Professional Documents

Culture Documents

Rento PDF

Uploaded by

Anonymous Lu6vjikOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rento PDF

Uploaded by

Anonymous Lu6vjikCopyright:

Available Formats

RENTO(XM) >2011 > G 3.

5 MPI > Engine > Engine Control > P0014 \'B\' Camshaft Position - Timing OverAdvanced or System Performance (Bank 1)

Component Location

General Description

The CVVT (Continuously Variable Valve Timing) system is installed to the chain sprocket of the camshaft. This system controls the

camshaft to provide the optimal valve timing for every driving condition. The PCM controls the Oil Control Valve(OCV), based on the

signals output from mass air flow, throttle position and engine coolant temperature. The CVVT controller regulates the camshaft

angle using oil pressure through the OCV. As result, the relative position between the camshaft and the crankshaft becomes

optimal, and the engine torque improves, fuel economy improves, exhaust emissions decrease under over all driving conditions.

DTC Description

The PCM monitors the CAM phasing and compares the phasing to the desired setting.

PCM determines that a fault exists and a DTC is stored while vehicle is tip - in and out driving for 5 minutes.

PCM monitors CAM phaser error while CMP signal is normally generating and vehicle is driving in 2000 ~ 3000rpm .

If the CAM phaser does not move although PCM commands OCV duty cycle PCM determines that a faultexists and a DTC is

stored.

PCM monitors OCV stuck while cam sinal is normally generating and Valve cleaning is not in progress .

If the CAM Acutal Position is too high or low and Difference between Cam Actual Positionand Desire Position is higher than 20

PCM determines that a fault exists and a DTC is stored.

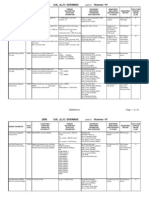

DTC Detecting Condition

Item

Detecting Condition

Case1

DTC Strategy

Case2, 3

Determines if the phaser is stuck or has steady-state error

Case4, 5

Determines if oil control valve is stuck

Case1

Enable

Conditions

Determines if the phaser is moving at an expected rate

CAM signal is normally generating

Accelerate and decelerate more than 10 times within 5 minutes while driving

Case2, 3

CAM signal is normally generating

Vehicle is on driving (2000 ~ 3000RPM) for 5 minutes.

Case4, 5

Valve cleaning not in progress

CAM signal is normally generating

Case1

Cam phasing is abnormally fast or slow

Case2

5 CAD < Cam Actual Position < 50 CAD

Duty Cycle > 90% or Duty Cycle < 10%

Threshold value

CAD : Crank Angle Degree

Case3

Cam Position error > 15 CAD

(Difference between Actual Postion and Desire Position is more than 15)

Timing Counter > 80

CAD : Crank Angle Degree

Case4

Cam Actual Position > 50 CAD and Difference between CAM Actual Position and Desire P

CAD : Crank Angle Degree

Case5

Cam Actual Position < 5 CAD and Difference between CAM Actual Position and Desire Po

CAD : Crank Angle Degree

Case1,2,3

Continuous (Within 5min.)

Case4, 5

Continuous (Within 1min.)

Diagnosis Time

MIL On Condition

2 Drive Cycles

Specification

OCV

Coil Resistance ()

Diagnostic Circuit Diagram

Signal Waveform & Data

Fig.1) Normal data of EX-CVVT at acceleration.

Fig.2) Normal graph of EX-CVVT at acceleration.

Fig.3) Normal waveform of CKPS & EX-CMPS at idle.

Fig.4) Normal waveform of CKPS & EX-CMPS at acceleration.

Fig.5) Normal data of EX-CVVT at idle.

This example shows a typical Crankshaft Position Sensor (CKPS) and Camshaft Position Sensor (CMPS) waveform at idle.(Fig1.) If

the 17th signal of the CKPS after missing tooth is aligned with the high signal of the CMPS at idle, PCM recognizes that

Synchronization between CKPS and CMPS is completed. Under acceleracting condition, the number of teeth between missing tooth

and tooth aligned with edge of the CMPS high signal is decreased from idle condition.(Fig2.)

Portions of materials contained herein are sourced from the Hyundai Kia Automotive Group

You might also like

- 08 GRP12b All EnginesDocument74 pages08 GRP12b All Engineseurospeed2No ratings yet

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- 2006 File 15Document63 pages2006 File 15eurospeed2No ratings yet

- Accent P0011 Camshaft Position-Timing Over-AdvancedDocument6 pagesAccent P0011 Camshaft Position-Timing Over-Advancedflash_24014910No ratings yet

- 2006 3.5L (L52) Engine Diagnostic Parameters: 2006file14Document31 pages2006 3.5L (L52) Engine Diagnostic Parameters: 2006file14eurospeed20% (1)

- Accent P0012 Camshaft Position-Timing Over-Retarded (Bank 1)Document5 pagesAccent P0012 Camshaft Position-Timing Over-Retarded (Bank 1)flash_24014910No ratings yet

- DTC Chart Power TrainDocument156 pagesDTC Chart Power TrainHuguito DiazNo ratings yet

- 07 GRP01 All EnginesDocument27 pages07 GRP01 All Engineseurospeed2No ratings yet

- 1999-2004 Discovery2 RR 38A Bosch GS8.87 TCMDocument13 pages1999-2004 Discovery2 RR 38A Bosch GS8.87 TCMBernard TrippNo ratings yet

- 08 GRP01 All Engines Engine Fault CodesDocument24 pages08 GRP01 All Engines Engine Fault Codescianurel2184No ratings yet

- GM - Cas VVT Sensor PDFDocument16 pagesGM - Cas VVT Sensor PDFDoDuyBac0% (1)

- DTC P0008 or P0009: Diagnostic InstructionsDocument2 pagesDTC P0008 or P0009: Diagnostic InstructionsJose Luis Velasquez RomeroNo ratings yet

- Sincronia YarisDocument8 pagesSincronia YarisJimmy AlemanNo ratings yet

- l26 Codigos de FallaDocument71 pagesl26 Codigos de FallaMikeNo ratings yet

- Accent P0016 Crankshaft Position-Camshaft Position CorrelationDocument8 pagesAccent P0016 Crankshaft Position-Camshaft Position Correlationflash_24014910No ratings yet

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0011Document3 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0011PeterNo ratings yet

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0010Document3 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0010PeterNo ratings yet

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0016Document3 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0016PeterNo ratings yet

- DTC P0335 CKP Sensor A Circuit Performance: 2000 Cadillac DevilleDocument5 pagesDTC P0335 CKP Sensor A Circuit Performance: 2000 Cadillac Devillealis13No ratings yet

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0011Document4 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0011PeterNo ratings yet

- 2006fileaveo MTDocument63 pages2006fileaveo MTeurospeed2100% (1)

- Tac PDFDocument3 pagesTac PDFZool Car زول كارNo ratings yet

- 2006trans13 CDocument26 pages2006trans13 Ceurospeed2No ratings yet

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0496Document2 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0496PeterNo ratings yet

- GR00005800C 13aDocument303 pagesGR00005800C 13aLuis David Leon GarciaNo ratings yet

- 14OBDG02 Engine DiagnosticsDocument502 pages14OBDG02 Engine DiagnosticsVASEK100% (1)

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0340Document3 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0340Julio SanchezNo ratings yet

- Land Rover-Freelander 2005Document85 pagesLand Rover-Freelander 2005Anderson Duarte100% (1)

- Diagnostic Trouble Code Charts for 6.0L Diesel EnginesDocument28 pagesDiagnostic Trouble Code Charts for 6.0L Diesel EnginesRogério MorenoNo ratings yet

- RM 61Document653 pagesRM 61joxeno907No ratings yet

- 7.3L Diesel Engine OBD System SummaryDocument26 pages7.3L Diesel Engine OBD System SummaryTigxMig75% (8)

- Continuously Variable Valve TimingDocument12 pagesContinuously Variable Valve TiminggamerpipeNo ratings yet

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0013Document3 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0013PeterNo ratings yet

- Diagnostic Trouble Code (DTC) Charts and DescriptionsDocument176 pagesDiagnostic Trouble Code (DTC) Charts and DescriptionsfredNo ratings yet

- 2006 File 17Document57 pages2006 File 17eurospeed2No ratings yet

- 08 Grp11 Hybrid EcmDocument67 pages08 Grp11 Hybrid Ecmeurospeed2No ratings yet

- 13OBDG09 Engine DiagnosticsDocument562 pages13OBDG09 Engine DiagnosticsEric Joseph GoldenNo ratings yet

- DTC P0016 Crankshaft Position - Camshaft Position Corre-Lation (Bank 1 Sensor A)Document2 pagesDTC P0016 Crankshaft Position - Camshaft Position Corre-Lation (Bank 1 Sensor A)robin blahoutNo ratings yet

- EC-268 DTC P0340, P0345 CMP SENSOR TROUBLESHOOTINGDocument8 pagesEC-268 DTC P0340, P0345 CMP SENSOR TROUBLESHOOTINGGuillermo RojasNo ratings yet

- 2006 File 4Document85 pages2006 File 4eurospeed2No ratings yet

- 2006 File 5Document46 pages2006 File 5eurospeed2No ratings yet

- Welcome To Today's Presentation Sponsored byDocument47 pagesWelcome To Today's Presentation Sponsored byfadrique54No ratings yet

- 2008 Chevrolet Aveo 2008 Chevrolet AveoDocument3 pages2008 Chevrolet Aveo 2008 Chevrolet AveoRonald FernandezNo ratings yet

- HosamDocument3 pagesHosamahmadshikemohmadNo ratings yet

- Ls1 ManualDocument113 pagesLs1 ManualMTNo ratings yet

- 8L90 IntroductionDocument66 pages8L90 IntroductionBrandon100% (5)

- 2006 Trans Eng12Document19 pages2006 Trans Eng12eurospeed2No ratings yet

- 2006 File 10Document49 pages2006 File 10eurospeed2No ratings yet

- 2002 DTC CodesDocument35 pages2002 DTC CodesJohn GroomeNo ratings yet

- P 0340Document3 pagesP 0340Carlos Medina CastilloNo ratings yet

- Diagnostic Trouble Code (DTC) Charts and DescriptionsDocument126 pagesDiagnostic Trouble Code (DTC) Charts and DescriptionsVicente GarciaNo ratings yet

- P0089 CaptivaDocument5 pagesP0089 CaptivaHOLMAN HUMBERTO FONSECA SALAMANCANo ratings yet

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P0713Document5 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P0713José Garcia.No ratings yet

- 2006 File 9Document19 pages2006 File 9eurospeed2No ratings yet

- A L L Diagnostic Trouble Codes (DTC) : P Code Charts P1345Document4 pagesA L L Diagnostic Trouble Codes (DTC) : P Code Charts P1345José Garcia.No ratings yet

- P1637Document3 pagesP1637ALEMAN GARAGE AUTOMOTRIZNo ratings yet

- Melling Performance Catalog PDFDocument237 pagesMelling Performance Catalog PDFLuis Ramón Argüello RealNo ratings yet

- 1 Check The Valve Travel AR05.00-B-1500B.fmDocument4 pages1 Check The Valve Travel AR05.00-B-1500B.fmLUKASNo ratings yet

- Gas Turbine Combustion SectionDocument19 pagesGas Turbine Combustion SectionInterogator5No ratings yet

- PCM 2.7L 1 de 4Document2 pagesPCM 2.7L 1 de 4Felix VelasquezNo ratings yet

- WP6G125E22 Engine Parts CatalogDocument87 pagesWP6G125E22 Engine Parts CatalogLinio Calixto De Jesus33% (3)

- Hatz Diesel Engine 2M41 BrochureDocument6 pagesHatz Diesel Engine 2M41 BrochureWarren TarrNo ratings yet

- Yamaha F130aet - 2016 - Parts CatalogueDocument74 pagesYamaha F130aet - 2016 - Parts Catalogueanon_674708607100% (1)

- C15-Testing & AdjDocument113 pagesC15-Testing & AdjJefMoreno100% (30)

- SID97-3C ADJUSTMENT of Continental Fuel InjectionDocument41 pagesSID97-3C ADJUSTMENT of Continental Fuel InjectionTito Teixeira100% (1)

- 2R1040 Spare Parts Manual PDFDocument84 pages2R1040 Spare Parts Manual PDFmanoj_doshi_1100% (1)

- SYLLABUS FOR AUTOMOBILE ENGINEERING 5TH SEMDocument30 pagesSYLLABUS FOR AUTOMOBILE ENGINEERING 5TH SEMAjayChouhanNo ratings yet

- 3515 Chevrolet Sprint L3-61-1.0 ManualDocument916 pages3515 Chevrolet Sprint L3-61-1.0 ManualOctavio Ramirez100% (2)

- Cat 3126 ManualsDocument2 pagesCat 3126 ManualsElibey Cuadros Berbesi87% (23)

- DOOSAN Engine Parts ListDocument268 pagesDOOSAN Engine Parts ListTobi Buchmann100% (1)

- Solar Centaur Turbine Engine Startup ProcessDocument32 pagesSolar Centaur Turbine Engine Startup ProcessFarhanNo ratings yet

- The Bourke Engine Is Public DomainDocument5 pagesThe Bourke Engine Is Public DomainricardoNo ratings yet

- Cat 320 D PDFDocument5 pagesCat 320 D PDFAditya Ramadhanch Aj100% (1)

- Gas Turbine Engine MaintenanceDocument7 pagesGas Turbine Engine Maintenancesathesh waranNo ratings yet

- Service Bulletin: Fuel Injection PumpDocument15 pagesService Bulletin: Fuel Injection PumpKrunoslavNo ratings yet

- Otto Cycle - WikipediaDocument13 pagesOtto Cycle - WikipediaMichaelle Angela ArnedoNo ratings yet

- 3 AVANZA Starting System ComponentsDocument1 page3 AVANZA Starting System Componentsaritw541214No ratings yet

- Terminals of Ecm: E3 E4 E5 E6Document5 pagesTerminals of Ecm: E3 E4 E5 E6suraj100% (2)

- lt1000d6 PDFDocument3 pageslt1000d6 PDFJo Ferry0% (1)

- CAT Manual-3406-320 - 365 - KVADocument156 pagesCAT Manual-3406-320 - 365 - KVAramsey100% (6)

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 44R677-0025-B1Document40 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 44R677-0025-B1Manuel CardozoNo ratings yet

- DENSO Common Rail Injector RDMFDocument1 pageDENSO Common Rail Injector RDMFJhonatan PabloNo ratings yet

- Engine Testing Modelling SUSSEXDocument27 pagesEngine Testing Modelling SUSSEXakozyNo ratings yet

- Pages From Revised SVR 889548Document1 pagePages From Revised SVR 889548Ahsan SabikNo ratings yet

- Toyota Obd1 Old1Document3 pagesToyota Obd1 Old1tomasykNo ratings yet

- 08 Exhaust Valve System (Sep 2015) PDFDocument21 pages08 Exhaust Valve System (Sep 2015) PDFValeriy Domashenko100% (1)