Professional Documents

Culture Documents

Visual Inspection Procedure for Piping Welds

Uploaded by

Pand AemonaEonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Visual Inspection Procedure for Piping Welds

Uploaded by

Pand AemonaEonCopyright:

Available Formats

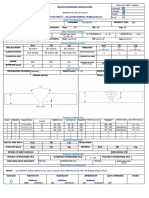

COSNTRUCTORA HOSTOTIPAQUILLO, S.A. DE C.V.

QUALITY CONTROL DEPARTMENT

QUALITY INSPECTION PROCEDURE (QIP)

VISUAL EXAMINATION PROCEDURE

VISUAL EXAMINATION PROCEDURE

CHANGES AND/OR MODIFICATIONS

REVISION

MODIFIED

PAGES

DESCRIPTION OF CHANGE

DATE

ILLUMINATION REQUIREMENTS

MAY 13/11

ALL

EDITORIAL CHANGES, NEW FORM VT-01 AND QCM

APPROVAL

FEB 16/14

NAME

SIGN/DATE

PREPARED AND

APPROVED BY

QCM

AUTHORIZED INSPECTOR

ACCEPTED BY

Procedure No.

HOSTO-QIP-01

POSITION

Revisin

2

Page 1 of 6

COSNTRUCTORA HOSTOTIPAQUILLO, S.A. DE C.V.

QUALITY CONTROL DEPARTMENT

QUALITY INSPECTION PROCEDURE (QIP)

VISUAL EXAMINATION PROCEDURE

INDEX

Procedure No.

HOSTO-QIP-01

1.

SCOPE

2.

REFERENCE CODES

3.

DIRECT VISUAL EXAMINATION

4.

REMOTE VISUAL EXAMINATION

5.

REQUIERED ILLUMINATION

6.

SURFACE PREPARATION

7.

WELD INSPECTION

8.

ACCEPTANCE CRITERIA

9.

REPORTS

10.

PERSONNEL QUALIFICATION & CERTIFICATION

11.

RECERTIFICATION OF PERSONNEL

12.

CERTIFICATION OF PROCEDURE

13.

ATTACHMENTS

Revisin

2

Page 2 of 6

COSNTRUCTORA HOSTOTIPAQUILLO, S.A. DE C.V.

QUALITY CONTROL DEPARTMENT

QUALITY INSPECTION PROCEDURE (QIP)

VISUAL EXAMINATION PROCEDURE

1.0 SCOPE

This document prescribes the minimum requirements for all visual inspection for Power Piping and

Parts.

2.0 REFERENCE CODES

2.1 ASME B31.1

2.2 ASME CODE SECT. V

3.0 DIRECT VISUAL EXAMINATION

Direct visual examination may be made when are accesses to the surface to be examined, and at an

angle not less than 30 deg to the surface to be examined. Mirrors may be used to improve the angle of

vision, and aids such as a magnifying lens may be used to assist examinations.

4.0 REMOTE VISUAL EXAMINATION

Remote techniques may be employed when difficult access makes direct examination impractical.

Remote visual examinations may be performed by use of mirrors, telescopes, borescopes, fiber optics,

cameras, or any other suitable instruments. When remote systems are necessary, the apparatus shall

have a demonstrated resolution capability at least equivalent to that obtained by direct visual

examination.

5.0 REQUIRED ILLUMINATION

Pipe weld component subjected to the examination may be illuminated any means. The minimum light

intensity at the examination surface /site shall be 100 footcandles (1000 lux).

6.0 SURFACE PREPARATION

Surfaces to be examined shall be in as welded condition provided the inherent surface condition will

not interferes whit the detection of those discontinuities intended to be revealed by the visual

examination. If surface conditions are not conducive to the proper performance of the examinations the

Procedure No.

HOSTO-QIP-01

Revisin

2

Page 3 of 6

COSNTRUCTORA HOSTOTIPAQUILLO, S.A. DE C.V.

QUALITY CONTROL DEPARTMENT

QUALITY INSPECTION PROCEDURE (QIP)

VISUAL EXAMINATION PROCEDURE

appropriate steps should be taken to attain a surface condition that will facilitate a proper visual

examination.

7.0 WELD INSPECTION

All welds shall be visually inspected for compliance whit the applicable welding procedure and

drawing specifications, and Code requirements.

Minimum visual inspection of welds shall be including the following items:

7.a)

Size of legs and throat of fillet welds.

7.b)

Contour and finish of outside surface of welds.

7.c)

Contour and surface condition of inside surface where possible

7.d)

Undercutting and overlap.

7.e)

Evidence of miss-handling.

7.f)

Excessive center punching or other impression marking.

7.g)

Excessive grinding.

7.h)

Cracking and porosity.

During evaluation, a light with two batteries AA size shall be used at distance of 12.

8.0 ACCEPTANCE CRITERIA.

The acceptance criteria will be as required by ASME B31.1. The following indications are

unacceptable:

8.a)

Cracks -external surface-;

8.b)

Undercut on surface which is greater than 1/32 (1mm) deep;

8.c)

Weld reinforcement greater than the specified on Table 127.4.2 on ASME B31.1;

8.d)

Lack of fusion on surface;

Procedure No.

HOSTO-QIP-01

Revisin

2

Page 4 of 6

COSNTRUCTORA HOSTOTIPAQUILLO, S.A. DE C.V.

QUALITY CONTROL DEPARTMENT

QUALITY INSPECTION PROCEDURE (QIP)

VISUAL EXAMINATION PROCEDURE

8.e)

Incomplete penetration (applies only when inside is readily accessible);

8.f)

Any other linear indication greater than 3/16 (5mm) long;

8.g)

Surface porosity with rounded indications having dimensions greater than 3/16 (5mm)

or four or more rounded indications separated by 1/16 (2mm) or less edge to edge in

any direction. Rounded indications are indications which are circular or elliptical with

their length less than three times their width.

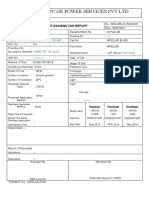

9.0 REPORTS.

9.1 Verification of this examination shall be documented on the ICL (Examination, Test and Inspection

Check List).

9.2 If required, an additional report shall be generated containing the following information as a

minimum:

9.2 a)

The date of the examination;

9.2 b)

Procedure identification and revision used;

9.2 c)

Technique used;

9.2 d)

Results of the examination;

9.2 e)

Examination personnel identity, and, when required by the referencing Code Section,

qualification level;

9.2 f)

Identification of the part or component examined;

9.2 g)

Illumination source;

9.2 h)

Other instruments and equipment;

9.2 i)

Results of the examination certified by the examiner.

Procedure No.

HOSTO-QIP-01

Revisin

2

Page 5 of 6

COSNTRUCTORA HOSTOTIPAQUILLO, S.A. DE C.V.

QUALITY CONTROL DEPARTMENT

QUALITY INSPECTION PROCEDURE (QIP)

VISUAL EXAMINATION PROCEDURE

10.0 PERSONNEL QUALIFICATION & CERTIFICATION.

10.1

Personnel who perform visual examinations shall be qualified and certified to the following

minimum requirements:

10.1.1 All inspectors shall be required to pass a vision test. This vision test shall be repeated annually.

Any corrective aids used during this test shall natural or corrected near distance acuity such that

they are capable of reading standard Jaegers J-1 test or equivalent for near vision.

10.1.2 8 hours of instruction in the fundamentals of visual examination and this procedure.

10.1.3 8 hours on the job training.

10.1.4

Upon completion of the instructional time and satisfactory performance during on the job

training period, the trainee must successfully complete a written examination and perform a

proper demonstration of the procedure designed to verify the trainee is capable of executing

the required and interpreting the results.

11.0 RECERTIFICATION OF PERSONNEL

Personnel who have not performed visual examinations as described in the written procedure for a

period of 1 year or more must be recertified by successfully meeting the requirements of the preceding

paragraph 10.1.3 and 10.1.4.

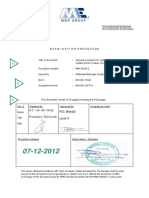

12.0 CERTIFICATION OF PROCEDURE

Hereby certify that this procedure has meat all the requirements of ASME Code B31.1.

13.0 ATTACHMENTS

FORM VT-01

Procedure No.

HOSTO-QIP-01

Revisin

2

Page 6 of 6

You might also like

- Liquid Dye Penetrant Test Inspection Sample ProcedureDocument8 pagesLiquid Dye Penetrant Test Inspection Sample Procedureم.ذكى فضل ذكىNo ratings yet

- Visual Examination ProcedureDocument10 pagesVisual Examination ProceduresantanuriniNo ratings yet

- Visual Examination ProcedureDocument10 pagesVisual Examination ProcedureBasar100% (2)

- Visual Examination ProcedureDocument10 pagesVisual Examination Proceduresantanurini50% (2)

- VISUAL TESTING PROCEDURE FOR WELDDocument4 pagesVISUAL TESTING PROCEDURE FOR WELDCoralSun CravensickNo ratings yet

- VT Report UpDocument1 pageVT Report UpRakesh Kumar MundaNo ratings yet

- GE Energy Management Visual Inspection RequirementsDocument10 pagesGE Energy Management Visual Inspection RequirementsKarthik P MuraliNo ratings yet

- ASNT Level-II Visual & Optical Testing ProcedureDocument5 pagesASNT Level-II Visual & Optical Testing ProcedureFadil WimalaNo ratings yet

- Visual Testing ProcedureDocument4 pagesVisual Testing ProcedureAnirban Sen Sharma100% (2)

- MM 88100 E r3 - ISO 17637 ISO 5817 - Algemeen - VTDocument27 pagesMM 88100 E r3 - ISO 17637 ISO 5817 - Algemeen - VTgueridi100% (2)

- WELDING INSPECTOR AWARENESS TRAINING ENG Rev00 31.12.2019Document65 pagesWELDING INSPECTOR AWARENESS TRAINING ENG Rev00 31.12.2019Ethem Güngör100% (1)

- Written PracticeDocument27 pagesWritten PracticeSefa KasapogluNo ratings yet

- Visual Examination Procedure: 1. PurposeDocument4 pagesVisual Examination Procedure: 1. PurposeElvin MenlibaiNo ratings yet

- VT Procedure: 1 - PurposeDocument4 pagesVT Procedure: 1 - PurposeElvin Menlibai100% (1)

- 4260Document10 pages4260Lipika GayenNo ratings yet

- Magnetic Particle Examination of WeldsDocument4 pagesMagnetic Particle Examination of WeldsshruthiNo ratings yet

- LPT Written ProcedureDocument8 pagesLPT Written ProcedureManikantaSumanthNo ratings yet

- Weld Visual ExaminationDocument11 pagesWeld Visual ExaminationAnonymous hBBam1n100% (3)

- Weld Joint Repaire Procedure - 08.04.14Document6 pagesWeld Joint Repaire Procedure - 08.04.14Raj AryanNo ratings yet

- Holiday Detection ProcedureDocument4 pagesHoliday Detection Proceduregst ajah100% (1)

- WPS ISO 15614-1 WeldNote MetricDocument1 pageWPS ISO 15614-1 WeldNote MetricVirgil SorcaruNo ratings yet

- LPT As Per Asme & IsoDocument2 pagesLPT As Per Asme & IsosbmmlaNo ratings yet

- Liquid Penetrant Test Record: Examinaion DetailsDocument1 pageLiquid Penetrant Test Record: Examinaion DetailschandraNo ratings yet

- BIX - RT ProcedureDocument36 pagesBIX - RT ProcedureEduard Abastillas100% (1)

- Penetrant Testing (PT)Document11 pagesPenetrant Testing (PT)Maria Cristina DijmarescuNo ratings yet

- Weld Visual Report Rev.0Document1 pageWeld Visual Report Rev.0John TerryNo ratings yet

- BPV IX-16-3 QW-283 - ButteringDocument1 pageBPV IX-16-3 QW-283 - ButteringyutweldingNo ratings yet

- Guidance To Prepare Wps PQR For WeldingDocument1 pageGuidance To Prepare Wps PQR For WeldingHamid MansouriNo ratings yet

- UT Personnel Mockup ProcedureDocument19 pagesUT Personnel Mockup ProcedureIksan Adityo Mulyo100% (1)

- PCN NDT Training Facility in ChennaiDocument17 pagesPCN NDT Training Facility in ChennaiAMITNo ratings yet

- Long Seam Inspection ProcedureDocument4 pagesLong Seam Inspection ProcedureDeepak100% (1)

- SNIS UT 578 - Steel PlatesDocument14 pagesSNIS UT 578 - Steel PlatesShailesh DeshmukhNo ratings yet

- NTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportDocument2 pagesNTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportBalkishan DyavanapellyNo ratings yet

- Ultrasonic Weld Examination ProcedureDocument16 pagesUltrasonic Weld Examination ProcedureramalingamNo ratings yet

- VT Procedure 1Document1 pageVT Procedure 1Mahmoud Alwasif50% (2)

- 12 MT ProcedureDocument17 pages12 MT ProcedureThân KhaNo ratings yet

- JNK SOP for Weld Visual InspectionDocument17 pagesJNK SOP for Weld Visual InspectionAvishek GuptaNo ratings yet

- Examination Procedure: G.C. Van Der Stoep Procedure TechnicianDocument30 pagesExamination Procedure: G.C. Van Der Stoep Procedure TechnicianEdAlmNo ratings yet

- UT Procedure GuideDocument15 pagesUT Procedure GuideAmir Reza RashidfarokhiNo ratings yet

- Flange 10 & 12 InchDocument2 pagesFlange 10 & 12 InchreniNo ratings yet

- UT Report KRC DCUDocument3 pagesUT Report KRC DCUAlzaki AbdullahNo ratings yet

- DPTDocument12 pagesDPTAMIT SHAH100% (2)

- Written Practice ProcedureDocument20 pagesWritten Practice ProcedureSenthil Kumaran50% (2)

- P 11 CNDT JP41 Ut-Aws D1.1 Rev 07Document22 pagesP 11 CNDT JP41 Ut-Aws D1.1 Rev 07Vimal MenonNo ratings yet

- VT ReportDocument1 pageVT ReportBauyrzhanNo ratings yet

- Visible Penetrant Examination Using The Water-Washable ProcessDocument6 pagesVisible Penetrant Examination Using The Water-Washable ProcessERNESTO ENRIQUE FERNANDEZ BAPTISTANo ratings yet

- Dye Penetrant Inspection ProcedureDocument13 pagesDye Penetrant Inspection ProcedureHafidzManaf100% (1)

- Holiday Detector ProcedureDocument2 pagesHoliday Detector ProcedurenathgsurendraNo ratings yet

- PMI Just in Case: Measurement of Ferrite Content in Austenitic & Duplex SteelDocument7 pagesPMI Just in Case: Measurement of Ferrite Content in Austenitic & Duplex Steelmahi1437100% (1)

- PQC-07 Rev 2 Examinacion VisualDocument6 pagesPQC-07 Rev 2 Examinacion Visualjose alberto gamiñoNo ratings yet

- SOP QC-101 ASME B31.9 Shop and Field Inspection - Rev.1Document5 pagesSOP QC-101 ASME B31.9 Shop and Field Inspection - Rev.1iplaruffNo ratings yet

- Leak Test Proce.-TankDocument7 pagesLeak Test Proce.-Tankpraveen 0064No ratings yet

- API 510 VesselsDocument11 pagesAPI 510 Vesselsmoonstar_dmeNo ratings yet

- Irc SP 47 P 2Document12 pagesIrc SP 47 P 2RameshNo ratings yet

- Asme Section V 2010 VisualDocument3 pagesAsme Section V 2010 Visualmvrengarajan100% (1)

- En Visual Testing ProcedureDocument7 pagesEn Visual Testing ProcedureAdham AhmedNo ratings yet

- VisualProcedure - LouDocument8 pagesVisualProcedure - Loujoshrathburn19800% (1)

- DPT ProcedureDocument4 pagesDPT ProcedureRohit Attri100% (1)

- Criterios de Aceptacion y Rechazo Asme ViiiDocument4 pagesCriterios de Aceptacion y Rechazo Asme ViiiGAlberto VillaPerezNo ratings yet

- R9621Document3 pagesR9621Pand AemonaEonNo ratings yet

- Damage MechanismDocument2 pagesDamage MechanismPand AemonaEonNo ratings yet

- Cause of Welding CrackDocument20 pagesCause of Welding CrackPand AemonaEonNo ratings yet

- PRBIv2 Equipment Template - PIPING Rev 2 (00000002)Document144 pagesPRBIv2 Equipment Template - PIPING Rev 2 (00000002)Pand AemonaEonNo ratings yet

- A Complete Guide To Volume Price Analysi - A. CoullingDocument242 pagesA Complete Guide To Volume Price Analysi - A. CoullingGiundat Giun Dat97% (129)

- Scheme of Examination: Cylindrical Shell SA516 GR 60 SA516 GR 60 Elliptical HeadDocument1 pageScheme of Examination: Cylindrical Shell SA516 GR 60 SA516 GR 60 Elliptical HeadPand AemonaEonNo ratings yet

- Quality Plan Review and UpdatesDocument1 pageQuality Plan Review and UpdatesPand AemonaEonNo ratings yet

- TA Quality PlanDocument5 pagesTA Quality PlanPand AemonaEonNo ratings yet

- MOM Insulation 31jan21Document1 pageMOM Insulation 31jan21Pand AemonaEonNo ratings yet

- PipingLineList - 23 05 2019 083842Document54 pagesPipingLineList - 23 05 2019 083842Pand AemonaEonNo ratings yet

- Scheme of Examination: Shell & Head SA516 Gr. 70Document1 pageScheme of Examination: Shell & Head SA516 Gr. 70Pand AemonaEonNo ratings yet

- Scheme of Examination: Shell & Head SA516 Gr. 70Document1 pageScheme of Examination: Shell & Head SA516 Gr. 70Pand AemonaEonNo ratings yet

- Scheme of Examination: Shell & Head SA516 GR 60Document1 pageScheme of Examination: Shell & Head SA516 GR 60Pand AemonaEonNo ratings yet

- Scheme of examination for LS Condensate CondenserDocument1 pageScheme of examination for LS Condensate CondenserPand AemonaEonNo ratings yet

- Report UTTM LCRDocument9 pagesReport UTTM LCRPand AemonaEonNo ratings yet

- Scheme of Examination: 1E Medium HighDocument5 pagesScheme of Examination: 1E Medium HighPand AemonaEonNo ratings yet

- Safe Depo FeesDocument2 pagesSafe Depo FeesPand AemonaEonNo ratings yet

- The Frequency of Release From Piping: A Case-Study To Compare Approaches Quantifying Organizational and Managerial FactorsDocument6 pagesThe Frequency of Release From Piping: A Case-Study To Compare Approaches Quantifying Organizational and Managerial FactorsPand AemonaEonNo ratings yet

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- SSI PlanningDocument2,009 pagesSSI PlanningPand AemonaEonNo ratings yet

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- T Header For AFC Calculation (PER UG-34) :, With The Limitation That Z Need Not Be Greater Than 2.5 (UG-34.B3)Document16 pagesT Header For AFC Calculation (PER UG-34) :, With The Limitation That Z Need Not Be Greater Than 2.5 (UG-34.B3)Pand AemonaEonNo ratings yet

- Reliability EngineeringDocument6 pagesReliability EngineeringPand AemonaEonNo ratings yet

- RJ GPP6Document1,920 pagesRJ GPP6Pand AemonaEonNo ratings yet

- Data ArchivingDocument63 pagesData ArchivingHot_sergio100% (1)

- Total Drill Cost CalculatorDocument3 pagesTotal Drill Cost CalculatorRenéAlvarezPolo100% (2)

- Report On Corporate Communication Strategy Analysis ofDocument38 pagesReport On Corporate Communication Strategy Analysis ofNAFISA ISLAMNo ratings yet

- JEDI Slides Intro1 Chapter 02 Introduction To JavaDocument17 pagesJEDI Slides Intro1 Chapter 02 Introduction To JavaredbutterflyNo ratings yet

- Holux M-1000C Bluetooth GPS Logger Manual GuideDocument22 pagesHolux M-1000C Bluetooth GPS Logger Manual Guidenabiloo2003No ratings yet

- Load-Modulated Arrays Emerging MIMO TechnologyDocument83 pagesLoad-Modulated Arrays Emerging MIMO TechnologysmkraliNo ratings yet

- MNDOT Distress Identification ManualDocument51 pagesMNDOT Distress Identification ManualcrojastNo ratings yet

- TM4C129XNCZAD MicrocontrollerDocument2,191 pagesTM4C129XNCZAD Microcontrollermamaligosu1No ratings yet

- Deutz 1013Document3 pagesDeutz 1013Retno Pudji LestariNo ratings yet

- Volvo 850 GLT Owners Manual 1993Document176 pagesVolvo 850 GLT Owners Manual 1993jpaulorosado2186No ratings yet

- TNB AR 2022 Corporate StructureDocument2 pagesTNB AR 2022 Corporate StructureZamzuri P AminNo ratings yet

- Updated After 11th BoS Course Curriculum - B.tech CSEDocument120 pagesUpdated After 11th BoS Course Curriculum - B.tech CSEAnonymous 9etQKwWNo ratings yet

- General Ledger Senior Accountant in Charlotte NC Resume Diana ShipeDocument1 pageGeneral Ledger Senior Accountant in Charlotte NC Resume Diana ShipeDianaShipeNo ratings yet

- IEC Certificate 1000V Single Glass 202304Document35 pagesIEC Certificate 1000V Single Glass 202304Marian ProzorianuNo ratings yet

- Dry Hands MinecraftDocument1 pageDry Hands MinecraftBrandon RotzankNo ratings yet

- Testing concrete and brick strengthDocument2 pagesTesting concrete and brick strengthlolenlennNo ratings yet

- Smart Payment MeterDocument2 pagesSmart Payment MeterJesus Castro OrozcoNo ratings yet

- Gillette and The Men's Wet Shaving Market: Group 8 Section BDocument12 pagesGillette and The Men's Wet Shaving Market: Group 8 Section BAmit Hemant JainNo ratings yet

- Multi-Stage Centrifugal Blower Design Pressure ConsiderationsDocument5 pagesMulti-Stage Centrifugal Blower Design Pressure ConsiderationsSATYA20091100% (1)

- Current Developments in Lens DesignDocument12 pagesCurrent Developments in Lens DesignMahabub HossainNo ratings yet

- Ref Paper 2Document4 pagesRef Paper 2Subhanjali MyneniNo ratings yet

- Geometric Design of Highways for EngineersDocument39 pagesGeometric Design of Highways for EngineersZeleke TaimuNo ratings yet

- DC Motor Direction Control ReportDocument6 pagesDC Motor Direction Control ReportEngr Farhanullah SarkiNo ratings yet

- Slurry Flo BrochureDocument4 pagesSlurry Flo BrochureChristian Andres Campa HernandezNo ratings yet

- I) CentrifugesDocument46 pagesI) Centrifugesiahim87No ratings yet

- August 2017Document72 pagesAugust 2017Treatment Plant Operator MagazineNo ratings yet

- Daily DAWN News Vocabulary With Urdu Meaning (05 April 2020) PDFDocument6 pagesDaily DAWN News Vocabulary With Urdu Meaning (05 April 2020) PDFAEO Begowala100% (2)

- ISO 128-25 Technical Drawings - General Principles of Presentation - Lines On Shipbuilding Drawings (1999)Document16 pagesISO 128-25 Technical Drawings - General Principles of Presentation - Lines On Shipbuilding Drawings (1999)SantoshNo ratings yet

- CV Summary for IT Position Seeking Recent GraduateDocument5 pagesCV Summary for IT Position Seeking Recent Graduateeang barangNo ratings yet

- Multi-Door Compact Type Controller (V4A) - Multi-Door Controller - ACS - SYRIS Technology Corp. (The RFID Total Solution.) - Powered by SYRISDocument2 pagesMulti-Door Compact Type Controller (V4A) - Multi-Door Controller - ACS - SYRIS Technology Corp. (The RFID Total Solution.) - Powered by SYRISSusheel GuptaNo ratings yet