Professional Documents

Culture Documents

Polymer Template-Assisted Microemulsion Synthesis of Large PDF

Uploaded by

Subhashini VedalaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polymer Template-Assisted Microemulsion Synthesis of Large PDF

Uploaded by

Subhashini VedalaCopyright:

Available Formats

J Solid State Electrochem

DOI 10.1007/s10008-013-2221-1

ORIGINAL PAPER

Polymer template-assisted microemulsion synthesis of large

surface area, porous Li2MnO3 and its characterization

as a positive electrode material of Li-ion cells

Tirupathi Rao Penki & D. Shanmughasundaram &

N. Munichandraiah

Received: 20 June 2013 / Revised: 6 August 2013 / Accepted: 9 August 2013

# Springer-Verlag Berlin Heidelberg 2013

Abstract Lithium-rich manganese oxide (Li2MnO3) is prepared by reverse microemulsion method employing Pluronic

acid (P123) as a soft template and studied as a positive

electrode material. The as-prepared sample possesses good

crystalline structure with a broadly distributed mesoporosity

but low surface area. As expected, cyclic voltammetry and

chargedischarge data indicate poor electrochemical activity.

However, the sample gains surface area with narrowly distributed mesoporosity and also electrochemical activity after

treating in 4 M H2SO4. A discharge capacity of about

160 mAh g1 is obtained. When the acid-treated sample is

heated at 300 C, the resulting porous sample with a large

surface area and dual porosity provides a discharge capacity of

240 mAh g1. The rate capability study suggests that the sample

provides about 150 mAh g1 at a specific discharge current of

1.25 A g1. Although the cycling stability is poor, the high rate

capability is attributed to porous nature of the material.

Keywords Lithium-ion cell . Mesoporous . Lithium excess

manganese oxide . Microemulsion route . Polymer template .

High rate capability

Introduction

Lithium-ion batteries have attracted global interest from both

consumers and researchers during the past a couple of decades

[1, 2]. The interest has arisen because of the extended applications, which are successful in small sizes at present and

anticipated in large sizes in the future. Although the energy

density of the present Li-ion batteries is greater than that of

T. R. Penki : D. Shanmughasundaram : N. Munichandraiah (*)

Department of Inorganic and Physical Chemistry, Indian Institute of

Science, Bangalore 560012, India

e-mail: muni@ipc.iisc.ernet.in

Pb-acid batteries by about four times, future requirements

such as electric vehicle applications require still greater energy

density. The next generation Li-ion batteries thus need novel

electrode materials which can provide greater discharge capacity than the materials in use at present, in addition to the

need that they should be safe, inexpensive, non-toxic, and

environmental-friendly.

The present Li-ion batteries employ positive electrode materials of the categoryLiCoO2, LiMn2O4, and LiFePO4

either in their pure state or with partial substitutions of the

transitional metals. The discharge capacity values of LiCoO2,

LiMn2O4,and LiFePO4 are 140, 130, and 170 mAh g1, respectively [3]. Li-ion batteries with greater energy density

than the present batteries require positive electrode materials

of greater discharge capacity. Compounds which can store

more than one lithium atom per transition metal atom are

expected to provide enhanced discharge capacity. Li2MnO3

belongs to this category of materials [4]. Li2MnO3 is considered isostructural to layered LiCoO2 and its formula can also

be represented as Li(Li0.33Mn0.67)O2. One third of the octahedral sites meant for Mn in the crystal lattice are occupied by Li

atoms. On the basis of extraction of the total available Li in

Li2MnO3, a discharge capacity of 456 mAh g1 is expected,

provided the compound is electrochemically active. Li2MnO3

was synthesized in single-phase from the reaction of LiOH

and MnO2 [5]. By treating the compound with H2SO4 or

HNO3, a discharge capacity of 199 mAh g1 was obtained

in the first chargedischarge cycle, which decreased rapidly to

143 mAh g1 in the eighth cycle. Following this report, several

publications have appeared with varying capacity values

[614]. Initial discharge capacity values are generally high

for the activated phases of Li2MnO3, but cycling instability is

observed in all reports.

In addition to the high discharge capacity, an electrode

material needs to possess high rate capability for the purpose

of fast charge or/and discharge. Porous materials are expected

J Solid State Electrochem

a

100

(iv)

9 % loss

(ii)

Weight loss / %

80

(iii)

I region

60

II region

59 % loss

40

8 % loss

(i)

20

170 C 240 C

455 C

0

100

200

300

400

500

600

700

800

Temperature / C

(202)

(060)

(330)/(061)

(201)

(132)

(130)

(020)

(110)

Intensity / a.u.

(131)

(001)

(iv)

(iii)

(ii)

(i)

10

20

30

40

50

60

70

80

2 / degree

Fig. 1 a Thermogravimetry recorded at a heating rate of 10 C min1 of

precursor gel (i ), sample S5 (ii ), sample S5A6 (iii ), and sample

S5A6H3 (iv ); and b powder XRD pattern of samples S4 (i ), S5 (ii ),

S6 (iii ), and S8 (iv )

to possess high rate capability because the electrolyte can

creep into particles and enhance the contact area of the

electroactive surface with the electrolyte [15]. As a result,

the material can withstand an enhanced specific current during

chargedischarge cycling. To the best of the authors' knowledge, there are no reports on the synthesis of porous Li2MnO3.

In the present study, the lithium excess oxide is prepared by

inverse microemulsion route assisted by soft polymer template, namely, Pluronic acid (P123). By treatment in dilute

acid and heating, the compound gains a large surface area and

dual mesoporosity, which result in providing a high initial

discharge capacity and also a high rate capability.

Experimental

High purity or analytical grade chemicals, namely lithium

nitrate (Aldrich), manganese nitrate tetrahydrate (Aldrich),

Pluronic acid [P123, poly(EO)20-poly(PO)70-poly(EO)20,

where EO and PO are ethylene oxide and propylene oxide

units, respectively; molecular weight, 5,800] (Aldrich), lithium dodecylsulfate (LDS, Aldrich), cyclohexane (Merck), nbutanol (SD Fine Chemicals), H2SO4 (SD Fine Chemicals),

lithium ribbon (0.75 mm thickness, Aldrich), acetylene black

(AB, Alfa Aesar), poly(vinylidene fluoride) (PVDF, Aldrich),

1-methyl-2-pyrrolidinone (NMP, Aldrich) and 1 M LiPF6

dissolved in ethylene carbonate, diethyl carbonate and

dimethyl carbonate (2:1:2v/v) electrolyte (Chameleon) were

used as received.

Li2MnO3 was prepared by reverse microemulsion route

employing P123 as a soft template. The oil and aqueous

phases were prepared separately. For the oil phase, 1.0 g

P123 was dissolved in a mixture consisting of 51.2 ml cyclohexane and 6.2 ml n -butanol by stirring for 2 h. Then, 0.225 g

LDS was added and stirred for 3 h to get a transparent

solution. Lithium nitrate (0.84 g) and manganese nitrate

tetrahydrate (1.074 g) were dissolved in 15 ml doubledistilled water. About 20 % of excess of lithium nitrate than

the stoichiometric quantity was used. The aqueous phase was

transferred to the oil phase and stirred for 12 h at ambient

temperature. The emulsion was slowly evaporated at 110 C.

A white gel was obtained. Samples of gel were calcined in air

at 400, 500, 600, 800 C for 6 h. Red colored powder samples

were obtained.

For activation of Li2MnO3, 1.0 g of a sample was added to

100 ml of 4 M H2SO4 and stirred at ambient conditions for

different durations from 2 to 24 h. The powder was separated

from the acid by centrifugation and washed with doubledistilled water thrice, finally rinsed with acetone, and dried

at 110 C for about 12 h. A black colored powder was

obtained. The acid-treated Li2MnO3 samples were heated at

either 300 or 500 C in air for 4 h. The color of the samples

remained black.

The powder X-ray diffraction (XRD) patterns were

recorded using a Bruker AXS D8 Advance X-ray diffractometer at 40 kV and 30 mA using Cu Ka ( =1.5418 ) radiation

source. Nitrogen adsorptiondesorption isotherms were

recorded at 196 C by using Micromeritics surface area

analyzer model ASAP 2020. The specific surface area was

calculated using the BrunauerEmmettTeller (BET) method

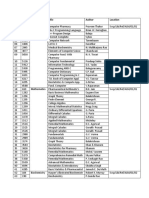

Table 1 Unit cell parameters obtained from XRD pattern

Sample a ()

b ()

c ()

()

Cell volume (3)

S4

S5

S6

S8

S5A6

8.523 (4)

8.534 (5)

8.530 (2)

8.537 (5)

8.672 (6)

5.008 (4)

5.015 (4)

5.022 (2)

5.026 (4)

5.045 (4)

109.14 (4)

109.20 (2)

109.12 (1)

109.27 (2)

110.29 (3)

199.29 (2)

199.35 (2)

199.49 (1)

199.87 (2)

206.90 (3)

4.942 (3)

4.934 (4)

4.929 (2)

4.935 (3)

5.042 (4)

J Solid State Electrochem

Fig. 2 Scanning electron

microscopy images of Li2MnO3

samples a S4, b S5, c S6, and d

S8

in the relative pressure (p/p 0) range 0.050.25 from adsorption branch of the isotherm. The pore size distribution was

calculated by BarrettJoynerHalenda (BJH) method from

desorption isotherm. The morphology was examined using a

FEI Co scanning electron microscope (SEM) model Sirion.

The chemical composition was analyzed by inductive coupled

plasma atomic emission spectroscopy using Varion inductively couple atomic emission spectrometer model Vista-PRO.

The elemental analysis for C and H was carried out by using

a Thermo Finnigan FLASH EA 1112 CHN analyzer.

Thermogravimetric analysis (TGA) was recorded from ambient temperature to 800 C at a heating rate of 10 C min1

under the flow of O 2 gas by using thermal analyzer

NETZSCH model TG 209 FI.

For fabrication of electrodes, the active material (80 wt%),

AB (15 wt%) and PVDF (5 wt%) were mixed in a mortar and

few drops of NMP were added to obtain a slurry. Stainless

steel disks (16 mm diameter) were cleaned with water, etched

in 30 % dilute HNO3, rinsed with double-distilled water

followed by acetone and air-dried. The slurry was applied on

a pre-treated stainless steel disk and dried at 110 C under

vacuum for 12 h. The mass of active material was 3

5 mg cm2. Lithium metal foil was used as a counter cum

reference electrode and Celgard porous polypropylene

membrane (2400) was used as a separator. A commercial

electrolyte of 1 M LiPF6 dissolved in ethylene carbonate,

diethyl carbonate and dimethyl carbonate (2:1:2v/v) was used

as the electrolyte. Coin-type cells CR2032 (Hohsen Corporation, Japan) were assembled in an argon-filled MBraun glove

box.

The cells were galvanostatically cycled in the voltage range

from 1.5 to 4.4 V at different current densities at room temperature. Cyclic voltammetry and chargedischarge cycling

experiments were carried out using an EG&G potentiostat

model Versastat and Biologic potentiostat/galvanostat model

VMP3. Rate capability with different current densities was

examined by using Bitrode battery cycling unit in an airconditioned room at 221 C.

Results and discussion

Soft chemical synthesis by inverse microemulsion route provides a control over particle size of the product. By dispersing

a small volume of aqueous phase consisting of the reactants in

a large volume of non-aqueous phase, the reactants are confined to micrometer sized reaction zones and particles of the

products are limited to the size of the aqueous droplets, which

J Solid State Electrochem

Sample

40

BET surface pore

area (m2 g1) diameter

(nm)

Conditions of preparation

Quantity of N2 adsorbed / cm g

-1

Table 2 Conditions of preparation, BET surface area and pore diameter

of different samples

S4

S5

S6

S8

S5A2

(iv)

20

(iii)

(ii)

(i)

0

0.0

0.3

0.6

0.9

o

Relative pressure (p/p )

0.0009

0.0006

-1

dVol/dDia / cm g nm

-1

0.0003

(iv)

(iii)

(ii)

(i)

Microemulsion400 C heating

Microemulsion500 C heating

Microemulsion600 C heating

Microemulsion800 C heating

Microemulsion500 C heating

2 h acid treatment

S5A6

Microemulsion500 C heating

6 h acid treatment

S5A12

Microemulsion500 C heating

12 h acid treatment

S5A24

Microemulsion500 C heating

24 h acid treatment

S5A2H3 Microemulsion500 C heating

2 h acid treatment3 h heating

at 300 C

S5A6H3 Microemulsion500 C heating

6 h acid treatment3 h heating

at 300 C

S5A12H3 Microemulsion500 C heating

12 h acid treatment3 h

heating at 300 C

S5A24H3 Microemulsion500 C heating

24 h acid treatment3 h

heating at 300 C

5.8

5.6

5.3

2.6

115

1045

1025

1030

1050

3.9

89

3.9

78

3.7

74

3.5

49

3.6 and 6.1

61

3.6 and 7

44

2.4 and 3.7

42

3.7

0.0000

30

60

90

120

150

Pore diameter / nm

Fig. 3 a Nitrogen adsorption/desorption isotherms and b pore size

distribution BJH curves of Li2MnO3 samples S4 (i), S5 (ii), S6 (iii),

and S8 (iv) samples. In a, curves (ii), (iii), and (iv) are, respectively,

vertically shifted by 5, 10, and 15 units of y-axis scale relative to the

position of curve (i)

are stabilized by surfactant molecules. Sub-micrometer/

nanosized product particles are synthesized by this route

[16]. The presence of polymeric templates such as P123 in

the reaction medium facilitates the product particles to develop porosity. The presence of hydrophilic EO block and hydrophobic PO block is considered to be responsible for generating porosity on the product particles [17]. By combining

the salient features of inverse microemulsion and polymeric

templates, synthesis of porous, sub-micrometer sizes cathode

materials, namely, LiFePO4 and LiNi1/3Mn1/3Co1/3O2, were

synthesized in our laboratory [1820]. A similar procedure

was adopted for preparation of Li2MnO3 in the present work.

The gel obtained after evaporation of solvents at 110 C

was subjected to thermal analysis (Fig. 1a, curve i). There is a

continuous loss of mass between ambient and about 240 C

due to the removal of solvents and decomposition of nitrates

and organic matter. About 58 % of weight loss is observed at

240 C. The mass of the sample is fairly constant between 240

and 450 C. There is about 8 % loss of mass between 240 and

450 C followed by stability up to 800 C. Therefore, samples

of the gel were heated at several temperatures from 400 to

800 C for 6 h. The samples prepared at 400, 500, 600, and

800 C are hereafter referred to as S4, S5, S6 and S8, respectively. Thermogravimetric analysis of the heated samples

(Fig. 1a, curve ii shown typically for sample S5) indicates

thermal stability of the compounds in the temperature range

from ambient to 800 C.

Powder XRD patterns of the samples prepared at different

temperatures are shown in Fig. 1b, which are similar for all

samples. The structure of Li2MnO3 was determined by using

single crystal X-ray diffraction by Strobel and LamberAndron [21]. Li2MnO3 was described as Li[Li1/3Mn2/3]O2

Table 3 Elemental analyses. Mn and Li were estimated by inductive

coupled plasma atomic emission spectroscopy; C and H by CHNS

analysis, and O is the balance

Sample

S5

S5A6

S5A6H3

Weight % of elements

Mn

Li

39.09

49.06

51.79

7.78

4.70

4.55

1.28

0.894

0.407

0.78

1.31

0.67

51.07

44.03

42.57

J Solid State Electrochem

a

4.5

st

1 ch

st

2 ch

Potential / V Vs Li/Li

4.0

3.5

3.0

2.5

2.0

st

1 dis

1.5

0

20

40

60

80

100

Specific discharge capacity / mAh g

120

Specific discharge capacity / mAh g

-1

120

-1

100

(ii)

(i)

80

(iii)

60

40

(iv)

20

0

10

11

Cycle number

Fig. 4 a Chargedischarge curves of Li 2 MnO 3 sample S5 at

100 A cm2 (specific current 33 mA g1) and b discharge capacity

variation of Li2MnO3 samples S4, S5, S6, and S8 on repeated charge

discharge cycling at a specific current of 3033 mA g1

structure of O3-type where the octahedral sites of inter-slab

are occupied by lithium-ion and octahedral sites of the slab by

lithium and manganese ions in 1:2 ratio. The XRD patterns

(Fig. 1b) agree well with the standard pattern of layered

structure (JCPDS file No. 841634). The (020) and (110)

reflections in 2 range 2023 indicate LiMn ordering in

the mixed cation layer and these superstructure reflections are

signatures for Li2MnO3. The XRD patterns of all samples

(Fig. 1b) were indexed to Li2MnO3 and lattice constants were

obtained (Table 1). Lattice constants are close to those reported in the JCPDS file 841634 (a =4.937 ; b =8.532 ; and

c =5.03 ). Similar agreement in lattice constants was

reported for Li2MnO3 prepared from aqueous sol gel method [22]. The average crystallite size of Li2MnO3 samples

were calculated from diffraction peaks of (001), (201), and

(131) planes using Scherrer equation [23] and the average

crystallite size was 140 nm. The unit cell parameters and

also the crystallite size were nearly the same for all S4S8

samples (Table 1).

SEM micrographs of the as-prepared samples of Li2MnO3

are presented in Fig. 2. The S5 sample appears to have layerlike morphology with several layers aggregated together and

edges projecting upwards. The thickness of layer is about

23 nm and length is about 190 nm. With an increase in

temperature of preparation, morphology changes to porous

sponge-like at 600 C (S6 sample) and plate-like morphology

at 800 C (S8 sample). Thus, the temperature of preparation

influences the morphology, particle nature, and as well as the

size.

Nitrogen adsorption/desorption isotherms and BJH porosity curves are presented in Fig. 3. The adsorption and desorption branches do not merge in the pressure region p/p 0 between 0.50 and 0.99 for all samples suggesting porous nature

of the samples. The amount of N2 adsorbed at p/p 0 =0.99 is

about 40 cm3 g1, which is considered as high. This is attributed to porosity of the materials. The porous nature is also

reflected in BJH curves (Fig. 3b). There is a broad distribution

of pores around 1040 nm diameter. The BET surface area and

average pore diameter obtained for all samples are listed in

Table 2. The surface area of S5 samples is 5.5 m2 g1 with

pore diameter of 1020 nm. There is a marginal decrease in

surface area by increasing the temperature of preparation

(Table 2). The porosity acquired by the Li2MnO3 samples is

attributed to the presence of the polymeric template in the

reaction medium of preparation.

Results of elemental analysis and the calculated composition for S5 sample, typically, are provided in Table 3. It is

likely that the origin for C and H is the polymer P123. The

composition is calculated assuming that Mn is present as per

the intended composition of Li2MnO3. The deficiency of Li

(1.57 against intended 2.0) is probably due to loss of Li in the

process of synthesis. It is reported that the XRD patterns of

compounds with Li/Mn ratio less than 2 also correspond to the

pattern of stoichiometric Li2MnO3 [24].

Cyclic voltammograms (not shown) of Li2MnO3 prepared

at different temperatures suggested poor electrochemical activity of the compound. In general, the positive electrode

materials of Li-ion cells exhibit well-defined reduction and

oxidation current peaks of cyclic voltammograms [25]. In the

present study, redox current peaks were absent for all asprepared samples. Poor electrochemical activity is also

reflected in galvanostatic charge/discharge cycling (Fig. 4a).

The electrodes were subjected to chargedischarge cycling

between 1.50 and 4.40 V at a specific current of 33 mA g1.

Although Li2MnO3 was reportedly [14] cycled between 1.50

and 4.80 V, the potentials greater than 4.50 V are expected to

be undesirable due to the possibility of decomposition of the

electrolyte and evolution of gases inside sealed cells. Hence,

the upper limit of cycling is limited to 4.40 V in the present

study, similar to the studies reported on Li2MnO3 electrodes

which were cycled between 1.50 and 4.50 V in order to avoid

decomposition of the electrolyte [26]. The discharge capacity

J Solid State Electrochem

Fig. 5 a Powder XRD pattern

and b SEM image of sample

S5A6

Intensity / a.u.

10

20

30

40

50

60

70

80

2 / degree

obtained at a specific current of 33 mA g1 rate is in the range

95115 mAh g1 for S4, S5 and S6 samples (Fig. 4). The

capacity of S8 sample is only about 22 mAh g1. On repeated

chargedischarge cycling (Fig. 4b), the discharge capacity of

S5 sample is fairly stable at 100 mAh g1, whereas the

capacity of S4 and S6 samples decreases gradually. The

capacity of S8 sample is stable at about 10 mAh g1. These

values are considerably lower than the theoretically expected

value of 456 mAh g1. The poor electrochemical of Li2MnO3

samples is because Mn is already in +4 oxidation state and

delithiation of it during charging process necessitates an increase in the oxidation state to +5, which is unlikely to exist

[5]. As the discharge capacity to the extent of 100 mAh g1 is

obtained from the S4, S5, and S6 samples, it is presumed that

these compounds are non-stoichiometric (Table 3) although

the XRD patterns (Fig. 1b) match with the standard pattern. It

is likely that the temperature of preparation influences stoichiometry of the compound. It was reported that discharge capacity of Li2MnO3 depended on the method of synthesis [25].

An initial capacity of about 70 mAh g1 was obtained when

Li2MnO3 was prepared from Mn3O4 at 900 C whereas less

than 20 mAh g1 was obtained when it was prepared from MnOOH precursor [26].

It is known that Li2MnO3 can be converted into electrochemically active phase by treatment in acid [5]. By treatment

in acid, the Li2MnO3 undergoes a partial dissolution of Li2O

thereby facilitating the insertion of Li+ ion into the resulting

sample during discharge. Thus, the sample gains electrochemical activity. As the quantity of removable Li2O depends on

duration of acid treatment, it was attempted to activate the

mesoporous Li2MnO3 samples by treatment in 4 M H2SO4

solution for different durations. The S5 and S8 samples were

treated in 4 M H2SO4 for a few hours, and then tested for

electrochemical activity after washing and drying. It was

found that both the samples delivered higher discharge capacity than the as-prepared samples, but the S5 sample delivered

higher capacity than the S8 sample after acid treatment.

Hence, detailed investigations were carried out with S5 sample of Li2MnO3. Sample S5 was subjected to treatment in 4 M

H2SO4 for different durations. Samples of S5, which were

treated for 2, 6, 12, and 24 h are hereafter referred to as

S5A2, S5A6, S5A12, and S5A24, respectively. The

thermogravimetry data S5A6 sample (Fig. 1a, curve iii) suggests a mass loss of 10 wt% at about 170 C. It is thus inferred

that the sample gains protons or H2O to the extent of about

10 wt%. There is a gradual mass loss between 170 and 800 C.

The sample retains about 75 % of its initial mass at 800 C.

Powder XRD pattern of S5A6 sample is shown in Fig. 5a.

There are some changes observed in the XRD pattern (Fig. 5a)

in comparison with the patterns of as-prepared samples

(Fig. 1b). The (001) reflection exhibits a split, the superlattice

structure is slightly altered at 2 =23, a new peak is developed next to (130) reflection and the (131) peak is diminished

(Fig. 5a). Nevertheless, the unit cell parameters of S5A6

sample calculated on the basis of Li2MnO3 structure are listed

in Table 1. There is a marginal increase in the values of a, b,

, and unit cell volume. Significant changes are not observed

in morphology (Fig. 5b) when compared with the data of the

as-prepared S5 sample (Fig. 2). However, marked changes are

observed in N2 adsorption/desorption isotherms and BJH

porosity curves (Fig. 6). BET surface area measured from

adsorption isotherms are significantly greater than the values

measured for the as-prepared sample (Table 2). The loop

between adsorption and desorption isotherms (Fig. 6a) is

J Solid State Electrochem

a

120

Quantity of N2 adsorbed / cm g

-1

140

100

80

60

40

(iv)

(iii)

(ii)

20

(i)

0

0.0

0.2

0.4

0.6

0.8

1.0

Relative pressure (p/p )

b

0.03

0.02

(ii)

-1

dVol/dDia / cm g nm

-1

(i)

0.01

(iii)

(iv)

0.00

10

12

14

Pore diameter / nm

Fig. 6 a Nitrogen adsorption/desorption isotherms and b BJH curves of

samples S5A2 (i), S5A6 (ii), S5A12 (iii), and S5A24 (iv). In a, curves

(ii), (iii), and (iv) are, respectively, vertically shifted by 5, 10, and 15 units

of y-axis scale relative to the position of curve (i)

wider in relation to the data of the as-prepared samples

(Fig. 3). The quantity of N2 adsorbed by the acid-treated

samples at p/p 0 =0.99 is about 120 cm3 g1 (Fig. 6a), which

is three times greater than the corresponding values for the asprepared samples (Fig. 3). Pore diameter decreases to a narrow

range at about 4 and pore volume is also greater (Fig. 6b)

than the as-prepared samples (Fig. 3). The increased surface

area and pore volume are thus attributed to the acid treatment

of Li2MnO3, which is already mesoporous before subjecting

to the acid treatment. The chemical analysis of S5A6

sample (Table 3) indicates a decrease in the Li content

and also in C and O contents. The quantity of H has increased

due to acid treatment, which is also reflected in TGA data

(Fig. 1a, curve iii).

The electrochemical results of acid-treated samples of

Li2MnO3 are presented in Fig. 7. Cyclic voltammogram of

S5A6 sample (Fig. 7a) shows an oxidation current peak at

3.20 V and a reduction current peak at 2.80 V. Thus, the peak

potential separation is about 0.40 V, which is an indication of

an irreversible nature of electrode process. In addition to the

major oxidation current peak observed at 3.20 V, there

is a minor oxidation peak at 4.20 V. Thus, the cyclic

voltammogram indicates that the inactive phase of the asprepared Li2MnO3 is converted into electrochemically active

phase on treating in 4 M H2SO4 for a few hours, although the

peak potential separation is 0.40 V. The chargedischarge

curves (Fig. 7b) contain potential plateaus at 3.20 and

2.80 V for charge and discharge process, respectively. The

discharge capacity calculated from Fig. 7b is 196 mAh g1 for

sample S5A6. This value is significantly greater than the value

obtained from the as-prepared sample (Fig. 4b). The variations

of discharge capacity of acid-treated samples on repeated

cycling at a specific current of 30 mA g1 are shown in

Fig. 7c. The discharge capacity values of samples S5A2,

S5A6, S5A12, and S5A24 in the first cycle are 179, 196,

183, and 182 mAh g1, respectively, and the corresponding

values in the tenth cycle are 135, 146, 161, and 110 mAh g1.

The coulombic chargedischarge efficiency throughout the

cycle-life test is greater than 95 % (Fig. 7c curve v, typically

for the sample S5A6). After mild acid treatment, thus,

Li2MnO3 samples gain electrochemical activity, but the cycling stability is poor. A gradual change in crystallographic

structure is perhaps responsible for the cycling instability.

As thermogravimetry of the acid-treated sample (S5A6)

indicated the presence of impurities which were removed at

170 C (Fig. 1a, curve iii), attempts were made to heat this

sample and to examine the electrochemical properties. Samples of S5A6 were heated for 4 h at 300 and 500 C, and tested

for chargedischarge capacity. The sample heated at 300 C

provided greater discharge capacity than the sample heated at

500 C. Therefore samples of S5A2, S5A6, S5A12, and

S5A24 were heated at 300 C for 4 h. The resulting samples

are hereafter referred as S5A2H3, S5A6H3, S5A12H3, and

S5A24H3, respectively. The thermogravimetry (Fig. 1a, curve

iv) of sample S5A6H3 indicates that the sample is stable up to

800 C and the impurities present in sample S5A6 were

removed by heating at 300 C for 4 h.

Powder XRD pattern of the S5A6H3 sample, typically, is

shown in Fig. 8a. The patterns of the other heated samples are

similar to this pattern. The patterns of these samples are

different from the patterns of the as-prepared samples

(Fig. 1b). Yu and Yanagida reported detailed structural analysis of Li2MnO3 and related compounds, recently [24]. During

acid treatment, there was a gradual reduction of O3 peaks

(ABCABC stacking) and an increase in the P3 peaks

(AABBCC stacking) as supported by a shift of the main

XRD peak from 2 =18.7 to 19.15, and also by the emergence of a peak at 2 =38.3 [24]. On the basis of XRD

patterns, Raman spectra, and TGA results, it was concluded

that after acid treatment and heating, Li2MnO3 transforms into

spinel Li4Mn5O12 phase [24]. The SEM image (Fig. 8b)

J Solid State Electrochem

a

-100

-2

-50

Current / mA cm

Fig. 7 a Cyclic voltammogram

of sample S5A6 at a sweep rate of

0.05 mV s1, b chargedischarge

curves of sample S5A6 at a

specific current of 30 mA g1, and

c variation of specific discharge

capacity of samples S5A2 (i),

S5A6 (ii), S5A612 (iii), and

S5A24 (iv). Variation of

coulombic efficiency is shown as

curve (v), typically, for sample

S5A6

0

50

100

150

1.5

2.0

4.5

2.5

3.0

3.5

+

Potential / V vs Li/Li

4.0

4.5

st

1 ch

2

Potential / V Vs Li/Li+

4.0

nd

ch

3.5

3.0

2.5

2.0

2

1.5

0

50

100

nd

dis

150

st

1 dis

200

Specific discharge capacity / mAh g

-1

100

200

80

(iii)

150

(ii)

(i)

(iv)

100

40

50

60

Coulombic efficiency / %

Specific discharge capacity / mAh g

-1

(v)

20

shows that the morphology of S5A6H3 sample is nearly the

same as S5 and S5A6 samples (Fig. 2 and 5b). Nevertheless,

significant changes are observed in N2 adsorption/desorption

5

6

7

Cycle number

10

0

11

isotherms and BJH curves (Fig. 9). The gap between the

adsorption and desorption isotherms has increased (Fig. 9a).

The quantity of N2 adsorbed at p /p 0 =0.99 by S5A6H3

J Solid State Electrochem

Fig. 8 a Powder XRD pattern

and b SEM image of sample

S5A6H3

Intensity / a.u

10

20

30

40

50

60

70

80

2 / degree

150

Quantity of N2 adsorbed / cm g

3 -1

100

(iv)

50

(iii)

(ii)

(i)

0

0.0

0.2

0.4

0.6

0.8

1.0

Relative pressure (p/p )

b

0.014

-1

-1

dVol/dDia / cm g nm

sample is about 160 cm3 g1, which is greater than the volume

(120 cm3 g1) adsorbed by S5A6 sample (Fig. 6a) and significantly greater than the volume (40 cm3 g1) adsorbed by the

as-prepared S5 sample (Fig. 3a). Furthermore, the presence of

two kinds of pores is observed in BJH curves (Fig. 9b). Pores

of narrow size distribution around 4 nm are present on all

samples S5A2H3S5A24H3, similar to the acid-treated samples (Fig. 6b). Additionally, another pore with broad distribution around 510 nm has evolved. Initiation of the secondary

pore is clearly visible for S5A2H3 sample (Fig. 9b, curve i).

Formation of the secondary pore around 7 nm is clearly

observed for S5A6H3 sample (Fig. 9, curve ii). For the sample

S5A12H3, the secondary pore diameter decreases to 6 nm

with decreased pore volume (Fig. 9b, curve iii) and it decreases further for the S5A24H3 sample (Fig. 9b, curve iv).

Dual porosity is beneficial for electrode materials because the

pores allow the electrolytes to creep and tolerate volume

expansion/contraction during chargedischarge cycling.

Thus, both the time of acid treatment and heating influence

to the formation of dual porosity. The chemical analysis of

S5A6H3 sample (Table 3) indicates a decrease in H and C

content in relation to S5A6 sample. However, the Mn and Li

contents in the samples are nearly the same.

Electrochemistry results are presented in Fig. 10. Cyclic

voltammogram of S5A6H6 sample recorded at a sweep rate of

0.05 mV s1 indicates sharp reductionoxidation pair of peaks

in the potential region 2.803.20 V (Fig. 10a). In addition to

this pair of peaks, there is another pair of small broad peaks

appearing at 4.204.50 V region. This is perhaps due to the

presence of some quantity of LiMn2O4 phase in the sample.

The discharge profiles (Fig. 10b) of S5A6H3 sample provides

a minor potential plateau at about 4.0 V and a major constant

0.007

(ii)

(iii)

(iv)

(i)

0.000

10

12

14

16

18

20

Pore diameter / nm

Fig. 9 a Nitrogen adsorption/desorption isotherm and b BJH curves of

samples S5A2H3 (i), S5A6H3 (ii), S5A12H3 (iii), and S5A24H3 (iv). In

a, curves (ii), (iii), and (iv) are, respectively, vertically shifted by 5, 10,

and 15 units of y-axis scale relative to the position of curve (i)

J Solid State Electrochem

Current density / mA cm

-2

600

400

200

-200

-400

1.5

2.0

2.5

3.0

3.5

4.0

4.5

Potential / V vs Li/Li+

4.5

st

1 ch

nd

ch

Potential / V Vs Li/Li

4.0

3.5

3.0

2.5

2.0

2

1.5

0

50

100

dis

st

1 dis

200

250

nd

150

Specific discharge capacity / mAh g

-1

300

100

90

-1

200

150

80

250

200

70

(i)

(iii)

150

60

100

(ii)

(iv)

50

50

0

0

10

11

40

Cycle number

100

30

20

50

10

0

10

15

20

25

30

Cycle number

35

40

45

50

Coulombic efficiency / %

300

250

Specific discharge capacity / mAh g

c

Specific discharge capacity / mAh g-1

Fig. 10 a Cyclic voltammogram

of at a sweep rate of 0.05 mV s1,

b chargedischarge curves at a

specific current of 30 mA g1, and

c cycle-life data of sample

S5A6H3. Cycle-life data of

S5A2H3 (i), S5A6H3 (ii),

S5A12H3 (iii), and S5A24H3

(iv) samples for 20 cycles at a

specific current of 30 mA g1 are

shown as inset in c

J Solid State Electrochem

sample provides about 150 mAh g1 at a specific discharge

current of 1.25 A g1. Further work is in progress on dualporosity lithium-rich electrochemically stable composites of

Li2MnO3.

Specific discharge capacity / mAh g

-1

300

250

200

Acknowledgments The authors thank Renault Nissan Technology and

Business Centre India Pvt. Ltd. for financial support, and Dr. Subramani

and Dr. Arockia Vimal for helpful discussions. The authors also thank Dr.

C. Shivakumara for his help in analysis of XRD patterns.

150

100

28

57

84

249

112

381

753

518

1250

1121

50

References

0

5,0

5,0

5,0

5,0

5,0

5,0

5,0

5,0

5,0

Cycle number

Fig. 11 Rate capability of sample S5A6H6. Current density in milliampere per gram is indicated. For each current density, a fresh cell was used

potential plateau at 2.80 V, which are followed by a gradual

potential fall from 2.80 to 1.50 V. The major charge and

discharge plateaus observed in 2.803.00 V region agree with

the results reported by Yu and Yanagida [24] for acid-treated

and heated samples. The discharge capacity obtained from the

first cycle is about 240 mAh g1. However, there is a rapid

capacity decrease on repeated chargedischarge cycling

(Fig. 10c). Similar results are obtained from all heated samples

(Fig. 10c inset).

The results of rate capability study are presented in Fig. 11.

For each current density, a fresh cell was employed and it was

subjected to five chargedischarge cycles. At each current,

there is a decrease in capacity similar to the data presented in

Fig. 10c. There is a gradual capacity decrease by increasing

the specific current. It is interesting to observe that about

150 mAh g1 of initial capacity is delivered as a specific

current as high as 1.25 A g1. This high rate capacity is

attributed to the porous nature of the samples.

Conclusions

Lithium-rich manganese oxide (Li2MnO3) was prepared by

reverse microemulsion method employing P123 as a soft

template and studied as a positive electrode material. The asprepared sample possessed good crystalline structure with a

broadly distributed mesoporosity with poor electrochemical

activity. However, the sample gained surface area with narrowly distributed mesoporosity and also electrochemical activity after treating in 4 M H2SO4. A discharge capacity of

about 160 mAh g1 was obtained. When the acid-treated

sample was heated at 300 C, the resulting sample with a large

surface area and dual porosity provided a discharge capacity

of 240 mAh g1. The rate capability study suggested that the

1. Winter M, Brodd RJ (2004) What are batteries, fuel cells, and

supercapacitors. Chem Rev 104:42454269

2. Matsuki K, Ozawa K (2009) Lithium ion batteries. Wiley, Tokyo

3. Wittingham MS (2004) Lithium batteries and cathode materials.

Chem Rev 104:42714301

4. Thackeray MM (1997) Manganese oxides for lithium batteries. Prog

Solid State Chem 25:171

5. Rossouw MH, Thackeray MM (1991) Lithium manganese oxides

from Li2MnO3 for rechargeable lithium battery applications. Mater

Res Bull 26:463473

6. Kalyani P, Chitra S, Mohan T, Gopukumar S (1999) Lithium metal

rechargeable cells using Li2MnO3 as the positive electrode. J Power

Sources 80:103106

7. Johnson CS, Korte SD, Vaughey JT, Thackeray MM, Bobinger TE,

Shao YH, Hackney SA (1999) Structural and electrochemical analysis of layered compounds from Li2MnO3. J Power Sources 81

82:491495

8. Tang W, Kanoh H, Wang KOY (2000) Preparation of a new type of

manganese oxide by selective lithium extraction from monoclinic

Li2MnO3 for lithium rechargeable batteries. J Mater Sci Lett

19:13611363

9. Robertson AD, Bruce PG (2002) The origin of electrochemical

activity in Li2MnO3. Chem Comm 23:27902791

10. Armstrong AR, Robertson AD, Bruce PG (2005) Overcharging

manganese oxides: extracting lithium beyond Mn4+. J Power Sources

146:275280

11. Pasero D, McLaren V, De Souza S, West AR (2005) Oxygen

nonstoichiometry in Li2MnO3: an alternative explanation for its

anomalous electrochemical activity. Chem Mater 17:345348

12. Park SH, Sato Y, Kim JK, Lee YS (2007) Powder property and

electrochemical characterization of Li2MnO3 material. Mater Chem

Phys 102:225

13. Yu DYW, Yanagida K, Kato Y, Nakamura H (2009) Electrochemical

activities in Li2MnO3. J Electrochem Soc 156:A417A424

14. Lim J, Moon J, Gim J, Kim S, Kim K, Song J, Kang J, Im WB, Kim J

(2012) Fully activated Li2MnO3 nanoparticles by oxidation reaction.

J Mater Chem 22:1177211777

15. Yang XY, Li Y, Lemaire A, Yu BJG, Su L (2009) Hierarchically

structured functional materials: synthesis strategies for multimodal

porous networks. Pure Appl Chem 81:22652307

16. Boutonnet M, Kizling J, Marie PSG (1982) The preparation of

monodisperse colloidal metal particles from microemulsions. Colloids and Surfaces 5:209

17. Kleitz F, Choi SH, Ryoo R (2003) Cubic Ia3d large mesoporous

silica: synthesis and replication to platinum nanowires, carbon

nanorods and carbon nanotubes. Chem Comm 17:21362137

18. Sinha NN, Munichandraiah N (2009) Synthesis and characterization

of carbon-coated LiNi1/3Co1/3Mn1/3O2 in a single step by an inverse

microemulsion route. ACS Appl Mater Interface 1:12411249

J Solid State Electrochem

19. Sinha NN, Shivakumara C, Munichandraiah N (2010) High rate

capability of a dual-porosity LiFePO4/C composite. ACS Appl Mater

Interface 2:20312038

20. Sinha NN, Munichandraiah N (2010) High rate capability of porous

LiNi1/3Co1/3Mn1/3O2 synthesized by polymer template route. J

Electrochem Soc 157:A647A653

21. Strobel P, Andron BL (1988) Crystallographic and magnetic structure

of Li2MnO3. J Solid State Chem 75:9098

22. Jain G, Yang J, Balasubramanian M, Xu JJ (2005) Synthesis,

electrochemistry, and structural studies of lithium intercalation

of a nanocrystalline Li2MnO3-like compound. Chem Mater 17:

38503860

23. Burton AW, Ong K, Rea T, Chan IY (2009) On the estimation of

average crystallite size of zeolites from the Scherrer equation: a critical

evaluation of its application to zeolites with one-dimensional pore

systems. Microporous Mesoporous Mater 117:7590

24. Yu DYW, Yanagida K (2011) Structural analysis of Li2MnO3 and

related LiMnO materials. J Electrochem Soc 158:A1015A1022

25. Park B, Kim YJ and Cho J (2004) in: Lithium batteries: Science and

Technology, G. A. Nazri, G. Pistoia. Kluwer, Boston

26. Park SH, Ahn HS, Park GJ, Kim J, Lee YS (2008) Cycle

mechanism and electrochemical properties of lithium manganese

oxide prepared using different Mn sources. Mater Chem Phys

112:696701

You might also like

- A Comprehensive Review of Li4Ti5O12-Based Electrodes For Lithium-IonDocument71 pagesA Comprehensive Review of Li4Ti5O12-Based Electrodes For Lithium-IonSubhashini VedalaNo ratings yet

- THow To IncreaseDocument31 pagesTHow To IncreaseSubhashini VedalaNo ratings yet

- Battery Market Development: Materials Requirements and TrendsDocument39 pagesBattery Market Development: Materials Requirements and TrendsSubhashini VedalaNo ratings yet

- Power Supply GlossaryDocument25 pagesPower Supply GlossarySubhashini Vedala100% (1)

- ZEUS Glossary of Battery Terms.03.26.2015Document4 pagesZEUS Glossary of Battery Terms.03.26.2015Subhashini VedalaNo ratings yet

- Three-Dimensional Hierarchical Co3O4CuODocument8 pagesThree-Dimensional Hierarchical Co3O4CuOSubhashini VedalaNo ratings yet

- Daniel Abraham PDFDocument2 pagesDaniel Abraham PDFSubhashini VedalaNo ratings yet

- Hydrothermal Synthesis of ZnO NanoparticlesDocument4 pagesHydrothermal Synthesis of ZnO NanoparticlesSubhashini VedalaNo ratings yet

- Oxygen Sensors Operation & Testing PPTDocument76 pagesOxygen Sensors Operation & Testing PPTAnkit Nayak100% (1)

- Diagnosis of Power Quality DisturbancesDocument6 pagesDiagnosis of Power Quality DisturbancesSubhashini VedalaNo ratings yet

- Wavelet Based Neural Networks For DetectionDocument1 pageWavelet Based Neural Networks For DetectionSubhashini VedalaNo ratings yet

- Polymers - Bioactive Composites Obtained From Bioactive Glass Particles Into Poly (Methyl Methacrylate)Document10 pagesPolymers - Bioactive Composites Obtained From Bioactive Glass Particles Into Poly (Methyl Methacrylate)Subhashini VedalaNo ratings yet

- Hung 06Document3 pagesHung 06Subhashini VedalaNo ratings yet

- Batteries 2012 Avicenne Energy Batteries Market Towards 20251Document34 pagesBatteries 2012 Avicenne Energy Batteries Market Towards 20251Jillam ParidaNo ratings yet

- A Fast Cryptography Pipelined Hardware Developed 2011Document6 pagesA Fast Cryptography Pipelined Hardware Developed 2011Subhashini VedalaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Formulation and evaluation of floating microspheres of ranolazineDocument8 pagesFormulation and evaluation of floating microspheres of ranolazineIkhsan SoesiloNo ratings yet

- 2021 January (1C) QPDocument36 pages2021 January (1C) QPKevin MattNo ratings yet

- Quiz 22: Multiple-Choice Questions On Batteries and Alternative Sources of EnergyDocument2 pagesQuiz 22: Multiple-Choice Questions On Batteries and Alternative Sources of EnergyRavi Kumar VermaNo ratings yet

- Syllabus of Chemistry H NEP 96 105 1Document10 pagesSyllabus of Chemistry H NEP 96 105 1Vijay Kumar VishvakarmaNo ratings yet

- Better Aluminium Mirrors by Integrating Plasma Pretreatment, Sputtering, and Plasma Polymerization For Large-Scale Car Headlight Production KDocument10 pagesBetter Aluminium Mirrors by Integrating Plasma Pretreatment, Sputtering, and Plasma Polymerization For Large-Scale Car Headlight Production Kani putkaradzeNo ratings yet

- TrimyristinDocument3 pagesTrimyristindinna_dinunNo ratings yet

- CM5241 Literature Review Project TopicsDocument3 pagesCM5241 Literature Review Project TopicsCheryldine LimNo ratings yet

- Design of Shell and Tube Heat Exchanger PDFDocument55 pagesDesign of Shell and Tube Heat Exchanger PDFShawez sayyed100% (1)

- CHE202.2 SPRING 2023 Course OutlineDocument11 pagesCHE202.2 SPRING 2023 Course OutlineZahra NasreenNo ratings yet

- Chapter 1: The Quantum Theory of The Submicroscopic WorldDocument28 pagesChapter 1: The Quantum Theory of The Submicroscopic WorldHun Qiu LimNo ratings yet

- Electro-Chemical Reaction Engineering: Electrode ReactionsDocument28 pagesElectro-Chemical Reaction Engineering: Electrode ReactionsJyothsna AnnepuNo ratings yet

- Daily Lesson Log TemplateDocument64 pagesDaily Lesson Log TemplateArlene ChavezNo ratings yet

- Starting With Zero: Create Your Own Topographic Map ProjectDocument4 pagesStarting With Zero: Create Your Own Topographic Map ProjectVinujah SukumaranNo ratings yet

- 2.0 Electric FieldsDocument4 pages2.0 Electric FieldsEdAnNo ratings yet

- Arlamol PS15E - 0314 PCDS256v2 PDFDocument2 pagesArlamol PS15E - 0314 PCDS256v2 PDFsimmiNo ratings yet

- Module-3.2 Sieve Tray Design 8Document56 pagesModule-3.2 Sieve Tray Design 8Harsh Garg 24601No ratings yet

- Distillation Problem 6Document3 pagesDistillation Problem 6Efraim AbuelNo ratings yet

- Brchembase LRDocument4 pagesBrchembase LRRavindra PawarNo ratings yet

- 06-11-2021 - SR Iit Co Sc-n120 - Jee Main Model - ptm-1 - QP FinalDocument14 pages06-11-2021 - SR Iit Co Sc-n120 - Jee Main Model - ptm-1 - QP FinalDeeip DNo ratings yet

- 40 International Chemistry Olympiad: Preparatory ProblemsDocument104 pages40 International Chemistry Olympiad: Preparatory ProblemsLê Hoàng MinhNo ratings yet

- Freeze-Drying Process Development For Protein PharmaceuticalsDocument23 pagesFreeze-Drying Process Development For Protein Pharmaceuticalsboddarambabu100% (1)

- D ILIPDocument30 pagesD ILIPAnonymous YloEbh0% (1)

- EE 224 - EE 314 - Lecture (Revised)Document78 pagesEE 224 - EE 314 - Lecture (Revised)rjaynipas031No ratings yet

- Chapter 16 Halogen DerivativesDocument11 pagesChapter 16 Halogen DerivativesSabina SabaNo ratings yet

- Nuclear Engineering and TechnologyDocument8 pagesNuclear Engineering and TechnologyBharat MahajanNo ratings yet

- Mas and e PDFDocument5 pagesMas and e PDFtulasi saladiNo ratings yet

- Design Basis Report-Nh208Document19 pagesDesign Basis Report-Nh208Atanu AdhiakryNo ratings yet

- Sri Vijay Vidyalaya College of Arts and Science, Bargur Book ListDocument4 pagesSri Vijay Vidyalaya College of Arts and Science, Bargur Book ListVelu SamyNo ratings yet

- CH 12 Solutions SGDocument3 pagesCH 12 Solutions SGjason bourne0% (1)

- Trixene Bi 7960 - TDS - enDocument2 pagesTrixene Bi 7960 - TDS - enEthling PortilloNo ratings yet