Professional Documents

Culture Documents

Welding QC 4 - Destructive Testing

Uploaded by

Exsan OthmanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding QC 4 - Destructive Testing

Uploaded by

Exsan OthmanCopyright:

Available Formats

T\VI

700t

THE WELDING INSTTTUTE

SECTION4

TWI

70[t

THE WELDING biSTTTUTE

DESTRUCTIVETESTING _

NPT - Lc \""l

Destructive tests on welded

joints are usually made as part

of the approval of a welding

procedure or a welder.

dqh"q!1,-7

f":'\

The test pieces are clrt from the

test weld and their locatronis often

specifiedin the standard.

British Standardsfor Testingof Welds

BS 709: 1983Methodsof testingfusion

weldediointsand weld metalin steel

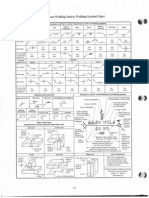

Commonlyused destructivetests

Bend

Tensile

\Jt

td,t Py

Fracturetests

(

Macrosection

\lo+dr'.*

[caf

Test weld along

tre of pla(e

Macro-seciion

R e n o v a (o f l e s t - p i e c e s

for deslruclive-l esling

WELDING TECHNOLOGY

,ssue0791

l t l

T\MI

a,L,U[

Tt-F \\:rT)i\a,

\ --:-T

B E N DT E S T S( i r a n s v e r saen d l o n g i t u d i n a l )

O biect

To determinethe soundnessof weid

metal, heat affectedzone and weld

These tests may also be used to give

some rneasLlreof the ductilityof the

weld zone. lt is not usualto use

lonqitudinal

and transverse

beod

T6Etsfor ihe s-;;r-applicr-iion.=_:

re.sronior rco i beno

----------

.--

i e s i o r e c ei o r

flce or.oot Dend

Surface in contact

is 9t'ound lLat

Method

vith

forner

The specimenis bent by the

movement of a former of prescribed

diameter,the relevantside of the

specimento be placedin tension.

Angle of bend and diameterof former

shouldbe as specifiedin the

appropriateapplicationstandard.

la)

Reporting Besults

1.

Thickness

of specimen-p.F*

2.

Directionof bend (rootor tace)

-

Angreof beno d

niimotor

nr rnrrnor

*. y

\U-'r*'{r

-1

':l

.r I

.v+r

ie.tt

,-:/--

-'l.t

F . r c eb e n d

tsi\

I

,-J-

Appearanceof jointafter bending,

e.g. type and locationof flaws.

R - Roller 1u')r)orl

4.2

WELDING TECHNOLOGY

lssue 0191

TWI

wgt

TIIE WELD i ]\GUVSTj.T1JTE-

SIDEBENDTEST

ObJect

To determinethe soundnessof a

weldedjoint in a crosssection.

This may be prefenedto the transverse

bendtest on thickmaterials.

Methocl

T h i ss i d ea n

forside

tension

ono

Te5t-piecelor ride bend

The testingmethodis the same

as that usedfor transversebends.

Force

ReportingResults

1.

Width and thicknessof specimen

z.

Angle of bend

.).

Diameterof former

R = Roller supporl

Appearanceof joint after bending

e.g. type and location of flaws

^f

<n*ifia.i

radrus

(r) at efld

WELDING TECHNOLOGY

lssue0191

TWI

700s

THE $,ELDINC TXST|N.]'I:

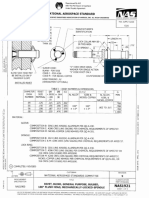

T R A N S V E R S ET E N S I L ET E S T

'

'-

a!

O bj e c t

Used to measurethe transversetensilestrenaihunderstaticrr ^! o- ,t .r 1r r, r^g^

loint employingbuttwelds.

^; ^ a, *

!/r c, UUtr

The test is not de-stgned_tq_g.iyq_theje

ns ile sttelglh ol llqlle lelnetat.

Method

The testpieceis clampedat each end and a load is applied by a hydraulicor

screw mechanism. The load is increaseduntil fractureoccurs.

Reporting Results

1.

Type of specimen(e.9.reducedsection)

2.

Whether excessweld metal is removedor not

J-

Tensile strengthin N/mmz,is calculatedfrom maximumload and original

cross sectionalareas. When excess weld metal is not removedthe

cross sectionalarea shall be the productof the parent metal thrckness

and the widthof the specimen.

Locationof fracture,whether in parent metal, heat affectedzone or weld

metal. lf the fractureis in the parent metal,the distancefrom the weld

zone shall be staied.

5.

ri/

Locationand type of any flaws present on the fracturesurfaces.

i.reld*-"-^-F

i+

)

"..-l4

()

.-., O\-TG

"

.F-.t""<

--J

\v<\r\c

&c'o--

s4

'^"o-Ll

11=--..-..y

o'l(-

w---+--Yg-L

Va,.o*[

o' - t'

.(A.e

g(I9 - ;ri+"';\-

[t-) t\"f"

--

r W6Tr--

.

A"a^r. - & *V,-Fr,--

1z'^".:\

Yr"<1Lu

f - {-.ac}'"-c

t=-a)'

a-

Lt-i

- b--;--,q-"-\+))4 vts'--\h-

WELDING TECHNOLOGY

lssue 0191

T\^/I

lulil7

-

- t-acp ag{lC H A R P YV I ' I O T C HI M P A C TT E S T

-Fh*',---iLr:\'

c,e-rq i:!

,s

l^$;..

itr,C't,*u

!.

tti---

L\Q_v

!!-n-7

<''a

-.',$-l

l

;F lzicce

trJ-}

Ob j e c t

C,':;'i,

:e::9r--aa

To

- ' - 'determine

' - - - ' : - - - , the amounto_fengrly

absorbed in fracturing a standardised

toc'rro^o

.t

c^d.;fi6.i

t.mperatufe.

Method

,ai>z

A machined,notcnedspecimenis

broken by one blowfrom a pendulum.

Because scattef occurs in the results,

at leastthree specimensare usedto

assess the .jointrepresented.

Rool radius

0 . 2 5n m

Testing is carried out at a

temperaturespecifiedin the

appropriateapplicationstandardin

accordancewith BS 131: n Z 1972.

Reporting Results

Location and orientationof the notch

-r^^+i^^

I c J L r r g r t r rr r P E / d t u r E - \ . - .

'"

/t,.!\ .r vr l*.,.':. .

l] 1

"

*

.1.

1-^^.,,-^

l| clLlurc

| ^^^r;^^

^^,,

dt iy

., i- .-:

t

. t

^l

ur

"

- "t

Enercv aosoroed

n^-^-i^+i^^

L./sJUr rPLrurr

',,

dPPEdr

'

-

dr rLc

'Tesl.ptece

Charpy inpac! machtne

^l

ur

A^1^^+^

utrlELl5

Test Drece

U-.

i r-\'.

-.,.!j

Testprecein posrtron

WELDING TECHNOLOGY

I s s u e0 1 9 1

-':

-.:,.,

E n e r g y a b 5 o f b e dd u r n q

I r a ct u r e ! r p . o p o r l | o n a l

rolA-B)

k,

TWI

vtir$

TE

\\ 3L-IllNG l-\ST:T1:i:

F I L L E T W E L D F R A C T U R ET E S T

O bj e c t

of the fracture

To break the jointthroughthe weld to permitexamination

sudaces.

Method

The specimenis cut to lengthand a saw cut, normally2mm deep,is made

alongthe centreof the weldface. The specimenis fracturedby bendingor by

hammerblows.

Reporting Results

1.

Thicknessof parent metal

Th i'oat thicknessand leg length

Locatronof fracture

Appearanceof joint after fracture

Depthof penetration,4ack

of penetration

or fusion

Hanner ar

lL.o

WELDING TECHNOLOGY

lgsue 0191

TWI

w[t

THE WELDiNC TNSTI]'UTE

.NICK'BREAK

TEST

Object

As for fillet weld fracture

Method

The specimen is ct,t transverselyto the weld, and a saw cut is appliedalong

the centre of the weld face. The soecimen is fracturedby bendingor by

hammer blows.

ReportingResults

.l.

Thicknessof material

2.

\l fi;+tr ^{ -^^^;-^^

t r r \ r L rI v r J P r i \ ? | | I t E l I

.).

Locationof fracture

Appearanceof joint after fracture

\t,r--V ot!<kA L')

\++z-DNv;<T61T

L\-..4".--' guLvtc

3;

$.-i.Ut

K-uzL'*J

g'-'r*-q

\

<-raJ. - !=".-.-I i"--. :\-. l-eJ c'tfi1q-4 2.",a

'*-<9--e]J

rtJ

l:,-["@'&*f, e- ]"*+

6w\2

\*r-\.V..-oA, !

v r

WELDINGTECHNOLOGY

lssue0191

--"1

--i

.

a

\caN I

A-Q,fi-.j^,'4

p<tlr-1 C--"-'-.,-vt- *

|3"

4.7

T\ryI

700){

THE WELDTNG LNSTITL,ITE

OUESTIONS

MECHANICALTESTINGOF WELDMENTS

Q1

From a tensiletest the followingitems were progressively

recorded

a)

b)

load

extension

lf the originallengthis also known,statewhat cin"bdassessed.

Q2

/a

LI'J

o4

Q5

{-"1,\.,4.4

't

os/+

\^;

] <:: '-,!

You might also like

- PETRONAS Employee Medical Top-Up PlanDocument2 pagesPETRONAS Employee Medical Top-Up PlanExsan OthmanNo ratings yet

- Farris Series 2600Document96 pagesFarris Series 2600johngoff100% (1)

- A-Health Advance - Application Form With InstructionsDocument14 pagesA-Health Advance - Application Form With InstructionsExsan OthmanNo ratings yet

- Senarai Nama Arkitek BerdaftarDocument150 pagesSenarai Nama Arkitek BerdaftarCgu Bola Tampar83% (6)

- Farris Valve ManualDocument11 pagesFarris Valve ManualsumsolcaggNo ratings yet

- April 2015. Any New Application Form Must Reach Us Before The Stipulated DateDocument1 pageApril 2015. Any New Application Form Must Reach Us Before The Stipulated DateExsan OthmanNo ratings yet

- RFET Technique Detects Local and Gradual DefectsDocument4 pagesRFET Technique Detects Local and Gradual DefectsExsan OthmanNo ratings yet

- SSI Guideline V3 PDFDocument34 pagesSSI Guideline V3 PDFSyed Mohd FirdausNo ratings yet

- AWS Weld Symbol ChartDocument1 pageAWS Weld Symbol ChartExsan OthmanNo ratings yet

- Engineering Your Future PDFDocument605 pagesEngineering Your Future PDFExsan OthmanNo ratings yet

- TUBE INSPECTION SOLUTIONS: SELECTION GUIDEDocument28 pagesTUBE INSPECTION SOLUTIONS: SELECTION GUIDEAkhileshNo ratings yet

- Asmt C 795Document4 pagesAsmt C 795Exsan OthmanNo ratings yet

- MetrodeHandbook - ZavarivanjeDocument416 pagesMetrodeHandbook - ZavarivanjetonicmiraNo ratings yet

- P91 T91 Engl PDFDocument3 pagesP91 T91 Engl PDFparmodrtkNo ratings yet

- Astm C 871Document5 pagesAstm C 871Exsan Othman100% (2)

- Calculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Document6 pagesCalculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Exsan OthmanNo ratings yet

- Astm C 692 PDFDocument7 pagesAstm C 692 PDFExsan Othman100% (1)

- AWS Specifications For Filler MaterialDocument9 pagesAWS Specifications For Filler MaterialExsan OthmanNo ratings yet

- Piping CalDocument13 pagesPiping CalglazetmNo ratings yet

- EPA RMP OSHA PSM State Law SummaryDocument1 pageEPA RMP OSHA PSM State Law SummaryExsan OthmanNo ratings yet

- Mechanical Design SpreadsheetDocument1 pageMechanical Design SpreadsheetHoney TiwariNo ratings yet

- MaterialsDocument181 pagesMaterialsExsan OthmanNo ratings yet

- Calculation Minimum Required Thickness For Bending Pipe r2Document11 pagesCalculation Minimum Required Thickness For Bending Pipe r2Exsan OthmanNo ratings yet

- Material CharacteristicsDocument4 pagesMaterial CharacteristicsExsan OthmanNo ratings yet

- Pipeline DataDocument4 pagesPipeline DataExsan OthmanNo ratings yet

- Hemispherical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageHemispherical Head Design Tool: Pressure Vessel Engineering LTDExsan OthmanNo ratings yet

- Nozzle Design Tool AnalysisDocument2 pagesNozzle Design Tool AnalysisArt G. EnziNo ratings yet

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Honey TiwariNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Effect of Nickel on Coating Thickness (Sandelin EffectDocument2 pagesEffect of Nickel on Coating Thickness (Sandelin EffectEng-Ahmed Allam100% (1)

- IG Deck Seal PumpDocument3 pagesIG Deck Seal PumpSergei KurpishNo ratings yet

- Esfuerzos Maximo Permisibles Tablas Ucs Ii Asme Viii Div 1 PDFDocument643 pagesEsfuerzos Maximo Permisibles Tablas Ucs Ii Asme Viii Div 1 PDFChuy Ramos0% (1)

- Bag Outdoor 2008Document67 pagesBag Outdoor 2008Lombrea AdrianNo ratings yet

- 430 Specification PDFDocument1 page430 Specification PDFGagat GongatNo ratings yet

- Nas1921 AiaDocument4 pagesNas1921 AiaGrandiosNo ratings yet

- Navsea S9074-Aq-Gib-010-248Document137 pagesNavsea S9074-Aq-Gib-010-248Brenno Moura MouraNo ratings yet

- Screwed Fiting BSP - 1 PDFDocument12 pagesScrewed Fiting BSP - 1 PDFNguyen Thanh NguyenNo ratings yet

- 5-b - Carbon and Alloy SteelsDocument43 pages5-b - Carbon and Alloy SteelszzirapovNo ratings yet

- ASTM MATERIAL COMPARISON TABLEDocument10 pagesASTM MATERIAL COMPARISON TABLEMardeOpamenNo ratings yet

- Alloying Elements and Their EffectsDocument5 pagesAlloying Elements and Their EffectsDimas Anugrah100% (2)

- Amassadeira Basculante Ferneto ABXxxxiDocument2 pagesAmassadeira Basculante Ferneto ABXxxxiFerneto SANo ratings yet

- Stainless Steel As Reinforcement: BY-Bhrugesh Patel SD-1210Document30 pagesStainless Steel As Reinforcement: BY-Bhrugesh Patel SD-1210Jay KushwahaNo ratings yet

- Chemical Composition - Al AlloysDocument4 pagesChemical Composition - Al Alloysamit2688No ratings yet

- Chapter 5, THE IRON-CARBON EQUILIBRIUM DIAGRAMDocument13 pagesChapter 5, THE IRON-CARBON EQUILIBRIUM DIAGRAMPAUL NDIRITUNo ratings yet

- Titanium and Reactivity SeriesDocument2 pagesTitanium and Reactivity SeriespappadakunduNo ratings yet

- Kabelske Stopice Cu Cijevne, Prema DIN 46235 Compression Cable Lugs Copper Tube, Acc. To DIN 46235Document15 pagesKabelske Stopice Cu Cijevne, Prema DIN 46235 Compression Cable Lugs Copper Tube, Acc. To DIN 46235registracijusNo ratings yet

- Structural Steel StandardsDocument4 pagesStructural Steel StandardsMunirajulu McNo ratings yet

- Material Conversion TableDocument1 pageMaterial Conversion TableravikumarangNo ratings yet

- Kennametal MasterCatalog SEM Preview en MinchDocument119 pagesKennametal MasterCatalog SEM Preview en MinchBeto CovasNo ratings yet

- Metal & Alloys Corporation, Delhi, IndiaDocument8 pagesMetal & Alloys Corporation, Delhi, IndiaVineet AgarwalNo ratings yet

- Ferrous and Non Ferrous Materials - Dr. ChalimbaDocument61 pagesFerrous and Non Ferrous Materials - Dr. ChalimbaTadala Angella GomondaNo ratings yet

- Iron Ore Railway Movement 02 07 2018Document89 pagesIron Ore Railway Movement 02 07 2018Bhavin SagarNo ratings yet

- ASTM A554 Stainless Steel Tubing SpecsDocument1 pageASTM A554 Stainless Steel Tubing SpecsALİ YİĞİTNo ratings yet

- Stainless Steel NotesDocument9 pagesStainless Steel Notesthouche007No ratings yet

- H - Review of WeldingDocument90 pagesH - Review of WeldingSUNDRAMNAGANo ratings yet

- Lincoln 2Document2 pagesLincoln 2kien phamNo ratings yet

- Ultrasonic Inspection Velocity TableDocument2 pagesUltrasonic Inspection Velocity Tableanwarhas05100% (1)

- 2009-04-CEN-TC121 N1574 Working Programme CEN TC 121Document28 pages2009-04-CEN-TC121 N1574 Working Programme CEN TC 121Manuel ValenteNo ratings yet

- Performance of Fittings For Use With Gasketed Mechanical Couplings Used in Piping ApplicationsDocument4 pagesPerformance of Fittings For Use With Gasketed Mechanical Couplings Used in Piping ApplicationsDarwin DarmawanNo ratings yet