Professional Documents

Culture Documents

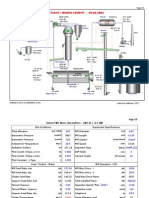

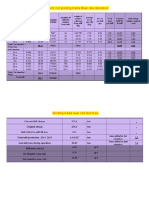

S. Description Symbol Unit No.: F.L. Smidth's ATOX Vertical Roller Mill

Uploaded by

vvijaybhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S. Description Symbol Unit No.: F.L. Smidth's ATOX Vertical Roller Mill

Uploaded by

vvijaybhanCopyright:

Available Formats

F.L.

Smidth's ATOX Vertical Roller Mill

S.

No.

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Description

Symbol

Unit

Mill Type

Mill Number

Grinding Pressure

Raw material

Density of Material

Density of Material under Roller

Coefficient of Friction

Power Input to Motor

Production Rate

Table Diameter

Roller Diameter

Roller Width

Mean Diameter of Track

Table Speed

Velocity of Track

Radiation Surface Area

Roller Pressure per Roller

Specific Roller Pressure

Gripping Angle

Maximum Material Pressure

Material Bed Thickness

Maximum Feed Size

Dam Ring Height

Compaction Ratio

Power /Over-Rolling of Material

Grinding Circulation

Mn

GP

RM

RMR

CoF

Pm

PR

Dtb

Dr

Wr

Dtk

N

Vt

Ar

Pr

Ps

a

MMP

T

Fm

DRH

CR

Po

n

Gn

bars

kg/m3

%surplus

kW

tph

mts

mts

mts

mts

rpm

m/s

m2

kN

kN/m2

radian

kN/m2

mm

mm

mm

kWh/t

times

kWhn/t

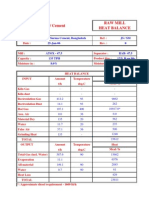

26

Grindability, design

27

Grindability, gross

Gg

kWhg/t

28

29

Material Retention Time

Design Power Consumption

t

Pd

sec

kW

.L. Smidth's ATOX Vertical Roller Mill

Relationship

Example

Input 1 for Raw Mill and 2 for Coal Mill

Input value

Input value

Input value

Input value

Input value

Input value

Input value

Mn / 10

0.6 * Dtb

0.2 * Dtb

0.8 * Dtb

56 / Dtb0.5

0.05235 * Dtk * N

0.3166 * Mn2

Dr * Wr * Ps

( GP + 46.67 ) / 0.283

3 * CoF

4 * Ps / a

30 * Dr

50 * Dr

36 * Dtb

2

[ ( Dr * a * 1000 ) / ( 4 x T ) ] + 1

[MMP * (CR-1) / 3 ] / [RM * {1+(RMR / 100)} * 3.6]

Pm / ( PR * Po )

1

40.0

151

Limestone

1500

33

0.10

2417

411

4.00

2.40

0.80

3.2

28.0

4.7

507

1341

698

0.30

9313

72

120

144

1.75

0.324

18

Pd / PR

4.59

Pm / PR

5.88

15 * Dtb

0.844 * CoF * Ps * Dtb2.5

30

1886

30, 32.5, 35, 37.5, 40, 42.5, 45, 47.5, 50, 52.5, 55, 57.5, 60

0.5

You might also like

- Filter DesignDocument6 pagesFilter DesignKamod RaiNo ratings yet

- Screw ConveyorDocument6 pagesScrew ConveyorJobsonReisNo ratings yet

- Ball Mill OptimizationDocument82 pagesBall Mill OptimizationRashek_119588% (16)

- Screw ConveyorDocument5 pagesScrew ConveyorEDUARDO100% (3)

- Earthing Calculation - Grid (Exm)Document33 pagesEarthing Calculation - Grid (Exm)balaeee123No ratings yet

- Ball Mill CalculationsDocument12 pagesBall Mill Calculationsvvijaybhan80% (15)

- Powerpoint VRMDocument14 pagesPowerpoint VRMAlisa Azizah100% (2)

- Kiln Control and Operation - Infinity For Cement EquipmentDocument74 pagesKiln Control and Operation - Infinity For Cement EquipmentRizwanKhanNo ratings yet

- Chuong 2-Roller MillDocument24 pagesChuong 2-Roller MillAmit Sharma0% (1)

- BELT FEEDER Preliminary Dimension IngDocument29 pagesBELT FEEDER Preliminary Dimension IngoscarjofkNo ratings yet

- Pyro ProcessingDocument29 pagesPyro ProcessingMKPashaPasha100% (2)

- Report On Cement MillDocument9 pagesReport On Cement MillYounas Khan100% (1)

- A Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BDocument4 pagesA Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BYhaneNo ratings yet

- False Air - Measuerment OverviewDocument11 pagesFalse Air - Measuerment OverviewVijay BhanNo ratings yet

- Finish Grinding by Roller PressDocument3 pagesFinish Grinding by Roller PressManish Verma100% (3)

- VRM Heat and Mass BalanceDocument1 pageVRM Heat and Mass BalanceRajeshRockNo ratings yet

- Clinker Production Kiln Surface Heat Loss FactorsDocument2 pagesClinker Production Kiln Surface Heat Loss FactorsvvijaybhanNo ratings yet

- Clinker Production Kiln Surface Heat Loss FactorsDocument2 pagesClinker Production Kiln Surface Heat Loss FactorsvvijaybhanNo ratings yet

- Clinker Production Kiln Surface Heat Loss FactorsDocument2 pagesClinker Production Kiln Surface Heat Loss FactorsvvijaybhanNo ratings yet

- Clinker Production Kiln Surface Heat Loss FactorsDocument2 pagesClinker Production Kiln Surface Heat Loss FactorsvvijaybhanNo ratings yet

- Design and Calculation AgitationDocument18 pagesDesign and Calculation AgitationDavid Lambert67% (3)

- Cement Kiln Performance CalculationsDocument9 pagesCement Kiln Performance Calculationsvvijaybhan0% (2)

- Roller Press 1Document4 pagesRoller Press 1bipinagarwalNo ratings yet

- Screw Conveyor CalculationDocument14 pagesScrew Conveyor Calculationvvijaybhan100% (2)

- VRM Gas FlowDocument16 pagesVRM Gas FlowIrfan AhmedNo ratings yet

- BALL MILL - Ball Charge Composition Piece Weight & Specific SurfaceDocument1 pageBALL MILL - Ball Charge Composition Piece Weight & Specific Surfacevvijaybhan100% (1)

- Kiln Performance & Efficiency Formulas (Updated and Completed) - InFINITY For CEMENT EQUIPMENTDocument3 pagesKiln Performance & Efficiency Formulas (Updated and Completed) - InFINITY For CEMENT EQUIPMENTBùi Hắc HảiNo ratings yet

- Apron FeederDocument7 pagesApron FeederEDUARDO0% (1)

- Blaine Reference Blaine Required e KDocument4 pagesBlaine Reference Blaine Required e KNael100% (3)

- Cement MillDocument28 pagesCement Millsaji kumar100% (2)

- Cement Kiln Pyro BalanceDocument45 pagesCement Kiln Pyro BalanceirfanNo ratings yet

- Roller Press Classifier Circulation FactorDocument9 pagesRoller Press Classifier Circulation Factorshahid2995100% (1)

- Separator Operation PDFDocument21 pagesSeparator Operation PDFAnoop Tiwari100% (1)

- Raw Mix Design SoftwareDocument7 pagesRaw Mix Design Softwarevvijaybhan100% (9)

- Ash Dyke Area RequirementDocument4 pagesAsh Dyke Area Requirementdasmrinalju023252No ratings yet

- Conversion Factor For NOx and SOx CalculationsDocument2 pagesConversion Factor For NOx and SOx CalculationsvvijaybhanNo ratings yet

- Mill Testing Optimisation and TargetingDocument134 pagesMill Testing Optimisation and TargetingArtemMirra90% (10)

- Cement Mill Gearbox Input & Output RatiosDocument1 pageCement Mill Gearbox Input & Output RatiosvvijaybhanNo ratings yet

- 01 Introduction To VRMsDocument35 pages01 Introduction To VRMsorcotes100% (1)

- Process Guidelines for Cement Production OptimizationDocument20 pagesProcess Guidelines for Cement Production OptimizationMKPashaPasha100% (4)

- Screw ConveyorDocument5 pagesScrew ConveyorsutanuprojectsNo ratings yet

- Ball Mill Grinding Media Max Ball Size CalculationDocument2 pagesBall Mill Grinding Media Max Ball Size Calculationvvijaybhan100% (1)

- 07 VRM PregrinderDocument22 pages07 VRM PregrinderVishnu Vardhan . C100% (9)

- Plant Kiln Fuel and Airflow ReportDocument1 pagePlant Kiln Fuel and Airflow ReportBùi Hắc HảiNo ratings yet

- Solid Fuel PreperationDocument1 pageSolid Fuel PreperationvvijaybhanNo ratings yet

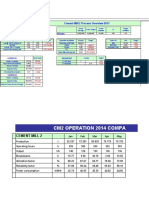

- Co2 Emission Per Ton ClinkerDocument5 pagesCo2 Emission Per Ton ClinkerJunaid Mazhar50% (2)

- Loesche Classifiers Modification Report at MCLDocument42 pagesLoesche Classifiers Modification Report at MCLnsprasad88No ratings yet

- Raw Mill Nozzle Ring Area AnalysisDocument6 pagesRaw Mill Nozzle Ring Area AnalysisMohd Ali100% (7)

- Vertical Raw Mill Heat Balance SolutionDocument3 pagesVertical Raw Mill Heat Balance SolutionVaibhav KhodakeNo ratings yet

- Raw Mill Heat BalanceDocument1 pageRaw Mill Heat BalanceElwathig Bakhiet100% (1)

- Material Residence Time in KilnDocument2 pagesMaterial Residence Time in KilnVijay Bhan100% (2)

- Doc VRM Measurements BATDocument15 pagesDoc VRM Measurements BATsaji kumarNo ratings yet

- Cement Vertical Mill Vs Ball MillDocument17 pagesCement Vertical Mill Vs Ball Millanrulo50% (2)

- Optimize Vertical Roller Mills OperationsDocument4 pagesOptimize Vertical Roller Mills OperationsSai Sricharan Reddy83% (6)

- Heat Calculation by SG.Document26 pagesHeat Calculation by SG.TIRIANTO0% (2)

- Max ball size by feed size and mill diameterDocument3 pagesMax ball size by feed size and mill diametervvijaybhan100% (1)

- Ball Mill Degree of Filling CalculationDocument4 pagesBall Mill Degree of Filling Calculationvvijaybhan100% (1)

- Cement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Document17 pagesCement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Salah Romdani100% (1)

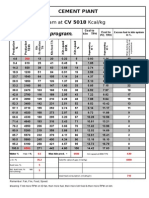

- Clinker Production Caliculation ProgramDocument3 pagesClinker Production Caliculation Programvvijaybhan100% (1)

- Clinker Production Caliculation ProgramDocument3 pagesClinker Production Caliculation Programvvijaybhan100% (1)

- Tromp Curve CalculationDocument6 pagesTromp Curve Calculationvvijaybhan80% (5)

- CM2 Process Media Mix Up 2014 2015Document31 pagesCM2 Process Media Mix Up 2014 2015Junaid MazharNo ratings yet

- Increasing cement grinding capacity with vertical roller mill technologyDocument7 pagesIncreasing cement grinding capacity with vertical roller mill technologymahreza189100% (2)

- Fan Flow CalculationDocument1 pageFan Flow CalculationvvijaybhanNo ratings yet

- FormulaeDocument163 pagesFormulaeilvspeedNo ratings yet

- Design of Agitator 8 Batch Volume PDFDocument3 pagesDesign of Agitator 8 Batch Volume PDFsandipNo ratings yet

- Cement IndustryDocument27 pagesCement IndustryAhmed Mahmoud100% (1)

- Pyro-processing system flow overviewDocument1 pagePyro-processing system flow overviewVijay BhanNo ratings yet

- Fuel and Combustion CalculationsDocument6 pagesFuel and Combustion Calculationsvvijaybhan100% (2)

- Refractory Thickness in Rotary KilnDocument3 pagesRefractory Thickness in Rotary KilnDileepSaragadamNo ratings yet

- Rotary Kiln Operation .Kiln Feed Vs Kiln Speed CalculationDocument1 pageRotary Kiln Operation .Kiln Feed Vs Kiln Speed CalculationVijay Bhan80% (5)

- Blaine Apparatus CalibrationDocument1 pageBlaine Apparatus Calibrationvvijaybhan50% (2)

- Rotary Kilns: Transport Phenomena and Transport ProcessesFrom EverandRotary Kilns: Transport Phenomena and Transport ProcessesRating: 4.5 out of 5 stars4.5/5 (4)

- Nozzle Ring Area of Raw MillDocument6 pagesNozzle Ring Area of Raw MillThaigroup CementNo ratings yet

- Foundation For Roller PressDocument3 pagesFoundation For Roller PressRollerJonny0% (1)

- Cement Mill Grinding Media Wear Rate Calculation PDFDocument2 pagesCement Mill Grinding Media Wear Rate Calculation PDFBùi Hắc HảiNo ratings yet

- Technical Datasheet for Wood Conveyor BeltsDocument10 pagesTechnical Datasheet for Wood Conveyor BeltsSankar GaneshNo ratings yet

- Lab Core Cuter MethodDocument7 pagesLab Core Cuter MethodAram Rashed BaperNo ratings yet

- Pt. Ossiana Sakti Ekamaju: Schedule A: Pricing Schedule Schedule A Part I: Schedule of RateDocument8 pagesPt. Ossiana Sakti Ekamaju: Schedule A: Pricing Schedule Schedule A Part I: Schedule of RateRendi Ahmadhusein PohanNo ratings yet

- Construction - Hammer MillDocument1 pageConstruction - Hammer MillvvijaybhanNo ratings yet

- Thermal Equivalents of Fuels in kcal and BtuDocument1 pageThermal Equivalents of Fuels in kcal and BtuvvijaybhanNo ratings yet

- Hammer Mill OperationDocument1 pageHammer Mill OperationvvijaybhanNo ratings yet

- Mill CIRCUIT SAMPLESDocument2 pagesMill CIRCUIT SAMPLESvvijaybhanNo ratings yet

- Cement Kiln StartupDocument1 pageCement Kiln StartupvvijaybhanNo ratings yet

- Gyratory Screen - LimestoneDocument1 pageGyratory Screen - LimestonevvijaybhanNo ratings yet

- Blaine Vs OutputDocument2 pagesBlaine Vs Outputvvijaybhan100% (1)

- Lime Stone Stock Pile CalculationDocument1 pageLime Stone Stock Pile CalculationvvijaybhanNo ratings yet

- Gera Box CalculationDocument1 pageGera Box CalculationvvijaybhanNo ratings yet

- Gera Box CalculationDocument1 pageGera Box CalculationvvijaybhanNo ratings yet