Professional Documents

Culture Documents

Wps

Uploaded by

neto-portoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wps

Uploaded by

neto-portoCopyright:

Available Formats

NATIONAL CERTIFIED PIPE WELDING BUREAU

WELDING PROCEDURE SPECIFICATION

NO. 1-7-1

FOR

GAS METAL ARC WELDING WITH FLUXCORE WIRE (GMAW-FC)

SEMI-AUTOMATIC OR MACHINE

OF

CARBON STEEL PIPE, VALVES, FITTINGS AND FLANGES

WITH AND WITHOUT POSTWELD HEAT TREATMENT

This document is the property of

(NCPWB Member Company Name)

This Welding Procedure Specification (WPS) and Procedure Qualification Record(s) (PQR)

are issued by the NCPWB for adoption by its members. Reproduction or

use of this WPS and PQR(s) by anyone other than members of the NCPWB is

prohibited

NCPWB

WELDING PROCEDURE SPECIFICATION (WPS)

Member Company Name:

WPS Number: 1-7-1

Revision: 3

Revision Date: 1/15/14

Welding Process: GMAW-FC, Semiautomatic or machine

Joints (QW-402)

Date issued: 1-3-05

Supporting PQRs: 87121, 87122

Joint Design: Single-V or U, Double-V or U, Fillets, Repairs, Build-up.

Details: See Typical Joint Designs

Backing: Required

Backing or Retainer type: Carbon steel when used.

Base Metals (QW-403)

P-Number: 1

to P-Number: 1

Filler Metals and Electrodes (QW-404)

Group No: 1, 2

Group No: 1, 2

Specification Number:

AWS Classification:

F-number:

A-Number:

Maximum Weld Metal Thickness:

Grooves:

Fillets:

Base Metal Thickness Range

Groove Welds: 3/16 to 8.0

Fillet Welds: All

Minimum Outside Diameter

Grooves Welds: 2-7/8 OD except 1 OD when

in flat position

Fillet Welds: 2-7/8 OD except 1 OD when

in flat position

Max. Bead Thickness:

Supplemental Filler Metal:

Penetration Enhancing Flux:

Consumable Insert:

Pulsed Power Supply:

SFA 5.20

E71T-1or E70T-1

6

1

8.0

All

3/16

Not Permitted

Not applicable

Not applicable

Not applicable

Postweld Heat Treatment (QW-407)

Temperature: None or 1100 to 1200F

Min. Holding Time: per construction Code

Preheat (QW-406)

Minimum metal temp.: 50 F

Interpass Temp. (Max): 500 F

Preheat Maintenance: None.

Positions (QW-405)

Positions permitted: All for E71 wire, flat

for E70T

Progression when in Vertical: Uphill

Gas (QW-408)

Shielding Gas: 75Ar-25CO2, 25 to 40 CFH

Backing Gas: None

Trailing Shield: None

Electrical Characteristics (QW-409) and Related Matters

Weld

Layer

Process

Electrode or Filler

Class

Diameter

Type/Pol

Current

Volts

WFS

Current (a)

Travel Speed

(ipm)*

Other

Transfer mode:

Spray and globular

Fill

and

fillets

GMAW

Flux-core

E71T-1

or E70T-1

0.045

0.052

1/16

DCEP

21-28

22-28

24-32

300-700

230-500

190-375

140-275

150-345

195-410

200 to 500

150 to 500

150 to 380

Parameters are for

Dual-Shield 7000

and 78. For other

products follow

mfgrs settings.

Technique (QW-410)

Tungsten Size/Type: None

Initial Cleaning: Remove grease or oil with solvent.

Shielding Gas Cup Size: 3/8 to 3/4 in ID

Remove cutting oxide by grinding.

Single or Multiple Pass per Side: Either

Interpass Cleaning: Remove slag with slag hammer, grinder or

Single or Multiple electrodes: Single

Wire brush. Remove slag between passes.

Contact-tube-to-work Distance (stickout): 3/8 to 1/2

Peening: Not permitted

Backgouging: Grinding or carbon arc followed by grinding

Other: Preheat to 175F for thickness over 1 in.

Repair Method: Grinding, Backwelding is permitted

Stringer or Weave Bead: Either

The undersigned contractor, a member of the Nation Certified Pipe Welding Bureau, hereby adopts this jointly

developed procedure as its company Welding Procedure Specification and certifies that this procedur e has been

qualified as shown on the attached Procedure Qualification Records.

Company:

By:

Date:

NCPWB Form QW-482/5-02

For use by NCPWB members only (NCPWB)

WPS 1-7-1

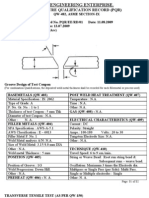

Typical Joint Designs

Other joint designs shown on Engineering drawings supersede these joint details

Butt welds

30 to 45

3/32 to

1/8

See note 1

30 to 45

3/32 to 1/8

See Note 1

3/16 Nom.

3/32 to 1/8

Note 1: 1/8 inch maximum except for B31.1 and B31.5 work, 1/16 inch maximum

Fillet, Nozzle and Branch Connection Welds

Throat

dimension

Size (leg)

Dimension

1/16

max

1/8

min

45 min

Socket and Slip-on Flange Welds

1/16 min

Y

1/16 min

Smaller of

T or 1/4

Approximately

1/16 before

welding

T = The nominal thickness of the pipe

X = the lesser of 1.4T or the hub thickness unless another size is shown on the engineering drawings

Y = the lesser of 1.1T or the fitting thickness unless another size is shown on the engineering drawings

Z = for B31.9 work, minimum of the greater of the pipe nominal wall thickness or 14 in. (6 mm) and face

fillet is not required unless specified by the design.

September 20, 2012

For use by NCPWB Members Only ( NCPWB)

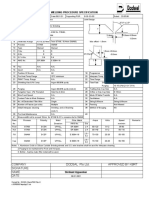

PROCEDURE QUALIFICATION RECORD (PQR)

WPS followed during welding of test coupon:

SP 124 AW. Rev 0 dated 11/25/81 Test Date:

Welding Process(s) used:

Fluxcore Arc Welding (GMAW-FC)

Base Metal Specification:

SA516 Grade 70

P-No:

Plate:

1

X

Group No:

Diameter If Pipe:

Filler Metal Specification:

A-No:

Weld Metals Deposit Thickness:

Preheat Temp (F)

Tungsten Type/Size:

AWS Classification:

5/64

Stringer/Weaver Bead:

500

DC

E70T-1

2.5

F-No:

Welding Position/Progression:

Polarity:

None

RP

6

None

Stringer

Backing Gas

Transfer Mode:

Single/Multi-Pass:

Multi

< 1/4

3G Uphill

Travel Speed:

Heat Treatment Time (Hrs):

72% Ar, 25% CO2 , 40 CFH

NA

Thickness:

Maximum Pass Thickness:

Current:

Postweld Heat Treatment (F):

Supplementary Filler Metal:

2.5

NA

Shielding Gas Composition:

Group No:

Single V-Groove with Steel backing strip.

Interpass Temp (F):

150

Oscillation:

Joint Type:

Filler Metal Size:

Semi-Automatic

to Base Metal Specification: SA516 Grade 70

to P-No:

SFA 5.20

Type:

12-15-83

NA

ipm

NA

None used

CFH

Spray/Globular

Single/Multi-Arc:

Single

Layer

Process

Filler Class

Diameter

Amperage

Volts

Travel Speed

Other

All

FCAW

E70T-1

5/64

280

26

10 ipm

19 Passes

Reduced Section Tensile Tests

Specimen No.

Width/Dia.

T1 top

Thickness

Area

Ult. Load(lbs)

Utl. Stress(psi)

Failure Location

0.506

0.201

16,700

83,300

Weld Metal

T1 Bottom

0.505

0.200

17,750

88,600

Base Metal

T2 top

0.504

0.200

16,700

83,700

Weld Metal

T2 Bottom

0.501

0.197

17,400

88,300

Base Metal

Guided Bend Tests [ X ] QW-452.2 (Side)

] QW-462.3(a) (Trans R&F)

] QW-462.3(b) (Long R&F)

Side

Pinhole - Acceptable

Side

No Defects - Acceptable

Side

No Defects - Acceptable

Side

No Defects - Acceptable

Welders Name:

Len Wertelet

Welding Witnessed by:

Stamp No.

James J. Sekely

LW

Test Number:

Specimens Evaluated by:

823218

Earl Gallagher, PTL

We certify that the statements in this record are correct, and that the test coupons were prepared,

welded and tested in accordance with the requirements of Section IX of the ASME Code.

NATIONAL CERTIFIED

PIPE WELDING BUREAU

Contractor:

By:

Date:

BY:

Chairman, Technical Committee

NCPWB Form QW-483 4/87

For use by NCPWB members only (NCPWB)

PQR Number: 87121

PROCEDURE QUALIFICATION RECORD (PQR)

WPS followed during welding of test coupon:

SP 124 SR, Rev 0 dated 11/25/81

Welding Process(s) used:

Fluxcore Arc Welding (GMAW-FC)

Base Metal Specification:

SA516 Grade 70

P-No:

Plate:

1

X

Group No:

Diameter If Pipe:

Filler Metal Specification:

A-No:

Tungsten Type/Size:

5/64

Oscillation:

500

DC

1150+50

E70T-1

F-No:

6

None

RP

Travel Speed:

CFH

Backing Gas:

NA

Single/Multi-Pass:

Multi

ipm

2.5

None used

Transfer Mode:

< 1/4

3G Uphill

Heat Treatment Time (Hrs):

Stringer

NA

2.5

Welding Position/Progression:

Polarity:

72% Ar, 25% CO2 , 40

Stringer/Weaver Bead:

Thickness:

Maximum Pass Thickness:

Current:

Postweld Heat Treatment (F):

Supplementary Filler Metal:

2.5

NA

Shielding Gas Composition:

Group No:

Single V-Groove with Steel backing strip.

Interpass Temp (F):

150

Type: Semi-Automatic

AWS Classification:

Weld Metals Deposit Thickness:

Preheat Temp (F)

Joint Type:

Filler Metal Size:

12-15-83

to Base Metal Specification: SA516 Grade 70

to P-No:

SFA 5.20

Test Date:

CFH

Spray/Globular

Single/Multi-Arc:

Single

Layer

Process

Filler Class

Diameter

Amperage

Travel Speed

Volts

Other

All

FCAW

E70T-1

5/64

280

26

10 ipm

19 Passes

Reduced Section Tensile Tests

Specimen No.

Width/Dia.

T1 top

Thickness

Area

Ult. Load(lbs)

Utl. Stress(psi)

Failure Location

0.504

0.200

16,400

82,200

Weld Metal

T1 Bottom

0.508

0.203

15,850

78,200

Base Metal

T2 top

0.504

0.200

16,500

82,700

Weld Metal

T2 Bottom

0.507

0.202

16,750

82,950

Base Metal

Guided Bend Tests [ X ] QW-452.2 (Side)

] QW-462.3(a) (Trans R&F)

] QW-462.3(b) (Long R&F)

Side

Pinhole Acceptable

Side

No Defects-Acceptable

Side

No Defects-Acceptable

Side

No Defects-Acceptable

Welders Name:

Len Wertelet

Stamp No.

Welding Witnessed by: James J. Sekely

LW

Test Number:

Specimens Evaluated by:

823773

Earl Gallagher, PTL

We certify that the statements in this record are correct, and that the test coupons were prepared,

welded and tested in accordance with the requirements of Section IX of the ASME Code.

NATIONAL CERTIFIED

PIPE WELDING BUREAU

Contractor:

By:

Date:

BY:

Chairman, Technical Committee

NCPWB Form QW-483 4/87

For use by NCPWB members only (NCPWB)

PQR Number: 87122

You might also like

- WPS 8 To 1-3-1 Rev2 (10-1-13)Document5 pagesWPS 8 To 1-3-1 Rev2 (10-1-13)ERA SSNo ratings yet

- Bolts Torque CalculatorDocument2 pagesBolts Torque Calculatorabs0001No ratings yet

- Blind Flange (10 Bar)Document7 pagesBlind Flange (10 Bar)SyedZainAliNo ratings yet

- DC - Traction Motor 752RS1A-Final Test ReportDocument5 pagesDC - Traction Motor 752RS1A-Final Test ReportGaurav ChaudharyNo ratings yet

- NAVSEA Section 528 Plumbing Drains, Plumbing Vents and Deck DrainsDocument12 pagesNAVSEA Section 528 Plumbing Drains, Plumbing Vents and Deck DrainsAnonymous Kr13NEBNo ratings yet

- S-Class Rudder Trunk Cracking: Problem, Analysis and In-Situ Repair SolutionDocument23 pagesS-Class Rudder Trunk Cracking: Problem, Analysis and In-Situ Repair SolutiondbasekicNo ratings yet

- Weld Joint 1Document81 pagesWeld Joint 1rajibali27100% (1)

- Construction Plans and Strength RequirementsDocument8 pagesConstruction Plans and Strength Requirementsstormriderbh100% (1)

- Lloyds Approved Welding Consumables SuppliersDocument16 pagesLloyds Approved Welding Consumables SuppliersadammzjinNo ratings yet

- Asme - Shell External Pressure REV ADocument1 pageAsme - Shell External Pressure REV APohn Myint HanNo ratings yet

- WPS Indosol 001 (ASME) RDocument2 pagesWPS Indosol 001 (ASME) RDoni HardiNo ratings yet

- WPS 11-23-1Document3 pagesWPS 11-23-1Anoop Raj RaoNo ratings yet

- Pneumatic TestDocument10 pagesPneumatic TestcrysNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- Seamless Steel Pipe for ShipbuildingDocument2 pagesSeamless Steel Pipe for ShipbuildingshahjadaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Daterohitbhat2345No ratings yet

- ITP For Piping SystemsDocument6 pagesITP For Piping SystemsGia Minh Tieu TuNo ratings yet

- WELDING PROCEDURE SPECIFICATION FOR TANK TK 5109/5110/5111Document15 pagesWELDING PROCEDURE SPECIFICATION FOR TANK TK 5109/5110/5111surya1960No ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- Smaw Manual See Permitted Figures (Right) or Per Constr. DWG Butt JointDocument3 pagesSmaw Manual See Permitted Figures (Right) or Per Constr. DWG Butt JointNirmala DeshaNo ratings yet

- Windows & Side ScuttlesDocument10 pagesWindows & Side Scuttlesdona_001No ratings yet

- PQR Asme Template EDITABLEDocument6 pagesPQR Asme Template EDITABLErcpretoriusNo ratings yet

- Bolts Torque CalculatorDocument2 pagesBolts Torque CalculatorsopapilasNo ratings yet

- GTAW Welding Procedure for TP-304 PipingDocument2 pagesGTAW Welding Procedure for TP-304 PipingproxywarNo ratings yet

- CPP-NA2-PM-PLN-0015 Procedure For Hydrostatic TestingDocument18 pagesCPP-NA2-PM-PLN-0015 Procedure For Hydrostatic TestingAdil Ijaz100% (1)

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- QW-482 201.1Document2 pagesQW-482 201.1Barwin CruzNo ratings yet

- Note 6 - Welder Test RequirementDocument29 pagesNote 6 - Welder Test RequirementMohamad Yusuf Helmi100% (1)

- Concast WPS - REV-01Document28 pagesConcast WPS - REV-01meena34No ratings yet

- Compresor Scroll Tech. Residential and Light Commercial, 50 HZ R407C - R22 - R410ADocument8 pagesCompresor Scroll Tech. Residential and Light Commercial, 50 HZ R407C - R22 - R410AArnulfo Rafael Álvarez OliverosNo ratings yet

- Childs Restaurant Final PlansDocument38 pagesChilds Restaurant Final PlansNell CaseyNo ratings yet

- Nozzle Reinforcement Pad DiameterDocument1 pageNozzle Reinforcement Pad Diameternaveenkumar_madasettNo ratings yet

- PQR REV. 2010a Interactive FormDocument2 pagesPQR REV. 2010a Interactive FormcosmicbunnyNo ratings yet

- SP0793-0000-1M05-005 - Standard Specification For Welding Rev0 Marzo 2022Document19 pagesSP0793-0000-1M05-005 - Standard Specification For Welding Rev0 Marzo 2022Nestor De Jesus Pico TorresNo ratings yet

- STD WPSDocument1 pageSTD WPSWaqas WaqasNo ratings yet

- QCF312 WPQRDocument2 pagesQCF312 WPQRminhnnNo ratings yet

- Boiler Hydrostatic TestingDocument2 pagesBoiler Hydrostatic Testingbonginkosi mathunjwaNo ratings yet

- Foster Cold Room ManualDocument45 pagesFoster Cold Room Manualamerican_guy10100% (1)

- Asme IX BQ Art 11Document5 pagesAsme IX BQ Art 11Maria Alexandra Lange LenzNo ratings yet

- MSG Flood Risk Assessment WSP - 70038867-r04 Fra01 v5 PDFDocument36 pagesMSG Flood Risk Assessment WSP - 70038867-r04 Fra01 v5 PDFabhay dubeyNo ratings yet

- QC 64247-1 Contact Plate Inspection ReportDocument2 pagesQC 64247-1 Contact Plate Inspection ReportSenthil KumarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- 5-Valve Manifold - Butt WeldDocument1 page5-Valve Manifold - Butt Weldhaisam sarwarNo ratings yet

- Lesson 0.1 - Precalculus - Math MedicDocument2 pagesLesson 0.1 - Precalculus - Math Medicfeng yanNo ratings yet

- Pressure Vessel RT TestDocument3 pagesPressure Vessel RT TestAriq FauzanNo ratings yet

- M25C MDO Maintenance Intervals PDFDocument4 pagesM25C MDO Maintenance Intervals PDFMYO WINNo ratings yet

- API-1000-11 Rev 0Document3 pagesAPI-1000-11 Rev 0Mahesh MishraNo ratings yet

- WPQ PDFDocument0 pagesWPQ PDFstanleyNo ratings yet

- Boiler and Pressure Vessel Engineering - Vessel Nozzle LoadingDocument7 pagesBoiler and Pressure Vessel Engineering - Vessel Nozzle Loadingvenkatrangan2003No ratings yet

- Rules For The Classification of Naval Ships: Part C - Machinery, Systems and Fire ProtectionDocument444 pagesRules For The Classification of Naval Ships: Part C - Machinery, Systems and Fire Protectionguichen wangNo ratings yet

- Ultrasonic inspection reports for 42Document5 pagesUltrasonic inspection reports for 42Anonymous tlznGAqNo ratings yet

- NAHAD Design Handbook SampleDocument10 pagesNAHAD Design Handbook SampleAnoop G PillaiNo ratings yet

- Welder Job Clearance Card: Nesma/TanmiaDocument8 pagesWelder Job Clearance Card: Nesma/TanmiaMohamed Reda Hussein SengarNo ratings yet

- Welding Electrode Filter Metal CalculationDocument3 pagesWelding Electrode Filter Metal CalculationjsvrrajuNo ratings yet

- Project Sprinkler Hydro Test ReportDocument1 pageProject Sprinkler Hydro Test ReportjajakaNo ratings yet

- Welding Procedure Specification (WPS) : in The Outer TubeDocument1 pageWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaNo ratings yet

- Hydrotest Welding and NDTDocument11 pagesHydrotest Welding and NDTALFA ENGINEERINGNo ratings yet

- Fcaw Wps-001a PDFDocument3 pagesFcaw Wps-001a PDFirfan bari100% (1)

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationSAKDA MAPRADITKULNo ratings yet