Professional Documents

Culture Documents

Reservoir Evaluation in Undersaturated Oil Using Modern Technology

Uploaded by

FabricetoussaintCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reservoir Evaluation in Undersaturated Oil Using Modern Technology

Uploaded by

FabricetoussaintCopyright:

Available Formats

Sci.

Int(Lahore),26(3),1089-10942014

ISSN 1013-5316; CODEN: SINTE 8

1089

RESERVOIR EVALUATION IN UNDERSATURATED OIL

RESERVOIRS USING MODERN PRODUCTION DATA ANALYSIS;

A SIMULATION STUDY

Joukar Mohammad*, Jamialahmadi Mohammad, Ashoori Siavash

Petroleum Engineering Department, Petroleum University of Technology, Ahwaz, Iran. Po.Box: 6198144471

Tel: +98 611 5551019

* Corresponding author e-mail: mohammad.joukar@gmail.com

ABSTRACT : Production data analysis methods are frequently applied to analyze long-term production

data including flow rate and pressure. The purpose of this analysis is to estimate the oil in place, ultimate

recovery and evaluation of reservoir parameters such as permeability and skin factor. The most important

priority of production data analysis to well test is that no shut-in is required for production data analysis

and the initial oil in place can be estimated as well. In this study, two modern production data analysis

methods are presented and their advantages, limitations and applications are discussed. For the purpose of

this study, a simulation model is designed and synthetic data are generated for different scenarios. In these

scenarios, the effects of rock and fluid compressibility on oil production rate are investigated for an

undersaturated oil reservoir. It was observed that any increase in total compressibility value, results in

lower decline rate and higher ultimate recovery. Then, the generated data sets are analyzed using different

analysis methods, and the results are compared. The results showed that although the Flowing Material

Balance method is unable to evaluate the reservoir parameters, it is more powerful in estimation of oil in

place rather than the Blasingame method.

Keywords: Production Data Analysis, Type Curve, Flowing Material Balance, Decline Curve, Material Balance Time

1. INTRODUCTION

Production data analysis methods are the methods available

to analyze long-term production data (flow rate and pressure

data) for different purposes such as estimation of oil in

place, ultimate recovery and reservoir parameters such as

permeability and skin factor. The analysis quality depends

on the quality and quantity of available production data.

Since pressure data is often not available for older wells,

these analyzes are more applicable for newer wells in which

the bottom-hole flowing pressure is recorded using

Permanent Down-hole Gauges (PDGs). Production data

analysis is accounted as a method to evaluate reservoir

parameters, as well-test is, but it uses different data types.

The most important priority of production data analysis to

well test analysis is that no shut-in is required for the

analysis and oil in place can be estimated as well.

Production data analysis methods can be divided into three

categories based on their history of development: traditional

methods, semianalytical methods and modern methods.

Traditional production data analysis methods were pure

empirical like Arps method [1]. In these methods the flow

rate data is analyzed using history matching process to tune

the parameters of an empirical relationship which forecasts

the flow rate at any time. In 1973 Fetkovich [2] presented a

semi-analytical method which could analyze flow rate data

for a well under constant bottom-hole flowing pressure.

After that different efforts were done to analyze production

data under variable rate/pressure production which are called

modern production data analysis [3-6].

In this study, two modern production data analysis methods

are presented and their advantages, limitations and

applications are discussed. Also the effects of rock and fluid

compressibility on oil production rate are investigated for

undersaturated oil reservoirs. For the purpose of this study, a

simulation model is designed and synthetic data are

generated for different cases. Then, the generated data sets

are analyzed using different analysis methods, and the

results are compared and discussed.

2. PRODUCTION DATA ANALYSIS METHODS

As mentioned before, the production data analysis methods

are categorized into traditional, semi-analytical and modern

methods. Two modern methods, Blasingame and flowing

material balance, are selected in this study to analyze the

production data.

2.1. Blasingame Analytical Type Curve

In 1980, Fetkovich constructed the first type curve for

production data analysis [2]. His type curve was a

combination of analytical stems for transient flow regime

and empirical Arps relations [1] for the boundary dominated

flow regime.

Blasingame tried to include the effect of variable

rate/pressure conditions by the concepts of material balance

time and normalized flow rate [3] in 1991. He constructed a

type curve similar to that of Fetkovich [2] in transient flow

regime, in which an analytical solution was used for

boundary dominated flow, instead of empirical Arps

relations which was used in Fetkovich type curve.

For transient flow regime, Fetkovich has used the solution of

governing equation with constant flowing pressure. He

showed that the solution to constant flowing pressure in

Laplace space is:

(1)

where

is the solution to the constant flow rate case used

in well test analysis which is:

July-August,2014

(2)

1090

ISSN 1013-5316; CODEN: SINTE 8

Fig. 1. Blasingame type curve (log-log scale)

K0 and K1 are second type modified Bessel functions of first

and second order respectively.

Fetkovich also defined the dimensionless flow rate and

dimensionless time for transient flow regime as below:

(3)

Sci.Int(Lahore),26(3),1089-1094,2014

Blasingame type curve can be used to estimate the values of

permeability, skin factor and oil in place by matching

production data history as plot of pressure normalized flow

rate versus material balance time on Blasingame type curve.

Permeability and skin factor values are estimated from the

concaved up transient part of the type curve and oil in place

is estimated using the boundary dominated part.

2.2. Flowing Material Balance (FMB) Method

Flowing Material Balance (FMB) method [4] is similar to

conventional material balance analysis but does not need any

shut-in pressure except initial reservoir pressure. This

method is based on analytical pseudo steady state equation

of undersaturated oil reservoir as follows:

(14)

After some mathematics and using dimensionless variables

definition and material balance time application [7], the

equation will become into the following form:

(15)

(4)

In order to model boundary dominated flow regime,

Blasingame derives an analytical relation [7] which suggests

a linear relationship between material balance time and

pressure normalized flow rate as follows:

(5)

where definition of different parameters comes below:

(6)

(7)

(8)

(9)

(10)

He also defines the dimensionless variables for boundary

dominated flow regime as:

So plotting

versus

on a Cartesian plot will

yield N (oil in place) as the x-intercept. As a result, FMB

method can be used for oil in place estimation and it cannot

evaluate reservoir parameters. Since FMB method uses the

material balance concept, oil in place can also be estimated

for the case of variable rate/pressure production data.

3. METHODOLOGY

In this research different scenarios are designed to monitor

the effect of rock and fluid compressibility values on oil

production. For this purpose, synthetic data sets are

generated by simulation and then analyzed by using modern

production analysis methods.

3.1. Designing a Controlled Simulation Model

A reservoir model is designed and simulated using a

commercial simulator in order to generate synthetic data of

different scenarios. The designed model is radial with a

centered well of 0.25 ft wellbore radius. The reservoir

external radius is 10,000 ft, so large to achieve a long

transient flow regime during the production scenarios. The

model is 300 ft in height with a porosity of 10% and

permeability of 100 md. The reservoir fluid properties are

summarized in the table 1.

Table 1. Model Fluid Properties

Property

Value

o (pcf)

51.78

Gravity (API)

39.02

Rsb (scf/STB)

1127

Bob (bbl/STB)

1.522

Pb (psi)

4043

(11)

(12)

Using Eq. (11) and (12), after some mathematics, the

analytical Eq. (5) can be changed into dimensionless form

as:

(13)

Blasingame type curve is plotted for three dimensionless

radii (

10, 100 and 100,000) by using above

definitions as shown in Fig. 1. He also introduced the rate

integral (qDdi) and rate integral-derivative (qDdid) stems to

smooth the noises in production data and reduce non-unique

solutions.

Both Fetkovich and Blasingame plots have a diagnostic

feature. Fetkovich says that the flow rate profile, in log-log

scale, is concaved up during the transient flow while it will

be concaved down as boundary dominated flow starts.

In each production scenario the bottom-hole pressure will be

set above the bubble point pressure and the reservoir will be

always undersaturated.

3.2. MODELS

In order to monitor the effects of both rock and fluid

compressibility values, the scenarios are categorized into

two model series, A and B.

3.2.1. Model Series A: Rock Compressibility Effect

In order to study the effect of rock compressibility, four rock

compressibility values are defined in different scenarios and

the other parameters such as reservoir conditions, rock and

July-August,2014

Sci.Int(Lahore),26(3),1089-10942014

ISSN 1013-5316; CODEN: SINTE 8

fluid properties are the same. The

compressibility values are given in table 2.

selected

rock

Table 2. Model Series A Specifications

Scenario Code

Rock Compressibility (psi-1)

A1

3.55E-06

A2

5.59E-06

A3

7.63E-06

A4

9.67E-06

previous model. In this model series, two scenarios are run

as given in table 3.

Scenario

Code

B1

B2

The reservoir initial pressure is set at 5000 psi. The well is

completed open hole and the bottom-hole pressure is kept

constant at the value of 4960 psi.

The simulation is run for an approximately 10 years of

production on constant bottom-hole pressure condition. The

flow rate profile and cumulative oil production curve for

different scenarios are presented in Figs. 2 and 3

respectively. Fig. 2 shows that the flow rate profile are

similar in different scenarios at early times but at late times,

the rate of decline in flow rate is greater for scenarios with

lower rock compressibility values. Also Fig. 3 declares that

the ultimate recovery holds a greater value for scenarios with

higher rock compressibility values.

1091

Table 3. Model Series B Specifications

Initial Reservoir

Bottom-hole

Pressure

Pressure (psi)

Pressure (psi) Drawdown (psi)

5000

4960

40

4500

4460

40

Like model series A, the models are run for approximately

10 years and Figs.4 and 5 show the flow rate profile and

cumulative oil production respectively.

Fig. 5. Cumulative production versus time for model series B.

4. ANALYZING PRODUCTION DATA SETS

Reservoir evaluation by using Blasingame method needs a

typecurve matching process which is carried out from a

Fig. 4. Flow rate versus time for model series B.

Fig. 2. Flow rate versus time for model series A.

Fig. 5. Cumulative production versus time for model series B.

Fig. 3. Cumulative production versus time for model series A.

3.2.2. Model Series B: Fluid Compressibility Effect

Another parameter that affects the oil production in an

undersaturated oil reservoir is the fluid compressibility. A

change in initial pressure condition and bottom-hole pressure

is applied in order to consider the effect of fluid

compressibility while the pressure drawdown is the same as

commercial production data analysis software. For the

estimation of oil in place by FMB method the Curve Fitting

toolbox of MATLAB software is used.

4.1. Blasingame Analysis

Plotting rate functions, rate, rate integral and rate integral

derivative, the following matches for Blasingame type curve

are obtained as illustrated in Fig. 6.

July-August,2014

1092

Fig. 6. Blasingame

ISSN 1013-5316;

type curveCODEN:

analysis of

SINTE

all the8 scenarios

Fig. 6. Blasingame type curve analysis of all the scenarios.

July-August,2014

Sci.Int(Lahore),26(3),1089-1094,2014

Sci.Int(Lahore),26(3),1089-10942014

ISSN 1013-5316; CODEN: SINTE 8

1093

4.2. Flowing Material Balance Analysis

Plotting

versus

and extrapolating the data

for x-intercept is done using Curve Fitting tool in MATLAB.

The constructed plots are shown in Figs. 7 and 8.

Fig. 9. Evaluated skin factor values

Fig. 7. FMB plot for model series A.

Fig. 8. FMB plot for model series B.

5. RESULTS AND DISCUSSION

The quantitative results of reservoir evaluation of the

scenarios are shown in Figs. 9 and 10.

The results show that the evaluation of reservoir

permeability and skin factor has an excellent accuracy in all

scenarios. One of the most reasons of this high accuracy is

that the reservoir has a relatively large amount of transient

flow regime data in all cases which is used in reservoir

evaluation methods. If early time data is lost, nonuniqueness solutions may cause significant errors in

reservoir evaluation.

Fig. 11 illustrates the calculated values of oil in place by

both the FMB and Blasingame methods.

As it can be seen, changes in compressibility values has not

changed the estimation of oil in place significantly.

Although the flow rate profiles are different in all scenarios,

the FMB plots are very similar in each model series and

have a higher accuracy. The good accuracy in estimation of

oil in place by the Blasingame method is because of using

enough data in boundary dominated flow regime which is

used for this purpose.

Recalling the flow rate behavior for model series A and B,

we may now discuss about the rock and fluid compressibility

effect. As Figs. 2 and 4 suggest, increase in compressibility

values causes the flow rate to decline with a lower speed.

Furthermore, Figs. 3 and 5, show that any increase in rock or

Fig. 10. Evaluated reservoir permeability values.

Fig. 11. Estimated oil in place values.

July-August,2014

1094

ISSN 1013-5316; CODEN: SINTE 8

fluid compressibility, causes a higher ultimate recovery due

to the increase in the total compressibility value.

6. CONCLUSIONS

From this study, the following conclusions may be drawn:

1) Any increase in total compressibility yields in lower

decline speed in an undersaturated oil reservoir. Also as

total compressibility increases, ultimate recovery will

also increase and a higher recovery factor will be

achieved.

2) Flowing material balance (FMB) method holds a higher

accuracy in estimation of oil in place while it cannot

evaluate reservoir parameters. According to this, the

Blasingame method is more powerful since both

estimation of oil in place and reservoir evaluation are

done at the same time by its type curve.

3) As the results show, production decline analysis method

has an excellent accuracy when production data are in

high frequency and quality. Recording production data

in such quality will allow engineers to have a cheap and

simple analysis which can estimate the oil in place and

evaluate the reservoir parameters.

Nomenclature

A

Bo

: Drainage area [acres]

: Oil formation volume factor [bbl/STB]

: Inverse productivity index [psi/bbl]

: Reservoir shape factor [-]

: Total compressibility [psi-1]

: Decline Factor [day-1]

: Net pay [ft]

: Permeability [md]

: Original oil in place [STB]

: Produced oil volume [STB]

: Flowing pressure drop [psi]

: Cumulative production [STB]

: Flow rate at time t [STB/day]

: Initial flow rate [STB/day]

: Dimensionless flow rate [-]

: Decline dimensionless flow rate [-]

: Decline dimensionless rate-integral [-]

: Decline dimensionless rate-integral-derivative [-]

: Pressure normalized rate [STB/day/psi]

R.E.% : Relative error percent [%]

: Reservoir radius [ft]

: Dimensionless radius [-]

: Dimensionless reservoir radius [-]

: Bubble point solution gas oil ratio [scf/STB]

: Wellbore radius [ft]

: Apparent wellbore radius [ft]

Sci.Int(Lahore),26(3),1089-1094,2014

: Material balance time [days]

: Dimensionless time [-]

: Dimensionless time based on area [-]

: Decline dimensionless time [-]

: Decline dimensionless material balance time [-]

: Laplace space variable

Greeks

: Porosity [fraction]

: Eulers constant

: Viscosity of oil [cp]

: Pressure drawdown [psi]

: Dimensionless pressure drawdown [-]

Subscripts

D

: Dimensionless

d

: decline

i

: initial

pss : pseudo steady state

REFERENCES

1. Arps, J.J.: Analysis of Decline Curves, Trans., AIME,

160, 228, 1945.

2. Fetkovich, M.J.: Decline Curve Analysis using Type

Curves, JPT (June 1980), 1065.

3. Blasingame, T.A, McCray, T.L, Lee, W.J.: Decline

Curve Analysis for Variable Pressure Drop/Variable

Flow Rate Systems, SPE Paper 21513 presented at the

SPE Gas Technology Symposium, January 23-24,

1991.

4. Mattar, L., Anderson, D.M.: A Systematic and

Comprehensive Methodology for Advanced Analysis of

Production Data, SPE Paper 84472 presented at the

SPE Annual Technical Conference and Exhibition held

in Denver, October 58, 2003.

5. Agarwal, R.G, Gardner, D.C, Kleinsteiber, S.W, and

Fussell, D.D.: Analyzing Well Production Data Using

Combined Type Curve and Decline Curve Concepts,

SPE Paper 57916 presented at the SPE Annual

Technical Conference and Exhibition, New Orleans,

September 27-30, 1998.

6. Blasingame, T.A., Johnston, J.L., Lee, W.J.: Type-Curve

Analysis Using the Pressure Integral Method, SPE

Paper 18799 presented at the SPE California Regional

Meeting held in Bakersfield, April 5-7, 1989.

7. Blasingame, T.A., Lee, W.J., Variable-Rate Reservoir

Limits Testing, SPE Paper 15028 presented at the

Permian Basin Oil & Gas Recovery Conference of the

Society of Petroleum Engineers held in Midland,

March 13-14, 1986.

July-August,2014

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Laminated Shaly Sand Reservoirs An Interpretation Model Incorporating New MeasurementsDocument12 pagesLaminated Shaly Sand Reservoirs An Interpretation Model Incorporating New MeasurementsFabricetoussaintNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- 1 Sca1996 22Document10 pages1 Sca1996 22FabricetoussaintNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Explicit Deconvolution of Well Test Data Dominated by Wellbore StorageDocument13 pagesExplicit Deconvolution of Well Test Data Dominated by Wellbore StorageFabricetoussaintNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Analysis of Transient Pressure From Permanent Down-Hole GaugesDocument235 pagesAnalysis of Transient Pressure From Permanent Down-Hole GaugesFabricetoussaintNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- MatLab Tutorial 5Document7 pagesMatLab Tutorial 5FabricetoussaintNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Numerical Modeling of Flow Processes Inside Geothermal WellsDocument24 pagesNumerical Modeling of Flow Processes Inside Geothermal WellsFabricetoussaintNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Archie's N Exponent The Rest of The StoryDocument18 pagesArchie's N Exponent The Rest of The StoryFabricetoussaintNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- No.21 - Archies Exponents in Complex Lithologies Derived From 3D Digital Core AnalysisDocument16 pagesNo.21 - Archies Exponents in Complex Lithologies Derived From 3D Digital Core AnalysisFabricetoussaintNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Archie's N Exponent The Rest of The StoryDocument18 pagesArchie's N Exponent The Rest of The StoryFabricetoussaintNo ratings yet

- Tax GuideDocument28 pagesTax GuidecharmysticNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Gas Condensate PVT WhitsonDocument28 pagesGas Condensate PVT WhitsonBolsec14No ratings yet

- Laplace Transform Deconvolution and Its Application To Perturbation Solution of Non Linear Diffusivity EquationDocument86 pagesLaplace Transform Deconvolution and Its Application To Perturbation Solution of Non Linear Diffusivity EquationFabricetoussaintNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 1-SCA1996-24 Effects of Wettability On The Electrical Properties of Reservoir RocksDocument10 pages1-SCA1996-24 Effects of Wettability On The Electrical Properties of Reservoir RocksFabricetoussaintNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Optimizing CO2-Injection by Compositional SimulationDocument223 pagesOptimizing CO2-Injection by Compositional SimulationFabricetoussaintNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Thesis Elena-Raluca LichiardopolDocument42 pagesThesis Elena-Raluca LichiardopolFabricetoussaintNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Evaluation of Skin Factor and Non Darcy Skin in Underground Reservoir StorageDocument11 pagesEvaluation of Skin Factor and Non Darcy Skin in Underground Reservoir StorageFabricetoussaintNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- SPE-167711-Numerical Simulation of Low Permeability Unconventional Gas ReservoirsDocument30 pagesSPE-167711-Numerical Simulation of Low Permeability Unconventional Gas ReservoirsFabricetoussaintNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Well Testing BrochureDocument24 pagesWell Testing BrochureFabricetoussaint100% (1)

- Pge 361Document89 pagesPge 361egv2000No ratings yet

- Investigation of Recovery Mechanisms in Fractured ReservoirsDocument197 pagesInvestigation of Recovery Mechanisms in Fractured ReservoirsFabricetoussaintNo ratings yet

- 1 Sca1996 22Document10 pages1 Sca1996 22FabricetoussaintNo ratings yet

- 3.osman Apaydin Dissertation 4.05.2012 FormatDocument141 pages3.osman Apaydin Dissertation 4.05.2012 FormatFabricetoussaintNo ratings yet

- Pge 361Document89 pagesPge 361egv2000No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Productivity and Critical Production Rate of Horizontal WellDocument6 pagesProductivity and Critical Production Rate of Horizontal WellFabricetoussaintNo ratings yet

- SPE-139222 Selection Methodology For Screening Evaluation of Enhanced Oil Recovery MethodsDocument11 pagesSPE-139222 Selection Methodology For Screening Evaluation of Enhanced Oil Recovery MethodsFabricetoussaintNo ratings yet

- Scaling Relationships in Fluvial Depostional SystemsDocument23 pagesScaling Relationships in Fluvial Depostional SystemsFabricetoussaintNo ratings yet

- Calculation of Imbibition Relative Permeability For Two and Three Phase Flow From Rock PropertiesDocument8 pagesCalculation of Imbibition Relative Permeability For Two and Three Phase Flow From Rock PropertiesSweetbee LibyaNo ratings yet

- SPE 13169 Fetkovich Decline TC Case HistoriesDocument20 pagesSPE 13169 Fetkovich Decline TC Case HistoriesFabricetoussaintNo ratings yet

- Reservoir Characterization From Production and Injections FluctuationsDocument68 pagesReservoir Characterization From Production and Injections FluctuationsFabricetoussaintNo ratings yet

- Ancon Channel & Bolt FixingsDocument20 pagesAncon Channel & Bolt FixingsatiattiNo ratings yet

- Lec08 (Topic 4 Define Classes)Document33 pagesLec08 (Topic 4 Define Classes)huaiencheengNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Hyd Schematic 2658487205 - 005Document3 pagesHyd Schematic 2658487205 - 005Angelo Solorzano100% (2)

- Stylistic and DiscourseDocument4 pagesStylistic and Discourseeunhye carisNo ratings yet

- Column and Thin Layer ChromatographyDocument5 pagesColumn and Thin Layer Chromatographymarilujane80% (5)

- CHEE319 Tutorial 4 SolnDocument13 pagesCHEE319 Tutorial 4 SolnyeshiduNo ratings yet

- 7 C's of Business LetterDocument3 pages7 C's of Business LetterGladys Forte100% (2)

- University Reserch Worksheet PDFDocument7 pagesUniversity Reserch Worksheet PDFapi-410567922No ratings yet

- 16SEE - Schedule of PapersDocument36 pages16SEE - Schedule of PapersPiyush Jain0% (1)

- PrEN 12271-10 - Factory Production ControlDocument17 pagesPrEN 12271-10 - Factory Production ControlPedjaNo ratings yet

- Crafting and Executing StrategyDocument33 pagesCrafting and Executing Strategyamoore2505No ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ISO 17000 2004 Terms & DefintionsDocument6 pagesISO 17000 2004 Terms & DefintionsSelvaraj SimiyonNo ratings yet

- COP Oil: For Epiroc Components We Combine Technology and Environmental SustainabilityDocument4 pagesCOP Oil: For Epiroc Components We Combine Technology and Environmental SustainabilityDavid CarrilloNo ratings yet

- Symbiosis Skills and Professional UniversityDocument3 pagesSymbiosis Skills and Professional UniversityAakash TiwariNo ratings yet

- Mock DataDocument56 pagesMock DataAnonymous O2bvbOuNo ratings yet

- U1L2 - Definitions of 21st Century LiteraciesDocument19 pagesU1L2 - Definitions of 21st Century LiteraciesJerry Glenn Latorre CastilloNo ratings yet

- Demand Performa For Annual DemandDocument10 pagesDemand Performa For Annual DemandpushpNo ratings yet

- Reflecting on UPHSD's Mission, Vision, and Core ValuesDocument3 pagesReflecting on UPHSD's Mission, Vision, and Core ValuesBia N Cz100% (1)

- Rúbrica de composición escritaDocument2 pagesRúbrica de composición escritafrancisco alonsoNo ratings yet

- PMMAEE Application FormDocument2 pagesPMMAEE Application Formshiero501100% (15)

- Y06209 November 2015Document28 pagesY06209 November 2015Fredy CoyagoNo ratings yet

- Be3000 Manual 2016Document77 pagesBe3000 Manual 2016Itzel JuárezNo ratings yet

- Company Profile HighlightsDocument7 pagesCompany Profile HighlightsRaynald HendartoNo ratings yet

- CommunicationDocument5 pagesCommunicationRyan TomeldenNo ratings yet

- The Production and Interpretation of Ritual Transformation Experience: A Study on the Method of Physical Actions of the Baishatun Mazu PilgrimageDocument36 pagesThe Production and Interpretation of Ritual Transformation Experience: A Study on the Method of Physical Actions of the Baishatun Mazu PilgrimageMinmin HsuNo ratings yet

- VLSI Physical Design: From Graph Partitioning To Timing ClosureDocument30 pagesVLSI Physical Design: From Graph Partitioning To Timing Closurenagabhairu anushaNo ratings yet

- Drag Embedded AnchorsDocument6 pagesDrag Embedded AnchorsrussellboxhallNo ratings yet

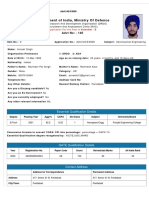

- DrdoDocument2 pagesDrdoAvneet SinghNo ratings yet

- Sulzer MC EquipmentDocument12 pagesSulzer MC EquipmentsnthmlgtNo ratings yet

- Saes H 201Document9 pagesSaes H 201heartbreakkid132No ratings yet

- The Big, Bad Book of Botany: The World's Most Fascinating FloraFrom EverandThe Big, Bad Book of Botany: The World's Most Fascinating FloraRating: 3 out of 5 stars3/5 (10)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 5 out of 5 stars5/5 (4)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 3.5 out of 5 stars3.5/5 (32)

- Last Child in the Woods: Saving Our Children From Nature-Deficit DisorderFrom EverandLast Child in the Woods: Saving Our Children From Nature-Deficit DisorderRating: 4 out of 5 stars4/5 (283)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorFrom EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorRating: 4.5 out of 5 stars4.5/5 (137)