Professional Documents

Culture Documents

Accumulator Maintenance Instructions Rev B

Uploaded by

John Néstor Ramirez CalderónCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Accumulator Maintenance Instructions Rev B

Uploaded by

John Néstor Ramirez CalderónCopyright:

Available Formats

MAINTENANCE INSTRUCTIONS

BLADDER ACCUMULATORS

General

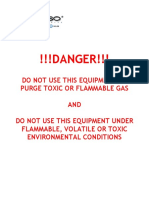

Hydraulic Accumulators are pressure vessels and may

contain compressed nitrogen gas or hydraulic fluid at

high pressures.

Only qualified personnel should perform

maintenance.

DO NOT weld on the accumulator shell.

Always use DRY NITROGEN for precharging.

Do not use automotive valve cores in place of high

pressure valve cores.

For maximum seal and bladder life, hydraulic fluid

should be kept clean, filtered to 10 micron or less.

HYDRAULIC PRESSURE MUST BE

REDUCED TO ZERO.

VENT all precharge gas prior to disassembly.

NEVER USE AIR OR OXYGEN for precharge

as this may result in an explosion!

PRECHARGING PROCEDURE

ISOLATE, VENT and DRAIN all fluid completely from

accumulator. Only check precharge when fluid

pressure is 0 psi.

Remove valve guard (8) and valve cap (7) (Figure 1).

Use PacSeal charging and gauging assembly, part

number 40-1618, to check and adjust precharge of the

accumulator.

Before using the assembly, verify that the bleed valve

(E) is closed and the air chuck (A) is turned fully

counter-clockwise (CCW) (Figure 2).

Connect the air chuck (A) to the gas fill valve (4) on the

accumulator.

Connect the hose assembly to the nitrogen bottle, then

connect it to the fill valve (D) on the charging unit.

Depress the valve core by turning the charging valve

clockwise (CW) until it stops (do not over torque).

SLOWLY open the valve on the nitrogen bottle and

allow gas to flow to the accumulator, noting pressure

on the gauge.

Rev B

Tel: 714-529-9495

Fax: 714-529-1366

Figure 1Exploded View Bottom Load Assembly

Figure 2Charging and Gauging Assembly

561 Tamarack Ave, Brea CA USA

www.pacsealhydraulics.com

Maintenance Instructions

Bladder Accumulators

(Precharging Instructions Continued)

When desired pressure is reached, close the valve

on the nitrogen bottle.

Turn air chuck (A) fully CCW and bleed trapped

pressure in the gas line to zero by opening the

bleed valve (E).

Remove the hose from the fill valve (D) and close

the bleed valve; wait a few minutes for the pressure

to stabilize.

Slowly turn the air chuck (A) CW until pressure is

read on the gauge,

To reduce gas precharge pressure, open the bleed

valve. To increase pressure, repeat previous

steps.

Turn the air chuck (A) CCW, bleed the line by

opening the bleed valve (E) and remove the hose

and charging unit. Replace valve cap and valve

guard. Accumulator is ready for use.

1

Shell

Bladder

Valve Nut

Gas Valve Body

Valve Core

O-Ring

Valve Cap

Valve Guard

Poppet

10

Spring

11

Plug Body

12

Plug, Pipe

13

Piston

14

Stop Nut

15

Anti-Extrusion Ring

16

Back-Up Washer

17

O-Ring

18

Back-Up Ring

19

Spacer

20

Lock Nut

Rev B

Tel: 714-529-9495

Fax: 714-529-1366

561 Tamarack Ave, Brea CA USA

Page 2

www.pacsealhydraulics.com

Maintenance Instructions

Bladder Accumulators

Examination of Components

DISASSEMBLY INSTRUCTIONS

ISOLATE, VENT and DRAIN all fluid completely

from accumulator. Only perform maintenance

when fluid pressure is 0 psi.

Inspect the fluid port assembly for nicks or gouges

and replace as necessary. Verify that the poppet

rotates 90o.

Remove accumulator from system, if applicable.

Securely clamp the accumulator.

Bladder, all seals and back-up rings should be

replaced.

Release all precharge pressure according to the

precharge instructions. Remove the valve core by

using the gas valve core tool (4).

Examine the interior of the shell to ensure that it is

free of debris, rough spots or chafe marks. Verify

that the fluid end is free of damage that would

interfere with sealing.

Drain the remaining fluid in the accumulator after it

is disconnected from the system.

Fluid Port Disassembly

Remove the bleeder plug (12). Unscrew the lock

ring (20) using a spanner wrench. Remove the

metal spacer ring (19), noting the that the lip of the

spacer ring faces into the shell opening to center

the fluid port body.

Push the fluid port assembly (9-14) into the

accumulator shell. Remove the back-up washer

(16), o-ring (17) and back-up ring (18).

Remove the anti-extrusion ring (15) by folding it in

half and sliding it through the shell opening.

Remove the fluid port assembly from the shell.

Remove the bladder stem lock nut (3) and gas

valve (4,6) from the gas side.

Verify that there is no corrosion on the exterior or

interior of the shell.

Verify that the extrusion ring is undamaged, and

that the rubber adheres to the steel without gaps.

If the rubber is cracked or shows signs of aging,

replace.

Through the bottom of the shell, compress the

bladder by hand to eliminate as much air as

possible.

Fold and bladder and remove it through the bottom

of the shell.

Rev B

Tel: 714-529-9495

Fax: 714-529-1366

561 Tamarack Ave, Brea CA USA

Page 3

pacsealhydraulics.com

Maintenance Instructions

Bladder Accumulators

REASSEMBLY INSTRUCTIONS

Lubricate the inside of the shell and the outside of

the bladder with clean system fluid. Add about

10% of the fluid volume to the inside of the shell to

act as a cushion.

If the bladder is inflated, remove the valve core and

completely press all air out of the bladder.

Reinstall the valve core to keep the bladder

deflated. Attach the bladder pull rod to the gas

valve.

Pull the rod and bladder through the shell fluid port

by folding the bladder lengthwise. Pull the rod

through the gas port opening of the shell.

Slide the lock nut over the pull rod and loosely

attach it to prevent the bladder from slipping back

into the shell. Remove the pull rod. Using two

wrenches, , tighten the lock nut. Do not twist the

bladder while tightening.

To protect the o-ring and back-up ring from

damage, use thread tape on the threads of the fluid

port body. Slide the fluid port assembly in the

accumulator shell.

Fold the extrusion ring in half and slide it through

the fluid opening. The steel ring of the extrusion

ring faces the shell opening.

Bring the fluid port assembly back through the

extrusion ring so that it firmly seats on the extrusion

ring.

Install the gas valve and valve core in to the

bladder stem. Using dry nitrogen SLOWLY inflate

the bladder to 5-10 psig to set and hold the fluid

port assembly in place.

Install the metal washer (16) onto the fluid port

through the gap between the shell opening and the

fluid port. Lubricate and install the o-ring (17) and

back-up ring (18) firmly against the washer. Use a

blunt tool to seat the seals. DO NOT TWIST,

ROLL OR CUT THE O-RING. Remove the thread

tape from the fluid port body.

1. Add 10% fluid as a lubricating cushion.

2. Attach pull rod to gas valve. If bag is compressed

with the valve core installed, do not remove the

core but roll the bag tightly. All gas must be out

of the bag to install. Reinstall valve core to

prevent re-inflation.

Install the metal spacer ring (19) with the lip against

the back-up ring to center the fluid port body.

Thread the locking ring (20) on the fluid port and

tighten securely with a spanner wrench.

Replace the bleeder plug in the fluid port body.

Precharge using DRY NITROGEN to the specified

pressure following the Precharging Instructions.

Install the yellow valve cap and protective valve

cap, tightening by hand.

Rev B

Tel: 714-529-9495

Fax: 714-529-1366

3. With the pull rod through the gas opening,

carefully pull/push the bag into the shell without

damaging or abrading the rubber.

561 Tamarack Ave, Brea CA USA

Page 4

pacsealhydraulics.com

Maintenance Instructions

Bladder Accumulators

Reassemblysee preceding text for detailed instructions

4. Loosely attach the attach the lock nut to the

bladder stem and remove the pull rod. Tighten

the lock nut with two wrenches, taking care not to

twist the bladder.

6. Fold the extrusion ring in half and slide it into the

shell opening with the steel ring facing the

opening.

5. Apply thread tape on the outer threads of the fluid

port to protect the o-ring and back-up ring.

7. Bring the fluid port back through the center of the

extrusion ring, firmly seating the ring to the shell.

5. Slide the fluid port fully into the shell..

Rev B

Tel: 714-529-9495

Fax: 714-529-1366

8. Attach the gas charging assembly (see

precharge directions), and slowly inflate the

bladder to 5-10 psig in order to set and hold the

fluid port in place. Remove the charging

equipment.

561 Tamarack Ave, Brea CA USA

Page 5

pacsealhydraulics.com

Maintenance Instructions

Bladder Accumulators

Reassemblysee preceding text for detailed instructions

9. Note the assembly order of the rings.

10. With a spanner wrench, torque the locking ring

to the to the fluid port.

9. Install all rings in order shown and with a blunt

tool, firmly press the o-ring and back-up ring

against the metal washer. Remove the thread

tape.

11. Install the bleeder plug with thread tape.

10. Note the orientation of the lip of the spacer ring

to the shell.

12. Precharge per instructions. Tag the assembly

with the precharge pressure. Attach yellow

valve cap and protective valve cap.

Rev B

Tel: 714-529-9495

Fax: 714-529-1366

561 Tamarack Ave, Brea CA USA

Page 6

pacsealhydraulics.com

You might also like

- Operating and Maintenance Instructions On Tobul AccumulatorsDocument8 pagesOperating and Maintenance Instructions On Tobul AccumulatorszhenyupanNo ratings yet

- Air CylinderDocument4 pagesAir Cylindersimbua720% (1)

- Operating and Maintenance Instructions On Tobul AccumulatorsDocument8 pagesOperating and Maintenance Instructions On Tobul AccumulatorsGuru VagaNo ratings yet

- PistonDocument5 pagesPistonAna Paula Maia LimaNo ratings yet

- Operating Instructions & Service Manual Blue Max Ii Hydrostatic Test PumpDocument10 pagesOperating Instructions & Service Manual Blue Max Ii Hydrostatic Test PumpdocrafiNo ratings yet

- CBX Bladder ReplacementDocument2 pagesCBX Bladder ReplacementdhlinvaNo ratings yet

- CAMERON France S.A.S: Front SheetDocument24 pagesCAMERON France S.A.S: Front SheetkrishnsgkNo ratings yet

- Liquid-Pump-75-HP-Series-Model-4B-S User ManualDocument26 pagesLiquid-Pump-75-HP-Series-Model-4B-S User ManualLuis Felipe Córdova RodríguezNo ratings yet

- API 6A Hydraulic Actuator Operation InstructionDocument7 pagesAPI 6A Hydraulic Actuator Operation InstructionSrikanth Bammhide100% (1)

- 980a2542 PDFDocument58 pages980a2542 PDFMichael DavenportNo ratings yet

- ArtMolds Pressure Pot Owner's ManualDocument4 pagesArtMolds Pressure Pot Owner's ManualAnonymous Wyb8Y1No ratings yet

- FVCPDocument14 pagesFVCPmichaelxiaoNo ratings yet

- 980a0670 PDFDocument42 pages980a0670 PDFMichael DavenportNo ratings yet

- Fristam Mainten Type FPH - 3542Document12 pagesFristam Mainten Type FPH - 3542Hafid NaufalNo ratings yet

- Farris Valve ManualDocument11 pagesFarris Valve ManualsumsolcaggNo ratings yet

- Disamble Cylinder HeadDocument17 pagesDisamble Cylinder HeadFredy Mauricio Diaz VargasNo ratings yet

- Install piston governorDocument2 pagesInstall piston governorJose ChuctayaNo ratings yet

- LADA Niva 1700 Part2Document80 pagesLADA Niva 1700 Part2g-simsNo ratings yet

- 5 Pierburg SingleDocument8 pages5 Pierburg Singlevanapeer100% (4)

- N2 Triplex Pump-MaintenanceDocument14 pagesN2 Triplex Pump-MaintenanceIbrahim AhmedNo ratings yet

- Fuel System Cessna 150Document21 pagesFuel System Cessna 150BookMaggotNo ratings yet

- W.RT. Reciprocating Air Compressor Explain The Cause of The Following FaultsDocument51 pagesW.RT. Reciprocating Air Compressor Explain The Cause of The Following FaultsSri VasanNo ratings yet

- Installation Instructions Supercharger System: 440 Rutherford St. P.O. Box 847 Goleta, CA 93116Document16 pagesInstallation Instructions Supercharger System: 440 Rutherford St. P.O. Box 847 Goleta, CA 93116ejamadahNo ratings yet

- 1987 RAM 50 2.6L Carburetor OverhaulDocument14 pages1987 RAM 50 2.6L Carburetor OverhaulMetalAnonNo ratings yet

- Midland PumpDocument12 pagesMidland Pumppeters petersNo ratings yet

- Model GP-1000 Pressure Reducing Valve For Steam Service: Installation and Maintenance InstructionsDocument2 pagesModel GP-1000 Pressure Reducing Valve For Steam Service: Installation and Maintenance InstructionsMykweall_Kenz_3204No ratings yet

- 50 GPM Users Guide 101102Document14 pages50 GPM Users Guide 101102Aprizal AzisNo ratings yet

- VAAS Fig 740 and 730 Series IOMDocument9 pagesVAAS Fig 740 and 730 Series IOMCarlos GutierrezNo ratings yet

- Manual CheetaDocument8 pagesManual CheetaJhon F. Aroca FlorezNo ratings yet

- Morton Water Softener Valve-Assembly ReplacementDocument2 pagesMorton Water Softener Valve-Assembly ReplacementBenjamin DoverNo ratings yet

- Assembly and Disaassembly of PumpsDocument5 pagesAssembly and Disaassembly of Pumpsshin deiru100% (1)

- Installation and Maintenance Instructions Figure C67 Fabri-Valve Bi-Directional Knife Gate ValveDocument6 pagesInstallation and Maintenance Instructions Figure C67 Fabri-Valve Bi-Directional Knife Gate Valveعبدالرحمن عمرNo ratings yet

- Single Cylinder Air Compressor Repair ManualDocument13 pagesSingle Cylinder Air Compressor Repair ManualGLNo ratings yet

- Membrane Loading 2Document6 pagesMembrane Loading 2Rochdi KherratNo ratings yet

- 980a3084 PDFDocument45 pages980a3084 PDFMichael DavenportNo ratings yet

- Troubleshooting The Divider Block SystemDocument3 pagesTroubleshooting The Divider Block SystemMarcus MorganNo ratings yet

- DAKE Press Model 75 H - 907003Document6 pagesDAKE Press Model 75 H - 907003mark_dayNo ratings yet

- Install and Service 1008 and 1010 Series PumpsDocument12 pagesInstall and Service 1008 and 1010 Series PumpsEdgar Eduardo Tellez RuizNo ratings yet

- Repair Information: Eaton Hydrualics DivisionDocument8 pagesRepair Information: Eaton Hydrualics DivisionZafiro Feliz GalanNo ratings yet

- Catálogo Bomba BanjoDocument8 pagesCatálogo Bomba BanjoVitchenzo Zimmer DezordiNo ratings yet

- Precharge Kit 5000PSI PDFDocument2 pagesPrecharge Kit 5000PSI PDFmetal_dung2No ratings yet

- Me Piston Replacement ProcedureDocument6 pagesMe Piston Replacement ProcedureGaurav MaithilNo ratings yet

- Sci Mop Bombas Espuma Cgp80 - ChemguardDocument13 pagesSci Mop Bombas Espuma Cgp80 - Chemguarddiuska13No ratings yet

- SB388CDocument13 pagesSB388CBenjamin LeedsNo ratings yet

- KF Series P3 - M3 IOMDocument3 pagesKF Series P3 - M3 IOMCarlos MantillaNo ratings yet

- Olaer Charging KitDocument4 pagesOlaer Charging KitA.m. Senthil KumarNo ratings yet

- DSA4 15M Tandem SidedoorDocument11 pagesDSA4 15M Tandem SidedoorДудла СтаніславNo ratings yet

- Disassembly and reassembly of piston style steering accumulatorsDocument4 pagesDisassembly and reassembly of piston style steering accumulatorsPablo MarquezNo ratings yet

- Cessna Fuel System Inspection GuideDocument7 pagesCessna Fuel System Inspection GuideJohan Louie RayosNo ratings yet

- ARMY TM 9-834 Vehicular General Purpose Unit Equipment JUN44Document110 pagesARMY TM 9-834 Vehicular General Purpose Unit Equipment JUN44RockWagonNo ratings yet

- Sachs Rear Husky 610Document14 pagesSachs Rear Husky 610GombosTamásNo ratings yet

- Series 60 - Section 6.3 Intake ManifoldDocument7 pagesSeries 60 - Section 6.3 Intake ManifoldJuan RiveraNo ratings yet

- Petrol Water Pump ManualDocument24 pagesPetrol Water Pump ManualdigitaltextNo ratings yet

- Maintenance and Repair InstructionsDocument12 pagesMaintenance and Repair InstructionsDhananjay NilkuteNo ratings yet

- Water Pump Remove and Replace: 2002 VTX 1800CDocument10 pagesWater Pump Remove and Replace: 2002 VTX 1800CGheorghe DanielNo ratings yet

- Assignment No:: ToolsDocument3 pagesAssignment No:: ToolsKapil VermaNo ratings yet

- PTE PW46 Wastegate InstructionsDocument9 pagesPTE PW46 Wastegate InstructionsAmenonFernandesRosaNo ratings yet

- P I F 3000 PSI B A: Recharging Nstructions OR Ladder CcumulatorsDocument2 pagesP I F 3000 PSI B A: Recharging Nstructions OR Ladder CcumulatorsRonaldNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Instruction Manual: Small Cylinder DryerDocument20 pagesInstruction Manual: Small Cylinder DryerJohn Néstor Ramirez CalderónNo ratings yet

- Mil DTL 6000Document17 pagesMil DTL 6000John Néstor Ramirez CalderónNo ratings yet

- IOM-149 Catalogo ProservDocument33 pagesIOM-149 Catalogo ProservJohn Néstor Ramirez CalderónNo ratings yet

- Inversor Secador Pct-AdwDocument38 pagesInversor Secador Pct-AdwJohn Néstor Ramirez CalderónNo ratings yet

- Accesorios de Alta Presion BauerDocument180 pagesAccesorios de Alta Presion BauerJohn Néstor Ramirez CalderónNo ratings yet

- 21 11 1072Document19 pages21 11 1072John Néstor Ramirez CalderónNo ratings yet

- Ccc1-Circ3 - Revised Guidance On The Continued Use of Existing Imo Type Portable Tanks and Road Tank Ve Secretariat 0Document66 pagesCcc1-Circ3 - Revised Guidance On The Continued Use of Existing Imo Type Portable Tanks and Road Tank Ve Secretariat 0Anonymous KIpkFtt6M5No ratings yet

- Desvalvuladora 21-11-1002Document30 pagesDesvalvuladora 21-11-1002John Néstor Ramirez CalderónNo ratings yet

- Code of Federal RegulationsDocument39 pagesCode of Federal RegulationsJohn Néstor Ramirez CalderónNo ratings yet

- Adapters Couplings and AccessoriesDocument6 pagesAdapters Couplings and AccessoriesJohn Néstor Ramirez CalderónNo ratings yet

- Code of Federal RegulationsDocument39 pagesCode of Federal RegulationsJohn Néstor Ramirez CalderónNo ratings yet

- Ac 20-42DDocument48 pagesAc 20-42DJohn Néstor Ramirez CalderónNo ratings yet

- Hand PumpsDocument1 pageHand PumpsJohn Néstor Ramirez CalderónNo ratings yet

- Sistemas ContraincediosDocument88 pagesSistemas ContraincediosJohn Néstor Ramirez CalderónNo ratings yet

- F 7722Document2 pagesF 7722John Néstor Ramirez CalderónNo ratings yet

- Tuthill2010 FullLineCatalog OnlineDocument92 pagesTuthill2010 FullLineCatalog OnlineJohn Néstor Ramirez CalderónNo ratings yet

- Literature Force Floating Ball Valve CatalogDocument16 pagesLiterature Force Floating Ball Valve CatalogJohn Néstor Ramirez CalderónNo ratings yet

- 49 CFR Ch. I (10-1-03 Edition) 171.3: 171.3 Hazardous WasteDocument3 pages49 CFR Ch. I (10-1-03 Edition) 171.3: 171.3 Hazardous WastejohnneracalNo ratings yet

- Literature Force Floating Ball Valve CatalogDocument16 pagesLiterature Force Floating Ball Valve CatalogJohn Néstor Ramirez CalderónNo ratings yet

- Literature Butterfly Valve CatalogDocument20 pagesLiterature Butterfly Valve CatalogJohn Néstor Ramirez CalderónNo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofAshish SontakkeNo ratings yet

- R.C ProjectDocument3 pagesR.C ProjectMustafa HusseinNo ratings yet

- Gravity Based Structure FoundationDocument8 pagesGravity Based Structure FoundationHa NgNo ratings yet

- Rule 1220: Elevators & Related EquipmentDocument10 pagesRule 1220: Elevators & Related EquipmentMonjo CasiñoNo ratings yet

- Japanese Garden Design ElementsDocument6 pagesJapanese Garden Design ElementsFARHANA SHAJINo ratings yet

- AdmixturesDocument27 pagesAdmixturesShubham ParmarNo ratings yet

- Kobelco Excavator Cyl Repair Kit SK60 SK450 K903 K916 SeriesDocument6 pagesKobelco Excavator Cyl Repair Kit SK60 SK450 K903 K916 SeriesPhilNo ratings yet

- Armoured Cables - Types, Standards and Uses ExplainedDocument2 pagesArmoured Cables - Types, Standards and Uses Explaineddaniel_silabanNo ratings yet

- Spectacle Blind FlangeDocument3 pagesSpectacle Blind Flangemaniastur365No ratings yet

- Sika Solutions For Waste Water Treatment Plants - Low PDFDocument48 pagesSika Solutions For Waste Water Treatment Plants - Low PDFsaber66No ratings yet

- ONGC Paper On Lean DSSDocument6 pagesONGC Paper On Lean DSSharan2000No ratings yet

- CV Resume Nik Faizor CM 2022Document2 pagesCV Resume Nik Faizor CM 2022HafiziNo ratings yet

- Delorean Headliner Installation GuideDocument4 pagesDelorean Headliner Installation GuideJames Pilcher0% (1)

- The Best Practice Guide For Environmental Protection in Construction SiteDocument50 pagesThe Best Practice Guide For Environmental Protection in Construction SiteGary LoNo ratings yet

- 0132497468-Ch13 ISMDocument48 pages0132497468-Ch13 ISMJeison Rincón Garzón100% (2)

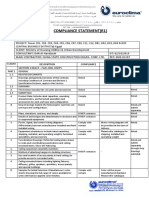

- Fan-Coil Units Compliance Statement for Egypt Tower ProjectsDocument9 pagesFan-Coil Units Compliance Statement for Egypt Tower ProjectsLi Liu100% (1)

- Astm C11Document8 pagesAstm C11Fitria RindangNo ratings yet

- Summary of Bid: Item No. Description Unit Quantity Unit Cost AmountDocument36 pagesSummary of Bid: Item No. Description Unit Quantity Unit Cost AmountMarkVincentTulinaoNo ratings yet

- Astm C 618 02 1Document4 pagesAstm C 618 02 1Ciro Arnold Gonzales PauccarNo ratings yet

- Engineering Geology Assignment 29.11.12Document4 pagesEngineering Geology Assignment 29.11.12Richard WestonyNo ratings yet

- List RDSO DrawingsDocument52 pagesList RDSO Drawingsprasagnihotri75% (4)

- Aluminium - Specifications, Properties, Classifications and Classes, Supplier Data by AalcoDocument2 pagesAluminium - Specifications, Properties, Classifications and Classes, Supplier Data by Aalcowongtathong1987No ratings yet

- ResumeABDULKALEEM A MDocument5 pagesResumeABDULKALEEM A MJenniferNo ratings yet

- Wms Ducting and InsultionDocument8 pagesWms Ducting and InsultiontanweerkhanNo ratings yet

- General Requirements For ValvesDocument16 pagesGeneral Requirements For ValvesKrishna Prasad R100% (1)

- The Use of Geosynthetics in Road ConstructionDocument47 pagesThe Use of Geosynthetics in Road ConstructionPaulo Nascimento100% (2)

- GEZE Installation Instructions en 742566Document120 pagesGEZE Installation Instructions en 742566PiotrNo ratings yet

- Brazing and Braze WeldsDocument13 pagesBrazing and Braze WeldsdocsdownforfreeNo ratings yet

- Home Heating and Cooling Solution: 0C - 0M - 71Y - 0KDocument12 pagesHome Heating and Cooling Solution: 0C - 0M - 71Y - 0KCarlos ManriquezNo ratings yet

- Kids pool diagram schematic overviewDocument1 pageKids pool diagram schematic overviewHarta Dwi AsmanaNo ratings yet