Professional Documents

Culture Documents

7 Compression Tanks.95110342

Uploaded by

Luis SabinoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7 Compression Tanks.95110342

Uploaded by

Luis SabinoCopyright:

Available Formats

Energy Efficient Building Design

College of Architecture

Illinois Institute Of Technology (IIT), Chicago

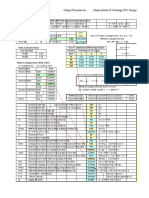

Pressurization Tank Sizing

Project Name

Project No.

System Type

Chilled Water

Date

Tank Identif. / Name

Tank Description

Cylindrical / Horizontal

Location (building)

Penthouse Equipt Room

Volume System Equipt

Properties of Water

Equipt Dscr

Volume

Temp

(replace/edit)

(cu.ft.)

T deg F

20

35

Chillers - Evap

Chillers - Cond

40

Cooling Towers

50

CHW Pumps

10

60

CW Pumps

70

Boilers - WT

80

HW Pumps

90

Heat Exchangers

100

Cooling Coils

50

110

Heating Coils

120

Radtrs, Convtrs

130

Fan Coil Units

30

140

Terminal Equipt

150

Miscell Equipt

10

Equip Vol (ft3)

120

System Vol (ft3) =

270

Contigency Factor ( %) =

10

Sys Vol + % age (ft3 ) = Vs

297

Equiv lbs of Water = Vp

18,555

Equiv gals of Water = Vg

2,226

E = Net Pressurization Factor for diaphragm tanks

T

90

0.004

110

0.008

130

100

0.006

120

0.010

140

Sizing Data (Enter as required by tank type & sizing method)

Maxim Water Temp - Tmax (F)

T2

% Exp of Water fr 35 F to T2

Tank Material (Steel / Copper)

Coeff of Exp of Tank Material

Tank Type (Open / Closed)

Closed Type (Normal / Diaphragm)

Tank Size (% of System Volume)

Default Diameter (inches)

Locatn w.r.t Pump (Suctn/Dischge)

System Height above Tank (ft)

Pr. Loss fr Tank to Pump (ft.Wtr)

Instructor: Varkie C. Thomas, Ph.D., P.E.

Skidmore, Owings Merrill LLP

276368672.xls

Energy Efficient Building Design

Pump Head (ft Wtr)

Instructor: Varkie C. Thomas, Ph.D., P.E.

College of Architecture

Skidmore, Owings Merrill LLP

Illinois Institute Of Technology (IIT), Chicago

PH

276368672.xls

Energy Efficient Building Design

College of Architecture

Illinois Institute Of Technology (IIT), Chicago

Volume of Pipes in System

Color Codes

Nom

User Input

Size

Calculated

(ins)

Reference Data

3/8

1/2

3/4

1

1 1/4

1 1/2

2

Sp.Vol

V ft3/lb

Temp Sp.Vol

2 1/2

% exp T deg FV ft3/lb % exp

0.01600

160

###

2.44

3 1/2

0.01602

0.12

170

###

2.81

0.01602

0.12

180

###

3.19

0.01604

0.25

190

###

3.56

0.01605

0.31

200

###

3.94

0.01607

0.44

210

###

4.38

10

0.01610

0.62

220

###

4.81

12

0.01613

0.81

230

###

5.25

14

0.01617

1.06

240

###

5.75

16

0.01620

1.25

250

###

6.25

18

0.01625

1.56

260

###

6.75

20

0.01629

1.81

270

###

7.44

22

0.01634

2.13

280

###

7.88

24

26

e = % Expansion of Water from 35 F to t

28

e = 100*( Vt - 0.016 ) / 0.016

30

t = Max temp of water (deg F)

32

Vt = Sp. Vol at temp t (ft3/lb)

34

a = Coeff of Exp of Steel (in / in) = 0.0000065

36

a = Coeff of Exp of Copper (in / in) = 0.0000095

Total Volume of Pipes (ft3) =

E = Net Exp of water (gals) heated from T1 to T2

0.012

150

0.018

0.015

160

0.021

T

e=

100

120

0.006

0.010

E = exp 13.4

22.3

200

Average Operating Temp (F

T

T1

3.94

Minim Water Temp - Tmin (F

Steel

Maxim Water Temp - Tmax (

T2

0.0000065

Specific Volume at Tmin (ft3

V1

Open

Specific Volume at Tmax (ft

V2

System Volume (ft3)

Vs

Normal

5

Min Press at Highest Point (

P1

24

Max Press to open Safety Va

P2

Suction

Atmospheric Pressure (psia)

Pa

90

Atmospheric Pressure (ft.Wt

A, Pa'

20

Venting Pressure (ft.Wtr)

Instructor: Varkie C. Thomas, Ph.D., P.E.

Skidmore, Owings Merrill LLP

V

276368672.xls

Energy Efficient Building Design

70

Instructor: Varkie C. Thomas, Ph.D., P.E.

College of Architecture

Illinois Institute Of Technology (IIT), Chicago

Maxim Operating Pressure (f

Po

Skidmore, Owings Merrill LLP

276368672.xls

Energy Efficient Building Design

Inside

College of Architecture

Volume

Length Volume

Diam

per ft

per size per size

(ins)

(cu.ft.)

0.49

0.001

0.62

0.002

0.82

0.004

20

0.07

1.05

0.006

30

0.18

1.38

0.010

1.61

0.014

30

0.42

2.07

0.023

20

0.47

2.47

0.033

30

1.00

3.07

0.051

20

1.03

3.55

0.069

4.03

0.088

5.05

0.139

6.07

(ft)

Illinois Institute Of Technology (IIT), Chicago

(cu.ft.)

0.00

0.00

0.00

0.00

30

2.65

0.201

50

10.03

7.89

0.340

30

10.19

10.02

0.548

11.94

0.777

20

15.55

13.13

0.940

15.00

1.227

16.88

1.553

18.81

1.931

0.00

20.75

2.348

0.00

22.64

2.796

0.00

25.25

3.477

0.00

27.25

4.050

0.00

29.25

4.666

0.00

31.25

5.326

0.00

33.25

6.030

0.00

35.25

6.777

0.00

0.00

0.00

0.00

70

###

0.00

150.3

rom T1 to T2

150

200

280

0.018

0.034

0.070

40.1

75.7

155.8

200

dt = T2-T1 =

160

40

(V2/V1 - 1) =

0.044

200

Pa / P1 =

0.588

0.0160

Pa / P2 =

0.368

0.0167

P1 / P2 =

0.625

297

Pa' / Po =

0.097

25.0

3*a*dt =

0.003

40.0

psi x

2.31

= ft

14.7

" Hg x

1.33

= ft

33.9

ft3 x

7.5

12

gals x

8.334

= gals

= lbs

Instructor: Varkie C. Thomas, Ph.D., P.E.

Skidmore, Owings Merrill LLP

276368672.xls

Energy Efficient Building Design

350

ft3 x

62.4

= lbs

Instructor: Varkie C. Thomas, Ph.D., P.E.

College of Architecture

Skidmore, Owings Merrill LLP

Illinois Institute Of Technology (IIT), Chicago

276368672.xls

Energy Efficient Building Design

College of Architecture

Illinois Institute Of Technology (IIT), Chicago

Pressurization Tank Sizing

Open Tank Sizing

Sizing assumes Open Tank is: (1) vented to atmosphere, (2) at

Vt

Basis of Sizing

(1) As a Percentage of Syst

Weight Volume

Tank Size

3' above highest point of system, & (3) connected to pump suc

gallons

lbs

ft3

D (in)

L (ft)

Vt =

Minimum Volume of Expansion Tank (gals)

111

928

15

24.0

4.7

Vt =

Vs * (% of System Volume / 100)

(2) Using Min, Max Temp, Exp 96

804

13

24.0

4.1

Vt =

Vs * (e/100) * 1.1

Exp Vol + 10%

from ASHRAE Systems 20 181

1508

24

24.0

7.7

Vt =

2 * Vs * [ (V2/V1 - 1) - (3ASHRAE 2000

Closed Tank Sizing

V = +ve venting pressure (= 12 ft if unknown)

Fill Pressure (Pf): The tank location w.r.t. the piping system affects the initial fill or

F=

minim

frictional

pressloss

at the

from

tank.

tank to pump in order to

The tank can be at three possible locations with respect to the system as shown maintain +ve venting pressure (ft)

Pf = Initial or

Pf

Pa/Pf

A = atmospheric pressure (ft)

Min

Pa/Pf

Pf/Po 1-Pf/Po

Fill

Pressure

Location of Tank

ft H2O

- Pa/Po

H = system static head (ft) = distance between

(ft)

(1) Tank is above the piping Pf = V + F + 65.9 0.51

0.42

0.19 0.81

tank and highest point of system

(2) Tank is on suction side o

Pf = V + H + 135.9

0.25

0.15

0.39

0.61

(3) Tank is on discharge sid

Pf = V + PH + 115.9

0.29

0.20

0.33

0.67

110

Vs =

297

(1) Closed Tank:: T <= 16 T2 =

150

dt =

V2 at T2 0.016

Location of Tank

Denom Vt gals

E = e*Vs

40

Lbs

ft3

D (ft)

(1) Tank is above the piping

0.42

96

798

13

24.0

4.1

(2) Tank is on suction side o

0.15

262

2185

35

24.0

11.1

(3) Tank is on discharge sid

0.20

204

1704

27

24.0

8.7

Using ASHRAE HdBk Syst 0.22

193

1608

26

24.0

8.2

Vs =

297

(2) Closed Tank:: 160 <= T <= T2 =

200

DenomGallons

Lbs

ft3

D (ft)

(1) Tank is above the piping

0.42

189

###

25.2

24.0

8.0

(2) Tank is on suction side o

0.15

517

###

69.0

24.0

22.0

(3) Tank is on discharge sid

0.20

403

###

53.8

24.0

17.1

410

3419

55

24.0

17.4

(3) Closed Chilled Water Tank

T=

Vs =

297

(0.00041 x T - 0.0466) 79

Location of Tank

DenomGallons

Lbs

ft3

D (ft)

L (ft)

(1) Tank is above the piping

0.81

97

809

13

24.0

4.1

(2) Tank is on suction side o

0.61

129

1074

17

24.0

5.5

(3) Tank is on discharge sid

0.67

118

982

16

24.0

5.0

Using ASHRAE HdBk Syst 0.22

205

1709

27

24.0

8.7

297

(4) Closed Diaphragm Water Ta T =

120

Vs =

E=

0.01

Num = E*Vs = 22

Location of Tank

DenomGallons

Lbs

ft3

D (ft)

L (ft)

(1) Tank is above the piping

0.19

118

985

16

24.0

5.0

(2) Tank is on suction side o

0.39

57

478

24.0

2.4

(3) Tank is on discharge sid

0.33

67

560

24.0

2.9

241

2010

32

24.0

10.3

Using ASHRAE HdBk Syst 0.38

References: (1) 1987 ASHRAE Handbook, pp. 13.11 - 13.15

Instructor: Varkie C. Thomas, Ph.D., P.E.

Minim Volume of Pressurization Tank (gals)

Vt =

ASHRAE 1987

(Pa/Pf) - (Pa/Po)

for T <= 160 F

E = Net expansion of water (gals) heated from 40 F to

Vt =

Vs *

[(V2/V1) - 1] - (3* ASHRAE

(Pa/P1) - (Pa/P 2000

L (ft)

Using ASHRAE HdBk Syst 0.22

90

at the top of the system

L (ft)

(0.00041 x T - 0.0466) 79

Location of Tank

Vt =

PH = pump head (ft) reqd to maintain +ve press

Vt =

(0.00041*T - 0.046 ASHRAE 1987

( Pa/Pf) - (Pa/P 160 <= T <= 280

(1) Tank Size is half of a hot water tank operating at 200

Vt =

(0.00041*T - 0.0466) * Vs

2 * [(Pa/Pf) - (Pa/Po)]

ASHRAE 1987

(2) Tank Size can be estimated from:

Vt =

Vt =

Vt =

(0.00041*T - 0.0466) * Vs

1 - (Pf/Po)

E * Vs

ASHRAE 1987

[ 1 - (Pf/Po) ]

for T <= 160 F

Vs *

[(V2/V1) - 1] - (3*a

ASHRAE

[ 1 - (P1/P2) ] 2000

(2) 2000 ASHRAE Handbook pp. 12.3 - 12.5

Skidmore, Owings Merrill LLP

276368672.xls

Energy Efficient Building Design

Instructor: Varkie C. Thomas, Ph.D., P.E.

College of Architecture

Skidmore, Owings Merrill LLP

Illinois Institute Of Technology (IIT), Chicago

276368672.xls

Energy Efficient Building Design

College of Architecture

Illinois Institute Of Technology (IIT), Chicago

mosphere, (2) at least

ted to pump suction

2 ft if unknown)

pump in order to

stance between

aintain +ve press.

Tank (gals)

ed from 40 F to T

operating at 200 F

Instructor: Varkie C. Thomas, Ph.D., P.E.

Skidmore, Owings Merrill LLP

276368672.xls

Energy Efficient Building Design

Instructor: Varkie C. Thomas, Ph.D., P.E.

College of Architecture

Skidmore, Owings Merrill LLP

Illinois Institute Of Technology (IIT), Chicago

276368672.xls

Energy Efficient Building Design

College of Architecture

Illinois Institute of Technology (IIT), Chicago

PRESSURIZATION TANKS

Pressurization tanks include expansion tanks and compression tanks. The term expansion tank is used with low

pressure systems where the tank is located at the highest point of the piping system (open or closed) and the ta

water surface is at atmospheric pressure. The height location of the expansion tank determines the static press

head available to the terminal equipment. The term compression tank applies to pressurized closed piping syste

Make-up water is supplied through the pressurization tank.

Pressurization tank types include (1) Open and (2) Closed

Closed pressurization tank construction can be:

A regular tank where the pressurizing air or gas is in contact with the liquid.

A diaphragm tank where the air charge and liquid are permanently separated by a diaphragm to prevent

corrosion of the tank or contamination of the fluid.

System Volume

Pressurization tank size is based on the volume capacity of the system. System volume consists of:

the physical inside volume of all the pipe sections in the system. The pipe volume is converted into gallon

liquid using the density of the liquid.

the liquid storage capacity of all the equipment in the system. The physical volume storage capacity of th

terminal equipment, primary equipment and miscellaneous equipment, etc., that is converted to liquid

volume using liquid density.

Open Tank Sizing

Open tank sizing assumes that the tank is:

vented to the atmosphere

at least three feet above the highest point in the piping system

connected to the suction side of the pump

Tank Volume

The tank volume size in gallons is estimated as a percentage of the total system volume The minimum reco

volume is 6% in accordance with 1987ASHRAE Handbook. An alternative to sizing the tank based on percenta

system volume, the system liquid expansion volume can be used to determinethe tank size. This expansion

is the difference in volumes at the maximum temperature of the piping system and at the minimum temperatur

Closed Tank Sizing

Fill Pressure: The tank location with respect to the piping system affects the initial fill or minimum pressure Pf

at the tank. The tank can be at three possible locations with respect to the system.

(1)

(2)

(3)

Pf = V + F + A

Pf = V + H + A

Pf = V + PH + A

Tank is above the piping system

V

= positive venting pressure; (assumes 12 ft of liquid if not known)

F

= frictional pipe losses from tank to pump that must be overcome in order to

obtain positive air venting pressure (ft of liquid as specified in input)

A

= atmospheric pressure (ft of liquid)

Tank is on suction side of the pump

H

= system static head = distance between tank and highest point of piping syste

Tank is on discharge side of the pump

PH = pump head (ft of liquid) required to maintain positive pressure attop of system

In all three cases, the atmospheric pressure A is added to obtain absolute pressure

You must specify either the initial fill pressure Pf or the system static head H.

Instructor: Varkie C. Thomas, Ph.D., P.E.

Skidmore, Owings Merrill LLP

276368672.xls

Energy Efficient Building Design

College of Architecture

Illinois Institute of Technology (IIT), Chicago

Tank Sizing Equations (closed tanks)

is used with low

losed) and the tanks

Vt =

s the static pressure

osed piping systems.

[( ) ( ) ]

Vt =

Pa

Pf

Pa

Po

(1) Tank with operating temperatures below 160 F

Vt = minimum volume of pressurization tank (gal)

E

= net pressurization of water in the system when heated from min to max temp (gal)

Pa = pressure in tank when water first enters tank (ft of water absolute); At atmos.press.

Pf = initial fill or minimum pressure of tank (ft of water absolute)

Po = maximum operating pressure of tank (ft of water absolute)

( 0 . 041 x T - 0 . 0466 ) x V s

[( ) ( )]

Pa

Pf

gm to prevent

( 0 . 041 x T - 0 . 0466 ) x V s

Vt =

[ ( )]

verted into gallons of

ge capacity of the

onverted to liquid

Vt =

Pa

Po

e Vs

[ ( )]

1-

Pf

Po

Pf

Po

(2) Tank with operating temperatures between 160 F and 280 F

T

= maximum average operating temperature (oF)

Vs = system volume calculated from the piping system dimensions (gal)

Error: Denominator is Pa/Pf - Pa/Po

(3) Chilled Water Tank

Error: Denominator is 1 - Pf/Po

Tank sizing for chilled water systems will result in tanks of very small size

because of the low pressurization coefficients (40 F to 90 F temperature range). Fo

reason, closed compression tanks applied to chilled water systems are sized as follo

(1) regular tank size is half the equivalent hot water size

(2) the piping system is considered to be operating from 70 F to 200 F

(4) Diaphragm Water Tank

Specific Volume of Water

(ASHRAE Chapter-6, Table-4)

e = net pressurization factor for water Tmp

F

0

The lowest temperature of chilled water equals the mini 32

design temperature. This can be assumed to be 35 o 40

inimum reco The highest temperature is the highest anticipated ambie 50

ed on percentaThe net pressurization factor e is obtained from table be 60

his expansion Source: 1987 ASHRAE Handbook, Table 2, p. 13.15

70

mum temperature.

80

Net Pressurization Facto Typical make-up water su 90

for Diaphragm Water Ta and expansion tank piping100

plain steel tanks

110

psia

ft3 / lb

0.0185

0.0886

0.0174

0.0175

0.1217

0.1781

0.2564

0.0160

0.0160

0.0160

0.3633

0.5074

0.0161 1.6667

0.0161 1.7500

0.0161 2.0000

0.0161 2.1667

0.6989

0.9503

Press.

120

1.2765

1.6947

F

90

Factor

e

0.004

130

140

2.2257

2.8926

100

110

0.006

0.008

150

160

3.7228

4.7469

120

130

0.010

0.012

170

180

190

5.9994

7.5194

9.3495

140

150

0.015

0.018

200

210

11.5375

14.1358

160

0.021

220

230

17.2010

20.7960

240

250

24.9873

29.8462

260

280

35.4502

49.2260

300

67.0350

Highest

um pressure Pf Temp

me in order to

Sp.Vol Expansion

ft3 / (F.lb)

* 1,000,000

Press

nt of piping system

e attop of system

Instructor: Varkie C. Thomas, Ph.D., P.E.

Skidmore, Owings Merrill LLP

0.0162 2.4286

0.0162 2.5000

0.0163 2.7778

0.0163 2.9000

0.0163 3.0909

0.0164 3.2500

0.0165 3.4615

0.0165 3.6429

0.0166 3.8000

0.0166 3.9375

0.0167 4.1176

0.0168 4.2778

0.0168 4.4211

0.0169 4.6000

0.0170 4.7619

0.0171 4.9091

0.0173 5.2500

0.0175 5.5769

276368672.xls

Energy Efficient Building Design

College of Architecture

Illinois Institute of Technology (IIT), Chicago

to max temp (gal)

e); At atmos.press.

ensions (gal)

erature range). For that

ms are sized as follows:

Sp.Vol

Exp: ft3

ft3 / gal

/ (F.gal)

* 1,000,000

* 1,000,000

###

###

###

###

###

###

###

8.6900

10.6845

###

###

13.5480

15.4570

###

###

18.0111

18.8850

###

###

###

21.4167

22.6086

24.3415

###

###

25.7855

27.6485

###

###

29.2453

30.6292

###

###

31.8401

33.3988

0.1398

0.1403

34.7843

36.0240

0.1410

0.1417

37.5564

38.9429

0.1423

0.1438

0.1454

40.2033

43.1035

45.8781

Instructor: Varkie C. Thomas, Ph.D., P.E.

Skidmore, Owings Merrill LLP

276368672.xls

Energy Efficient Building Design

College of Architecture

Illinois Institute of Technology (IIT), Chicago

PROPERTIES OF LIQUIDS

Liquid

Water

Glycol

Brine

Diesel

Petrol

Properties

-30

Density (lb/cu ft)

Specific Gravity ( = Density / 6

Kinematic viscosity (sq ft/sec)

Specific heat (Btu/lb oF)

Density (lb/cu ft)

67.98

Specific Gravity ( = Density / 6 1.09

Kinematic viscosity (sq ft/sec) ###

0.70

Specific heat (Btu/lb oF)

Density (lb/cu ft)

78.59

Specific Gravity ( = Density / 6 1.26

Kinematic viscosity (sq ft/sec) ###

Specific heat (Btu/lb oF)

0.66

Density (lb/cu ft)

59.20

Specific Gravity ( = Density / 6 0.95

Kinematic viscosity (sq ft/sec) ###

Specific heat (Btu/lb oF)

0.47

Density (lb/cu ft)

46.10

Specific Gravity ( = Density / 6 0.74

Kinematic viscosity (sq ft/sec) 11.00

Specific heat (Btu/lb oF)

0.47

67.55

1.08

190.00

0.73

78.21

1.25

77.50

0.67

57.40

0.92

161.50

0.48

45.50

0.73

9.80

0.48

Temperature

30

60

100

150

62.42

62.37

62.00

61.20

1.00

1.00

0.99

0.98

0.00

12.17

7.39

4.76

1.00

1.00

1.00

1.00

67.11

66.55

65.74

64.68

1.08

1.07

1.05

1.04

85.40

48.60

22.60

12.50

0.76

0.78

0.81

0.85

77.71

77.21

76.09

1.25

1.24

1.22

34.70

21.80

8.90

0.68

0.69

0.71

56.10

54.90

53.00

51.10

0.90

0.88

0.85

0.82

80.70

48.30

29.10

7.50

0.49

0.50

0.51

0.52

44.90

44.70

44.30

42.40

0.72

0.72

0.71

0.68

8.80

7.00

5.50

3.00

0.49

0.50

0.51

0.52

PROPERTIES OF HIGH TEMPERATURE HOT WATER

Temp

deg F

212

220

240

260

280

300

350

400

450

Satur.

Press

psig

0

2.5

10.3

20.7

34.5

52.3

119.9

232.6

407.9

Density Specific Kinem Sp. Heat

lb/cu ft Gravity = ViscosBtu/lb oF

Density/62.4sq ft/sec

0.96

1.006

59.81

3.2

0.96

1.007

59.63

3

0.95

1.01

59.1

2.7

0.94

1.015

58.51

2.5

0.93

57.94

2.3

1.02

0.92

57.31

2.1

1.26

0.89

55.59

1.9

1.044

0.86

53.65

1.7

1.067

0.83

51.55

1.5

1.095

Instructor: Varkie C. Thomas, Ph.D., P.E.

Skidmore, Owings Merrill LLP

210

59.81

0.96

3.20

1.01

63.12

1.01

6.40

0.88

Increase in Frictional Pressure Loss

due to Pipe Age

Hydraulic Handbook by Colt Industries

Multipliers

Pipe Age

Years

0

5

10

15

20

25

30

35

40

45

50

60

Small

1 - 3

1

1.4

2.2

3.6

5

6.3

7.25

8.1

8.75

9.25

9.6

10

Medium Large

4 to 12 14 - 48

1

1

1.35

1.3

1.9

1.6

2.7

1.8

3.5

2

4.2

2.1

4.73

2.2

5.2

2.3

5.58

2.4

5.93

2.6

6.23

2.86

7

3

276368672.xls

Energy Efficient Building Design

College of Architecture

Illinois Institute of Technology (IIT), Chicago

ressure Loss

olt Industries

Instructor: Varkie C. Thomas, Ph.D., P.E.

Skidmore, Owings Merrill LLP

276368672.xls

You might also like

- CCTV Commissioning CertificateDocument1 pageCCTV Commissioning CertificateLuis SabinoNo ratings yet

- CommissioningDocument32 pagesCommissioningLuis SabinoNo ratings yet

- Reflex Pressure Vessels Design and CalculationDocument52 pagesReflex Pressure Vessels Design and CalculationcsharpplusNo ratings yet

- HBS-Brochure Stud Welding Fasteners-Engl 100920 01Document12 pagesHBS-Brochure Stud Welding Fasteners-Engl 100920 01Luis SabinoNo ratings yet

- DOE Mechanical Science Volume 2 of 2 DOE-HDBK-10182-93Document130 pagesDOE Mechanical Science Volume 2 of 2 DOE-HDBK-10182-93Titer100% (1)

- Plastic Packaging Waste Management Options - Wrap - Jun 08Document78 pagesPlastic Packaging Waste Management Options - Wrap - Jun 08Luis SabinoNo ratings yet

- UK-SPEC guide for EngTech, IEng, CEngDocument48 pagesUK-SPEC guide for EngTech, IEng, CEngDavide BoreanezeNo ratings yet

- DOE Fundamentals Handbook, Mechanical Science, Volume 1 of 2Document122 pagesDOE Fundamentals Handbook, Mechanical Science, Volume 1 of 2Bob VinesNo ratings yet

- Plastic Pipe - PE - Chapter01Document9 pagesPlastic Pipe - PE - Chapter01garisa1963No ratings yet

- Industrial Drying - Principle and PracticeDocument94 pagesIndustrial Drying - Principle and PracticeRajeev Maheshwari63% (8)

- API 650 Crude Oil Storage Tank DesignDocument8 pagesAPI 650 Crude Oil Storage Tank Designlecongdinh100% (1)

- Sample Commissioning PlanDocument104 pagesSample Commissioning PlanLuis SabinoNo ratings yet

- Fire Alarm System Record of CompletionDocument4 pagesFire Alarm System Record of CompletionLuis SabinoNo ratings yet

- Project AbbreviationsDocument4 pagesProject AbbreviationsLuis SabinoNo ratings yet

- BeamsDocument14 pagesBeamsLuis SabinoNo ratings yet

- D1e 101Document40 pagesD1e 101Wirna_Wirdani_9320No ratings yet

- Engineering GuideDocument34 pagesEngineering GuideNandhakumaran RajagopalanNo ratings yet

- BeamsDocument14 pagesBeamsLuis SabinoNo ratings yet

- A Chinese Biogas ManualDocument135 pagesA Chinese Biogas ManualDaniel Judy100% (1)

- 1980 National Waste Processing Conference 34Document11 pages1980 National Waste Processing Conference 34premNo ratings yet

- 30004DDZDocument168 pages30004DDZLuis SabinoNo ratings yet

- Powder and Bulk Dot Com Help Forums - Trommel CalculationDocument2 pagesPowder and Bulk Dot Com Help Forums - Trommel CalculationLuis SabinoNo ratings yet

- Drawing Page: Download Iso 10511 Standards Accreditation Spot Welding Consumables Welding TablesDocument3 pagesDrawing Page: Download Iso 10511 Standards Accreditation Spot Welding Consumables Welding TablesLuis SabinoNo ratings yet

- MSW TreatmentDocument65 pagesMSW TreatmentLuis SabinoNo ratings yet

- Smooth FM PlaylistDocument3 pagesSmooth FM PlaylistLuis SabinoNo ratings yet

- Pipe Components GuideDocument172 pagesPipe Components Guideninju1No ratings yet

- LC MS Nitrogen GeneratorDocument15 pagesLC MS Nitrogen GeneratorLuis SabinoNo ratings yet

- Diesel Fuels & Diesel Fuel Systems: Application and Installation GuideDocument64 pagesDiesel Fuels & Diesel Fuel Systems: Application and Installation GuideEd CalheNo ratings yet

- VentingDocument28 pagesVentingWalter DelgadoNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Mies Van Der RoheDocument176 pagesMies Van Der RoheRusu Paul HoreaNo ratings yet

- Restoration of Crown HallDocument8 pagesRestoration of Crown HallDipti AgrahariNo ratings yet

- Amrit SOP IitDocument2 pagesAmrit SOP IitAlok Kumar Verma100% (1)

- Conversations With: Mies Van Der RoheDocument96 pagesConversations With: Mies Van Der RoheRicardo100% (2)

- Brief of IIT - C Programs - 10-03-11Document4 pagesBrief of IIT - C Programs - 10-03-11misak88No ratings yet

- FireSmoke Control Stair PressurizationDocument10 pagesFireSmoke Control Stair PressurizationMohamed AsifNo ratings yet

- HoA3 (3.4 Mies Van Der Rohe - Contribution To Architecture)Document10 pagesHoA3 (3.4 Mies Van Der Rohe - Contribution To Architecture)003. M.priyankaNo ratings yet

- Current Grad BulletinDocument415 pagesCurrent Grad BulletinchessgeneralNo ratings yet

- Mies Van Der Rohe WorksDocument34 pagesMies Van Der Rohe WorksAshish HoodaNo ratings yet

- Mies Van Der Rohe BibliographyDocument28 pagesMies Van Der Rohe BibliographyEcaterina OnicaNo ratings yet

- Theory of Design: Ar. Achyut Prakash KanvindeDocument33 pagesTheory of Design: Ar. Achyut Prakash Kanvindeank25795No ratings yet

- Without Within Mark Pimlott 1-29Document12 pagesWithout Within Mark Pimlott 1-29Negar SB100% (1)

- Illinois Tech Int'l Student Cost & Funding PlanDocument1 pageIllinois Tech Int'l Student Cost & Funding PlanRajat SinghNo ratings yet

- Aaron Mikottis Architectural Portfolio 2014/TITLEDocument50 pagesAaron Mikottis Architectural Portfolio 2014/TITLEMelodyFranciscoNo ratings yet

- Mies Van Der RoheDocument12 pagesMies Van Der RoheYvan Moreno100% (3)

- Mies' Speech To Architecture Students. IIT 1938Document2 pagesMies' Speech To Architecture Students. IIT 1938Ignacio Fernández Solla100% (2)

- Container Design: InnovativeDocument24 pagesContainer Design: InnovativeUbaid KhanNo ratings yet

- Mies van der Rohe Architectural ReportDocument34 pagesMies van der Rohe Architectural ReportAshish Hooda100% (1)

- UGA Viewbook 2023-24 - INTLDocument22 pagesUGA Viewbook 2023-24 - INTLsarishdNo ratings yet

- Vraj Usa Illinois Tech Computer Science (M.a.S.)Document3 pagesVraj Usa Illinois Tech Computer Science (M.a.S.)Hardik PatelNo ratings yet

- Connections in Steel Structures PDFDocument54 pagesConnections in Steel Structures PDFsmmsajediNo ratings yet

- Architects and Their PhilosophiesDocument11 pagesArchitects and Their PhilosophiesAdrianNo ratings yet

- CaseStudy MindanaoStateUniversityDocument9 pagesCaseStudy MindanaoStateUniversityJessa Mae Banse LimosneroNo ratings yet

- Aso Alumni Newsletter Issue 1Document8 pagesAso Alumni Newsletter Issue 1api-246594047No ratings yet

- History PresentationDocument25 pagesHistory PresentationvaishaliNo ratings yet

- Undergraduate Bulletin 2012 2014Document318 pagesUndergraduate Bulletin 2012 2014chessgeneral50% (2)

- Theory of Design: Ar. Achyut Prakash KanvindeDocument33 pagesTheory of Design: Ar. Achyut Prakash KanvindeArnav DasaurNo ratings yet

- Perspectives Charter Schools Annual Report 2012Document12 pagesPerspectives Charter Schools Annual Report 2012Perspectives Charter SchoolsNo ratings yet

- 4 - FireSmoke Control Stair Pressurization.28122850Document8 pages4 - FireSmoke Control Stair Pressurization.28122850CTHNo ratings yet