ratings yet

- API 610 Pump Selection and Curve EvaluationDocument4 pagesAPI 610 Pump Selection and Curve EvaluationbbmokshNo ratings yet

- Chem 210 Lab Report 1Document6 pagesChem 210 Lab Report 1Mxokzah Cmoh100% (1)

- Test Standard Benefits ArticleDocument8 pagesTest Standard Benefits Articleverat81No ratings yet

- Select Hydraulic Institute Standards-Pump Operations, Efficiency, Testing & SystemsDocument4 pagesSelect Hydraulic Institute Standards-Pump Operations, Efficiency, Testing & SystemsHongwei GuanNo ratings yet

- Centrifugal Pump Literature ReviewDocument6 pagesCentrifugal Pump Literature Reviewea7gjrm5100% (1)

- SPE 137184 Statistical Approach For PCP StandardizingDocument10 pagesSPE 137184 Statistical Approach For PCP StandardizingJosé TimanáNo ratings yet

- Literature Review Centrifugal PumpDocument5 pagesLiterature Review Centrifugal Pumpea44a6t7100% (1)

- Low NPSH & Cases of Vertical Barrel (VS6) Type Pump Selection PDFDocument12 pagesLow NPSH & Cases of Vertical Barrel (VS6) Type Pump Selection PDFMuhammad ImranNo ratings yet

- 2 - Pump Best Practi - 2011 - Forsthoffer S Best Practice Handbook For RotatingDocument67 pages2 - Pump Best Practi - 2011 - Forsthoffer S Best Practice Handbook For RotatingKevin_INo ratings yet

- BDocument11 pagesBDany MedinaNo ratings yet

- Centrifugal Pump Selection and SpecificationDocument2 pagesCentrifugal Pump Selection and Specificationferchosb12No ratings yet

- Oil & Gas Pump Selection GuideDocument79 pagesOil & Gas Pump Selection GuideArunkumarNo ratings yet

- Pumping System Parameters To Consider For Your Medical Instrument-KNF - PumpingSystemDocument4 pagesPumping System Parameters To Consider For Your Medical Instrument-KNF - PumpingSystemRobby RenzNo ratings yet

- 6 - Pumping Systems - Ministry of Water DCOM ManualDocument5 pages6 - Pumping Systems - Ministry of Water DCOM ManualNassif Abi AbdallahNo ratings yet

- Design Considerations When Rod Pumping Gas WellsDocument12 pagesDesign Considerations When Rod Pumping Gas Wellssurakhi2011No ratings yet

- Factory Performance Testing of Vertical Turbine PumpsDocument3 pagesFactory Performance Testing of Vertical Turbine PumpsSrećko BlaževićNo ratings yet

- Pump Piping Requirements for Optimal PerformanceDocument1 pagePump Piping Requirements for Optimal Performanceferchosb12No ratings yet

- Importance of Right Pump SelectionDocument3 pagesImportance of Right Pump SelectionsahildhingraNo ratings yet

- API 610 VS4 Performance Curve Criteria RevBDocument4 pagesAPI 610 VS4 Performance Curve Criteria RevBChevronelleNo ratings yet

- Artical On Artifical Lifts 1Document5 pagesArtical On Artifical Lifts 1Chandhini BatchalaNo ratings yet

- Artical On Artifical Lifts 1Document5 pagesArtical On Artifical Lifts 1Chandhini BatchalaNo ratings yet

- Catalysis - Volume 28Document294 pagesCatalysis - Volume 28Amal ..No ratings yet

- Multicomponent DistillationDocument120 pagesMulticomponent DistillationCharles BaileyNo ratings yet

- Emergy Basis of Forest Systems - Tilley David PDFDocument310 pagesEmergy Basis of Forest Systems - Tilley David PDFdjcafNo ratings yet

- UTN FRM Cemento Portland - 2015Document51 pagesUTN FRM Cemento Portland - 2015djcafNo ratings yet

- Internal Inventory Listing of Dialysis MachinesDocument2 pagesInternal Inventory Listing of Dialysis MachinesdjcafNo ratings yet

- Internal Inventory Listing of Dialysis MachinesDocument2 pagesInternal Inventory Listing of Dialysis MachinesdjcafNo ratings yet

- How To Make A Universal Duct Traversal Airflow Measurement AnDocument3 pagesHow To Make A Universal Duct Traversal Airflow Measurement AnVin KenNo ratings yet

- ASME B16.10 Face To Face and End To End Dimension of ValvesDocument39 pagesASME B16.10 Face To Face and End To End Dimension of ValvesMurali DharanNo ratings yet

- Manual Cabezal 764 TwinDocument40 pagesManual Cabezal 764 Twindjcaf100% (1)

- 16 PowerDown HeinbergDocument69 pages16 PowerDown HeinbergHumza AftabNo ratings yet

- Cerebral Venous Sinus Thrombosis Review: Diagnosis and Treatment AdvancesDocument11 pagesCerebral Venous Sinus Thrombosis Review: Diagnosis and Treatment AdvancesdjcafNo ratings yet

- Energetic Limits To GrowthDocument7 pagesEnergetic Limits To Growth::nyxNo ratings yet

- Craneoplastia y Regulacion FSC Germany 00Document9 pagesCraneoplastia y Regulacion FSC Germany 00djcafNo ratings yet

- Solvay Process PresentationDocument19 pagesSolvay Process PresentationRiki Mandol67% (3)

- Craniocervical Junction Fusions in Patients With Hindbrain IOWA 08Document9 pagesCraniocervical Junction Fusions in Patients With Hindbrain IOWA 08djcafNo ratings yet

- Enfoque Integral Arnol Chiari en Niños Iowa 99Document9 pagesEnfoque Integral Arnol Chiari en Niños Iowa 99djcafNo ratings yet

- Aspergilus Flavus Brain AbscessDocument4 pagesAspergilus Flavus Brain AbscessdjcafNo ratings yet

- Pediatrics CPP 2013Document9 pagesPediatrics CPP 2013djcafNo ratings yet

- Empiema Subdural Meningitis 2012Document7 pagesEmpiema Subdural Meningitis 2012djcafNo ratings yet

- Falla 3ventrulostomia en Est - Acueductal Paris 99Document15 pagesFalla 3ventrulostomia en Est - Acueductal Paris 99djcafNo ratings yet

- Cerebral AspergillomaDocument3 pagesCerebral AspergillomadjcafNo ratings yet

- Oncologia Seguimiento Largo Plazo RecuperadosDocument69 pagesOncologia Seguimiento Largo Plazo RecuperadosdjcafNo ratings yet

- Neurosurgical Operative Atlas Neuro Oncology.40Document5 pagesNeurosurgical Operative Atlas Neuro Oncology.40djcafNo ratings yet

- Thermocouple Color CodesDocument8 pagesThermocouple Color CodesMohsin ShaukatNo ratings yet

- Energetic Limits To GrowthDocument7 pagesEnergetic Limits To Growth::nyxNo ratings yet

- Comprehensive View On Garment Dyeing and FinishingDocument6 pagesComprehensive View On Garment Dyeing and Finishingapi-26494555No ratings yet

- Industrial & Engineering Chemistry Research Volume 43 Issue 15 2004 [Doi 10.1021_ie049846s] Honkela, Maija L.; Ouni, Tuomas; Krause, A. Outi I. -- Thermodynamics and Kinetics of the Dehydration of Tert -Butyl AlcoholDocument6 pagesIndustrial & Engineering Chemistry Research Volume 43 Issue 15 2004 [Doi 10.1021_ie049846s] Honkela, Maija L.; Ouni, Tuomas; Krause, A. Outi I. -- Thermodynamics and Kinetics of the Dehydration of Tert -Butyl AlcoholJoshita KusumadewiNo ratings yet

- Ball PistonDocument15 pagesBall PistonNm5793100% (1)

- Points For PPT On AdmixturesDocument9 pagesPoints For PPT On AdmixturesAvinash MaratheNo ratings yet

- METALLODRUGSDocument21 pagesMETALLODRUGSAditya Verma100% (1)

- Analysis of Current Methods of Flexural Design for High Strength Concrete BeamsDocument330 pagesAnalysis of Current Methods of Flexural Design for High Strength Concrete BeamsMisael AlejandroNo ratings yet

- Chemistry Investigatory Project: Stomach Acid, Its Composition and NeutralizationDocument25 pagesChemistry Investigatory Project: Stomach Acid, Its Composition and NeutralizationAkaar bellaneyNo ratings yet

- MCQ Gad 2Document8 pagesMCQ Gad 2AlhanNo ratings yet

- Ferodo - Brake Pads Data Sheets enDocument7 pagesFerodo - Brake Pads Data Sheets enfranziskaner79No ratings yet

- DPR Nag River Volume IIIDocument290 pagesDPR Nag River Volume IIIashutosh_shahu1No ratings yet

- Compatibility of Materials With Liquid Oxygen (Impact Sensitivity Threshold and Pass-Fail Techniques)Document12 pagesCompatibility of Materials With Liquid Oxygen (Impact Sensitivity Threshold and Pass-Fail Techniques)Ahmed AlzubaidiNo ratings yet

- Biochemistry of Bone & Muscle: Dr. Syahrijuita, M.Kes, SP - THT-KLDocument69 pagesBiochemistry of Bone & Muscle: Dr. Syahrijuita, M.Kes, SP - THT-KLyantiNo ratings yet

- BT 203 Basic Mechanical Engineering May 2019 PDFDocument2 pagesBT 203 Basic Mechanical Engineering May 2019 PDFKunta PatleNo ratings yet

- User Manual of Laser Engraving Machine PDFDocument36 pagesUser Manual of Laser Engraving Machine PDFRobby SubhansyahNo ratings yet

- A Review of Aqueous Organic Reactions For The Undergraduate Teaching LaboratoryDocument14 pagesA Review of Aqueous Organic Reactions For The Undergraduate Teaching LaboratoryBer GuzNo ratings yet

- DA Series Diaphragm Accumulators: Previously Known As ELM SeriesDocument18 pagesDA Series Diaphragm Accumulators: Previously Known As ELM SeriesglobalindosparepartsNo ratings yet

- Surface TextureDocument27 pagesSurface Texturesohkimfai6340100% (5)

- Millman Halkias - Integrated ElectronicsDocument14 pagesMillman Halkias - Integrated ElectronicsSushruti Richaa KashyapNo ratings yet

- Chemcad Features2Document18 pagesChemcad Features2Aditi PhalakNo ratings yet

- HF Scientific Online Chlorine Monitors and Reagents - CLXDocument3 pagesHF Scientific Online Chlorine Monitors and Reagents - CLXMCE ProcessNo ratings yet

- PCR Purification QiagenDocument1 pagePCR Purification Qiagenthethoi126No ratings yet

- DS2000 Manually EU ENDocument6 pagesDS2000 Manually EU ENLuis Manso PeñaNo ratings yet

![Industrial & Engineering Chemistry Research Volume 43 Issue 15 2004 [Doi 10.1021_ie049846s] Honkela, Maija L.; Ouni, Tuomas; Krause, A. Outi I. -- Thermodynamics and Kinetics of the Dehydration of Tert -Butyl Alcohol](https://imgv2-1-f.scribdassets.com/img/document/249581212/149x198/5265f135b4/1418085576?v=1)