Professional Documents

Culture Documents

Pipe-Routing Algorithm - Case Study PDF

Uploaded by

mechanical_engineer11Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe-Routing Algorithm - Case Study PDF

Uploaded by

mechanical_engineer11Copyright:

Available Formats

Expert Systems with Applications 23 (2002) 299309

www.elsevier.com/locate/eswa

Pipe-routing algorithm development:

case study of a ship engine room design

Jin-Hyung Park*, Richard L. Storch

Industrial Engineering, University of Washington, Box 352650, Seattle, WA 98105, USA

Abstract

This study presents an automatic pipe-routing algorithm accommodating all major detail-design facets. First, the algorithm uses patternmatch methods to provide candidate paths. A cell-generation method is developed which satisfies geometric constraints. This makes the

generation and evaluation of paths effective and efficient. Next, various non-geometric aspects, such as material costs, installation costs, and

valve operability, are assessed from a fiscal point of view. Then, from a tree of combinations, the algorithm chooses an appropriate path for

each pipeline from the candidate paths. Finally, a general approach toward detail design automation is suggested. The software

implementation was done with Microsoft Visual Basic 6.0 and Access 2000, Heide Corporation Intent! for AutoCAD 2000, and AutoDesk

AutoCAD 2000. q 2002 Elsevier Science Ltd. All rights reserved.

Keywords: Pipe-routing; Design automation; Expert system; Cell generation method

1. Introduction

Piping-system design for ships usually has five consecutive phases: preliminary design, functional design, detail

design, production engineering, and system-support information (ISO/CDC, 1996). Pipe routing is the most important

activity during the detail-design phase because it takes over

50% of the total detail-design man-hours and all other

activities of detail design depend on it. Since detail design is

characteristically less creative and more routine than the

earlier steps in the design process (Kang, Myung, & Han,

1999), a computer program that has an automatic piperouting capability might offer an attractive way to cut down

on dull and irksome work, leading to saving of time and

money. Pipe routing has traditionally been done largely by

eye (Wangdahl, Pollock, & Woodward, 1974), and developing pipe-routing programs has been constrained by various

considerations, such as:

(a)

(b)

(c)

(d)

(e)

obstacle avoidance

minimum equipment clearance requirements

accessibility of valves by hand or by reach-rods

maximization of support sharing with other pipelines

minimization of pipeline length and number of bends

Although pipe-routing algorithms have already been

developed, to date they have striven to accommodate mainly

* Corresponding author. Tel.: 1-206-543-5348; fax: 1-206-685-3072.

E-mail address: j23346@yahoo.com (J.-H. Park).

constraint (a) (Ito, 1999; Kobayashi, Wada, & Kiguchi,

1986; Schmidt-Traub, Koster, Holtkotter, & Nipper, 1998;

Wangdahl et al., 1974; Zhu & Latombe, 1991), and have

paid little or no attention to constraints (b) (d). They have

used the constraint (e) as an optimal criterion. In addition,

even though pipelines without branches are uncommon,

only Newell (1972) was concerned with branching

pipelines.

These design constraints can be divided into two groups:

restrictive constraints (a) (c), and quantifiable constraints

(d) (e). To satisfy restrictive constrains the proposed

algorithm uses pattern-match techniques to provide some

good feasible paths for a given pipeline, generating cells

so that a series of cells can lead a pipeline from a starting

point (nozzle) to an end point (nozzle). On the other hand,

for the quantifiable constrains, the algorithm assesses them

from a fiscal point of view to find the best path among the set

of feasible paths.

2. Routing algorithms

2.1. Maze algorithm

Lee (1961) proposed a maze algorithm, also called Lees

algorithm or the grid expansion algorithm. This algorithm

posits a grid of cells. Obstacles are marked X on the cells

corresponding to them. The algorithm begins from a starting

cell S, and the cells adjoining that cell are labeled with a

0957-4174/02/$ - see front matter q 2002 Elsevier Science Ltd. All rights reserved.

PII: S 0 9 5 7 - 4 1 7 4 ( 0 2 ) 0 0 0 4 9 - 0

300

J.-H. Park, R.L. Storch / Expert Systems with Applications 23 (2002) 299309

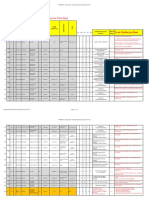

Table 1

Earlier studies on pipe routing

Algorithm

Network optimization

Au thor

Year

Dimension

Domain

Operation/Maintenance

Installation

Safety

Branch

Newell

1972

3D

General

X

X

X

P

Wangdahl

1974

2D

Shipbuilding

X

X

X

X

Maze

Guiradello

1993

3D

Plant

X

P

X

X

Zhu

1991

2D/3D

Robotics

X

X

X

X

Rourke

1975

3D

General

X

X

X

X

Mitsuta

1986

3D

General

X

X

F

X

Escape

GA

Schmidt

19

3D

Plant

X

P

X

X

Ito

1999

2D

General

X

P

X

X

X: not considered, P: partially implemented, F: fully implemented.

one. Cells adjoining these are labeled two. This process

is continued until the target cell is reached (Rourke, 1975).

This algorithm guarantees a solution, if one exists, but it

requires a lot of memory space (Kai-jian & Hong-e, 1987).

Mitsuta, Kobayashi, Wada, and Kiguchi (1986) and Rourke

(1975) adopted this algorithm.

2.2. Escape algorithm

connectivity graphs to find an appropriate path, and an Ap

algorithm for optimality, which is:

f N gN hN:

The term g(N ) is a function of a weighted sum of a given

length and its number of turns, and h(N ) is a function of the

Manhattan distance between the center of the cell of node N

and the terminal.

Hightower (1969) proposed an escape algorithm, otherwise

called the line-search algorithm or the vector algorithm.

This method starts with two perpendicular lines through the

starting point S. It tries to find a point such that an escape line

will extend beyond one of the previous boundaries of point S. If

such an escape point is found, it becomes the new point S. This

method repeats the process until the line segment crosses the

target point G. The escape algorithm is fast and uses less

memory space, but it cannot guarantee a solution (Kai-jian &

Hong-e, 1987). Schmidt-Traub et al. (1998) utilized both the

maze and the escape methods to ascertain the optimal pipe

route for plant layout.

2.5. Genetic algorithm

2.3. Network optimization algorithm

Obstacles. Detail-design pipe designers need not only

system diagrams, but also many drawings from other

designers for such things as structural design, machinery

design, electrical system design, and HVAC system design.

All of these restrict feasible areas. As the avoidance of

obstacles is essential to routing, all research has been forced

to address this constraint.

Operability. As certain valves should be readily

accessible during normal operation or easily accessible in

an emergency, piping system designers want to locate these

valves within arms reach. This has a direct effect on

pipeline paths.

Material costs. This is obviously one of the most

important constraints. Material costs are tied to the length

and the number of turns of each pipeline. Designers place

the biggest pipelines first so as to avoid having bigger

pipelines go around smaller ones. Bending or elbows are

used to make right-angled turns, but bending is preferred

because it is less costly. Elbows are substituted when there

is not enough space for bending.

Installation cost. A pipeline is associated with a series of

Pipe-routing can be done using network optimization

algorithms. Each vertex vi denotes a junction of possible

pipe racks or pipe segments between junction i and j, and

each edge eij has a cost cij :

G V; E;

where V is the set of vertices and E is the set of edges. Then

the problem becomes one of finding the shortest path

between a node origin s and a node destination t (Guiradello,

1993). Wangdahl et al. (1974) and Guirardello (1993) used

Dijkstars algorithm (Mandl, 1979). Newell (1972) adopted

Nicholsons method (1966).

2.4. Ap algorithm

Zhu and Latombe (1991) developed an approach based

on robot-path planning techniques, regarding each pipe as

the trace of a rigid object, either a disc (2D case) or a sphere

(3D case). This method used cell decomposition and

Ito (1999) employed to a genetic algorithm (GA)

approach to find the best path. Each cell is given a potential

value, according to its situation. The potential value of cells

located next to the wall is lowest because the path is more

favorable, and the value for obstacle cells is correspondingly high. This method tests crossover between possible

paths, excluding obstacle cells.

3. Understanding constraints

J.-H. Park, R.L. Storch / Expert Systems with Applications 23 (2002) 299309

301

Fig. 2. Cost comparison.

Fig. 1. Pipe routes with directional specification.

supports. These may support other pipelines as well.

Having a support hold two or more pipelines can make it

possible to save material costs for the supports themselves, and the man-hours required for the welding of

support legs to the structure. Sometimes, the need to

provide welders with good positions or the shortening of

support legs so as to reduce vibration leads to changing or

lengthening routes.

Flow direction. Some pipelines, such as sewage

pipelines, use gravity to create flows. Loops are not

recommended for pipelines for steam or gas because of

potential drainage problems.

If a pipe-routing designer were to disregard a

constraint, an acceptable outcome would be unlikely.

Table 1, however, shows that earlier studies have ignored

some important constraints. Since maze algorithms and

network optimization algorithms have been developed to

find the shortest path, studies using them might be limited

at the outset in taking account of the whole gamut of

constraints.

4. Cell-generation method

4.1. Background

Many early studies on routing have been carried out

either by means of cell-decomposition methods or by means

of optimization network techniques. A major problem of

cell-decomposition methods is the number of cells. As the

number of cells increases, the difficulty in dealing with them

grows exponentially. And the main difficulty of optimization network techniques is to define all nodes before an

algorithm runs. Nodes are the places where pipelines are

forked, joined, or turned. Anticipating locations for these

nodes is also a demanding task. This suggests the need to

develop a cell-generation method.

A cell-generation method has been developed to satisfy

geometric constraints, including interference, valve operability, and safety. This method uniquely uses directional

specifications to choose an appropriate basic pipe pattern. It

also considers possible modified pipe patterns so as to

enable a pipeline to run together with others. To make

interference checking easier, each obstacle will be fitted

with a cubic box large enough to contain it. If an obstacle

requires a minimum clearance for safety concerns, the size

of cube would increase accordingly. Before the algorithm

proceeds to generate cells, it checks whether any obstacles

are in the way.

4.2. Directional specifications

When designers start laying out pipes, equipment

locations have already been determined. Since information

on the start/end coordinates and the directional specifications for a given pipeline is known, taking such factors into

consideration makes pipe routing more feasible. For

instance, as shown in Fig. 1(a), a pipeline should start

from a tank nozzle ( p1) heading left and end up going in the

same direction to complete a connection between a tank and

a pump.

Fig. 1(b) shows that without the specification of direction

either path A or path B would look feasible. As seen in

Fig. 1(c), however, the specification of direction at both

ends rules out paths A and B of Fig. 1(b) and suggests,

instead, a new path C. This is called a one-variable style

throughout this paper because the dimension a will be

established depending upon boundaries and other pipeline

routes after the evaluation of all other possible routes.

302

J.-H. Park, R.L. Storch / Expert Systems with Applications 23 (2002) 299309

defining that freedom. Some detour styles, according to the

nature of the obstacles are shown in Fig. 4.

All pipelines have a basic style. To avoid failure

occasioned by obstacles, pipelines can have a detour style

instead of a basic style.

When it is possible for a pipeline A to run together with a

pipeline B, the algorithm provides appropriate connectors,

like freeway access ramps, so that both ends of pipeline A,

respectively, can access the established route cell which has

been built for pipeline B. The top row of Fig. 5 shows

possible ramp styles and the bottom row shows detour ramp

styles.

4.4. Generating cells

Fig. 3. Basic routing styles.

4.3. Basic vs modified patterns

Pipeline diameter may have the largest effect on piperouting. The bigger the pipeline diameter, the higher is its

priority. Higher priority pipelines would be routed preferentially and have basic routing styles, which means

minimizing length and turns. One the other hand, lower

priority pipelines tend toward modified routing styles, with

longer lengths and more turns permitted, in order to run

together with other pipelines as much as possible and/or to

avoid obstacles. Two or more pipelines running together can

share pipe supports, leading to decreased installation costs.

For instance, Fig. 2(a) has two pipelines that have the same

basic pattern. The smaller diameter pipeline route can be

modified as shown in Fig. 2(b), which results in a significant

cost reduction.

Depending upon end point and directional specifications,

it is possible to recognize nine basic styles, as in Fig. 3. Onevariable basic styles have one degree of freedom, and branch

pipelines, pipeline length, and boundaries are factors for

Terminal cells. Based on directional specification and

pipe diameter, the algorithm makes terminal cells. Each cell

is a hexahedron and its size is dependent on pipe diameter.

The center of the originating face is located at the endpoint

of the pipeline and cells grow along the direction of the

directional specification. If two or more terminal cells

should touch each other, a new cell, big enough to hold

them, will be generated. The old cells will be eliminated.

Bridge cells for basic styles. The algorithm selects an

appropriate basic style for each pipeline, given its endpoints

and the directional specifications. Cells are generated in

descending order of pipe diameters.

Bridge cells for modified styles. Establishing one or more

connections with modified styles is like accessing freeways

from local roads. Bridge cells for basic styles serve as

freeways, and generating bridge cells for modified styles

corresponds to the construction of on/off ramps for

freeways. All bridge cells will be endowed with information

with regard to directly connected neighbor cells.

An example. Fig. 6 is an example of cell generation, with

three pipelines. First, generate six terminal cells at the

endpoints (Fig. 6(b)). After merging two cells 10 and 20

(Fig. 6(c)), generate a bridge cell 12 to connect the fourinch pipeline, which is the largest pipeline, because a

Fig. 4. Detour routing styles.

J.-H. Park, R.L. Storch / Expert Systems with Applications 23 (2002) 299309

Fig. 5. Ramp styles for modified routes.

Fig. 6. An example: cell-generation procedure.

303

304

J.-H. Park, R.L. Storch / Expert Systems with Applications 23 (2002) 299309

Fig. 7. Routing branch pipelines.

straight-line type is the basic pattern (Fig. 6(c)). Then,

generate a bridge cell 22 for the two-inch pipeline because

an L type is the basic pattern and the algorithm has already

supplied cell 12 as part of the L (Fig. 6(d)). Generate two

bridge cells 32 and 33 to form another L type connection

(Fig. 6(e)). Once basic patterns have been built for each of

the pipelines, the algorithm starts to try out modified

connections. The four-inch pipeline does not get a modified

connection because it is the largest pipeline. The two-inch

pipeline has a basic style and cannot have a modified style in

conjunction with the four-inch pipeline. But the two-inch

pipeline can have a modified style in conjunction with the

one-inch pipeline by generating 41 and 42 to access cell

33 and by generating 43 to access cell 32 (Fig. 6(f)). At the

same time, the one-inch pipeline has a modified style with a

basic style of the two-inch pipeline using cells 41, 42, and

43. Fig. 6(g) shows the final cells. The four-inch pipeline

has only one possible route, and the two-inch and the oneinch pipelines each have two possible routes.

4.5. Branches

While arranging pipelines, the main difficulty in dealing

with branches is uncertainty as to the physical location of

branch point. To make this question manageable, the

algorithm regards any branch pipeline as a compound of

two simple forms: end-forked and middle-forked.

End-forked form. This form has branches near one or

both endpoints of a pipeline. The general steps to achieve

proper routes are as follows. First, make a basic route

between forked ends of one side. Then, define an imaginary

endpoint on the route based on the system diagram and

attribute possible directional specifications to the imaginary

endpoint (Fig. 7(b)). Consider the prospective pipeline as a

normal pipeline defined by the imaginary point and the

endpoint of other side to be joined.

Middle-forked form. Since decreases in the length of

daughter pipelines and in their number of turns usually

means increases in them of the mother pipeline, the

comparison between mother pipeline losses and daughter

pipelines gains should be carried out. When the mother

pipeline losses are greater, branch pipelines should not exert

an important effect upon the routing of the mother pipeline.

Branch points are located where branch pipelines have a

minimum length orthogonally with respect to mother

pipelines.

Recursively-forked form. Sometimes a branch pipeline

has a daughter branch pipeline associated with it and the

daughter, in turn, has a daughter, and so on, which may be

called a recursively-forked form. This form might be a

combination of subsets of an end-forked form and a middleforked form. From the main pipeline, which is the largest

and longest pipeline, try out combinations of end-forked

forms and/or middle-forked forms recursively. Fig. 7(a) is a

sample system diagram, representing a schematic map of

pipelines and instrumentation. The pipeline from the

Central Coolers to the Air Conditioning Plant is obviously

the main pipeline with end-forked forms at both ends, and

the smaller diameter pipeline to the M/E Air Coolers is a

middle-forked form. Therefore, two different basic routing

J.-H. Park, R.L. Storch / Expert Systems with Applications 23 (2002) 299309

305

Fig. 9. Mounting heights for handwheel valves with stem vertical.

Fig. 8. Pipe size and bending cost comparison.

styles can be built for the main pipeline Fig. 7(b). The

pipeline to the M/E Air Coolers has an end-forked form and

can be connected either to P001 or to P002 (Fig. 7(c)). Then,

the three-inch pipeline can be treated as a main pipeline, in

turn, and the two-inch pipeline is a middle-fork form (Fig.

7(d)).

high frequency bending is used for large pipes (Fig. 8). The

bigger the pipeline diameter, the more costly the bending,

because it takes more man-hours. As for installation cost, it

is directly related to pipe-support costs, for pipelines require

a series of pipe-supports. Pipe-support cost is comprised of

the costs for raw materials, paint, transportation, welding,

and u-bolts. The distance between supports varies in

accordance with the pipe size and the particularities of the

underlying steel structure.

5. Evaluation

5.2. Operability cost

Since the main factors in the evaluation of pipelines have

to do with material cost, installation cost, and operability

(valve locations), a penalty function can be developed by

combining these factors based on cost;

The last term in the penalty function, operability cost,

can be derived from the following formula:

Ppenalty function material cost installation cost

accessibility cost

5.1. Material cost and installation cost

The raw material cost of pipe and elbows depends on

pipe size and length. The bending cost follows a step

function because cold bending is used for small pipes and

Table 2

Operability coefficientsstem vertical case

Pipe size (inch)

First choice

Second choice

Third choice

2

3

4

6

8

10

12

14

16

18

20

24

0.25

0.38

0.50

0.75

1.00

1.25

1.50

1.75

2.00

2.25

2.50

3.00

0.78

1.17

1.56

2.34

3.12

3.90

4.68

5.46

6.24

7.02

7.80

9.36

1.89

2.84

3.79

5.68

7.57

9.46

11.36

13.25

15.14

17.03

18.93

22.71

O Co TotalHoursOfOperation HourlyWage

Operability coefficient Co . The operability coefficient Co

reflects the difficulties and discomfort inherent in operating

the valves. Difficulty is taken as proportional to handwheel

diameter. As for discomfort, the ABS guidelines (1998)

plotted in Fig. 9 show that the first choice is better than the

second choice and much better than the third choice.

Research by Karwowski and Salvendy (1998) found a linear

relationship between gravitational load and body discomfort

as shown in Fig. 10.

The numbers in the bars are the degree of comfort. The

degree of comfort for operating in the first choice zone can

be averaged as 2.65 and that for the second choice would be

0.65. In other words, the second choice is 3.12 times more

uncomfortable than the first choice, while the third choice is

7.57 times more uncomfortable. Table 2 shows the

operability coefficients. The underlying assumption is that

the operation of the valves for an eight-in pipe is taken as a

norm and assigned a value of 1. When valves are located

within the same zone with regard to a standing body, the

coefficient varies with handwheel diameter. Coefficients for

the second choice zone are derived by multiplying the first

choice coefficients by 3.12.

Total hours of operation. This factor is given as the

TimeRequiredToOperateEachTime times TotalNumOf

Operation. The term TotalNumOfOperation means the

total number of operations through a valves lifetime and

306

J.-H. Park, R.L. Storch / Expert Systems with Applications 23 (2002) 299309

Fig. 10. Ranking of postures, based on maximum holding time (MHT).

differs widely from pipeline to pipeline. On a ship, for

instance, valves for the bilge system are operated frequently,

both when the ship is at anchor and at sea. On the other

hand, valves for the return-line system are always open and

those for the ballast system are usually automatic. So the

total number of operations for these valves is relatively low.

than the N2 costs that the difference between the best case

of the N2 descendant nodes and the worst case of N1

descendant nodes could not be made up, the node N2 and

its dependents can be deleted. In Fig. 12, as B2 is low

enough, B1, B3 and their dependents are pruned.

Similarly, the algorithm deletes C3 and D2.

5.3. Tree of combinations

The tree of combinations is to help visualize the

schematic relationship among all candidate pipelines.

From Fig. 11, (A1, B1, C1, D1) and (A1, B2, C3, D2) are

possible combinations. As (A1, B2, C1, D1) always

dominates, which means always less costly than, (A1, B2,

C2, D1), (A1, B2, C2, D1) is eliminated from the tree.

Blocking is another cause for elimination. An example is the

combination (A1, B1, C3, D1), where B1 blocks C3.

A unique characteristic of this tree is that the higher the

level the bigger the assigned value because the algorithm

starts from the largest pipeline. Consider a node N1 and its

sibling node N2. When the N1 costs are so much lower

6. Implementation

6.1. Input data

The input data, mainly from system diagrams and

equipment arrangement drawings, has to do with boundaries, equipment, preferred operation area for valves, and

pipelines to be routed. Information on pipelines consists of

the pipeline number, diameter, directional specification, the

types and coordinates of endpoints, and branch pipeline

number. Daughter pipelines are given the mother pipeline

number, instead of an endpoint type.

Fig. 11. Tree of combinations.

J.-H. Park, R.L. Storch / Expert Systems with Applications 23 (2002) 299309

307

Fig. 12. Pruning tree branches.

6.2. Data structure

Fig. 13 shows a data structure for any given pipeline. A

pipeline has a series of nodes as endpoints, branch points,

and valve points. Whenever a pipelines make a turn, a new

node will be dynamically generated and endowed with an

elbow or bending specifications. Table 3 lists all node types.

As seen in Fig. 14, any given cell knows which pipelines

go through that cell and which cells are connecting to it for

ease in pipeline route-tracking. Each cell has as many slots

as pipelines going through that cell, and slots are used for

physical pipeline routing. Touching between slots, therefore, should be avoided. Given locations of boundaries and

confirmed slots, it is possible to choose an adequate pipesupport type for slots yet to be determined.

6.3. Implementation

The algorithm and GUIs have been developed with

Microsoft Visual Basic 6.0. Microsoft Access 2000 is used

for data about pipe costs, elbow costs, and bending costs

because they are subject to change.

Fig. 13. Data structure of pipeline.

The final values from Visual Basic are transmitted to

AutoCAD 2000 for visualization through Intent! For

AutoCAD 2000. Fig. 15 is the output produced by the

algorithm, which has fifteen pipelines. A pipeline from A1

to A2 is an instance of modified style.

7. A generalization of detail-design automation method

Design can be viewed as a constraint-satisfaction process

(Yoon, 1992). If all constraints are quantifiable, optimization techniques can be introduced into the design process to

find the most appropriate alternative (Radford & Greo,

1988). Design constraints, however, especially in the detaildesign phase, lack comprehensive formulations (Yoon,

1992). To overcome this limitation, it is possible to produce

some good-feasible solutions, such as to satisfy restrictive

constraints, by pattern-match on a case-by-case basis. This

narrows down the range of possible solutions to a

Table 3

Pipe node types

Node type

Description

2

10

14

20

21

22

23

24

30

35

40

55

56

65

66

68

Start point, known

Start point with valve, known

End point, known

End point with valve, known

Branch start point, not determined

Branch start point, determined

Branch end point, not determined

Branch end point, determined

Branch end point with valve, determined

Middle point for valve, not determined

Middle point for valve, determined

Middle point for daughter pipeline, not determined

Middle point for daughter pipeline, determined

Middle point for turn, type not determined

Middle point for bending, determined

Middle point for elbow, determined

308

J.-H. Park, R.L. Storch / Expert Systems with Applications 23 (2002) 299309

Fig. 14. Data structure of cell.

manageable size. Then, quantifiable constraints are

exploited to find the most beneficial solution. Fig. 16 is a

representation of the success stages of this process.

Fig. 16. Constraints-based design automation.

8. Conclusion

In this paper, a cell-generation driven pipe-routing

method has been developed to supply candidate paths.

From a tree of combinations, the algorithm chooses an

appropriate path for each pipeline from the candidate paths

after various non-geometric aspects, such as material costs,

installation costs, and valve operability, are assessed from a

fiscal point of view.

The methodology showing how various design constraints might be accommodated by suitable algorithms can

be a cornerstone for the evolution of design automation for a

domain fraught with complications. The algorithm presented here is for pipe routing. Further research will look

into applications of this algorithm for electric harness and

HVAC ducts.

Acknowledgments

The authors would like to acknowledge David Evans,

Lawrence Pierce, and Randy Bird of Integration Partners,

Inc., San Diego, CA, for providing software and valuable

technical advice. They also would like to thank pipe-routing

experts, Jung-Hyun Park, Jin-Soo Youn, Young-Min Kang,

Pil-Joong Nam and Woo-Jong Kim of Samsung Heavy

Industries, Korea, for indispensable advice.

Fig. 15. Pipe-routing using the algorithm.

J.-H. Park, R.L. Storch / Expert Systems with Applications 23 (2002) 299309

References

The American Bureau of Shipping (ABS) (1998). Guidance notes on the

application of ergonomics to marine systems.

Guiradello, R. (1993). Optimization of process plant layout. PhD

Dissertation, University of Wisconsin: Madison.

Hightower, D. W. (1969). A solution to line routing problems on the

continuous plane. Proceedings of Sixth Design Automation Workshop,

IEEE (pp. 1 24).

ISO/CDC 10303-217 (1996). Product Data Representation and Exchange

Part: 217, Application Protocol: Ship Piping.

Ito, T. (1999). A genetic algorithm approach to piping route path planning.

Journal of Intelligent Manufacturing, 10, 103 114.

Kai-jian, S., & Hong-e, Z. (1987). Efficient routing algorithm. ComputerAided Design, 19(7), 375379.

Kang, S., Myung, S., & Han, S. (1999). A design expert system for autorouting of ship pipes. Journal of Ship Production, 15(1), 19.

Karwowski, W., & Salvendy, G. (1998). Ergonomics in manufacturing.

Dearborn, MI: Society of Manufacturing Engineers.

Kobayashi, Y., Wada, Y., & Kiguchi, T. (1986). Knowledge representation

and utilization for optimal route search. IEEE Transactions on Systems,

Man, and Cybernetics, SMC-16(3), 454 462.

Lee, C. Y. (1961). An algorithm for path connections and its applications.

IRE Transactions on Electronic Computers, EC-10, 346 365.

Mandl, C. (1979). Applied network optimization. New York: Academic

Press.

Mitsuta, T., Kobayashi, Y., Wada, Y., & Kiguchi, T. (1986). A knowledgebased approach to routing problems in industrial plant design.

Proceedings of the Sixth International Workshop Expert System and

Their Applications (pp. 237 253). France.

Newell, R. G. (1972). An interactive approach to pipe routing in process

plant. Information processing 71. Proceedings of IFIP Congress 71 (pp.

10801085). London.

Nicholson, T. A. J. (1966). Finding the shortest route between two points in

a network. The Computer Journal, 9(3), 275 280.

Radford, A. D., & Gero, J. S. (1988). Design by Optimization in

309

Architecture, Building and Construction. New York: Van Nostrand

Reinhold.

Rourke, P. W. (1975). Development of a three-dimensional pipe routing

algorithm. PhD Dissertation, Lehigh University.

Schmidt-Traub, H., Koster, M., Holtkotter, T., & Nipper, N. (1998).

Conceptual plant layout. Computers Chemical Engineering, 22(Suppl.),

s499 s504.

Wangdahl, G. E., Pollock, S. M., & Woodward, J. B. (1974). Minimumtrajectory pipe routing. Journal of Ship Research, 18(1), 4449.

Yoon, B. K. (1992). A constraint model of space planning. Boston:

Computational Mechanics Publications.

Zhu, D., & Latombe, J. (1991). Pipe routing path planning (with many

constraints). Proceedings of the 1991 IEEE International Conference

on Robotics and Automation (pp. 1940 1947). Sacramento, California.

Jin Hyung Park is a PhD candidate in Industrial Engineering at the

University of Washington of the USA. He worked in the shipbuilding

industry for five years before he received his Masters degree at KAIST

in Korea in 1997.

Richard Lee Storch is a professor of Industrial Engineering at the

University of Washington. His research has concentrated on productivity and quality improvement in ship production and large

assembly manufacturing systems. He is a member of SNAME, IFIP

WG 5.7, IIE, and ASNE. He serves on the editorial boards of the

Journal of Ship Production and the Journal of Marine Science and

Technology.

You might also like

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityFrom EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo ratings yet

- Pipe RoutingDocument38 pagesPipe RoutingHadisupriadiNo ratings yet

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionFrom EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNo ratings yet

- Theoretical External Collapsing Pressure For Pipelines (Method Is Not Per ASME.)Document1 pageTheoretical External Collapsing Pressure For Pipelines (Method Is Not Per ASME.)NakkolopNo ratings yet

- Free Span Rectification by Pipeline Lowering (PL) MethodDocument10 pagesFree Span Rectification by Pipeline Lowering (PL) MethodJangdiniNo ratings yet

- Pipeline Heat TransferDocument2 pagesPipeline Heat TransferAhmed Rashied100% (1)

- Pipe Stress Analysis Complete Course From PassDocument2 pagesPipe Stress Analysis Complete Course From Passsleiman shokrNo ratings yet

- Igat6 D PL Me SPC 0011 03 Geotextile SpecificationDocument5 pagesIgat6 D PL Me SPC 0011 03 Geotextile Specificationamini_mohiNo ratings yet

- Puma5 Elena Cosmo5 EpcDocument16 pagesPuma5 Elena Cosmo5 EpcermusatNo ratings yet

- Research Progress On Pipeline Transportation Technology of Hydrogen-Mixed Natural GasDocument11 pagesResearch Progress On Pipeline Transportation Technology of Hydrogen-Mixed Natural GaschaimaleghNo ratings yet

- PPSC - Product Data Sheet Concrete Weight CoatingsDocument1 pagePPSC - Product Data Sheet Concrete Weight CoatingsjulianpirahNo ratings yet

- Ipc2012 90620Document17 pagesIpc2012 90620Marcelo Varejão CasarinNo ratings yet

- Pipng Stress Analysis Design Guide: Pagmi Phase I Project PROJECT NO.3235-200Document11 pagesPipng Stress Analysis Design Guide: Pagmi Phase I Project PROJECT NO.3235-200Salma BacharNo ratings yet

- Engineering Failure Analysis: Hossein Ghaednia, Sreekanta Das, Rick Wang, Richard KaniaDocument12 pagesEngineering Failure Analysis: Hossein Ghaednia, Sreekanta Das, Rick Wang, Richard KaniaJennifer Julieth Triana ForeroNo ratings yet

- HERTEL Metal GasketsDocument40 pagesHERTEL Metal Gasketshvdb72No ratings yet

- Basics of Pipe Stress Analysis A Presentation-Part 2 of 2Document6 pagesBasics of Pipe Stress Analysis A Presentation-Part 2 of 2iaftNo ratings yet

- Jun 94Document16 pagesJun 94Ashok KumarNo ratings yet

- AutoPIPE TutorialDocument158 pagesAutoPIPE Tutorialmario_gNo ratings yet

- Oil Pipeline Valve AutomationDocument12 pagesOil Pipeline Valve Automationhamza2085No ratings yet

- CTR-12 - FPSO Firenze - Clarification Report - Ph-1 Presv ItemsDocument3 pagesCTR-12 - FPSO Firenze - Clarification Report - Ph-1 Presv ItemsSri100% (1)

- Catalogue PDFDocument64 pagesCatalogue PDFkhan_mmusaNo ratings yet

- GeoMatt Datasheet TB11 Ed1 2017 ASTM ADDocument1 pageGeoMatt Datasheet TB11 Ed1 2017 ASTM ADganmosesNo ratings yet

- Data Sheet FanDocument2 pagesData Sheet Fantanbqtb03No ratings yet

- Commercial Gas Pipe Sizing PART 2 - Using The Pressure Drop Calculator (PDC)Document12 pagesCommercial Gas Pipe Sizing PART 2 - Using The Pressure Drop Calculator (PDC)Catalin StrugariuNo ratings yet

- Standards For Pipeline Coatings: CanadDocument11 pagesStandards For Pipeline Coatings: CanadMohamed DewidarNo ratings yet

- Civil DesignDocument2 pagesCivil Designarunasagar_2011No ratings yet

- #2 Pipes Class & Thickness (Handout)Document19 pages#2 Pipes Class & Thickness (Handout)farhanNo ratings yet

- Final As-Built Documentation FOR Muscat Sohar Products Pipeline (MSPP) ProjectDocument11 pagesFinal As-Built Documentation FOR Muscat Sohar Products Pipeline (MSPP) ProjectSiva baalan100% (1)

- Fatigue Analysis Using CAESAR IIDocument7 pagesFatigue Analysis Using CAESAR IIayoungaNo ratings yet

- Double Block and Bleed Valves - Instrumentation - Oliver ValvesDocument4 pagesDouble Block and Bleed Valves - Instrumentation - Oliver ValvesKehinde AdebayoNo ratings yet

- Design, Operation and Optimization of Constructed Wetland For Removal of PollutantDocument40 pagesDesign, Operation and Optimization of Constructed Wetland For Removal of PollutantKhairi OmarNo ratings yet

- 4-PU101-PR-DI-029 14 SheetsDocument16 pages4-PU101-PR-DI-029 14 SheetsBurhan Ayub100% (1)

- CV - Graduate Mechanical Engineer - Murat IslamDocument2 pagesCV - Graduate Mechanical Engineer - Murat IslamMurat IslamNo ratings yet

- Gea31375 Mooney Regulators Specdata r11Document24 pagesGea31375 Mooney Regulators Specdata r11mateuNo ratings yet

- AutoPIPE Tutorial PDFDocument156 pagesAutoPIPE Tutorial PDFdhaktodesatyajitNo ratings yet

- The Feasibility of Transporting Hydrogen in Existing PipelinesDocument9 pagesThe Feasibility of Transporting Hydrogen in Existing PipelinesomiitgNo ratings yet

- BS en Iso 11299-1-2018 - (2019-01-06 - 09-13-21 Am)Document26 pagesBS en Iso 11299-1-2018 - (2019-01-06 - 09-13-21 Am)wodonit136No ratings yet

- SECTION 15180 Heating and Cooling Piping Rev 0Document34 pagesSECTION 15180 Heating and Cooling Piping Rev 0mohamad damerlyNo ratings yet

- Chapter 12 - Wave Forces On Slender CylinderDocument78 pagesChapter 12 - Wave Forces On Slender CylinderJuan Carlos GonzálezNo ratings yet

- Remove Support: Issued For ConstructionDocument1 pageRemove Support: Issued For Construction86tejasNo ratings yet

- Autopipe TutorialDocument198 pagesAutopipe TutorialMuhammad Nashir100% (1)

- Engineered Spring SupportsDocument43 pagesEngineered Spring SupportsNestor Barranco RadaNo ratings yet

- Trapped Key Interlock For ValvesDocument7 pagesTrapped Key Interlock For Valvesra9622No ratings yet

- Determine-The-Optimal-Span-Between-Pipe Supports-For-Thin-Walled-Piping-Systems PDFDocument10 pagesDetermine-The-Optimal-Span-Between-Pipe Supports-For-Thin-Walled-Piping-Systems PDFLuis Pereira PeñaNo ratings yet

- 3 Sewage and Sewer DesignDocument25 pages3 Sewage and Sewer DesignMuhammad AmirNo ratings yet

- Aga Manual Stability Pipe - SearchDocument2 pagesAga Manual Stability Pipe - SearchDanar Tri YurindatamaNo ratings yet

- Piping Engineering NotesDocument46 pagesPiping Engineering NoteslightsonsNo ratings yet

- NZ-NZOS Pressure RegulatorDocument12 pagesNZ-NZOS Pressure Regulatorravirebba96950% (1)

- DNV OS C104 Elev UnitsDocument26 pagesDNV OS C104 Elev UnitsSaid ElhamydyNo ratings yet

- Checklist GD BandlockDocument3 pagesChecklist GD BandlockdeogmozyxNo ratings yet

- Model Pipe Resting On The Seabed Floor - AutoPIPE - Pipe Stress and Vessel Design - Wiki - Pipe Stress and Vessel Design - Bentley CommunitiesDocument7 pagesModel Pipe Resting On The Seabed Floor - AutoPIPE - Pipe Stress and Vessel Design - Wiki - Pipe Stress and Vessel Design - Bentley CommunitiesLK AnhDungNo ratings yet

- DNV 1996Document22 pagesDNV 1996ankeshkatochNo ratings yet

- Increase Allowable Stress CodeDocument9 pagesIncrease Allowable Stress Codewenny_tpdNo ratings yet

- Offshore Magazine November 2015Document88 pagesOffshore Magazine November 2015Shu En SeowNo ratings yet

- API 6D-IsO 14313 23rd Edition Errata 6Document3 pagesAPI 6D-IsO 14313 23rd Edition Errata 6adil_farooq_6100% (1)

- VIV Span EngineeringDocument15 pagesVIV Span EngineeringDianoDeNo ratings yet

- CAESAR II Software BasicsDocument28 pagesCAESAR II Software BasicsanishsrNo ratings yet

- Fpso-Sfa Guideline by ABSDocument44 pagesFpso-Sfa Guideline by ABSChristian ChineduNo ratings yet

- PipingDocument4 pagesPipingramthecharm_46098467No ratings yet

- Wall Theo PDFDocument23 pagesWall Theo PDFFranklin UkaohaNo ratings yet

- Ideation BrainstormingDocument20 pagesIdeation Brainstormingmechanical_engineer11No ratings yet

- Energy Facility Summary SlidesDocument3 pagesEnergy Facility Summary Slidesmechanical_engineer11No ratings yet

- Est01 - So You Think You'Re An EstimatorDocument6 pagesEst01 - So You Think You'Re An Estimatormechanical_engineer11No ratings yet

- P0412039496 PDFDocument3 pagesP0412039496 PDFmechanical_engineer11No ratings yet

- Risk01 - Managing Risk For Global Energy ProjectsDocument3 pagesRisk01 - Managing Risk For Global Energy Projectsmechanical_engineer11No ratings yet

- 03 en PSI Kebu Anti Corrosion TapesDocument13 pages03 en PSI Kebu Anti Corrosion Tapesmechanical_engineer11No ratings yet

- What Is The Value of The Value IndexDocument8 pagesWhat Is The Value of The Value Indexmechanical_engineer11No ratings yet

- Pipe Routing AlgorithmDocument10 pagesPipe Routing Algorithmmechanical_engineer11No ratings yet

- Native Data Sheet Asme b73.1Document4 pagesNative Data Sheet Asme b73.1Akhmad Faruq Alhikami100% (1)

- Improve On-Time DeliveriesDocument24 pagesImprove On-Time DeliveriesUdayNo ratings yet

- GP1 Q1 Week-1Document18 pagesGP1 Q1 Week-1kickyknacksNo ratings yet

- PEH Q3 Long QuizDocument1 pagePEH Q3 Long QuizBenedict LumagueNo ratings yet

- Liver: Anatomy & FunctionsDocument18 pagesLiver: Anatomy & FunctionsDR NARENDRANo ratings yet

- Goliath 90 v129 eDocument129 pagesGoliath 90 v129 eerkanNo ratings yet

- Considerations For Impeller Trimming - Empowering Pumps and EquipmentDocument8 pagesConsiderations For Impeller Trimming - Empowering Pumps and Equipment김기준No ratings yet

- H107en 201906 r4 Elcor Elcorplus 20200903 Red1Document228 pagesH107en 201906 r4 Elcor Elcorplus 20200903 Red1mokbelNo ratings yet

- NAT-REVIEWER-IN-PHYSICAL EDUCATIONDocument4 pagesNAT-REVIEWER-IN-PHYSICAL EDUCATIONMira Rochenie CuranNo ratings yet

- Niir Integrated Organic Farming Handbook PDFDocument13 pagesNiir Integrated Organic Farming Handbook PDFNatalieNo ratings yet

- The FOA Reference For Fiber Optics - Fiber Optic TestingDocument19 pagesThe FOA Reference For Fiber Optics - Fiber Optic TestingvsalaiselvamNo ratings yet

- Piriformis Syndrome: Hardi Adiyatma, Shahdevi Nandar KusumaDocument6 pagesPiriformis Syndrome: Hardi Adiyatma, Shahdevi Nandar Kusumaismael wandikboNo ratings yet

- Circle The Best Answer A, B, C, D or EDocument4 pagesCircle The Best Answer A, B, C, D or Ewilder jackNo ratings yet

- Bảng giá FLUKEDocument18 pagesBảng giá FLUKEVăn Long NguyênNo ratings yet

- RACI Matrix Design For Managing Stakeholders in PRDocument12 pagesRACI Matrix Design For Managing Stakeholders in PRRheza Nugraha Prabareswara100% (1)

- Prestige Institute of Management & Research: Guided By:-Submitted By: - Prof. Arpit Loya Sumeet RattanDocument21 pagesPrestige Institute of Management & Research: Guided By:-Submitted By: - Prof. Arpit Loya Sumeet RattanSumeet700005No ratings yet

- Murata High Voltage CeramicDocument38 pagesMurata High Voltage CeramictycristinaNo ratings yet

- Innerwear Industry Pitch PresentationDocument19 pagesInnerwear Industry Pitch PresentationRupeshKumarNo ratings yet

- Ali Erdemir: Professional ExperienceDocument3 pagesAli Erdemir: Professional ExperienceDunkMeNo ratings yet

- BC-6000 Installation Guide V7.0 enDocument111 pagesBC-6000 Installation Guide V7.0 enmentule88No ratings yet

- Owner'S Manual: 2023 Chassis CabDocument444 pagesOwner'S Manual: 2023 Chassis CabDmitry DimasNo ratings yet

- Manual Wire Rope Winches Wall-Mounted Wire Rope Winch SW-W: Equipment and ProcessingDocument1 pageManual Wire Rope Winches Wall-Mounted Wire Rope Winch SW-W: Equipment and Processingdrg gocNo ratings yet

- Ham Radio Balu N ManualDocument7 pagesHam Radio Balu N Manualcolinbeeforth100% (1)

- EXP4 The Diels Alder ReactionsDocument3 pagesEXP4 The Diels Alder ReactionsLaura GuidoNo ratings yet

- American BreakfastDocument4 pagesAmerican BreakfastHamilton Valenzuela ChipongianNo ratings yet

- Effects of Climate ChangeDocument3 pagesEffects of Climate Changejiofjij100% (1)

- 3rd Quarter Exam (Statistics)Document4 pages3rd Quarter Exam (Statistics)JERALD MONJUANNo ratings yet

- ZF-FreedomLine TransmissionDocument21 pagesZF-FreedomLine TransmissionHerbert M. Zayco100% (1)

- Harmonics PatternsDocument4 pagesHarmonics PatternsIzzadAfif1990No ratings yet

- Combined Shear and TensionDocument16 pagesCombined Shear and TensionDAN MARK OPONDANo ratings yet

- Certified Solidworks Professional Advanced Weldments Exam PreparationFrom EverandCertified Solidworks Professional Advanced Weldments Exam PreparationRating: 5 out of 5 stars5/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- AutoCAD 2010 Tutorial Series: Drawing Dimensions, Elevations and SectionsFrom EverandAutoCAD 2010 Tutorial Series: Drawing Dimensions, Elevations and SectionsNo ratings yet

- Product Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesFrom EverandProduct Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesRating: 4 out of 5 stars4/5 (4)