Professional Documents

Culture Documents

Automotive Quality Director Bilingual in Tyler Texas Resume Cesar Ruiz de Chavez

Uploaded by

Cesar Ruiz de ChavezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automotive Quality Director Bilingual in Tyler Texas Resume Cesar Ruiz de Chavez

Uploaded by

Cesar Ruiz de ChavezCopyright:

Available Formats

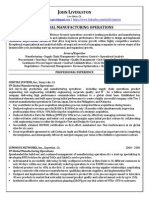

CESAR ANTONIO RUIZ DE CHAVEZ OCHOA

Jacksonville, TX 75766

M: (903)721-5870 e-mail: carcho55@yahoo.com

LINKEDIN URL: www.linkedin.com/in/CesarRuizdeChavez

AUTOMOTIVE QUALITY DIRECTOR, BILINGUAL with 20+ years of international

original equipment manufacturing (OEM) and supplier experience in the automotive

industry. Applies Six Sigma methodologies and strategic planning to improve

processes and productivity while reducing overhead costs. Expert in labor contract

renewal with multiple unions. Offers a history of career growth to high visibility roles.

Fluent in Spanish.

Core competencies span:

Cost Reduction

Project Management

Environmental Control

Customer Satisfaction

Six Sigma

Lean Manufacturing

Capital Plan Investments

Energy Management

Just-In-Time Methodologies

Budget Review/Approval

Problem Solving/Troubleshooting Total Productive Maintenance

CAREER HIGHLIGHTS

COST CONTROL

Successfully launched an operational excellence program and trained employees in lean

manufacturing techniques, converting a loss of $4M into a positive EBIT of $8M in one year.

Rescheduled plant operations, avoiding fines and eliminating more than 240 air leaks,

enabling a company to retain 8% of KWs used per ton and save $321K.

Completed four projects using Six Sigma methodologies to facilitate annual savings of

$12M.

Incorporated a Cyclical Tool Change system, enabling insert and tool change prior to

wear, reducing machining scrap to less than 1% in one year, lowering tool costs from $1.50 to

under $0.50, and decreasing customer rejects from 1,250ppm to less than 50ppm.

Oversaw a $2.5M new water treatment project for plant expansion, attaining the

Chryslers CHEER Award as the first plant to achieve Zero Water Discharged.

CONTINUOUS PROCESS IMPROVEMENTS

Increased pieces per hour from 33 to 45 as well as restructured employee headcount,

reducing labor hours from 38.5 to 27.4 in three months.

Increased productivity 13% in one year by implementing Lean manufacturing strategies,

reducing manpower from 700 to 500 employees.

Developed quality and technical teams for individual molding lines, lowering total plant

rejects from 22% to 9.5% and saving $1M annually, while enhancing client relations and

satisfaction.

Improved efficiencies 50% in a two-year period through executing cell manufacturing,

consolidating machining operations from four to two, and cutting labor from 300 to 140 workers.

Revised a company manual to integrate TS and Environmental ISO 14000 requirements

into one system, aiding the company in becoming the first in Mexico to achieve TS 16649 and

ISO 14000 certifications.

Obtained Hayes Lemmerz International Chairmans Award for Safety five consecutive

years.

Continued. . .

CESAR ANTONIO RUIZ DE CHAVEZ OCHOA

Jacksonville, TX 75766

M: (903)721-5870 e-mail: carcho55@yahoo.com

LINKEDIN URL: www.linkedin.com/in/CesarRuizdeChavez

Page Two

PROFESSIONAL SUMMARY

Founder of LinkedIn group; Texas Automotive Quality

Directors, OEM & Suppliers. Attending Networking Events, Researching Industry Leaders,

Tracking Industry Trends, Participating in Industry Discussions.

Superior Die Cast, LLC. Quality Assurance Manager 2014- 2015

Review Quality System to successfully obtained ISO 9001 certification, responsible to update all

process sheets and tooling for all customers. Implemented Daily Production Rate for all parts

numbers made.

BOCAR, S.A. Quality Assurance Director (Consultant) 2006 - 2014

Directing quality control, ISO TS 16949, change quality systems and coordinate Bocar

Operating System, continuous improvement for all ten facilities such as: High Pressure Die

Casting, Semi permanent mold Castings, Injection Molding, Machining and assembly of

automotive parts. Reduced Customer complaints by 75 % and PPMs were improved from 420

to 40 within one year. Reduced Quality Costs from 10 % to 3 % of sales in three years,

CIFUNSA Director of Operations, Foundry Grey Iron Cylinder Blocks & Heads 2005-2006

Oversaw four green sand molding lines for grey and malleable iron castings with an annual

capacity of 230,000 tons. Managed the foundry, maintenance, and pattern shop in addition to a

small cubing facility, with 2,500 employees working on three shifts six days a week. Supported

$220M in automotive and diesel cylinder blocks and heads castings annual sales.

HAYES LEMMERZ INTERNATIONAL, INC.

Plant Manager/Director of Mexican Operations 2002-2005

Directed a facility composed of three plants, including green sand aluminum foundry, machining,

and lost core polymer injection molding. Supported $72M in sales. Enhanced productivity 13%

each consecutive year by implementing Lean manufacturing concepts. Oversaw the successful

launch of several new jobs. Plant achieved exceptional status within the corporation. Obtained

ISO TS1694 & ISO 14000 certifications. Managed capital investments.

Plant Manager/General Director 2000-2002

Oversaw a facility for the brakes business unit generating $33M in sales. Achieved ISO 14000

and TS 1694 certifications. Improved productivity 50% in two years by implementing cell

manufacturing and reducing machining operations from four to two, while decreasing labor from

300 personnel to 140 personnel. Managed capital investments.

Machining & Polymers Plant Manager 1995-1999

Oversaw a facility for the Powertrain business unit generating $30M in sales. Achieved QS

9000 certification. Launched four new products on time, within budget, and to specification.

Headed APQP teams, promoting a program manager for each new product. Managed capital

investments.

CHRYSLER DE MEXICO, S.A. Quality Control & Product Engineering Manager 1992-1995

Directed quality control, product engineering changes, and parts approval at the Saltillo Engine

Plant. Managed water treatment plans. Launched three new four cylinder DOHC engines with

zero manufacturing quality issues while maintaining the old engine family. Implemented a

quality system.

EDUCATION

Bachelor of Science in Mechanical Engineering

Escuela Superior de Ingeniera Mecnica y Elctrica, Instituto Politcnico Nacional, Mxico,

D.F.

Manufacturing of Construction Equipment Certificate

Komatsu, Ltd. Nagoya and Awazu, Japan as part of Mxico and Japan Scholarship interchange.

You might also like

- A Study of the Supply Chain and Financial Parameters of a Small BusinessFrom EverandA Study of the Supply Chain and Financial Parameters of a Small BusinessNo ratings yet

- Plant Manager or VP of OperationsDocument6 pagesPlant Manager or VP of Operationsapi-77811453No ratings yet

- Plant Manager or Operations ManagerDocument4 pagesPlant Manager or Operations Managerapi-121389384No ratings yet

- VP Director Operations Manufacturing in Chicago IL Resume Erik PetersonDocument2 pagesVP Director Operations Manufacturing in Chicago IL Resume Erik PetersonErikPeterson1No ratings yet

- General Manager Lean Manufacturing in Orlando FL Resume Kevin KelseyDocument2 pagesGeneral Manager Lean Manufacturing in Orlando FL Resume Kevin KelseyKevinKelseyNo ratings yet

- VP of Manufacturing or OperationsDocument4 pagesVP of Manufacturing or Operationsapi-79310704No ratings yet

- Director VP Quality Manufacturing in Los Angeles CA Resume Thomas ZhuDocument3 pagesDirector VP Quality Manufacturing in Los Angeles CA Resume Thomas ZhuThomasZhu2No ratings yet

- Vice President Manufacturing Operations in Milwaukee WI Resume Dennis ThomasDocument2 pagesVice President Manufacturing Operations in Milwaukee WI Resume Dennis ThomasDennisThomasNo ratings yet

- Senior Quality Engineer in Houston TX Resume Frank MedranoDocument2 pagesSenior Quality Engineer in Houston TX Resume Frank MedranoFrankMedranoNo ratings yet

- Chief Operations Officer in Chicago IL Resume Pat KestnerDocument2 pagesChief Operations Officer in Chicago IL Resume Pat KestnerpatkestnerNo ratings yet

- Plant Manager Production in Madison WI Resume Bill StechDocument2 pagesPlant Manager Production in Madison WI Resume Bill StechBillStechNo ratings yet

- Manager Equipment Engineering Operations in Dallas Houston TX Resume Phillip TapiaDocument3 pagesManager Equipment Engineering Operations in Dallas Houston TX Resume Phillip TapiaPhillip TapiaNo ratings yet

- Process Improvement Manager Analyst in Portsmouth New Hampshire Resume William HartinDocument2 pagesProcess Improvement Manager Analyst in Portsmouth New Hampshire Resume William HartinWilliam HartinNo ratings yet

- Vice President Manufacturing in Charlotte North Carolina Resume Bruce EmmettDocument3 pagesVice President Manufacturing in Charlotte North Carolina Resume Bruce EmmettbruceemmettNo ratings yet

- CEO Chief Operating Officer in Seattle WA Resume Donald GongawareDocument3 pagesCEO Chief Operating Officer in Seattle WA Resume Donald GongawareDonaldGongawareNo ratings yet

- Production Manager or Production SupervisorDocument3 pagesProduction Manager or Production Supervisorapi-121382640No ratings yet

- Controller or CFO or Vice President-FinanceDocument2 pagesController or CFO or Vice President-Financeapi-78312792No ratings yet

- VP or Director or Plant Manager or Production ManagerDocument3 pagesVP or Director or Plant Manager or Production Managerapi-78509303No ratings yet

- Lean Enterprise Plant Manager in Indiana IN Resume Michael MakarewichDocument3 pagesLean Enterprise Plant Manager in Indiana IN Resume Michael MakarewichMichaelMakarewichNo ratings yet

- VP Manufacturing Supply Chain in Denver CO Resume Thomas DespresDocument3 pagesVP Manufacturing Supply Chain in Denver CO Resume Thomas DespresThomasDespresNo ratings yet

- Plant Manager Manufacturing Operations in Syracuse NY Resume Samuel BeamanDocument3 pagesPlant Manager Manufacturing Operations in Syracuse NY Resume Samuel BeamanSamuelBeamanNo ratings yet

- Vice President Engineering in Seattle WA Resume Roger McGheeDocument2 pagesVice President Engineering in Seattle WA Resume Roger McGheeRogerMcGheeNo ratings yet

- Chemical Process Engineer in Los Angeles Orange County CA Resume Tessa KelleyDocument2 pagesChemical Process Engineer in Los Angeles Orange County CA Resume Tessa KelleyTessaKelleyNo ratings yet

- Derrell James CVDocument5 pagesDerrell James CVapi-78745273No ratings yet

- Plant Manager in Rockford IL Resume Thomas McGinnissDocument2 pagesPlant Manager in Rockford IL Resume Thomas McGinnissThomasMcGinnissNo ratings yet

- Director Operations Manufacturing Production in Philadelphia PA Resume Charles AltmanDocument3 pagesDirector Operations Manufacturing Production in Philadelphia PA Resume Charles AltmanCharlesAltmanNo ratings yet

- Manufacturing or Operations Manager / Director or Plant ManagerDocument3 pagesManufacturing or Operations Manager / Director or Plant Managerapi-77839020No ratings yet

- CV - Lider Oficina PMO PDFDocument3 pagesCV - Lider Oficina PMO PDFHector OlveraNo ratings yet

- Todd ShuderDocument3 pagesTodd ShuderToddShuderNo ratings yet

- VP Global Manufacturing Operations in Santa Clara CA Resume John LivingstonDocument2 pagesVP Global Manufacturing Operations in Santa Clara CA Resume John LivingstonJohn Livingston2No ratings yet

- Facilities Manager Manufacturing Director in Orange County CA Resume Mark LevitzDocument2 pagesFacilities Manager Manufacturing Director in Orange County CA Resume Mark LevitzMarkLevitzNo ratings yet

- Jaime M. Ramirez: Engineering / Operations / Plant ManagerDocument4 pagesJaime M. Ramirez: Engineering / Operations / Plant ManagerjaimejaimearturoNo ratings yet

- Process Engineer Lean Manufacturing in Freeport TX Resume Douglas WilkinsDocument2 pagesProcess Engineer Lean Manufacturing in Freeport TX Resume Douglas WilkinsDouglasWilkinsNo ratings yet

- Manufacturing Process Engineering Manager in Huntsville AL Resume Michael FranzeseDocument3 pagesManufacturing Process Engineering Manager in Huntsville AL Resume Michael FranzeseMichaelFranzeseNo ratings yet

- Plant Manager or Production Manager or Production SupervisorDocument3 pagesPlant Manager or Production Manager or Production Supervisorapi-77414806No ratings yet

- Quality Technical Leader in Marietta GA Resume Wayne BoldenDocument2 pagesQuality Technical Leader in Marietta GA Resume Wayne BoldenWayneBoldenNo ratings yet

- Manufacturing ManagementDocument4 pagesManufacturing Managementapi-77722965No ratings yet

- Business Process Improvement ManagerDocument3 pagesBusiness Process Improvement Managerapi-77800516No ratings yet

- Engineering Project Manager Continuous Improvement in Richmond VA Resume Richard MestlerDocument2 pagesEngineering Project Manager Continuous Improvement in Richmond VA Resume Richard MestlerRichardMestlerNo ratings yet

- Head Manufacturing - ResumeDocument6 pagesHead Manufacturing - Resumerkgnanduri100% (4)

- Professional Resume For Tom RandallDocument3 pagesProfessional Resume For Tom RandalltomrandallNo ratings yet

- VP Director Operations Product in Chicago IL Resume Robert RathDocument3 pagesVP Director Operations Product in Chicago IL Resume Robert RathRobert RathNo ratings yet

- Vice President Procurement Sourcing in USA Resume John GoebDocument2 pagesVice President Procurement Sourcing in USA Resume John GoebJohnGoebNo ratings yet

- Resume Higdon Joe 2019Document3 pagesResume Higdon Joe 2019api-469696047No ratings yet

- Plant Manager Manufacturing Operations in Charlotte NC Resume John LuikeyDocument2 pagesPlant Manager Manufacturing Operations in Charlotte NC Resume John LuikeyJohnLuikeyNo ratings yet

- VP Director Supply Chain in Atlanta GA Resume Seon JonesDocument4 pagesVP Director Supply Chain in Atlanta GA Resume Seon JonesSeonJonesNo ratings yet

- Plant Operations Engineering Manager in Minneapolis ST Paul Resume Wade WoodsDocument3 pagesPlant Operations Engineering Manager in Minneapolis ST Paul Resume Wade WoodsWadeWoodsNo ratings yet

- Resume Stephen SouthernDocument2 pagesResume Stephen SouthernstevesouthernNo ratings yet

- Lean Consultant Sample CV 3 PDFDocument4 pagesLean Consultant Sample CV 3 PDFArnabNo ratings yet

- Plant Operations Director Manager in Dallas FT Worth TX Resume Kevin HuurmanDocument2 pagesPlant Operations Director Manager in Dallas FT Worth TX Resume Kevin HuurmanKevinHuurmanNo ratings yet

- Production Manager or SuperisorDocument4 pagesProduction Manager or Superisorapi-121360557No ratings yet

- Quality ManualDocument38 pagesQuality ManualsathyabalaramanNo ratings yet

- Vice President Manufacturing Operations in Chicago IL Resume Timothy KelleherDocument2 pagesVice President Manufacturing Operations in Chicago IL Resume Timothy KelleherTimothyKelleherNo ratings yet

- Quality Manager or Quality EngineerDocument3 pagesQuality Manager or Quality Engineerapi-77217896No ratings yet

- VP General Manager Operations in Grand Rapids MI Resume David MackDocument4 pagesVP General Manager Operations in Grand Rapids MI Resume David MackDavidMack2No ratings yet

- Manager Manufacturing Operations in Boston MA Resume Joseph HigdonDocument2 pagesManager Manufacturing Operations in Boston MA Resume Joseph HigdonJosephHigdon0% (1)

- Operations Continuous Improvement Manager in Phoenix AZ Resume Paul RobertsDocument2 pagesOperations Continuous Improvement Manager in Phoenix AZ Resume Paul RobertsPaulRoberts2No ratings yet

- Pankaj NaikDocument4 pagesPankaj NaikPankaj.S.NaikNo ratings yet

- Production Manager, Plant Superintendent, Plant Manager, ProjectDocument3 pagesProduction Manager, Plant Superintendent, Plant Manager, Projectapi-76771249No ratings yet

- 5036 Asm 1Document15 pages5036 Asm 1Nguyen Tuan Anh (BTEC HN)No ratings yet

- Safety, Health and Competition in The Global MarketplaceDocument12 pagesSafety, Health and Competition in The Global MarketplaceJoannah claire AlforqueNo ratings yet

- The Riverview Hotel, Notown USADocument22 pagesThe Riverview Hotel, Notown USAmadhav30No ratings yet

- EEOC Guide To Writing Appeal Briefs For Unrepresented ComplainantsDocument50 pagesEEOC Guide To Writing Appeal Briefs For Unrepresented ComplainantsC4CNo ratings yet

- Saudi Arabia Women Rights Human Rights ViolationsDocument17 pagesSaudi Arabia Women Rights Human Rights ViolationsAlysha Chandra100% (2)

- 06 Activity 1Document2 pages06 Activity 1mike ApostolNo ratings yet

- Chapter 1 Business Communication in The Digital AgeDocument12 pagesChapter 1 Business Communication in The Digital AgeCoralyMartinezPerezNo ratings yet

- Hersey Blanchard ModelDocument2 pagesHersey Blanchard ModelFoaad AhmadNo ratings yet

- Term Paper-HRM 603.1Document17 pagesTerm Paper-HRM 603.1Farhana Rashed 2035196660No ratings yet

- PAS 24 Related Party DisclosuresDocument12 pagesPAS 24 Related Party DisclosuresTripp WarrenNo ratings yet

- Attrition in Educational SectorDocument18 pagesAttrition in Educational Sectorsurbhi123No ratings yet

- VCF TransferDocument1 pageVCF Transfermanish tripathyNo ratings yet

- Answer KeyDocument14 pagesAnswer KeyGemaiNo ratings yet

- Full Download Ebook Ebook PDF Organizational Behaviour Understanding Managing 10th PDFDocument41 pagesFull Download Ebook Ebook PDF Organizational Behaviour Understanding Managing 10th PDFcolleen.wilkerson32997% (39)

- Allan D. Cruzat: Position Applied: Pipe Fitter Educational AttainmentDocument15 pagesAllan D. Cruzat: Position Applied: Pipe Fitter Educational AttainmentRaymond Manalo PanganibanNo ratings yet

- Mechanical EngineeringDocument320 pagesMechanical EngineeringZack NormanNo ratings yet

- Job Finding FormulaDocument26 pagesJob Finding FormulaJobSearchExpert100% (2)

- Human Resource Management Course Code: MKT-213: Jeta MajumderDocument21 pagesHuman Resource Management Course Code: MKT-213: Jeta MajumderMaliha TribhuNo ratings yet

- Development of HRM ConceptDocument30 pagesDevelopment of HRM Conceptmanisha_ms0% (1)

- ACN Nurse Leadership White Paper FINALDocument14 pagesACN Nurse Leadership White Paper FINALChiwong Koer100% (1)

- Accounting For Labour Ma AccaDocument28 pagesAccounting For Labour Ma AccasimranNo ratings yet

- Professionalism in The Work Place-Longer VersionDocument12 pagesProfessionalism in The Work Place-Longer VersionNo Tn100% (3)

- Pooja KhannaDocument4 pagesPooja KhannaIm__NehaThakurNo ratings yet

- EDA Manufacturing Final Report (Final September 28)Document33 pagesEDA Manufacturing Final Report (Final September 28)Kyle LangsleyNo ratings yet

- Recognition of Trade UnionsDocument11 pagesRecognition of Trade Unions18038 ARUNJEET SINGH100% (1)

- Hse Hanbook Final 2010Document38 pagesHse Hanbook Final 2010wferry27100% (2)

- JD - SbaDocument2 pagesJD - SbaGreg AdamsNo ratings yet

- Questions For Articles On UnemploymentDocument2 pagesQuestions For Articles On UnemploymentMitch FallonNo ratings yet

- Riply Position Paper For ComplainantDocument7 pagesRiply Position Paper For ComplainantMarc Joseph Aguilar100% (1)

- Jan09.2016 Bcommittee On Appropriations Approves "Comprehensive Nursing Law"Document2 pagesJan09.2016 Bcommittee On Appropriations Approves "Comprehensive Nursing Law"pribhor2No ratings yet

- Workbook to Accompany Maintenance & Reliability Best PracticesFrom EverandWorkbook to Accompany Maintenance & Reliability Best PracticesRating: 3.5 out of 5 stars3.5/5 (3)

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- FreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsFrom EverandFreeCAD | Step by Step: Learn how to easily create 3D objects, assemblies, and technical drawingsRating: 5 out of 5 stars5/5 (1)

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- SketchUp Success for Woodworkers: Four Simple Rules to Create 3D Drawings Quickly and AccuratelyFrom EverandSketchUp Success for Woodworkers: Four Simple Rules to Create 3D Drawings Quickly and AccuratelyRating: 1.5 out of 5 stars1.5/5 (2)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)From EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Rating: 5 out of 5 stars5/5 (2)

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesFrom EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesRating: 4.5 out of 5 stars4.5/5 (2)

- Certified Solidworks Professional Advanced Weldments Exam PreparationFrom EverandCertified Solidworks Professional Advanced Weldments Exam PreparationRating: 5 out of 5 stars5/5 (1)

- Beginning AutoCAD® 2020 Exercise WorkbookFrom EverandBeginning AutoCAD® 2020 Exercise WorkbookRating: 2.5 out of 5 stars2.5/5 (3)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Autodesk Inventor 2020: A Power Guide for Beginners and Intermediate UsersFrom EverandAutodesk Inventor 2020: A Power Guide for Beginners and Intermediate UsersNo ratings yet